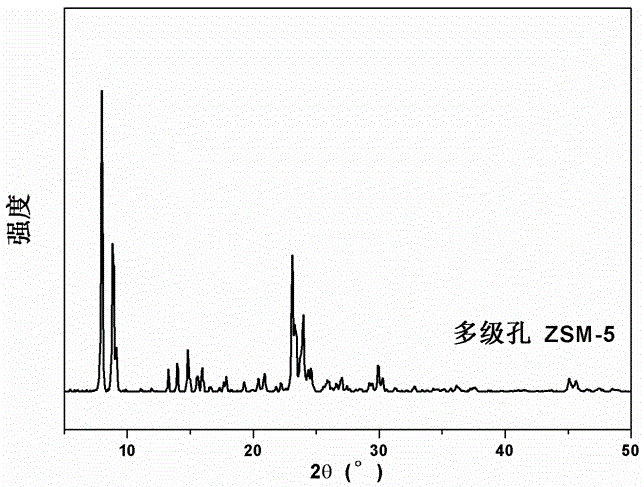

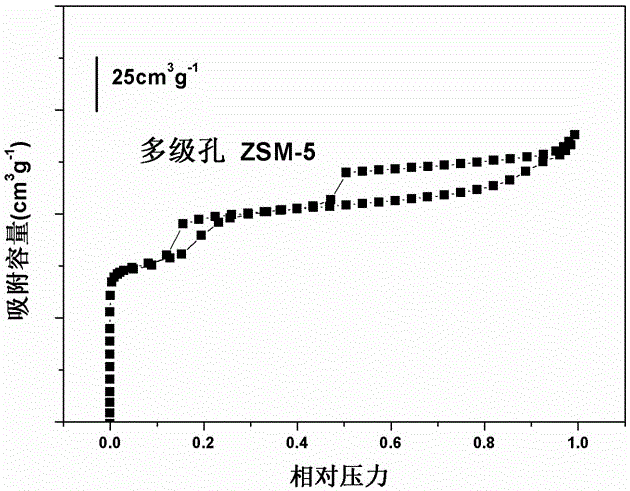

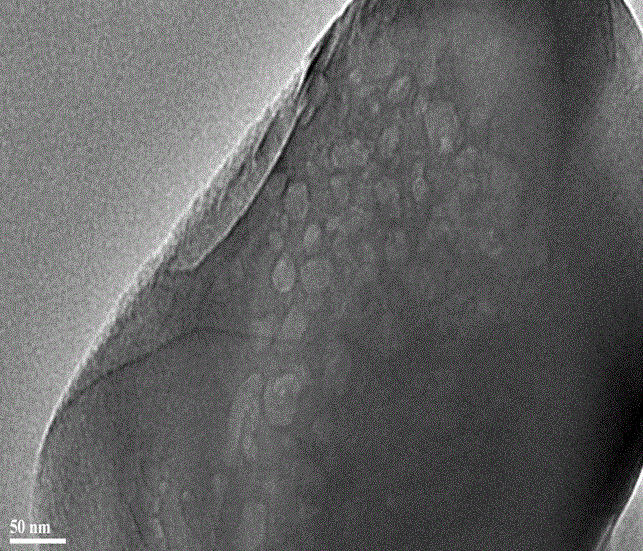

Multistage pore ZSM-5 catalyst for preparing acrolein by glycerol dehydration and preparation method of catalyst

A ZSM-5 catalyst technology, applied in the field of multi-stage molecular sieve catalyst and its preparation, to achieve high selectivity, suitable for large-scale production, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (a) Take the silicon source as sodium silicate crystal, the aluminum source as sodium metaaluminate, the template agent as tetrapropylammonium bromide and deionized water, and weigh each material according to the molar ratio, that is, SiO 2 :Al 2 o 3 : Templating agent: H 2 O=1:0.0025:0.3:30, one-step feeding to prepare a mixed solution; heat the mixed solution to 80°C for ultrasonic dissolution, ultrasonic frequency 40KHZ, wait for 10 minutes of ultrasonication, then immediately lower the temperature to 40°C quickly, add After a certain amount of ethanol (ethanol / Si=0.1), then quickly add sulfuric acid dropwise under stirring (stirring speed: 180r / min) to adjust the pH to 8-10 to form a gel;

[0032] (b) Stir the obtained gel for 48 hours at a rotation speed of 250r / min, and control the ambient temperature at 40°C while stirring;

[0033] (c) Transfer the obtained precursor into an autoclave for crystallization at 180 °C for 48 h. After crystallization, cool and fi...

Embodiment 2

[0037] (a) Take the silicon source as tetraethyl orthosilicate, the aluminum source as aluminum nitrate, the template agent as tetrapropylammonium hydroxide and deionized water, and weigh each material according to the molar ratio, that is, SiO 2 :Al 2 o 3 : Templating agent: H 2 O=1:0.0025:0.1:40, one-step feeding to prepare a mixed solution; heat the mixed solution to 70°C for ultrasonic dissolution, the ultrasonic frequency is 80KHZ, wait for 15 minutes of ultrasonication, then immediately reduce the temperature to 40°C quickly, add After a certain amount of ethanol (ethanol / Si=0.2), then quickly add sulfuric acid dropwise under stirring (stirring speed: 200r / min) to adjust the pH to 8-10 to form a gel;

[0038] (b) Stir the obtained gel for 24 hours at a rotational speed of 350r / min, and control the ambient temperature at 40°C while stirring;

[0039] (c) Transfer the obtained precursor into an autoclave for crystallization at 150 °C for 60 h. After crystallization, co...

Embodiment 3

[0043] (a) Take silicon source as white carbon black, aluminum source as aluminum sulfate, template agent as tetrapropylammonium bromide and deionized water, and weigh each substance according to the molar ratio, that is, SiO 2 :Al 2 o 3 : Templating agent: H 2 O=1:0.002:0.2:60, one-step feeding to prepare a mixed solution; heat the mixed solution to 75°C for ultrasonic dissolution, ultrasonic frequency 50KHZ, wait for 10 minutes of ultrasonication, then immediately lower the temperature to 40°C quickly, add After a certain amount of ethanol (ethanol / Si=0.1), then quickly add sulfuric acid dropwise under stirring (stirring speed: 200r / min) to adjust the pH to 8-10 to form a gel;

[0044] (b) The obtained gel was stirred for 40 hours at a rotation speed of 300r / min, and the ambient temperature was controlled at 40°C during stirring;

[0045] (c) Transfer the obtained precursor into an autoclave for crystallization at 170 °C for 55 h. After crystallization, cool and filter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com