Soluble fluorine-containing polyaryl ether ketone high-performance material, preparation method thereof and mixed film of the same and epoxy resin

A polyaryletherketone and epoxy resin technology, applied in the field of blended film materials, can solve the problems of single processing method, limited application, poor solubility, etc. Use the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

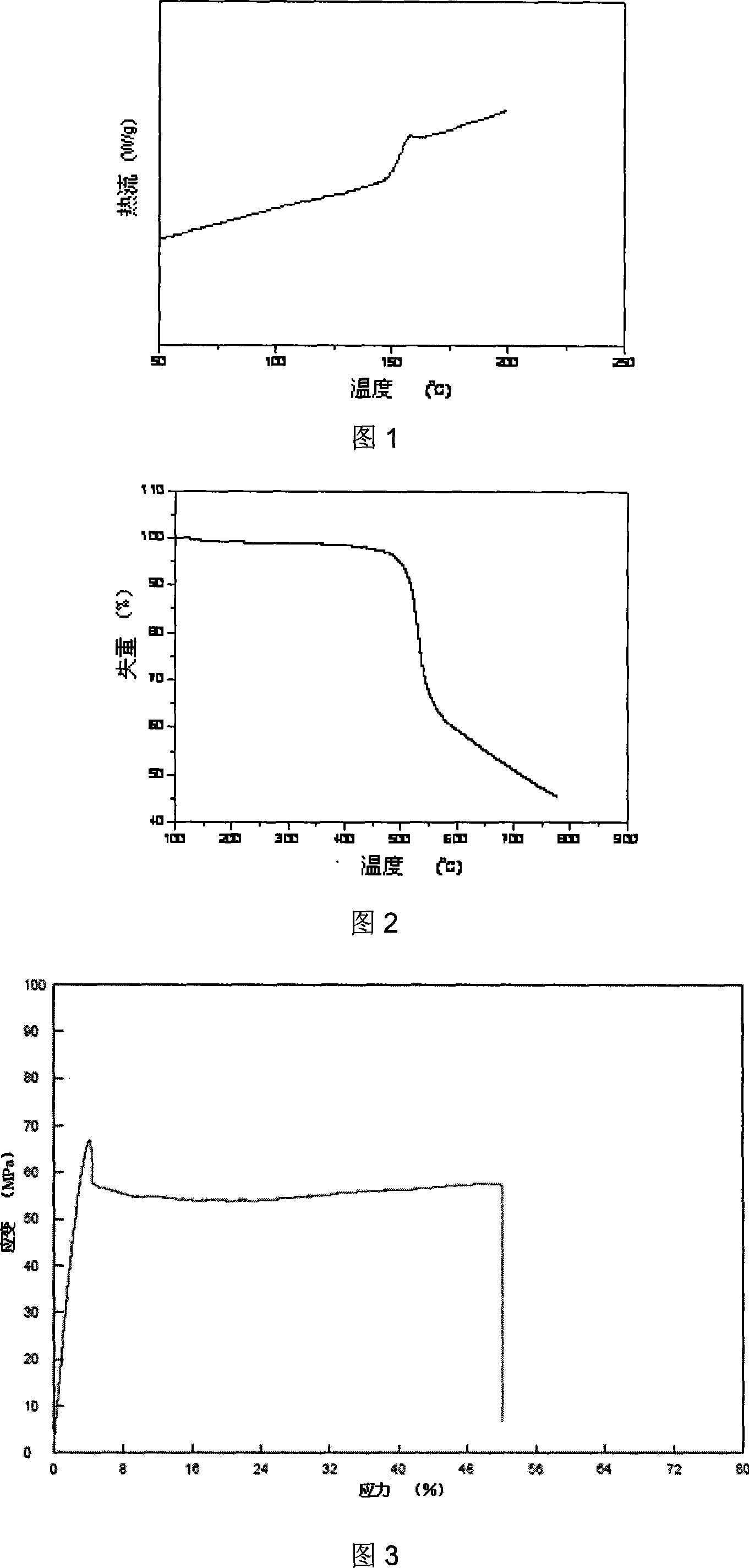

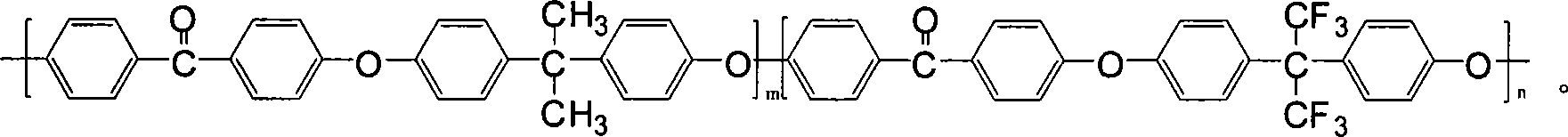

Embodiment 1

[0047]Add 43.64g (0.20mol) 4,4'-difluorobenzophenone, 50.05g (0.16mol) of bisphenol A, hexafluorobisphenol A to a 1000ml three-necked flask equipped with mechanical stirring, thermometer and nitrogen gas. 13.59g (0.04mol), sulfolane 195ml (solid content is 30%), toluene 100ml, after heating and melting, add 28.98g (0.21mol) of anhydrous potassium carbonate, stir and heat up to 120°C for 2 hours, and the water generated by the reaction is completely dissolved. Then, the temperature is raised to the next reaction temperature interval, and toluene is emitted during the heating process. Raise the temperature to 200°C for 1 hour, and finally raise the temperature to 230°C to continue the reaction for 3 hours. The reaction product is discharged in cold water. The crude product is pulverized by a pulverizer, boiled and washed with distilled water for 6 to 8 times to remove the organic solvent sulfolane and inorganic salts. The final product was dried at 120° C. for 12 hours to obtain...

Embodiment 2

[0053] The method is as in Example 1, keeping the molar number of 4,4'-difluorobenzophenone unchanged (0.20mol), and changing the molar content of hexafluorobisphenol A to 0.06mol, 0.08mol, 0.10mol, 0.12mol in turn, The molar content of bisphenol A is changed to 0.14mol, 0.12mol, 0.10mol, 0.08mol in turn, after the same treatment as in Example 1, soluble fluorine-containing polyarylenes with a molecular weight between 30,000 and 40,000 are obtained respectively. A white powder sample of ether ketone, the yield is between 96% and 98%. The thermal properties and mechanical properties of the resulting product are similar to those of the product in Example 1.

Embodiment 3

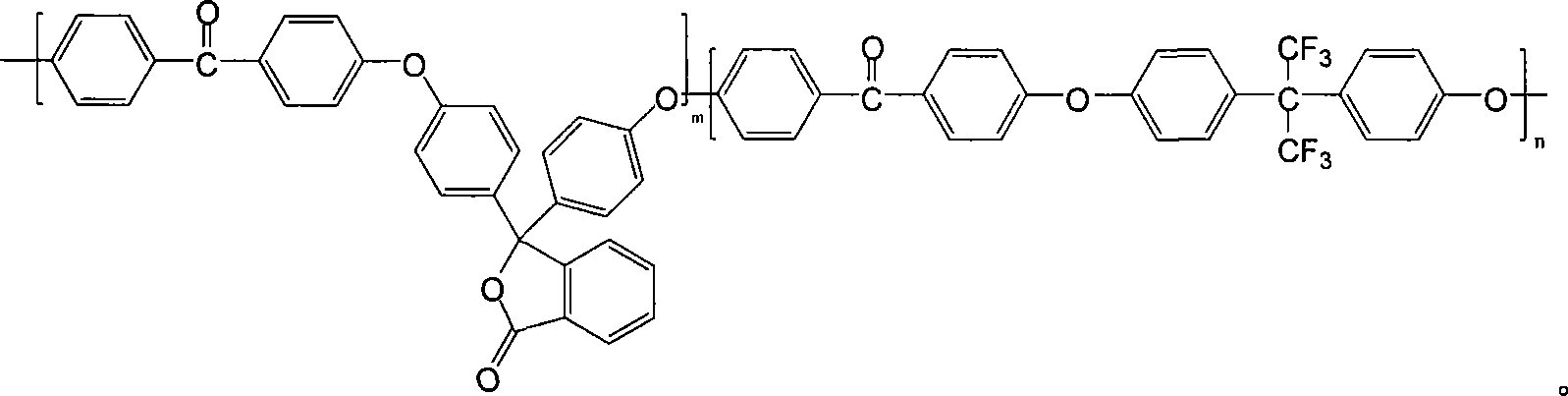

[0055] Add 43.64g (0.20mol) of 4,4'-difluorobenzophenone, 13.59g (0.04mol) of hexafluorobisphenol A, and 50.93g of phenolphthalein into a 1000ml three-necked flask equipped with mechanical stirring, thermometer and nitrogen gas (0.16mol), sulfolane 200ml, toluene 100ml, after heating and melting, add 28.98g (0.21mol) of anhydrous potassium carbonate, stir and heat up to 120°C for 2 hours, completely take out the water generated by the reaction, and then raise the temperature to release toluene. Raise the temperature to 200°C for 1 hour, and finally raise the temperature to 230°C to continue the reaction for 3 hours. The reaction product is discharged in cold water. The crude product is pulverized by a pulverizer, boiled and washed with distilled water for 6 to 8 times to remove the organic solvent sulfolane and inorganic salts. The final product was dried at 120° C. for 12 hours to obtain a white soluble fluorine-containing polyaryletherketone powder sample with a molecular wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com