Quicksand-type stuffing with long shelf life and resistant to bake and premixed flour and manufacturing method thereof

A shelf-life and baking-resistant technology, applied in the field of pastry fillings, can solve problems that affect the quality of baked products and food safety, cannot meet the needs of product circulation, and complex storage and processing, etc., to achieve inhibition of oxidation and destruction, excellent water retention performance, cost-effective high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

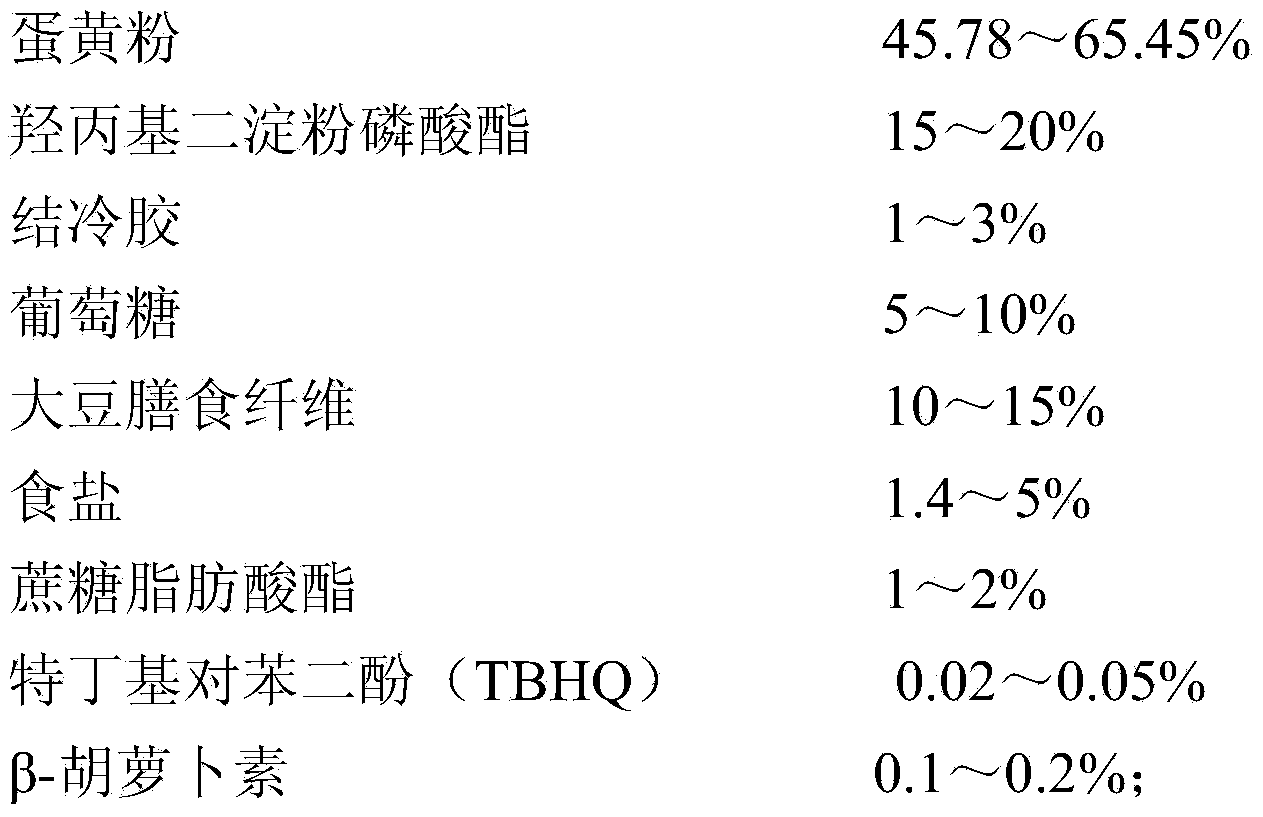

Method used

Image

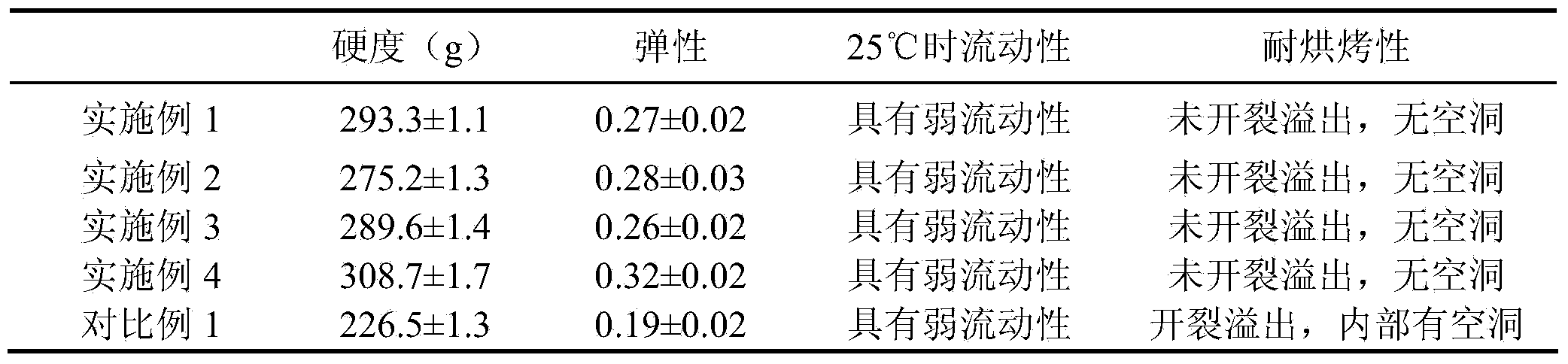

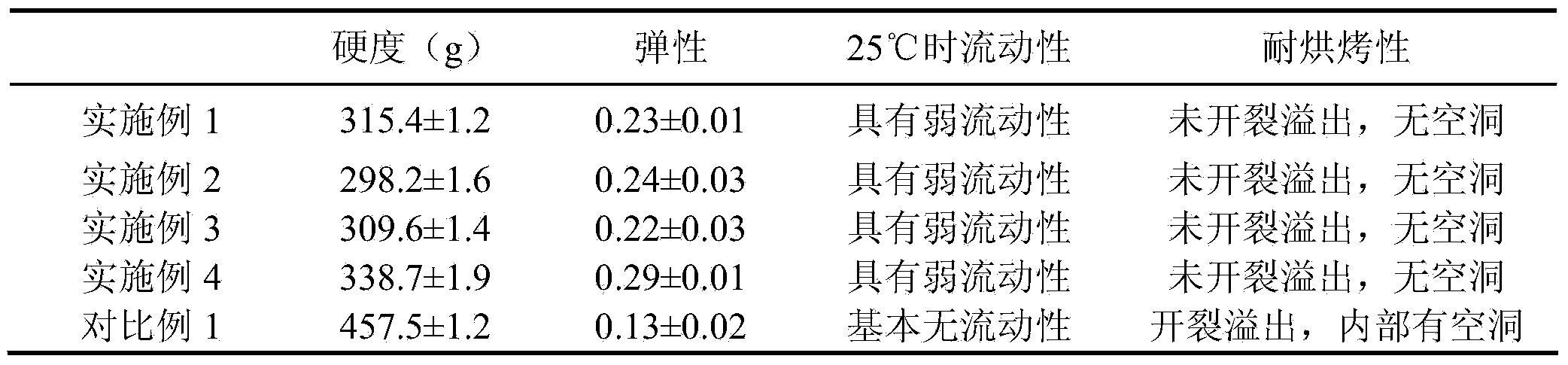

Examples

Embodiment 1

[0057](1) With egg yolk powder 457.8g, hydroxypropyl distarch phosphate (French Roquette company, waxy corn modified starch, model is CR3020) 200g, gellan gum (viscosity is 2100cp, 1% gellan gum aqueous solution ) 30g, glucose 100g, soybean dietary fiber 150g, salt 50g, sucrose fatty acid ester (HLB value is 11) 10g, tert-butyl hydroquinone 0.2g, beta-carotene 2g mix, stir in mixing mixer, Pass No. CQ20 sieve, obtain quicksand stuffing premix powder 1000g.

[0058] (2) Put the filling premix powder obtained in step (1) into the sandwich pot, then add 1500 g of maltose syrup (solid content is 80%) and 6 g of potassium sorbate, stir and mix for 3 minutes at a speed of 30 rpm to obtain a uniform and smooth mixture of yellow paste.

[0059] (3) Pour 2500g of water, 800g of anhydrous ghee and 200g of edible glycerin into the jacketed pot, stir at a stirring speed of 60rpm for 5 minutes until no particles are visible to the naked eye, then turn on the steam in the jacketed pot, and...

Embodiment 2

[0063] (1) egg yolk powder 521g, hydroxypropyl distarch phosphate (French Roquette company, waxy corn modified starch, model is CR3020) 185g, gellan gum (viscosity is 2100cp, 1% gellan gum aqueous solution) 22g, glucose 92g, soybean dietary fiber 130g, salt 35g, sucrose fatty acid ester (HLB value is 11) 13g, 0.3g of tert-butyl hydroquinone, β-carotene 1.7g are mixed, stir in mixing mixer, Obtain 1000 g of quicksand filling premix powder.

[0064] (2) Put the filling premix powder obtained in step (1) into the jacketed pot, then add 1800 g of maltose syrup (solid content is 80%) and 5.6 g of potassium sorbate, stir and mix at a speed of 30 rpm for 3 minutes, pass CQ20 No. sieve to obtain a uniform and smooth yellow slurry.

[0065] (3) Pour 2200g of water, 770g of anhydrous ghee and 230g of edible glycerin into the jacketed pot, stir at a stirring speed of 60rpm for 5 minutes until no particles are visible to the naked eye, then turn on the steam in the jacketed pot, and heat...

Embodiment 3

[0069] (1) egg yolk powder 595.2g, hydroxypropyl distarch phosphate (French Roquette company, waxy corn modified starch, model is CR3020) 170g, gellan gum (viscosity is 2100cp, 1% gellan gum aqueous solution ) 16g, glucose 60g, soybean dietary fiber 115g, salt 25g, sucrose fatty acid ester (HLB value 11) 17g, tertiary butyl hydroquinone 0.4g, β-carotene 1.4g mix, stir in the mixing mixer , pass No. CQ20 sieve, obtain quicksand stuffing premix powder 1000g.

[0070] (2) Put the filling premix powder obtained in step (1) into the jacketed pot, then add 2200 g of maltose syrup (solid content is 80%) and 5.6 g of potassium sorbate, stir and mix for 3 minutes at a speed of 30 rpm to obtain a uniform Smooth yellow paste.

[0071] (3) Pour 1800g of water, 730g of anhydrous ghee and 270g of edible glycerin into the jacketed pot, stir at a stirring speed of 60rpm for 5 minutes until no particles are visible to the naked eye, then turn on the steam in the jacketed pot, and heat the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com