Method for preparing acrolein by dehydrating glycerin

A technology of acrolein and glycerin aqueous solution, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of glycerin acrolein selectivity to be improved, poor catalyst stability, and complex catalyst preparation, etc., to achieve High conversion rate of glycerin and selectivity of acrolein, low carbon deposition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

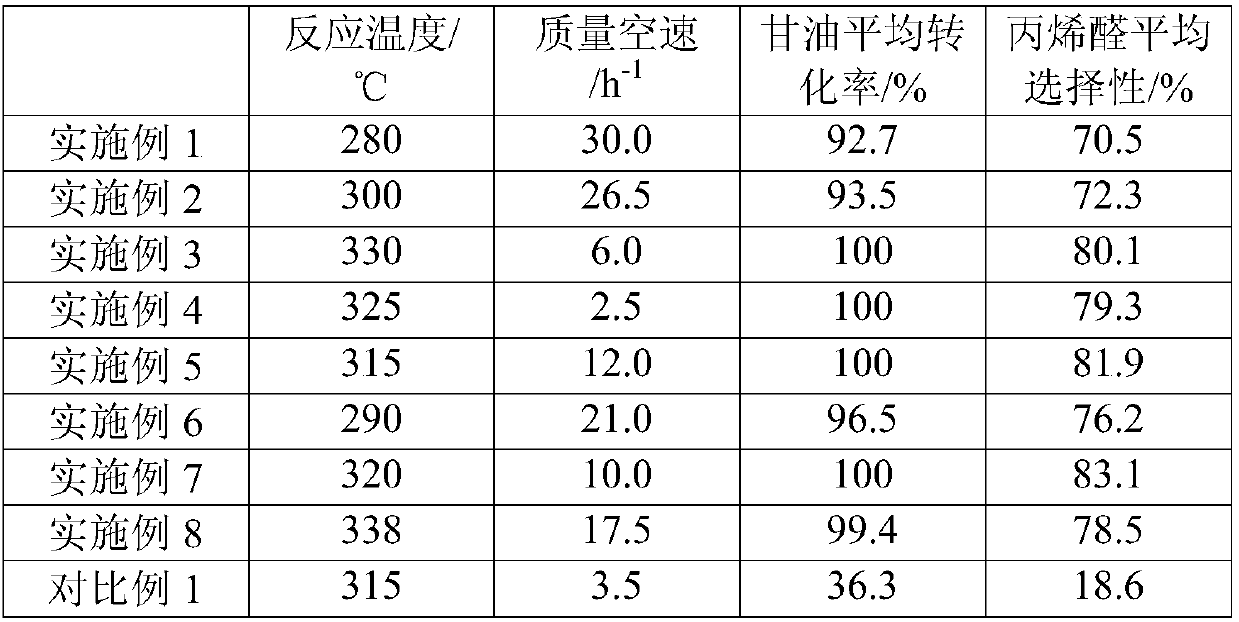

Examples

Embodiment 1

[0025] Take 30g of HZSM-5 molecular sieve (Si / Al=25.8), add it to 310ml of 0.12mol / L oxalic acid solution, stir magnetically at 78°C for 1.1h, then filter and wash until neutral, and dry in an oven at 120°C for 12h; Take 10 g of the obtained molecular sieve and add it to 210 ml of 0.22 mol / L NaOH solution, stir magnetically at 88°C for 1.2h, then filter and wash until neutral, and dry in an oven at 120°C for 12h. Add the obtained molecular sieve into 0.90mol / L ammonium nitrate solution, the solid-to-liquid ratio is 1:30, stir magnetically at 85°C for 2h, then filter and wash, dry in an oven at 120°C for 12h, and then place in a muffle furnace for 410 Baking at ℃ for 3.1h.

[0026] The above-mentioned catalyst (0.5 g, 20-40 mesh) was loaded into a fixed-bed reactor, and activated at 500° C. for 2 h under a nitrogen atmosphere (20 ml / min). Carry out the continuous reaction of glycerol dehydration system acrylic acid subsequently, be that 16wt% glycerol aqueous solution is raw m...

Embodiment 2

[0028] Take 20g of HZSM-5 molecular sieve (Si / Al=31.2), add it to 260ml of 0.11mol / L oxalic acid solution, stir magnetically at 75°C for 1.2h, then filter and wash until neutral, and dry in an oven at 120°C for 12h; Take 10 g of the obtained molecular sieve and add it to 310 ml of 0.21 mol / L NaOH solution, stir magnetically at 83°C for 0.8h, then filter and wash until neutral, and dry in an oven at 120°C for 12h. Add the obtained molecular sieve into 0.90mol / L ammonium nitrate solution, the solid-to-liquid ratio is 1:30, stir magnetically at 85°C for 2h, then filter and wash, dry in an oven at 120°C for 12h, and then place it in a muffle furnace for 450 Baking at ℃ for 3.5h.

[0029] The above-mentioned catalyst (0.5 g, 20-40 mesh) was loaded into a fixed-bed reactor, and activated at 500° C. for 2 h under a nitrogen atmosphere (20 ml / min). Carry out the continuous reaction of glycerin dehydration system acrylic acid subsequently, be that 42wt% aqueous glycerin is raw materia...

Embodiment 3

[0031] Take 35g of HZSM-5 molecular sieve (Si / Al=37.7), add it to 680ml of 0.10mol / L oxalic acid solution, stir magnetically at 71°C for 1.4h, then filter and wash until neutral, dry in an oven at 120°C for 12h; Add 15 g of the obtained molecular sieves to 580 ml of 0.19 mol / L NaOH solution, stir magnetically at 69°C for 0.7h, then filter and wash until neutral, and dry in an oven at 120°C for 12h. Add the obtained molecular sieve into 0.90mol / L ammonium nitrate solution, the solid-to-liquid ratio is 1:30, stir magnetically at 85°C for 2h, then filter and wash, dry in an oven at 120°C for 12h, and then place in a muffle furnace for 480 Roasting at ℃ for 4.6h.

[0032]The above-mentioned catalyst (0.5 g, 20-40 mesh) was loaded into a fixed-bed reactor, and activated at 500° C. for 2 h under a nitrogen atmosphere (20 ml / min). Carry out the continuous reaction of glycerol dehydration system acrylic acid subsequently, be that 50wt% glycerol aqueous solution is raw material with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com