Liner rubber material of liner rubber butterfly valve and preparation method thereof

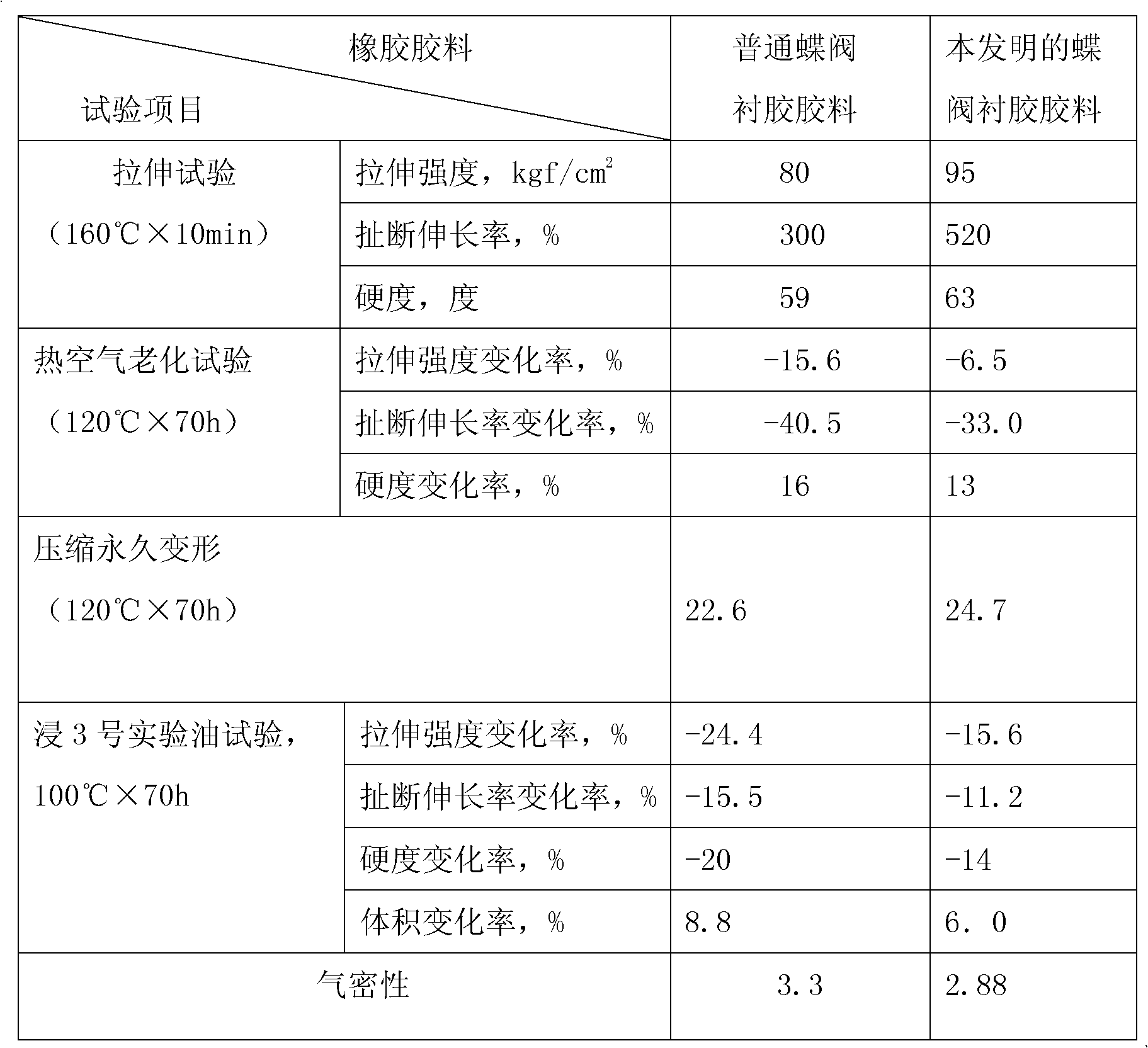

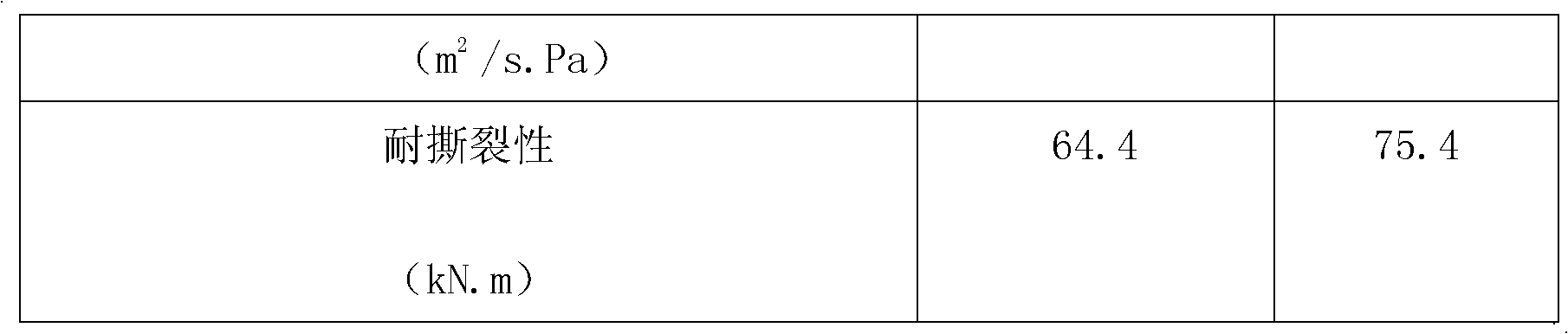

A technology of rubber lining and rubber material, which is applied in the rubber lining rubber material of rubber-lined butterfly valve and its preparation field, can solve the problems of high cost, expensive raw materials, relatively high requirements for sealing and corrosion resistance, and achieve good air tightness, The effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Raw material preparation:

[0032] Preparation of raw materials for rubber compound:

[0033] Weigh nitrile rubber 3304 90 sulfur 0.4, zinc oxide 5, stearic acid 2, antioxidant 2,5-ditert-butylhydroquinone-DTBHQ1, antioxidant RD 1.5, antioxidant OD 1.5, paraffin 2, Fast extrusion carbon black N66024, high wear-resistant carbon black N330 63, dioctyl ester 20, attapulgite 30, accelerator M 2, accelerator DM 1, accelerator PZ 1,

[0034] Preparation of raw materials for B rubber compound:

[0035] Weigh fluorine rubber 246 90, zinc stearate 1, anti-aging agent RD 2, glue Yisu T-780.5, rhine wax 1.5, quick press carbon black 50, pottery clay 12, dioctyl ester 6, dilead tetroxide 5, Vulcanizing agent DTDM 0.8, accelerator CZ 1.5.

[0036] 2. The preparation method of the rubber-lined rubber material of the rubber-lined butterfly valve includes the following steps:

[0037] The first step: Prepare A rubber material and B rubber material respectively

[0038] 1. Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com