Method for preparing hydroxyacetone by glycerol dehydration

A technology of hydroxyacetone and glycerol, which is applied in the field of preparing hydroxyacetone by dehydration of glycerol, can solve the problem of not preparing simple hydroxyacetone and the like, and achieve the effect of good environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Dilute sodium metaaluminate, phosphoric acid, 40% silica sol, and distilled water according to n(Al):n(P):n(Si):n(H 2 O) The molar ratio is 1:1:0.1:40 and mixed, stirred for 20 minutes to obtain a gel, and the template agent isopropylamine is added according to the molar ratio n (template agent): n (P) is 2:1, and the stirring is continued until the formation is uniform Gel, put the gel in a reaction kettle, crystallize at 170°C for 1 day; the crystallized product is quenched, filtered, and washed to a pH value of 8, dried at 120°C for 12 hours, and baked in a muffle furnace at 550°C The template agent was removed to obtain the synthetic SAPO-11 molecular sieve.

[0027] 2) The configuration concentration is 12g / L copper bromide salt solution and the concentration is 6g / L chromium chloride salt solution, is dissolved in water with molar ratio 1: 2 and is formulated into mixed solution, adds the SAPO-11 prepared as described in step 1) Molecular sieves, soaked for 24...

Embodiment 2

[0030] 1) Dilute sodium metaaluminate, phosphoric acid, 40% silica sol, and distilled water according to n(Al):n(P):n(Si):n(H 2 O) The molar ratio is 1:1:0.1:40 mixed, stirred for 20 minutes to obtain gel II; the slurry I is added to the gel II, stirred for 30 minutes, according to the molar ratio n (template agent): n (P) is 2:1 Add the template agent isopropylamine, continue to stir until a uniform gel is formed, put the gel into the reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, and washed with water until the pH value was 8, dried at 120°C for 12 hours, and calcined in a muffle furnace at 550°C to remove the template agent to obtain SAPO-11 molecular sieve.

[0031] 2) The configuration concentration is 7g / L copper nitrate salt solution and 12g / L chromium nitrate salt solution, dissolved in water at a molar ratio of 1:2 to prepare a mixed solution, adding the SAPO-11 molecular sieve prepared as described in step 1), im...

Embodiment 3

[0034] S1, put glycerin into the preheater and heat to 80°C;

[0035] S2. Import the preheated glycerin into the reactive distillation column, control the vacuum degree in the column at -0.1Mpa, control the temperature of the reboiler at 130°C, and let the glycerin fully contact the catalyst on the surface of the packing layer on the tray for dehydration For the reaction, rectification was carried out with a reflux ratio of 4:1. When the temperature of the overhead distillate reached 120°C, the main product of the 130°C fraction was collected.

[0036] Calculated with the amount of glycerol, the ratio of agent to oil is 0.1%; the reactive distillation rectification column packing is stainless steel corrugated wire mesh and catalyzer; the catalyzer is the prepared loading Cr 2 Cu 2 o 5 / SAPO-11 catalyst.

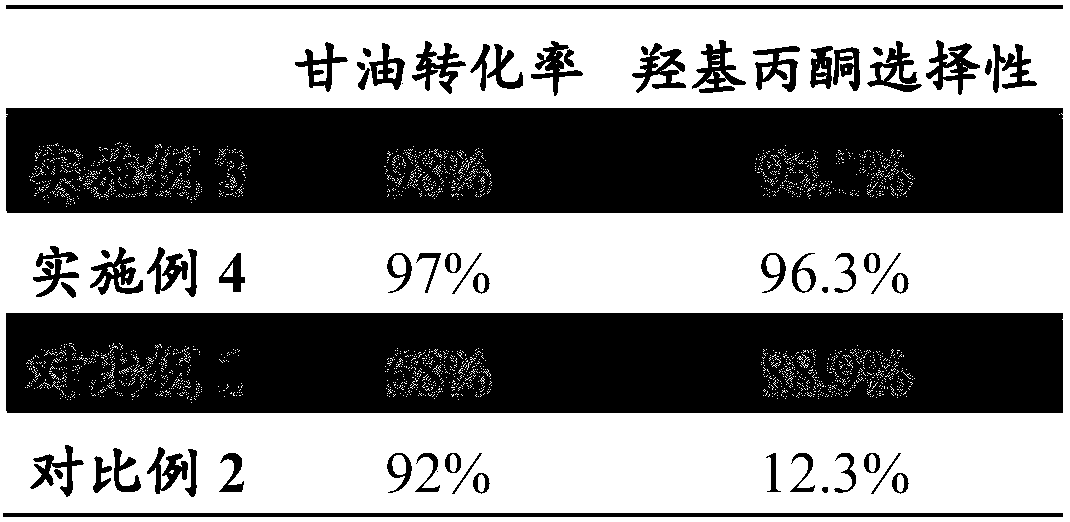

[0037] The conversion of glycerol and the yield of hydroxyacetone were determined by calibrated GC analysis, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com