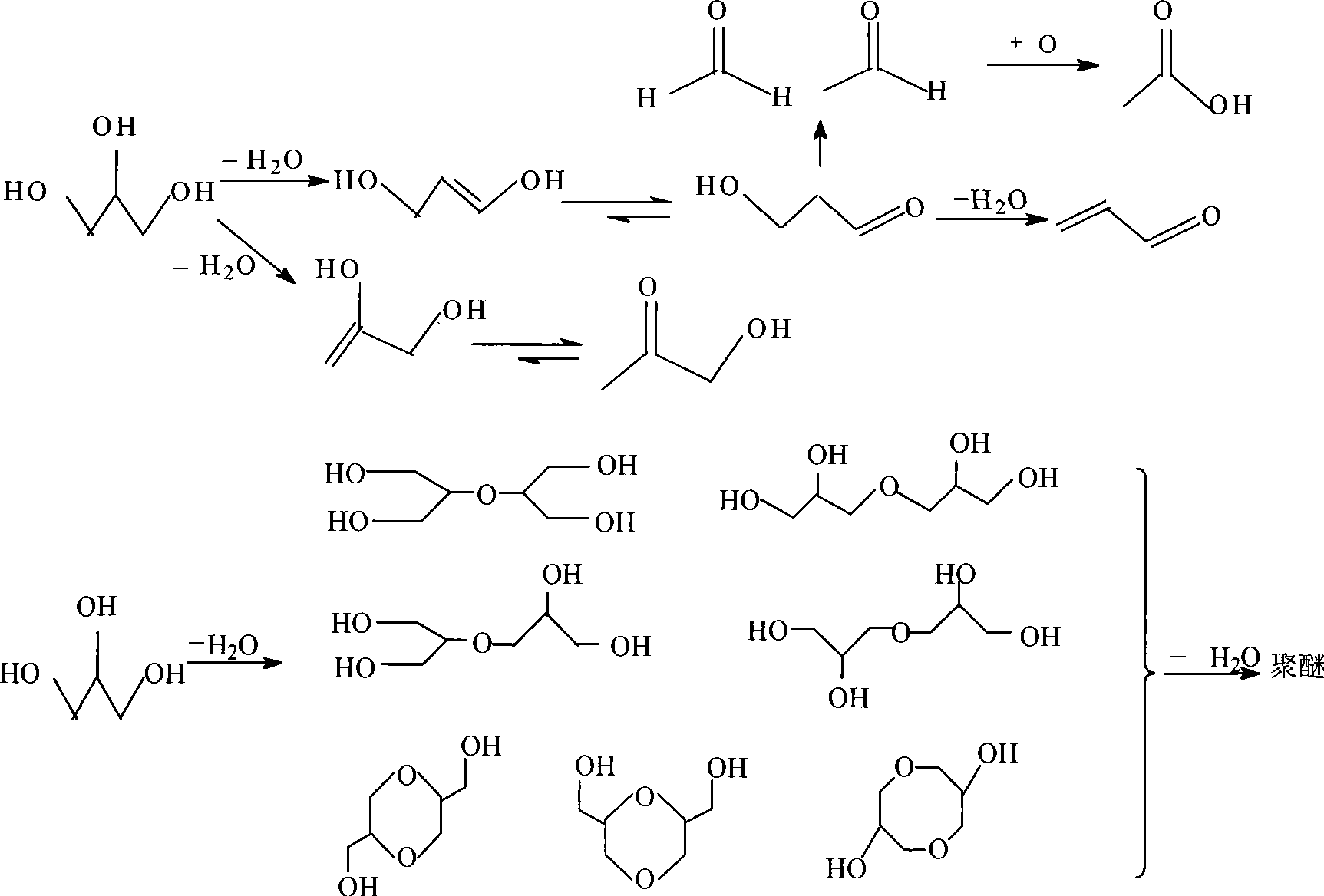

Method for preparing acrylic aldehyde by biological glycerol dehydration

A technology for acrolein and glycerin, which is applied in the preparation of carbon-based compounds, organic compounds, chemical instruments and methods, etc., can solve the problem of no obvious change in the molar selectivity of acrolein, low conversion rate of acrolein to glycerin, and the conversion of glycerin The efficiency is not high, to achieve the effect of renewable use of corrosion, molar selectivity, high conversion rate of glycerin, and fast rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh Mn(NO 3 ) 2 About 1.9g of the solution was dissolved in 35ml of distilled water to prepare 2.5% Mn(NO 3 ) 2 aqueous solution. Then measure 10ml of 2.5% Mn(NO 3 ) 2 aqueous solution, with 10g Al 2 o 3 Molecular sieves were mixed, heated and stirred in a 100ml beaker at 80°C for 4 hours, then dried in an oven at 120°C for 8 hours, and the dried modified zeolite molecular sieves were put into a muffle furnace and roasted at 350°C for 4 hours, and finally It is crushed to 18-30 mesh.

[0043] Prepare 18-30 mesh modified zeolite molecular sieve loaded heteropolyacid catalyst, prepare the catalyst by equal volume impregnation method, calculate the amount of silicotungstic heteropolyacid used according to the loading capacity of 20%, and then according to the calculated amount of heteropolyacid, weigh Take 2g of heteropoly acid to prepare an aqueous solution, and then mix the broken 18-30 mesh modified Al 2 o 3 The zeolite molecular sieve carrier was poured int...

Embodiment 2

[0046] Weigh Ca(NO 3 ) 2 About 2.4g, dissolved in 57.6ml of distilled water, prepared to obtain 4% Ca(NO 3 ) 2 aqueous solution. Then measure 10ml of 4% Ca (NO 3 ) 2 aqueous solution, with 10g Al 2 o 3 Molecular sieves were mixed, heated and stirred in a 100ml beaker at 80°C for 4 hours, then dried in an oven at 120°C for 8 hours, and the dried modified zeolite molecular sieves were put into a muffle furnace and roasted at 350°C for 4 hours, and finally It is crushed to 18-30 mesh to obtain Ca-Al 2 o 3 carrier.

[0047] Prepare 18-30 mesh modified zeolite molecular sieve loaded heteropolyacid catalyst, prepare the catalyst by equal volume impregnation method, calculate the amount of phosphotungstic heteropolyacid used according to the loading capacity of 20%, and then according to the calculated amount of heteropolyacid, weigh Take 2g of heteropoly acid to prepare an aqueous solution, and then mix the broken 18-30 mesh modified Al 2 o 3 The zeolite molecular sieve ...

Embodiment 3

[0050] Weigh 2.9gCo(NO 3 ) 2 , dissolved in about 55ml of distilled water to prepare 5% Co(NO 3 ) 2 aqueous solution, and then measure 10ml of 5% Co(NO 3 ) 2 aqueous solution, with 10g Al 2 o 3 Molecular sieves were mixed, heated and stirred in a 100ml beaker at 80°C for 4 hours, then dried in an oven at 120°C for 8 hours, and the dried modified zeolite molecular sieves were put into a muffle furnace and roasted at 350°C for 4 hours, and finally It is crushed to 18-30 mesh to obtain 5% Co-Al 2 o 3 carrier; then weigh about 2.4g Cu(NO 3 ) 2 , dissolved in about 45.6ml of distilled water, prepared to obtain 5% Cu(NO 3 ) 2 Aqueous solution, measure 10ml of 5% Cu(NO 3 ) 2 aqueous solution, with 10g 5% Co-Al 2 o 3 Molecular sieves were mixed, heated and stirred in a 100ml beaker at 80°C for 4 hours, then dried in an oven at 120°C for 8 hours, and the dried modified zeolite molecular sieves were put into a muffle furnace and roasted at 350°C for 4 hours to obtain Co ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com