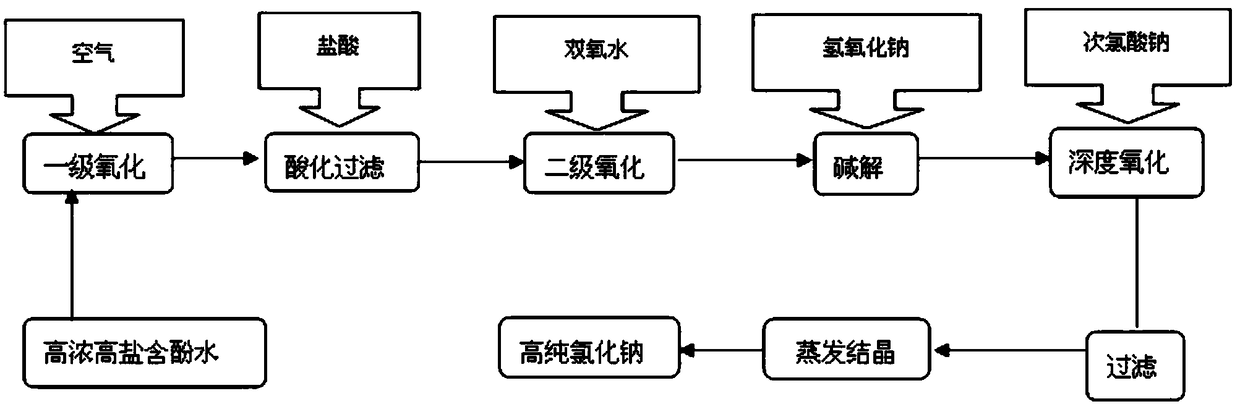

Process for harmless disposal of high-concentration high-salt phenol-containing wastewater and recovery of high-purity sodium chloride

A technology for phenol wastewater and sodium chloride, which is applied in the field of harmless disposal of high-concentration and high-salt phenol-containing wastewater and high-purity sodium chloride recovery process, can solve the waste of resources, the difficulty in treatment of high-concentration and high-salt phenol-containing wastewater, To deal with high cost problems, to achieve the effect of reducing material cost, realizing resource utilization and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

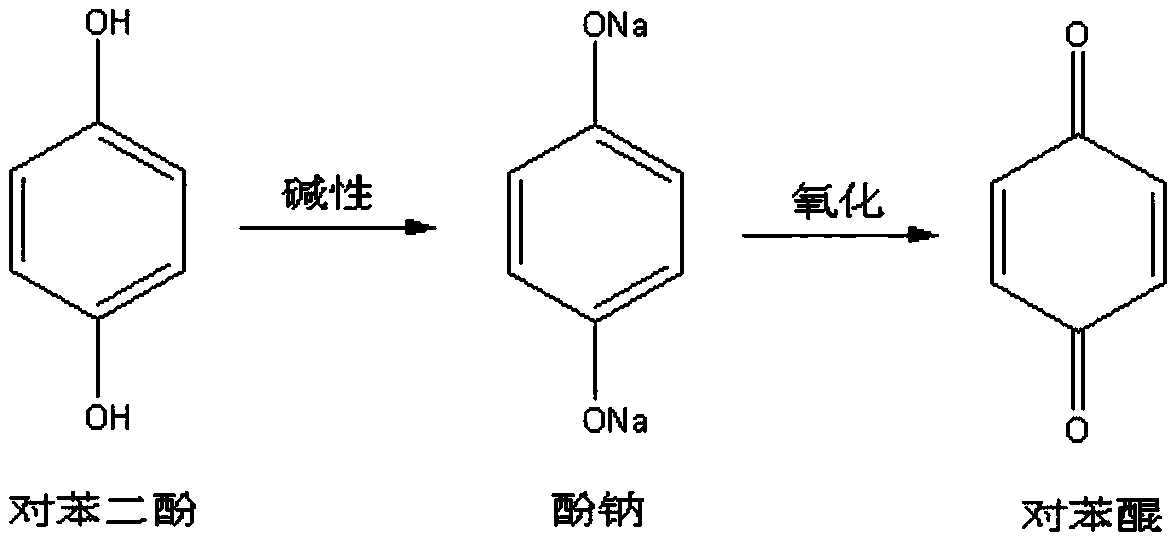

Method used

Image

Examples

Embodiment 1

[0020] Take 500ml of high-concentration and high-salt phenolic wastewater (COD Cr : 65736mg / L, ammonia nitrogen: 1419.2mg / L, full salt: 69460mg / L, pH=11.8), place in the laboratory vertical air flotation device, open the air compressor,

[0021] At 20°C, air is introduced into the waste water for primary oxidation. During the primary oxidation process, the air flow rate is 22L / min, and the oxidation time is 5h. After the oxidation is complete, transfer the wastewater in the air flotation device to a four-necked flask, adjust the pH value of the water sample to 3.2 with 30% hydrochloric acid, stir for 10 minutes, filter, and remove the precipitate to obtain acidic wastewater, water quality COD Cr Reduced to 37287mg / L;

[0022] Add hydrogen peroxide to the acidic wastewater after primary oxidation for hydrogen peroxide oxidation. During the secondary oxidation process, add 8ml of hydrogen peroxide to each liter of acidic wastewater, and the oxidation time is 3h. After the seco...

Embodiment 2

[0026] Take 500ml of high-concentration and high-salt phenolic wastewater (COD Cr : 57321mg / L, ammonia nitrogen: 1273.2mg / L, full salt: 47683mg / L, pH=12.1), be placed in laboratory vertical air flotation device, open air compressor,

[0027] At 20°C, air is introduced into the waste water for primary oxidation. During the primary oxidation process, the air flow rate is 26L / min, and the oxidation time is 4.5h. After the oxidation is complete, transfer the wastewater in the air flotation device to a four-necked flask, adjust the pH value of the water sample to 3.8 with 30% hydrochloric acid, stir for 10 minutes, filter, and remove the precipitate to obtain acidic wastewater, water quality COD Cr Reduced to 23563mg / L;

[0028] Add hydrogen peroxide to the acidic wastewater after primary oxidation for hydrogen peroxide oxidation. During the secondary oxidation process, add 10ml of hydrogen peroxide to each liter of acidic wastewater, and the oxidation time is 2h. After the secon...

Embodiment 3

[0032] 1000L of high-concentration and high-salt phenolic wastewater (COD Cr: 42400mg / L, ammonia nitrogen: 1018mg / L, full salt: 4592.0mg / L, pH=10.5), carry out the workshop pilot test amplification, utilize the pump to transfer in the R105A reactor, open the reactor to stir and carry out the wastewater system stirring, open the workshop The wind line, under the condition of 20 ℃, feeds air into the R105A reactor for primary oxidation. During the primary oxidation, the air flow rate is 30L / min, and the oxidation time is 4h. After the primary oxidation, transfer the wastewater in the R105A reactor to the R105B reactor, use 30% hydrochloric acid in the workshop storage tank to adjust the pH value of the water sample to 3.5, turn on the R105B and stir for 10 minutes, and then pour the wastewater in the R105B reactor into the M105A board box for filtration, the filtered water quality COD Cr Reduced to 24245mg / L.

[0033] Perform secondary oxidation on the filtered acidic wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com