Method of prolonging service life of catalyst in dehydration of glycerol for production of acrolein

A catalyst, acrolein technology, applied in chemical instruments and methods, separation/purification of carbonyl compounds, organic chemistry, etc. Good activity, the effect of the price without pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

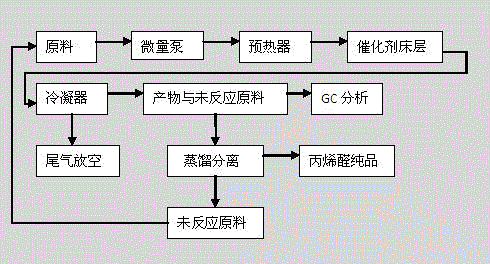

Method used

Image

Examples

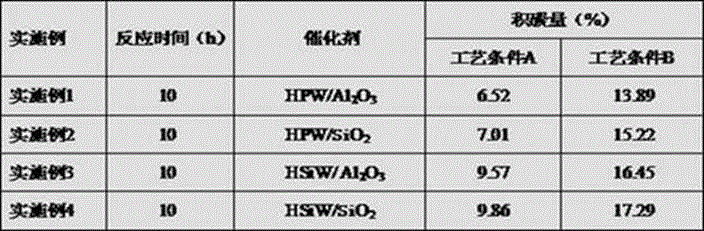

Embodiment 1~4

[0021] Weigh 3g of HPW and HSiW and 7g of active Al ground to below 40 mesh 2 o 3 and SiO 2 , put into a 100ml flask equipped with a stirrer, then add 15ml of deionized water, heat and stir in a constant temperature water bath at 60°C, dry in an oven at 100°C after 4 hours, grind to 20-30°C after tableting For this purpose, the worthwhile solid-supported catalyst is: HPW / Al 2 o 3 , HPW / SiO 2 、HSiW / Al 2 o 3 and HSiW / SiO 2 (both loads are 30%).

[0022] Fixed bed process condition A: the reaction temperature is 240°C, the volume space velocity is 15 h -1 , the concentration of glycerin aqueous solution is 15%, normal pressure, and the catalyst loading is 30%.

[0023] Fixed bed process condition B: the reaction temperature is 300°C, the volume space velocity is 6h -1 , the concentration of glycerin aqueous solution is 20%, normal pressure, and the loading capacity of catalyst is 30%.

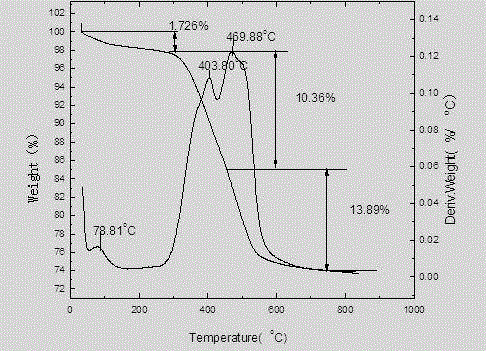

[0024] Determination of the carbon deposition amount of the catalyst: select th...

Embodiment 5

[0029] The preferred loading is 30%HPW / Al 2 o 3 as a catalyst, the reaction temperature is 240°C, and the volume space velocity is 15 h -1 , the concentration of glycerol aqueous solution was 15%, and the normal pressure was used to investigate the change of acrolein selectivity within 100 hours. The specific results are shown in Table 2.

[0030] Table 2

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com