Polyether-ether-ketone resin as well as preparation method and application thereof

A polyether ether ketone resin, polymerization reaction technology, applied in the field of polyetheretherketone resin, polyether ether ketone resin application, polyether ether ketone resin preparation, can solve the problem of deep color resin, volatile, oxidative deterioration, etc. problem, to achieve the effect of resin color improvement, controllability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

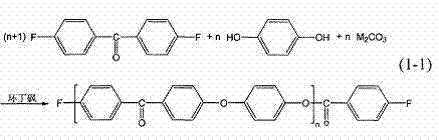

[0045] The invention discloses a preparation method of polyether ether ketone resin, comprising the following steps:

[0046] Step 1, remove the air in the solvent sulfolane and the reaction vessel with a protective gas.

[0047] The protective gas is high-purity nitrogen or high-purity argon, and the air in the liquid phase and the reaction vessel is replaced by first vacuumizing and then filling the high-purity protective gas into the solvent.

[0048] Step 2: Add 4,4'-difluorobenzophenone and carbonate and / or bicarbonate to the reaction vessel under the condition of a protective gas and stirring, and heat the reaction vessel.

[0049] The specific process is to add 4,4'-difluorobenzophenone and carbonate / Bicarbonate, heat the reaction vessel, and discharge the moisture and air in the system. At this time, the water is the water contained in the raw materials. When the temperature of the system rises above 100°C, the water contained in the system evaporates from the syste...

Embodiment 1

[0067] Add 277kg of solvent sulfolane into a 300L reaction vessel, replace the liquid phase and the air in the reaction vessel by vacuuming and passing high-purity argon into the solvent. The flow rate of high-purity argon is 3Nm / min. After about 30min, use The oxygen content in the exhausted air is detected online by a gas-phase oxygen analyzer to be 0.06% (V / V), such as the inPro 6900 gas-phase oxygen detector from METTLER TOLEDO; start stirring, and then react under the protection of 0.5Nm / min argon Add 37.46kg of 4,4'-difluorobenzophenone and 19.82kg of high-purity anhydrous sodium carbonate to the container, heat the reaction container, and set the argon opening to 1.0Nm / min to discharge the moisture in the system. At 100°C, the water in the system evaporates from the system and is taken out of the reactor by the protective gas. After 45 minutes, when the temperature of the system rises to 180°C, the water in the system evaporates from the system and is taken out of the re...

Embodiment 2

[0070] According to the method of Example 1, the solvent sulfolane is 196kg, the protective gas is high-purity nitrogen, and the oxygen content in the discharged air is detected online by a gas phase oxygen detector to be 0.08% (V / V), and 40.06kg4,4' is added to the reaction vessel -Difluorobenzophenone and 22.53kg of high-purity anhydrous sodium carbonate, heating the reaction vessel to discharge the water in the system, the water content in the exhaust gas measured by an online hygrometer is 0.09% (V / V), indicating that the water in the system has evaporated completely , Add 18.72kg hydroquinone and 15kg water-carrying agent toluene. After adding water, the moisture content in the exhaust gas was measured by an online hygrometer to be 0.02% (V / V), and the condensed water was measured as 3.05kg, indicating that the water in the system evaporated completely, and the reaction stopped after 4.5 hours when the temperature was raised to 260-265°C. Release the reaction product, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com