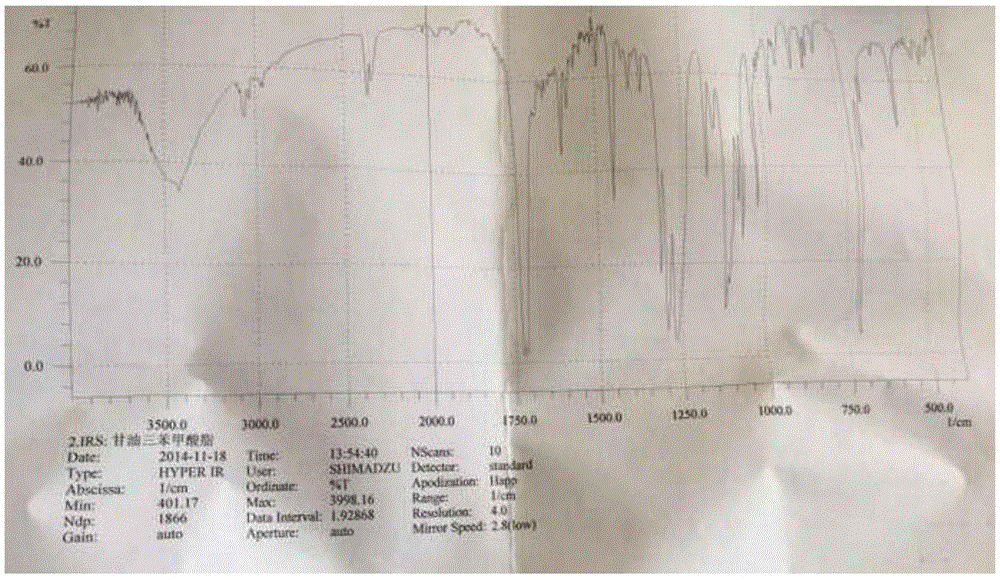

Production method of glycerin tribenzoate

A technology of glycerol tribenzoate and its production method, which is applied in the chemical field, can solve the problems of deep color of the reaction system, low atom economy, and many side reactions, and achieve stable color, short process flow, and low solvent unit consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 1000L reactor, add 184Kg of glycerin, 0.3Kg of sodium hydroxide, 732Kg of benzoic acid, and 50Kg of toluene, stir and raise the temperature until it dissolves and becomes clear, and then continue to raise the temperature to 220°C. Heat preservation and reflux dehydration reaction until almost no water evaporates, and continue heat preservation reaction for 1 hour. After the reaction is complete, toluene and benzoic acid are reclaimed by distillation, and the residual benzoic acid is steamed out by nitrogen distillation. After the material in the kettle is put into a square pan to cool, 800.5Kg of white solid is obtained, with a content of 98.3%. The distilled benzoic acid and toluene can be directly applied to the next batch after water separation.

Embodiment 2

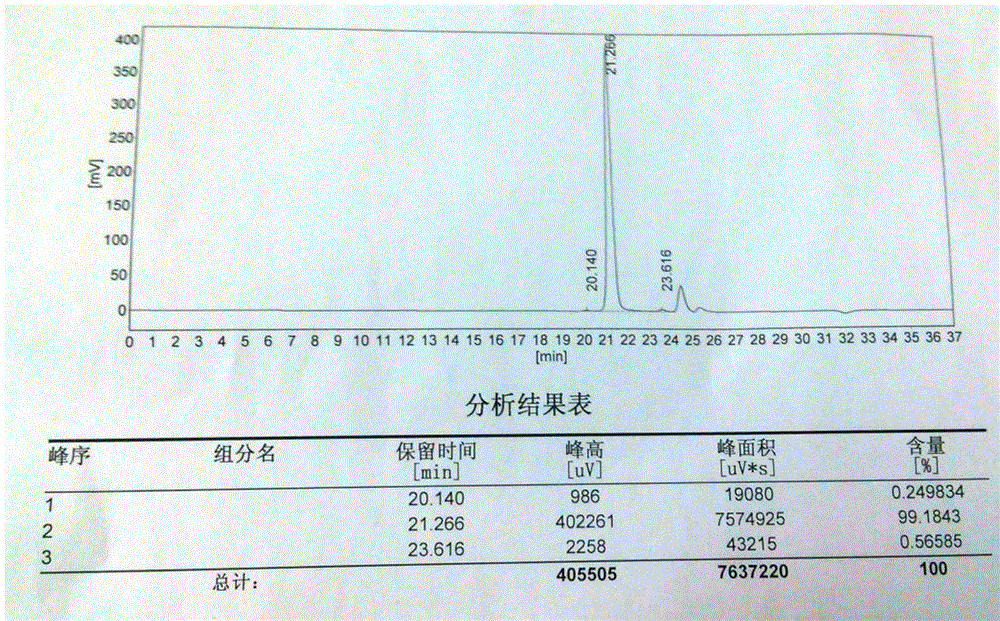

[0024] In a 1000L reaction kettle, add 184Kg of glycerin, 2Kg of potassium carbonate, 750Kg of benzoic acid, and 80Kg of xylene, stir and raise the temperature until dissolved and clear, and continue to raise the temperature to 220°C. Heat preservation and reflux dehydration reaction until almost no water evaporates, and continue heat preservation reaction for 1 hour. After the reaction is completed, xylene and benzoic acid are recovered by distillation. Nitrogen distillation was carried out to distill the residual benzoic acid, and the material in the still was put into a square pan to cool to obtain 806.1 Kg of white solid with a content of 99.1%. The distilled benzoic acid and xylene can be directly applied to the next batch after water separation.

Embodiment 3

[0026] In a 1000L reactor, add 184Kg of glycerin, 0.8Kg of sodium benzoate, 750Kg of benzoic acid, and 60Kg of n-octane, stir and raise the temperature until dissolved and clarified, and continue to raise the temperature to 220°C. Heat preservation and reflux dehydration reaction until almost no water evaporates, and continue heat preservation reaction for 1 hour. After the reaction is completed, n-octane and benzoic acid are recovered by distillation. The residual benzoic acid was steamed out by nitrogen distillation, and the material in the still was put into a square pan to cool to obtain 805.3 Kg of white solid with a content of 98.5%. The distilled benzoic acid and n-octane can be directly applied to the next batch after water separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com