Method for preparing acrolein by glycerol dehydration

A technology of acrolein and glycerin aqueous solution, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve problems such as catalyst deactivation, and achieve high catalytic activity, improved yield, and excellent anti-deactivation resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

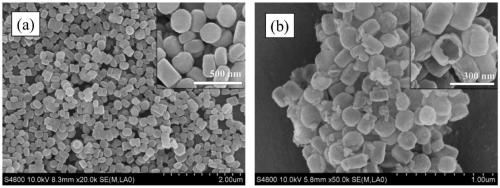

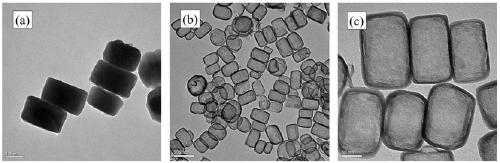

[0024] The preparation of the anti-coking hollow ZSM-5 molecular sieve catalyst and its application in the reaction of glycerol dehydration to prepare acrolein comprises the following steps:

[0025] (1) Mix deionized water and NaAlO 2 After mixing and stirring evenly, add tetrapropylammonium hydroxide aqueous solution with a mass fraction of 25%, and obtain a mixed solution after fully stirring; add tetraethyl orthosilicate dropwise to the mixed solution, and stir fully to hydrolyze tetraethyl orthosilicate Completely, put the above mixed solution into a hydrothermal kettle, crystallize at 120°C for 2h, then heat up to 170°C for 3d, centrifuge, wash, dry, and roast to obtain Na-ZSM-5 molecular sieve; among them, deionized water , NaAlO 2 , The molar ratio of tetrapropylammonium hydroxide aqueous solution and tetraethylorthosilicate is: 500:0.5:2:10;

[0026] (2) Put 1g of Na-ZSM-5 molecular sieve into 20mL of 0.1M inorganic alkali aqueous solution, mix and stir evenly, heat...

Embodiment 2

[0032]The preparation of the anti-coking hollow ZSM-5 molecular sieve catalyst and its application in the reaction of glycerol dehydration to prepare acrolein comprises the following steps:

[0033] (1) Mix deionized water and NaAlO 2 After mixing and stirring evenly, add tetrapropylammonium hydroxide aqueous solution with a mass fraction of 25%, and obtain a mixed solution after fully stirring; add tetraethyl orthosilicate dropwise to the mixed solution, and stir fully to hydrolyze tetraethyl orthosilicate Completely, put the above mixed solution into a hydrothermal kettle, crystallize at 120°C for 4h, then raise the temperature to 170°C for 4d, centrifuge, wash, dry, and roast to obtain Na-ZSM-5 molecular sieve; among them, deionized water , NaAlO 2 , The molar ratio of tetrapropylammonium hydroxide aqueous solution and tetraethylorthosilicate is: 1000:0.2:1:10;

[0034] (2) Put 1g of Na-ZSM-5 molecular sieve into 30mL of 0.2M inorganic alkali aqueous solution, mix and sti...

Embodiment 3

[0040] The preparation of the anti-coking hollow ZSM-5 molecular sieve catalyst and its application in the reaction of glycerol dehydration to prepare acrolein comprises the following steps:

[0041] (1) Mix deionized water and NaAlO 2 After mixing and stirring evenly, add tetrapropylammonium hydroxide aqueous solution with a mass fraction of 25%, and obtain a mixed solution after fully stirring; add tetraethyl orthosilicate dropwise to the mixed solution, and stir fully to hydrolyze tetraethyl orthosilicate Completely, put the above mixed solution into a hydrothermal kettle, crystallize at 100°C for 6h, then raise the temperature to 170°C for 3d, centrifuge, wash, dry, and roast to obtain Na-ZSM-5 molecular sieve; among them, deionized water , NaAlO 2 , The molar ratio of tetrapropylammonium hydroxide aqueous solution and tetraethylorthosilicate is: 600:0.25:2.5:10;

[0042] (2) Put 1g of Na-ZSM-5 molecular sieve into 30mL of 0.15M inorganic alkali aqueous solution, mix and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com