High oil-resistant sealing element rubber material and its preparation method

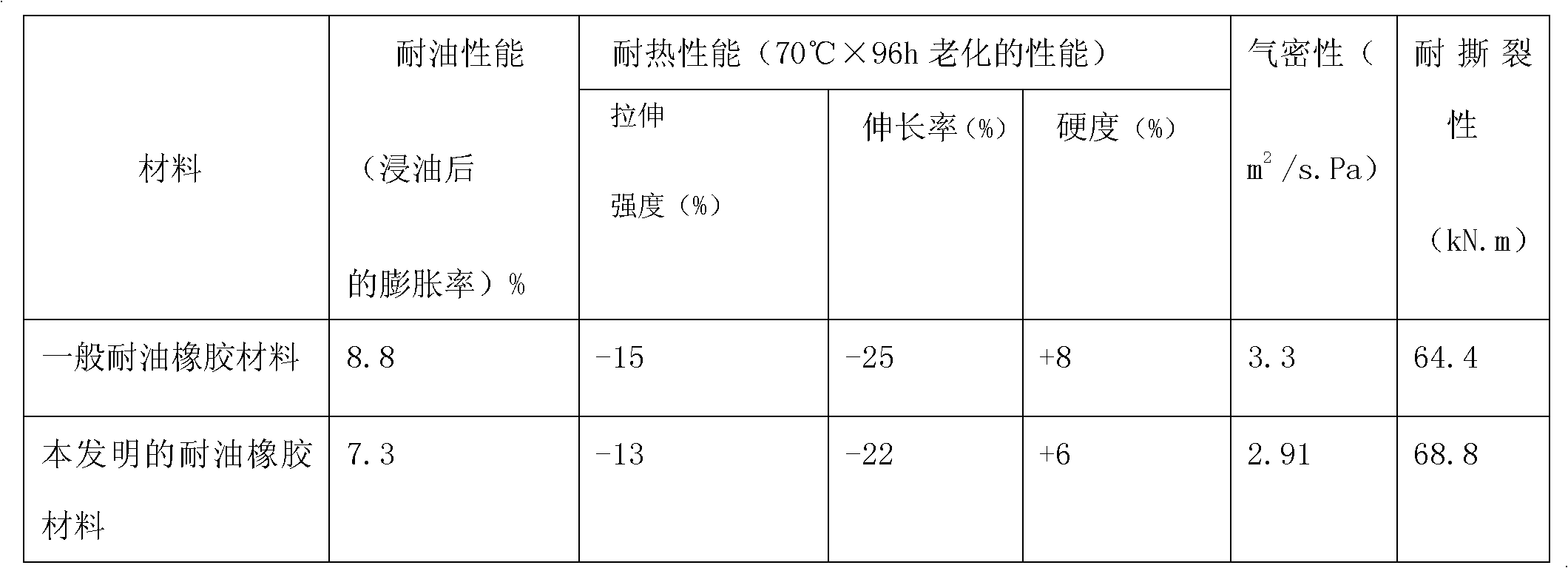

A technology for rubber materials and seals, which is applied in the field of rubber materials for oil-resistant seals and its preparation, can solve the problems of high cost, high price of hydrogenated nitrile rubber and chlorohydrin rubber, and achieve low cost, good oil resistance, and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Raw material preparation:

[0032] Preparation of raw materials for rubber compound:

[0033] Weigh nitrile rubber N41 90 sulfur 0.4, zinc oxide 5, stearic acid 2, antioxidant 2,5-ditertbutylhydroquinone-DTBHQ1, antioxidant RD 1.5, antioxidant 4010NA 1.5, paraffin wax 2, Fast extrusion carbon black N660 24, high wear-resistant carbon black N330 63, dioctyl ester 20, calcium carbonate 30, accelerator DM 2, accelerator TMTD1, accelerator TETD1,

[0034] Preparation of raw materials for B rubber compound:

[0035] Weigh one-component homopolychlorohydrin rubber 85, copolychlorohydrin rubber 15, zinc stearate 1, anti-aging agent RD 2, gelatin T-78 0.5, rhine wax 1.5, quick-extrusion carbon black 50, diatomaceous earth 12. Dioctyl ester 6, dilead tetroxide 5, sulfur 0.5, accelerator Na-22 1.5.

[0036] 2. A method for preparing a rubber material for a high oil-resistant seal, comprising the following steps:

[0037] The first step: Prepare A rubber material and B rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com