Patents

Literature

38results about How to "Does not require high temperature and pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

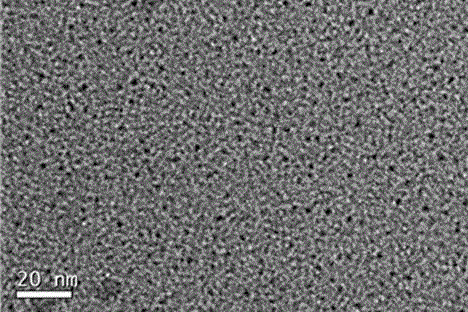

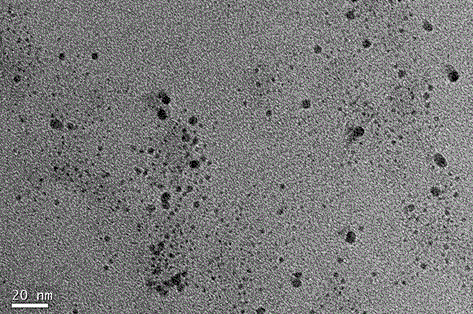

Preparation method of N-doped porous carbon coated nano-particles of Co-Ir core-shell structure and application of N-doped porous carbon coated nano-particles of Co-Ir core-shell structure to catalytic water splitting

InactiveCN108048866AThe preparation process is simple and straightforwardReduce energy consumptionTransportation and packagingMetal-working apparatusIridiumPorous carbon

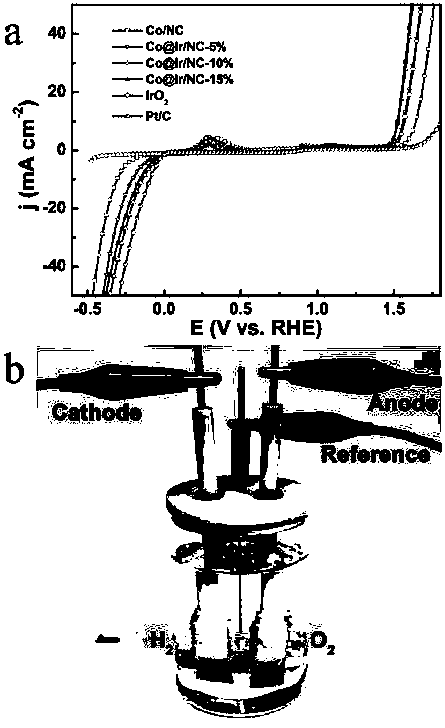

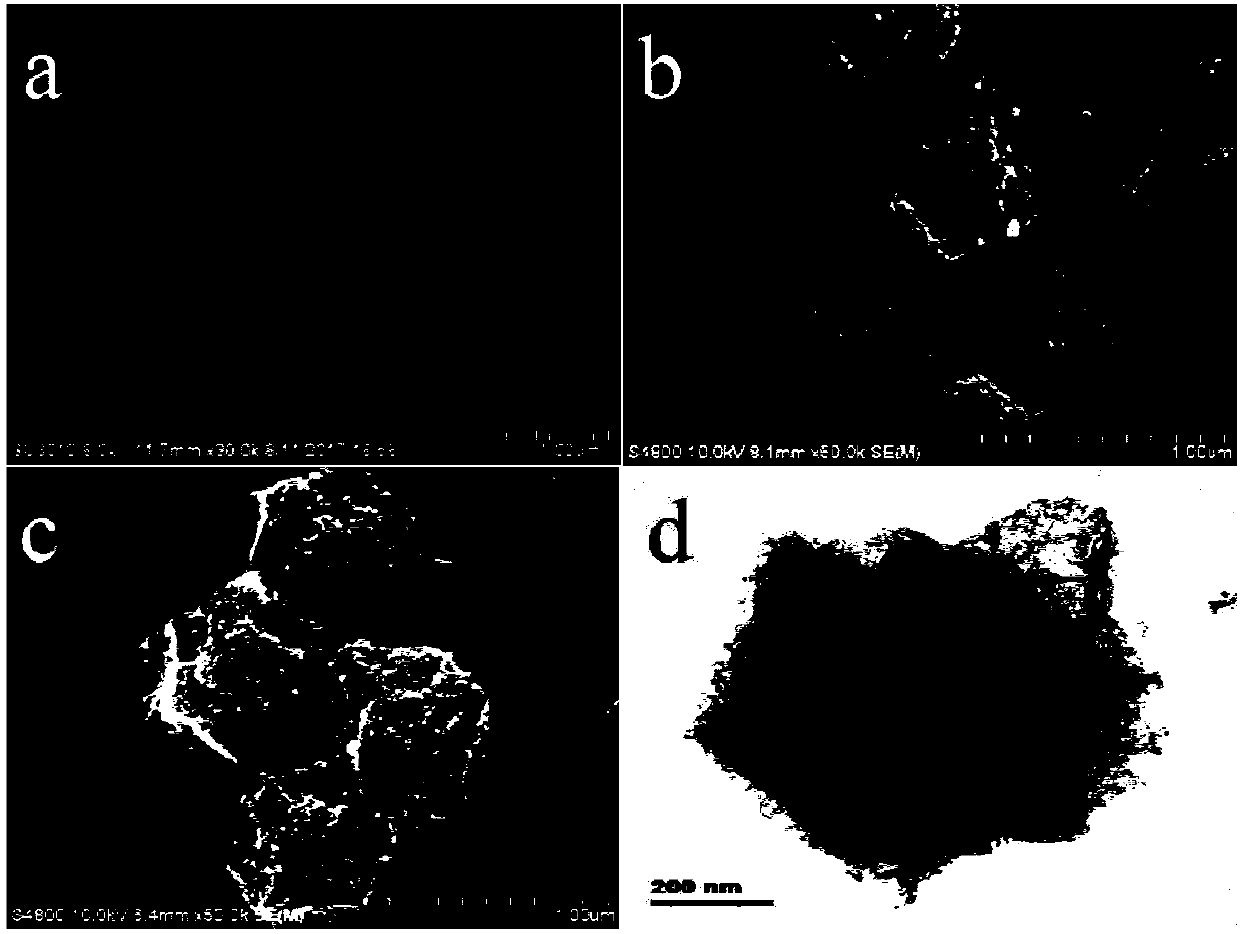

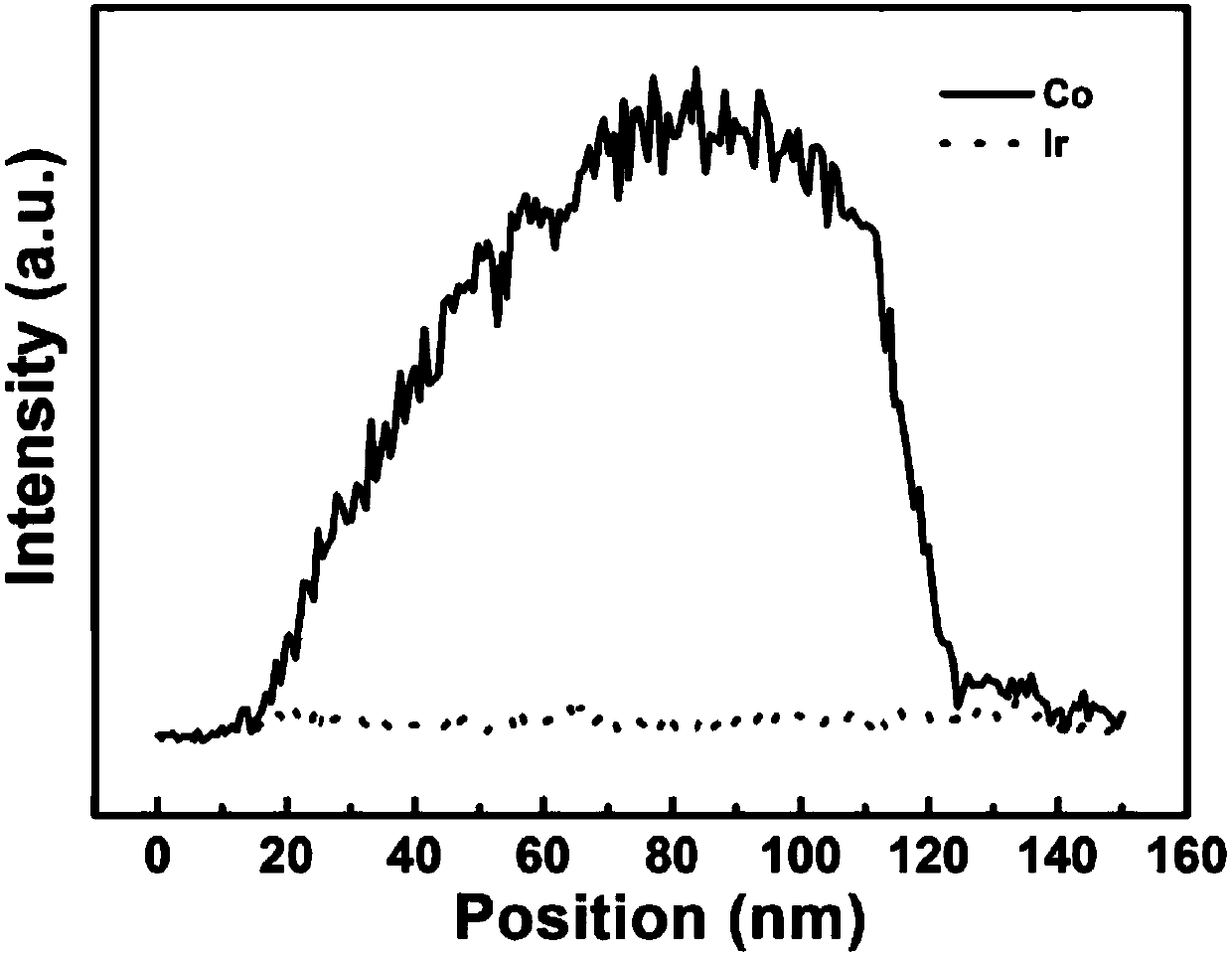

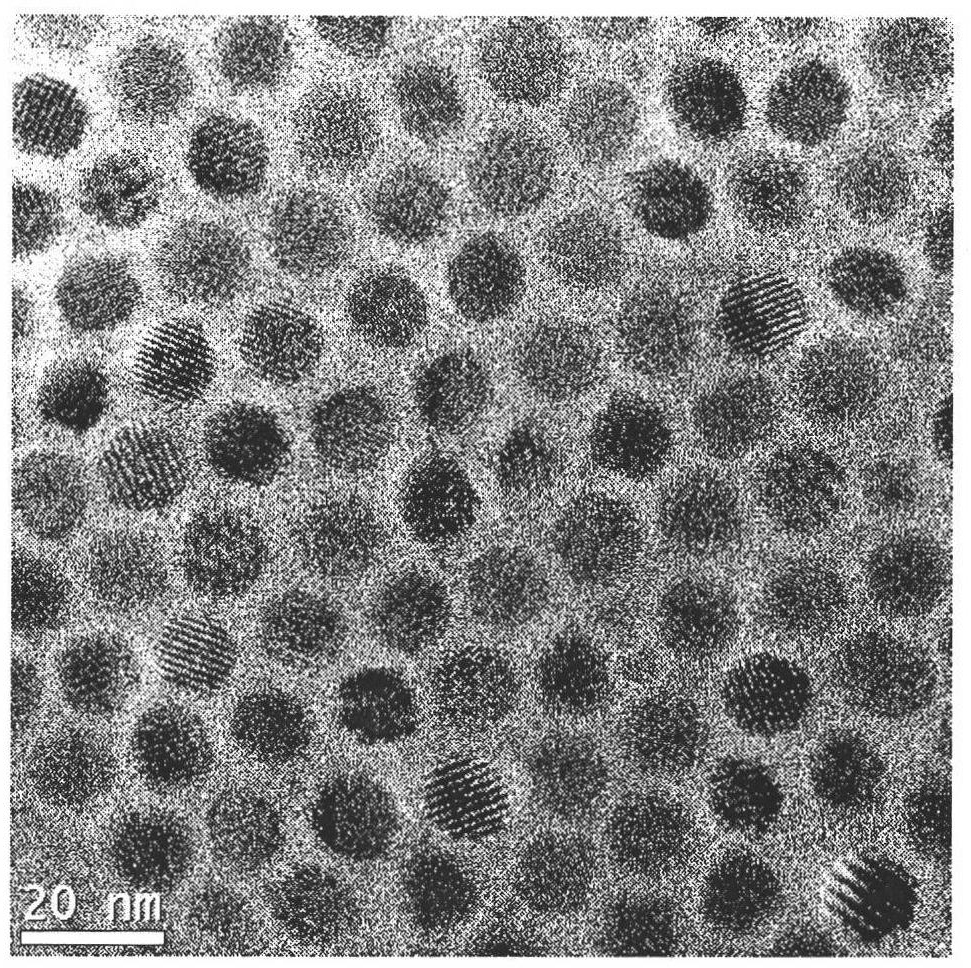

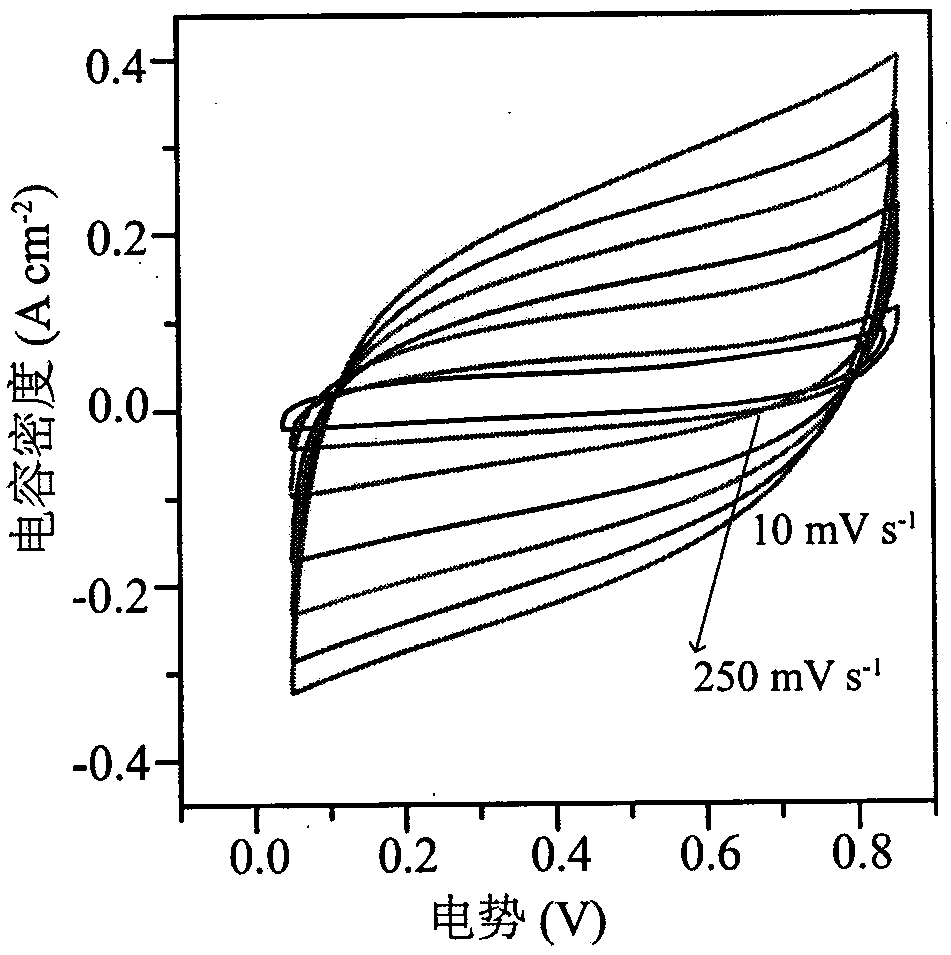

The invention discloses a preparation method of N-doped porous carbon coated nano-particles (Co@Ir / NC-x, and x is the quality ratio of Ir) of a Co-Ir core-shell structure and application of the N-doped porous carbon coated nano-particles of the Co-Ir core-shell structure to catalytic water splitting. The preparation method has the advantages that (1) the preparation process is simple and direct, and energy consumption is low, specifically, Co / NC obtained after a zeolite imidazole framework material (ZIF-67 for short) is calcined is directly subjected to Galvanic replacement with Ir<3+> at theroom temperature, high temperature and high pressure are not needed, and accordingly the energy consumption is low; (2) the catalytic performance is good, and the stability is high, specifically, a Co@Ir / NC-10% sample is in a 1M KOH solution, in an oxygen producing test, the current density is 10 mA cm<-2>, the overpotential is 280 mV, and the performance is higher than IrO2; in a hydrogen producing test, the current density is 10 mA cm<-2>, the overpotential is -121 mV; besides, after a stability test of 12 h, the oxygen producing activity of IrO2 is attenuated by 55.8% while the oxygen producing activity of Co@Ir / NC-10% is attenuated only by 20.6%, and the hydrogen producing stability of Co@Ir / NC-10% is far higher than that of commercial Pt / C under the same conditions; and (3) the catalyst cost is low and the Co source is wide, specifically, the nano-particles are of the core-shell structure with Co as a core and Ir as a shell, the amount of Ir is reduced on the basis of more exposedcatalytic activity sites, a core metal precursor Co is wide in source and low in cost, the catalyst cost is greatly reduced, and great commercial application prospects are achieved.

Owner:SOUTH CHINA UNIV OF TECH

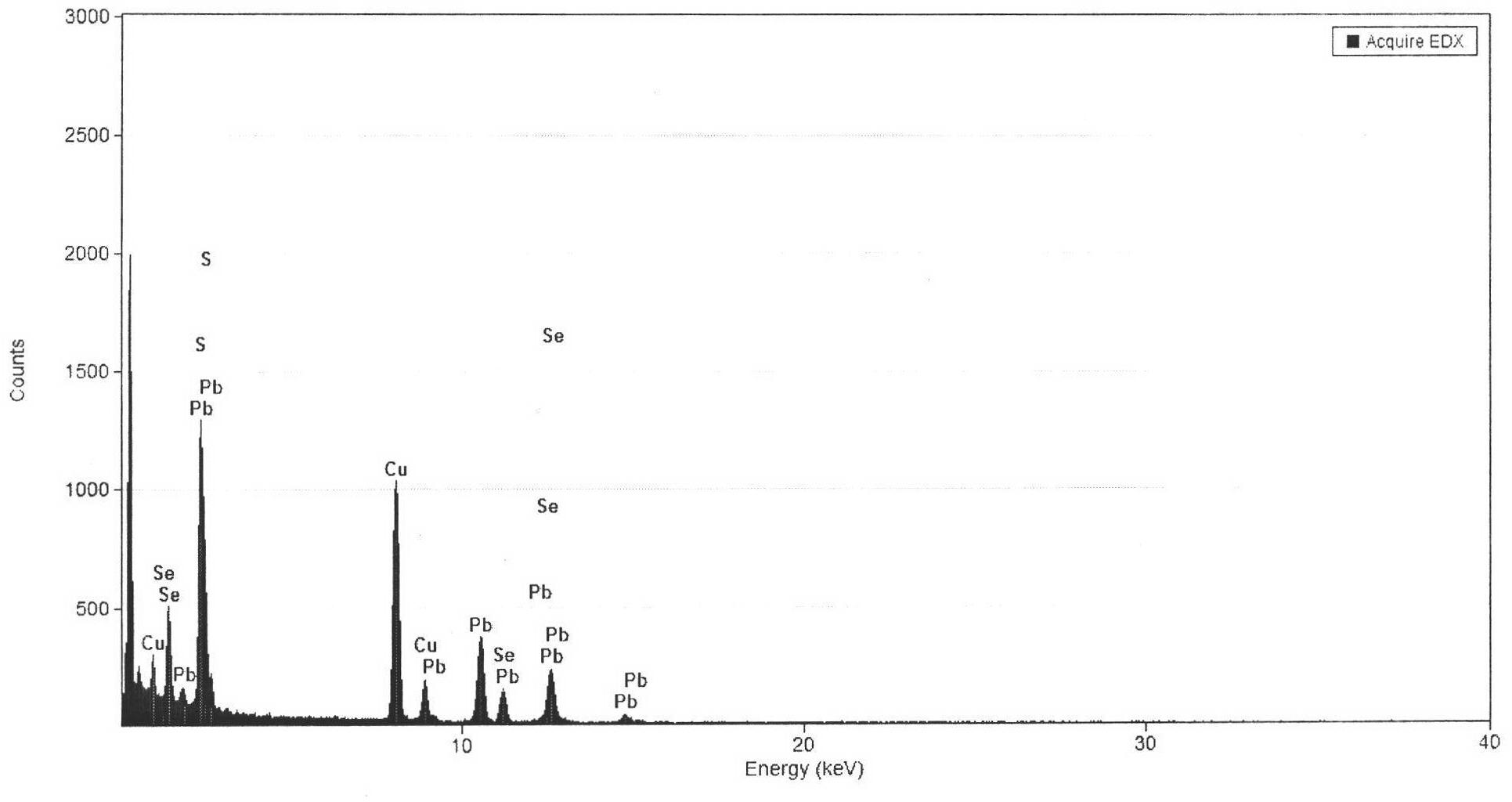

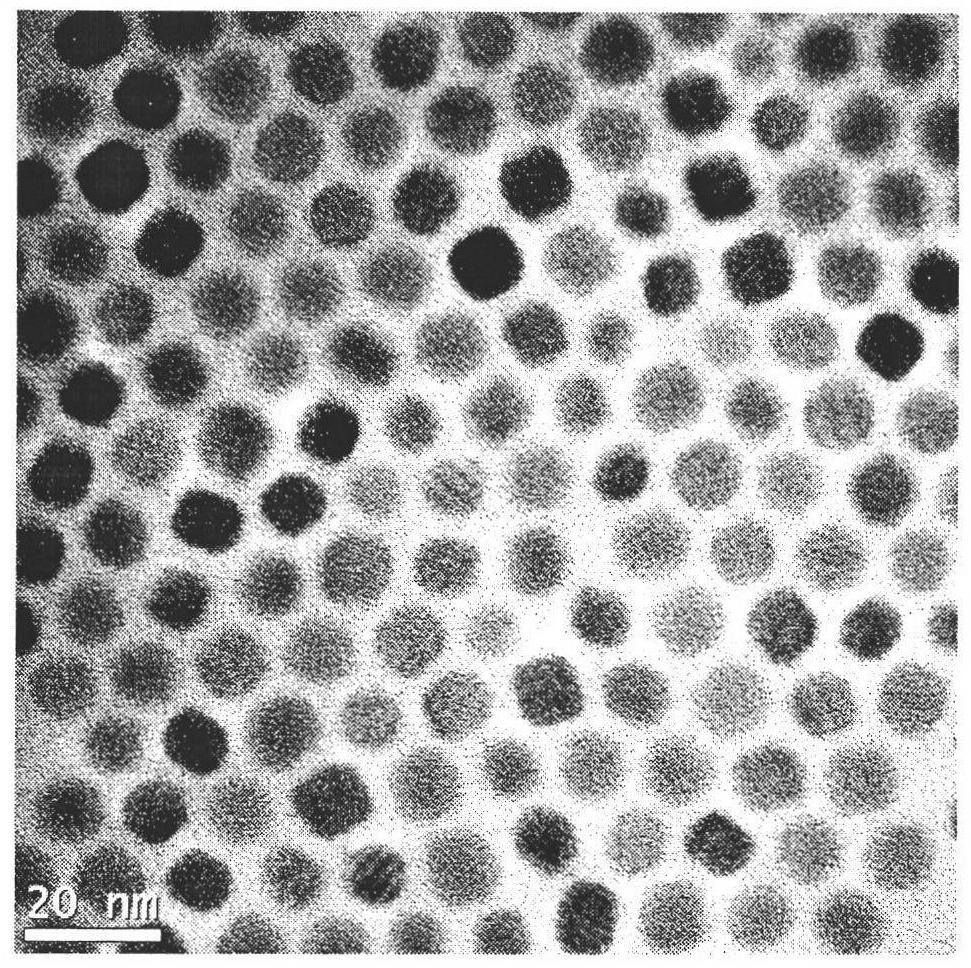

Preparation method of PbSxSe1-x ternary nanocrystal

InactiveCN102633239ASimple methodEasy to operateSelenium/tellurium compundsEnergy inputEthyl ChlorideEthanol

The invention discloses a preparation method of PbSxSe1-x ternary nanocrystal. The method disclosed by the invention comprises the following steps of: mixing selenium powder and sulfur powder according to a certain proportion, slowly adding alkylamine which has long chain and has boiling point more than 180 DEG C, sufficiently stirring, heating (the selenium powder and the sulfur powder) amine mixed liquor into 180-260 DEG C, forming into settled solution at constant temperature, and adding the alkylamine which is dissolved with lead chloride and has the long chain and the boiling point more than 180 DEG C, so that a system is naturally cooled into room temperature after being sufficiently reacted, adding 10mL of chloroform into the system, and adding ethanol of which the volume is twice as high as the volume of the reaction solution into the reaction system, so that PbSxSe1-x ternary nanocrystal particle precipitate is separated out, therefore, the PbSxSe1-x ternary nanocrystal particle can be obtained.

Owner:LANZHOU UNIVERSITY

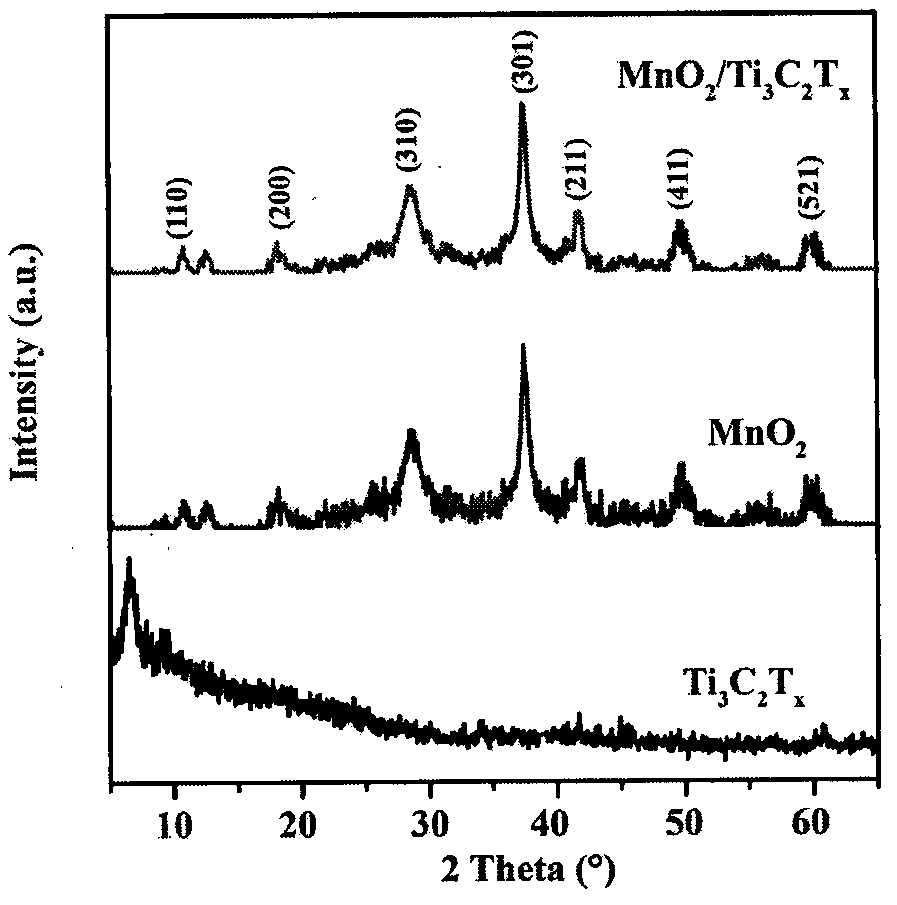

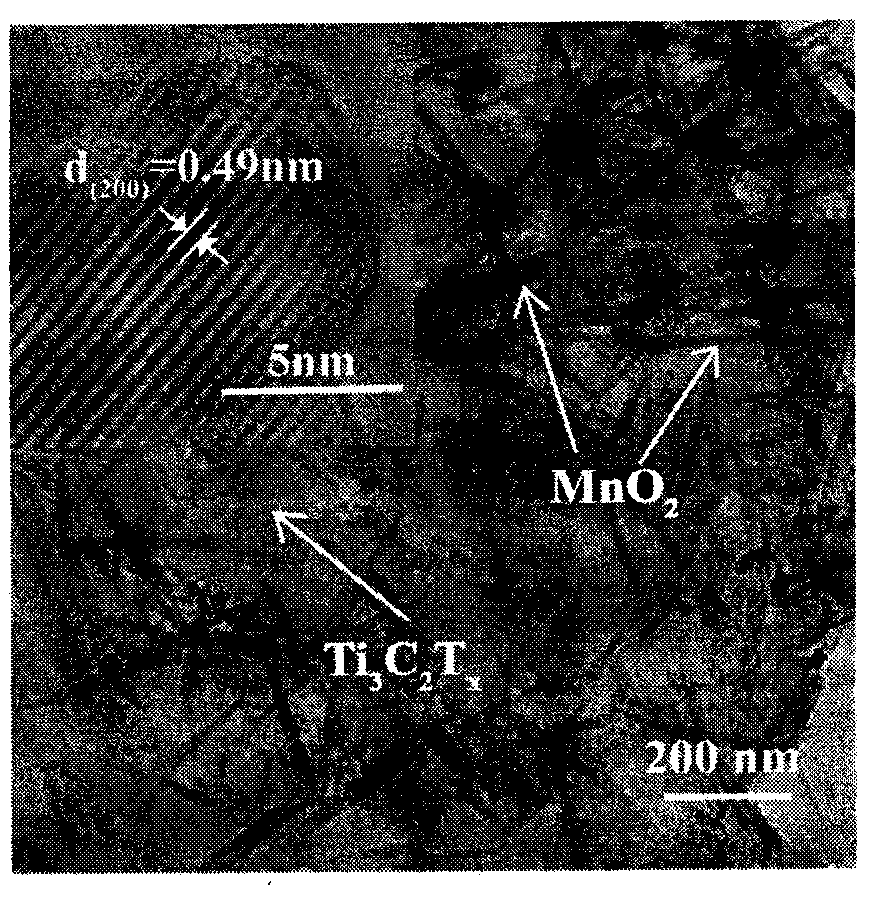

Preparation method of MnO<2>/Ti<3>C<2>T<x>Mxene flexible supercapacitor electrode material

PendingCN108807003AImprove conductivityImprove flexibilityMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHigh energy

Owner:重庆化工职业学院 +1

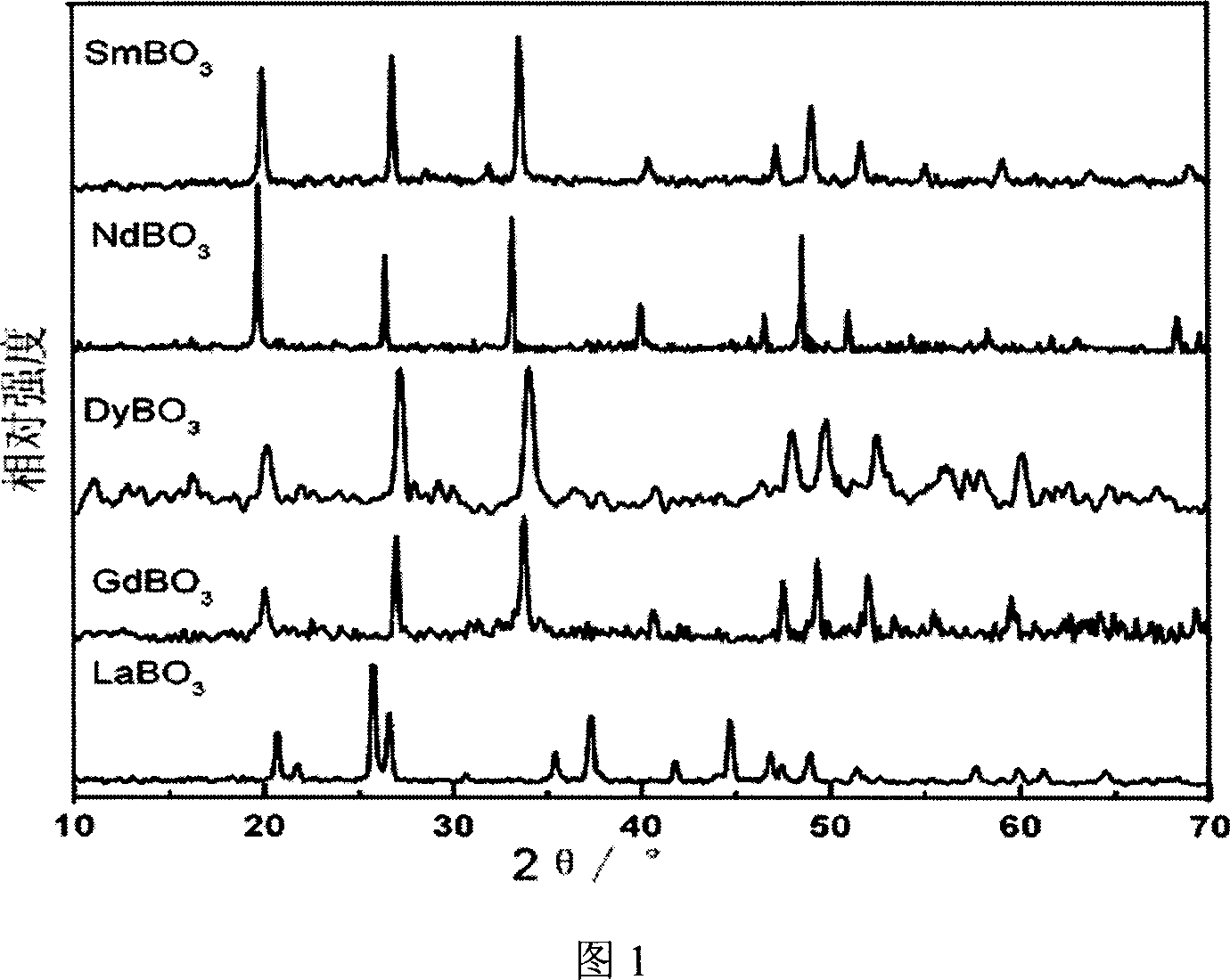

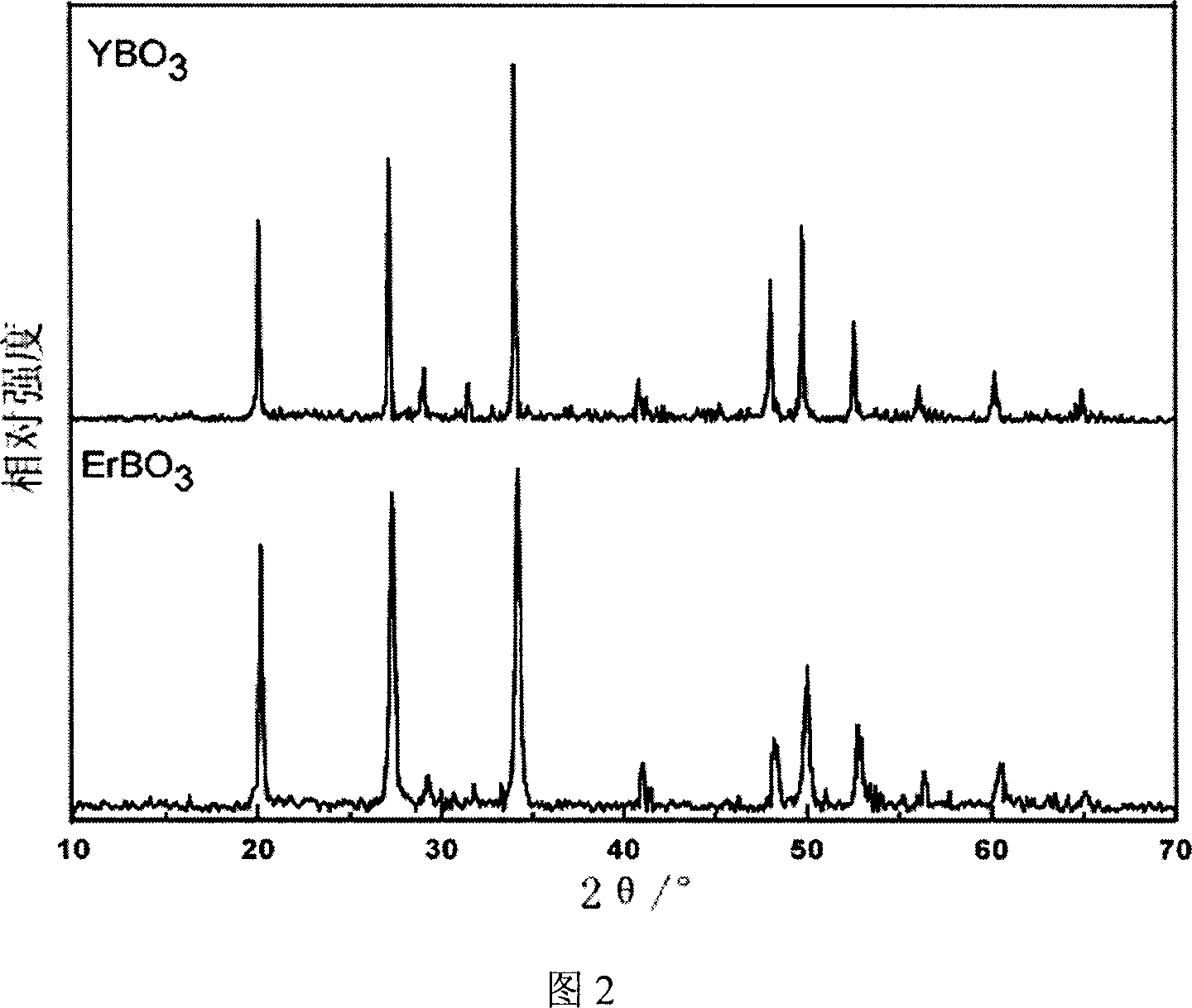

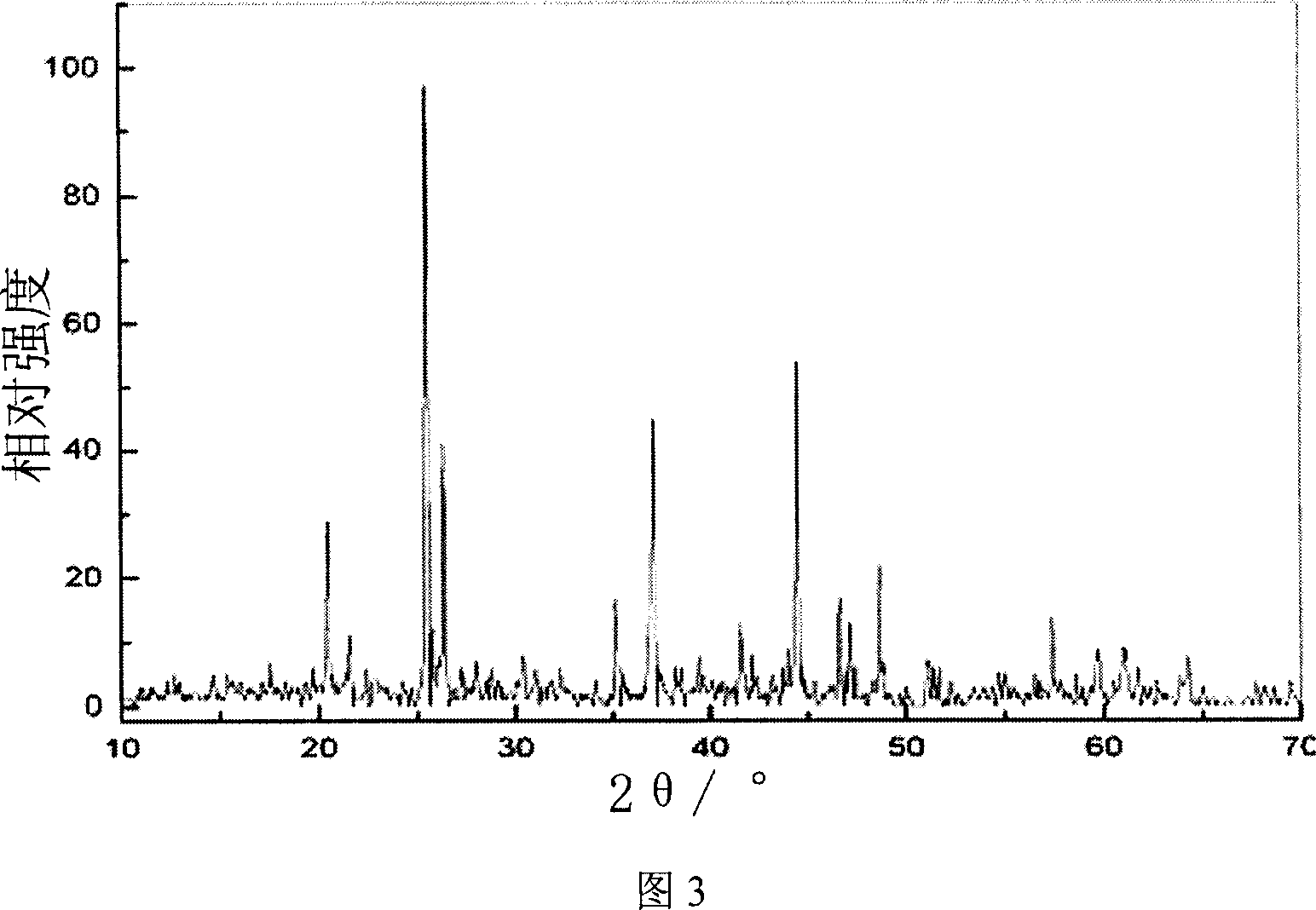

Low temperature process of preparing RE borate crystal with oxide as precursor

InactiveCN1974885AMeet the requirements of sustainable developmentEasy to operatePolycrystalline material growthFrom normal temperature solutionsRare earthHydrothermal synthesis

The present invention belongs to the field of micron / nanometer material preparing technology and hydrothermal synthesis technology, and is especially low temperature process of preparing RE borate crystal with oxide as precursor. In the hydrothermal system, insoluble RE oxide and hydrated boron trioxide or boron trioxide as the boron source and precursor are reacted at 190-280 deg.c for 12-48 hr, and through further washing, the required RE borate crystal is obtained. The present invention provides one inorganic synthesis way, and the production process has no any pollution. The present invention has simple technological process, easy-to-constitute reaction system, high product purity and other advantages, and is suitable for industrial production.

Owner:TONGJI UNIV

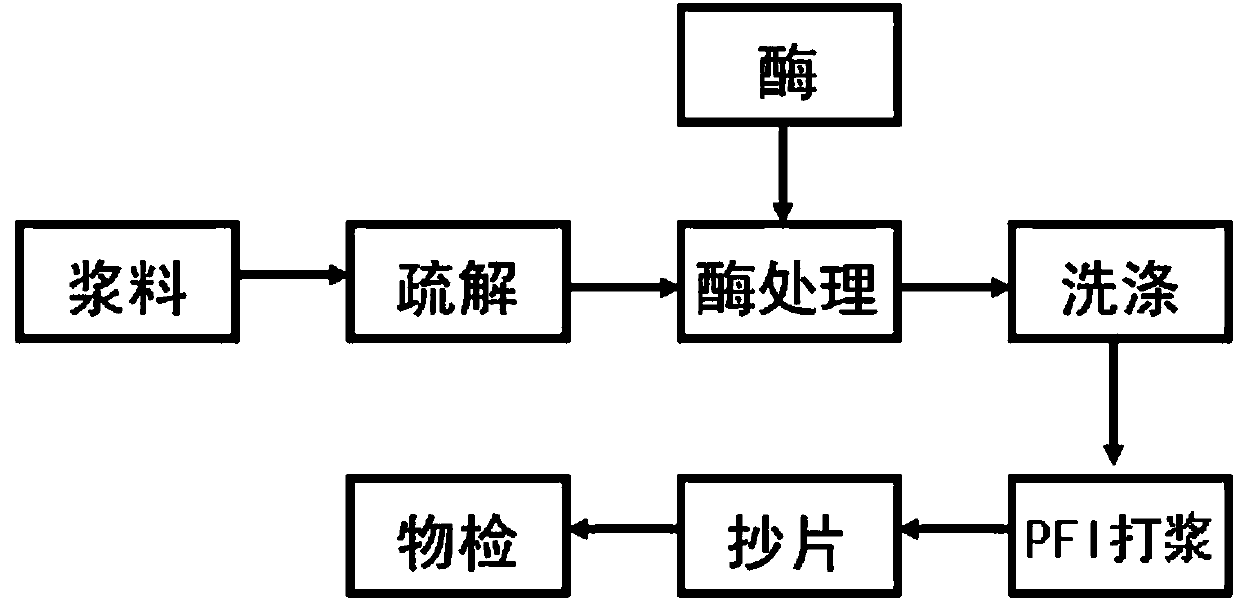

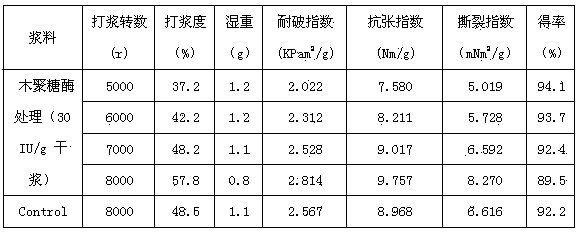

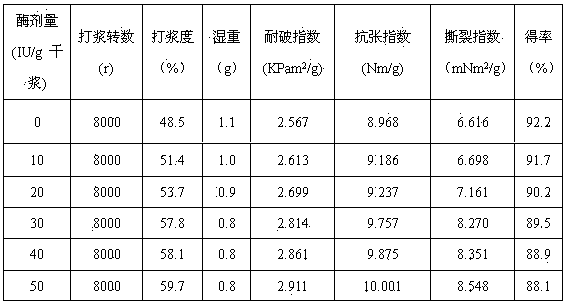

Enzymatic beating process for natural-color bagasse pulp

The invention discloses an enzymatic beating process for natural-color bagasse pulp. Xylanase is used in the enzymatic beating process for the natural-color bagasse pulp. The process comprises the steps of sizing agent defibering, enzyme treatment, washing, PFI beating, sheet making and physical detection. By adopting the process, the beating energy consumption of the natural-color bagasse pulp can be lowered effectively; the beating degree can be increased greatly up to 19.2 percent when enzyme treatment is performed on the xylanase at the dry pulp dosage of 30IU / g; meanwhile bagasse pulp cellulase can be protected from being damaged, and the process has important significance to the production of industrial paper from bagasse pulp.

Owner:GUANGXI UNIV

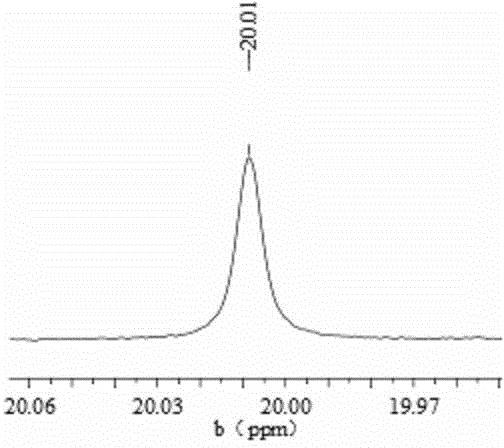

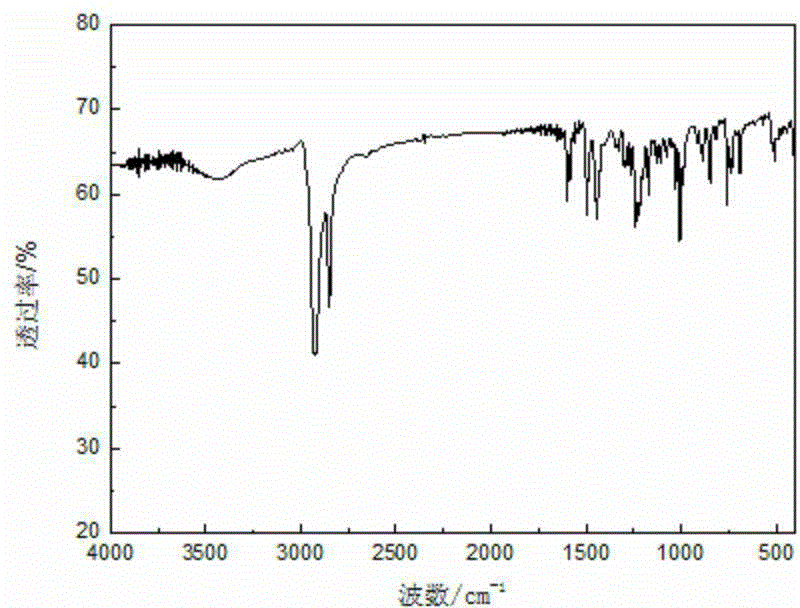

Preparation method and application of ruthenium-carbene catalyst

InactiveCN104558049AReasonable useSimple equipmentRuthenium organic compoundsPolymer sciencePtru catalyst

The invention discloses a preparation method and application of a ruthenium-carbene catalyst. According to the invention, a ruthenium-carbene complex is prepared by a method of olefin metathesis, the device and technology used for preparation are simple, only two-step reaction is needed, the cost is lower, and the production rate can reach 95%. According to the invention, the ruthenium-carbene complex is used as a catalyst for a ring-opening metathesis polymerization reaction of dicyclopentadiene so as to prepare polydicyclopentadiene. The activity of the ring-opening metathesis polymerization reaction is high, the transformation rate to the polymerization of the dicyclopentadiene is 99.8%, the reaction condition is moderate, high temperature and high pressure are not needed, resources are reasonably utilized, the reaction has no bad influence on the environment, and therefore, the method disclosed by the invention is a green process route, and is suitable for industrial popularization.

Owner:CHANGCHUN UNIV OF TECH

Preparation method of 1,2,3-trimethoxy-5-allylbenzene

InactiveCN104230681AHigh yieldHigh purityOrganic compound preparationEther preparation by ester reactionsBiochemical engineeringCombinatorial chemistry

The invention provides a preparation method of 1,2,3-trimethoxy-5-allylbenzene. The synthetic route of the preparation method is as shown in the specification. According to the preparation method disclosed by the invention, the synthetic process conditions are simple, the cost is low, the total yield of the reaction can be above 49% and the preparation method is suitable for industrialized mass production and has significant business values.

Owner:程文峰

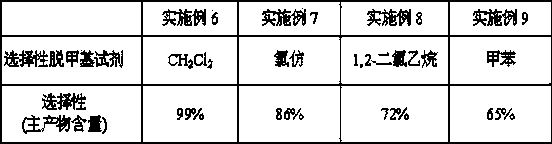

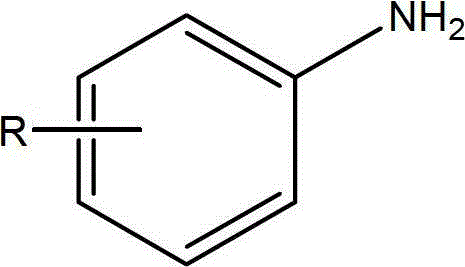

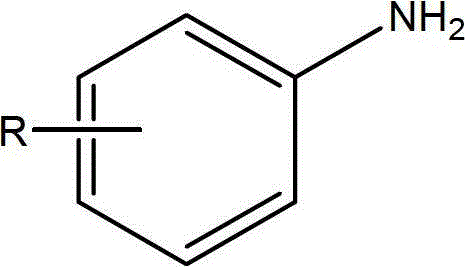

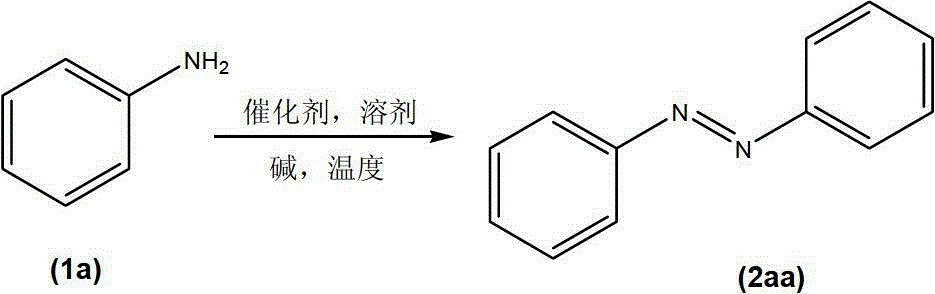

Method for preparing aromatic azoic compound by catalyzing aromatic amine with metal nanocrystals

InactiveCN102718680ASimple processImprove versatilityOrganic chemistryChemical recyclingAir atmosphereOrganic solvent

Disclosed is a method for preparing an aromatic azoic compound by catalyzing aromatic amine with metal nanocrystals. In the method, the aromatic amine serves as a substrate, the metal nanocrystals serve as catalysts, the substrate, the catalysts and alkali are dissolved in organic solvents in normal-pressure air atmosphere, and the aromatic azoic compound is prepared by means of reaction. The method has the advantages of simplicity and convenience in process, environmental friendliness, catalyst recyclability, high universality of metal catalysts and the like, and avoids the shortcomings that environment-unfriendly metal salt catalysts or oxidants are used in an existing synthetic route, high temperature and high pressure are needed, the catalysts are poor in universality, asymmetric aromatic azoic compound is synthesized by a two-step method and the like. A series of aromatic azoic compounds can be prepared, and the method has a wide industrial application prospect.

Owner:TSINGHUA UNIV

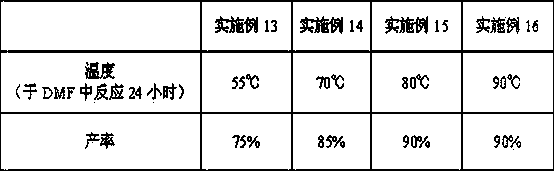

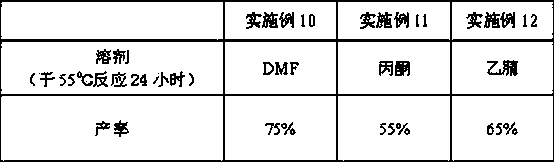

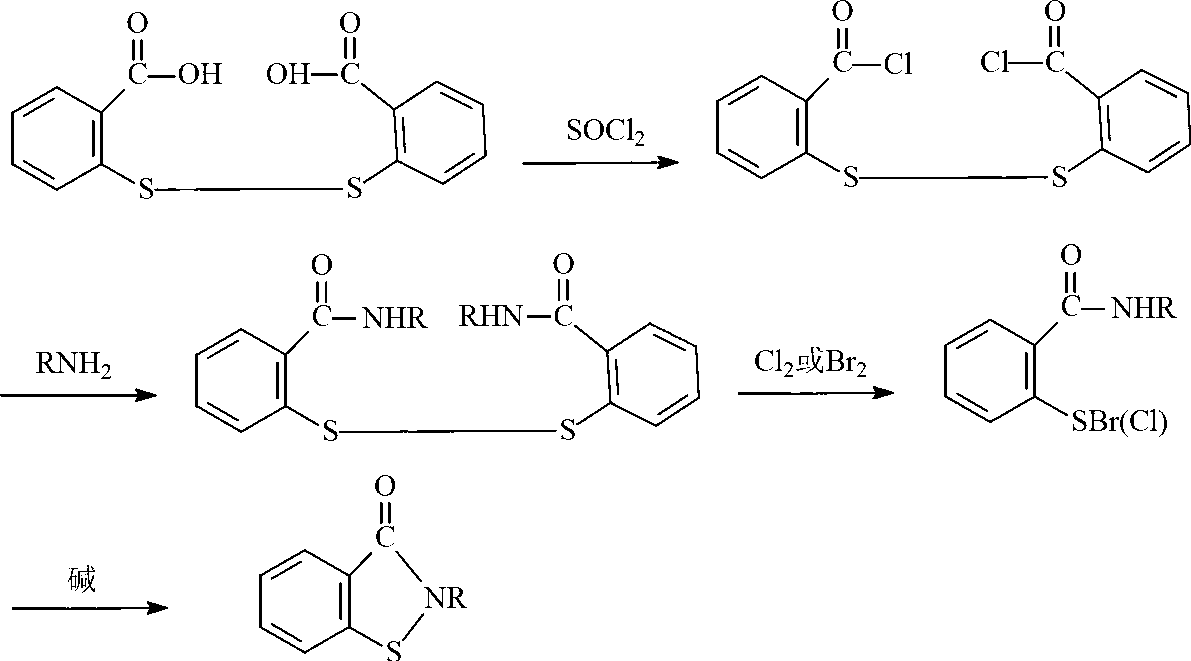

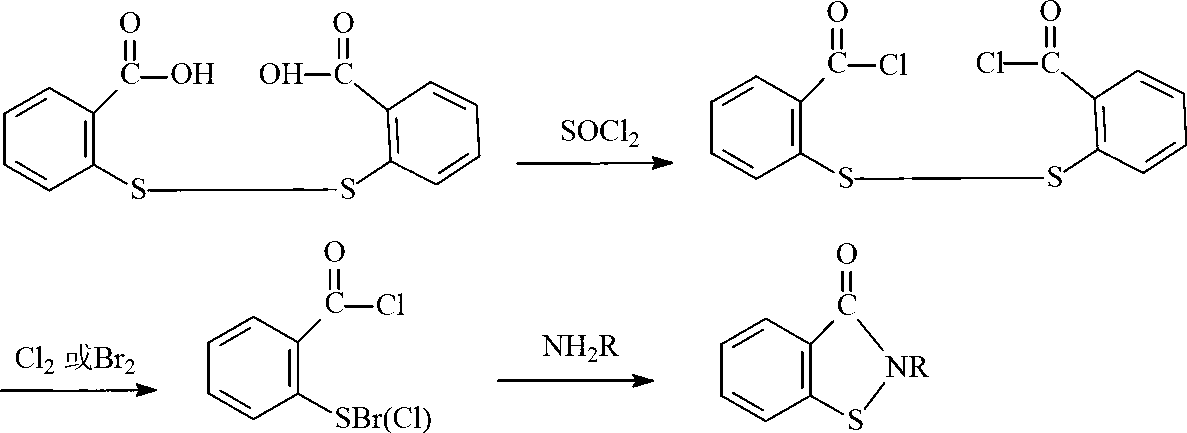

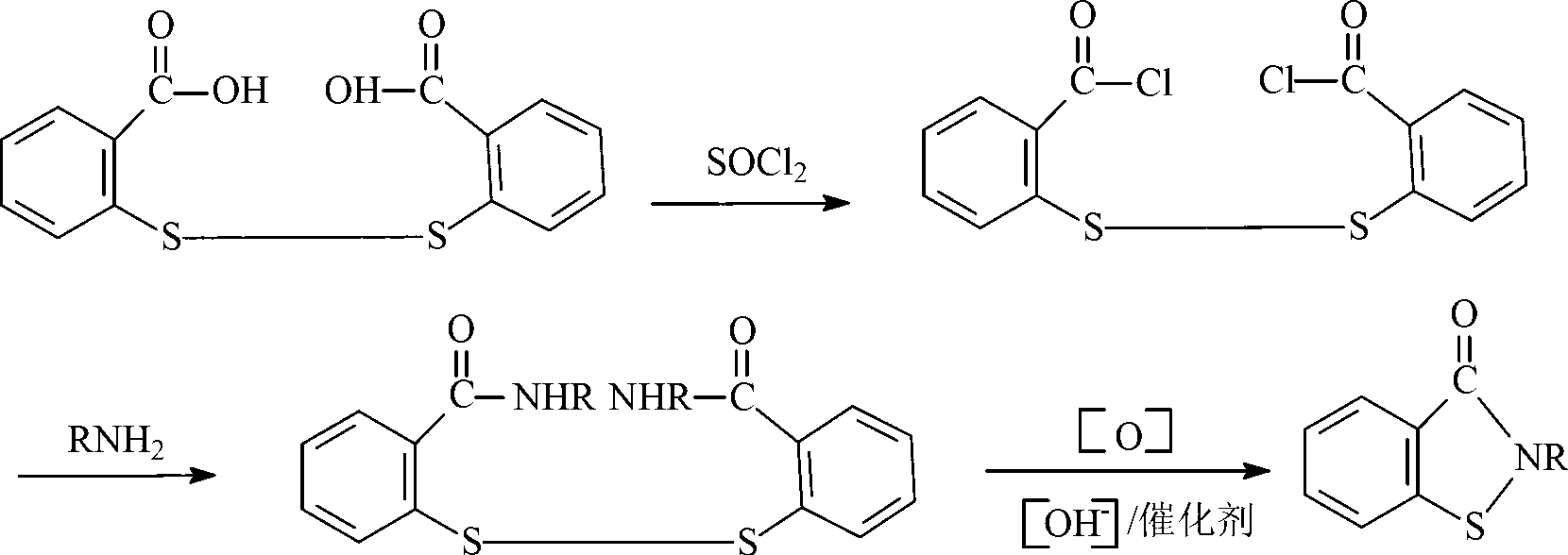

Preparation method of N-butyl-1,2-benzo isothiazolin-3-ketone

The invention relates to a preparation method of N-butyl-1,2-benzo isothiazolin-3-ketone. The preparation method comprises the steps that 2,2'-disulfide diphenyl formyl chloride serves as a raw material and is transformed into N-butyl-2,2'-disulfide diphenyl formyl amine by amidation; and an oxidant is added to disproportionately synthesize N-butyl-1,2-benzo isothiazolin-3-ketone in an alkaline environment and with the existence of a catalyst. The preparation method has the following characteristics that (1), the oxidant (or an oxygen releasing agent) is adopted to replace halogen (chlorine or liquid bromine), the defect of using highly toxic chemicals is avoided, the operation is easier, the cost is lowered, and the pressure of environmental protection is reduced greatly; (2), the process during a reaction course is simple and high temperature and high pressure are not needed; and (3), the preparation method is simple in process, low in manufacturing cost, high in product yield, and suitable for commercial production, and the process is clean and does not pollute an environment.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

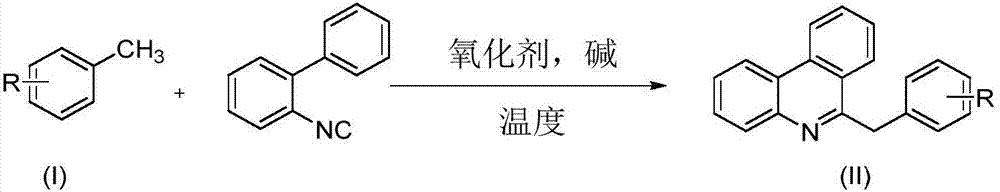

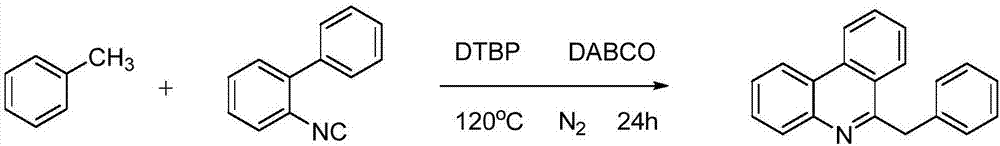

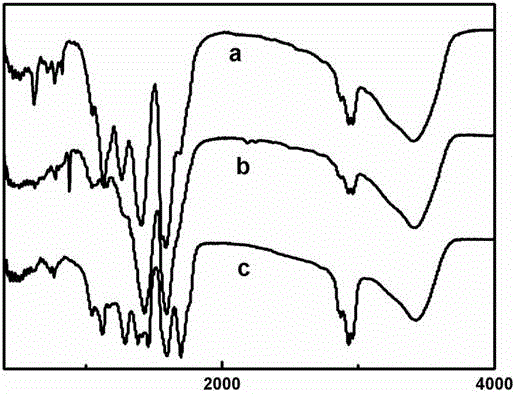

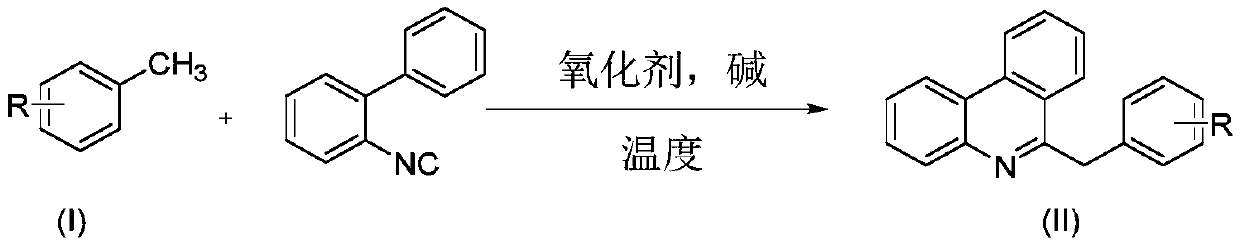

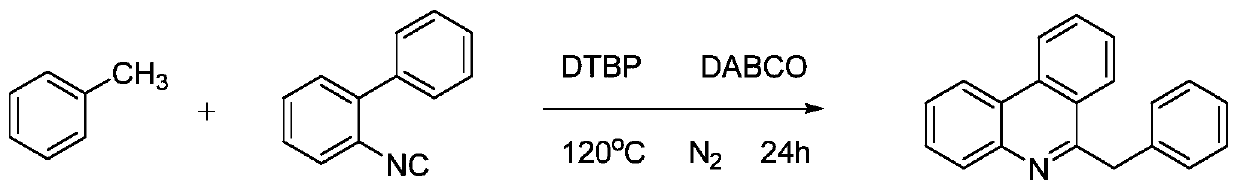

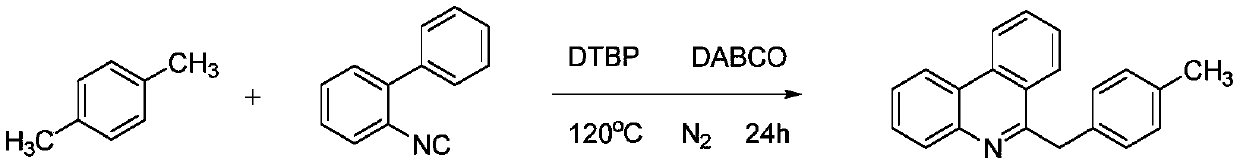

Synthetic method of 6-benzyl phenanthridine compounds

ActiveCN107235900APost-processing is simpleSimple and fast operationOrganic chemistryHydrogenHigh pressure

The invention discloses a synthetic method of 6-benzyl phenanthridine compounds. A reaction equation is as follows: formula (shown in the description), wherein R represents hydrogen, fluorine, chlorine, methyl, methoxyl or a naphthalene ring. The synthetic method has the beneficial effects that (1) the operation of the preparation process is simple and convenient, and the post-treatment of obtained products is easy; (2) high temperature and high pressure conditions are not required, and reaction conditions are mild; (3) a catalyst is not required, and the synthetic cost is lowered; (4) functional groups of a reaction substrate are high in tolerance, and the substrate is wide in range and easy to prepare; (5) an oxidant is cheap, easily available and relatively economic; (6) the reaction is efficient and high in yield; and (7) the synthetic method is pollution-free and environment-friendly.

Owner:WENZHOU UNIVERSITY

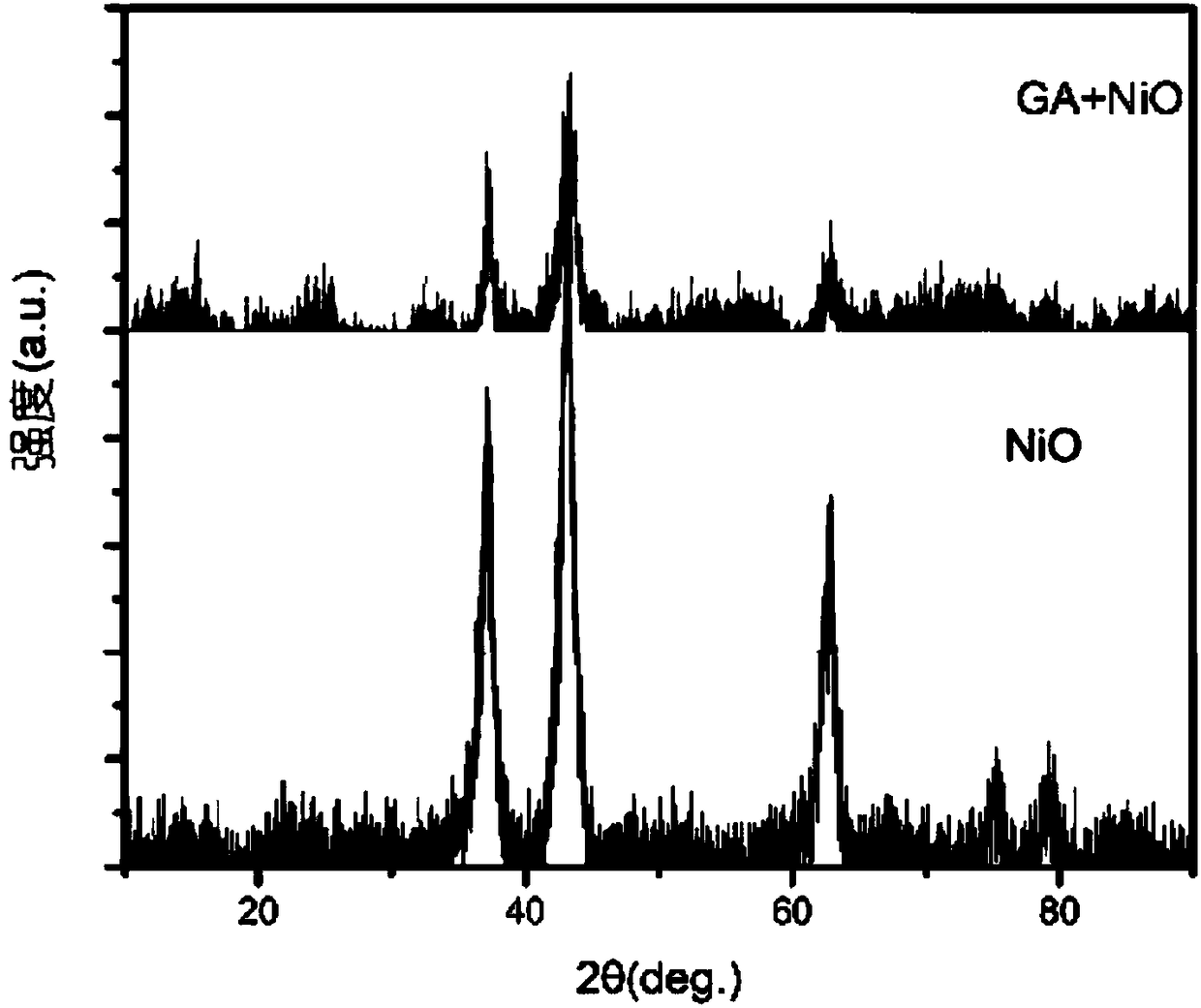

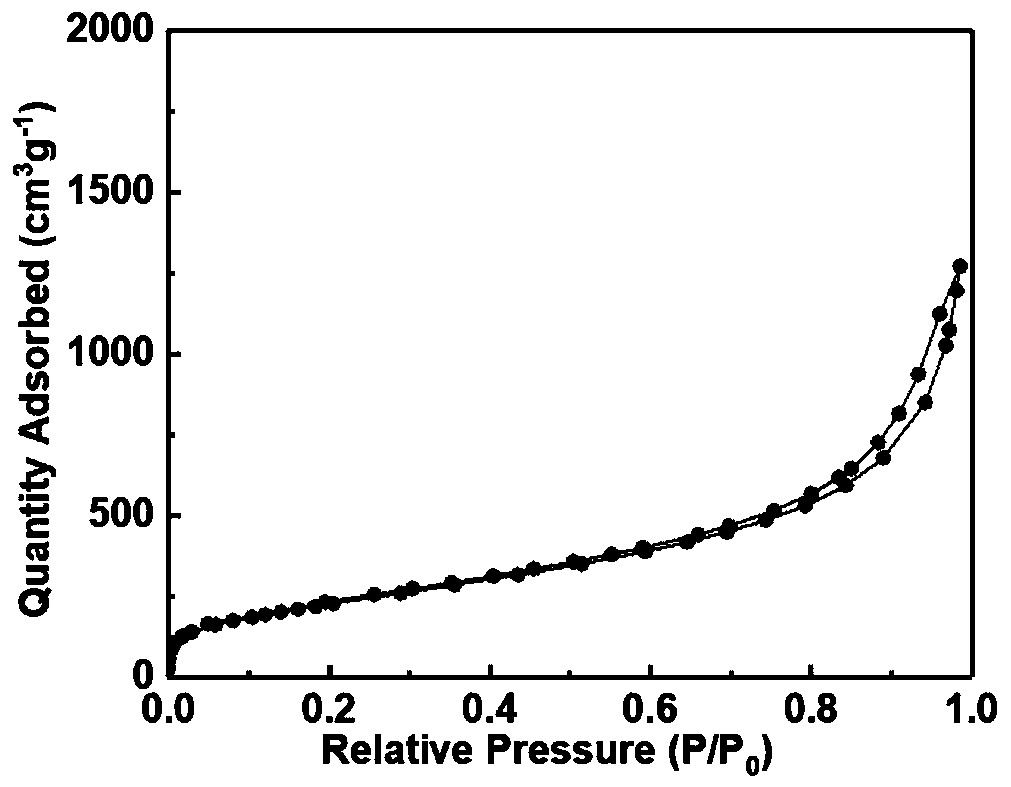

Burning rate catalyst and preparation method thereof

InactiveCN108147931AHigh specific surface areaHigh porosityNon-explosive/non-thermic compositionsLarge poreOxide

The invention belongs to the technical field of nanometer energy materials, and discloses a novel burning rate catalyst. The burning rate catalyst is characterized in that graphene aerogel is taken asa carrier, and a metallic oxide is taken as a carried matter and is dispersed in the graphene aerogel in the form of nanoparticles. The invention further discloses a preparation method of the burningrate catalyst. The burning rate catalyst disclosed by the invention has a larger specific surface area, a larger large pore volume, high heat conductivity and high catalytic activity; transitional metallic oxide nanoparticles are uniformly dispersed inside the aerogel without aggregation; the burning rate catalyst has excellent catalytic activity. The preparation process of the catalyst is simple, and the reaction conditions are mild.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

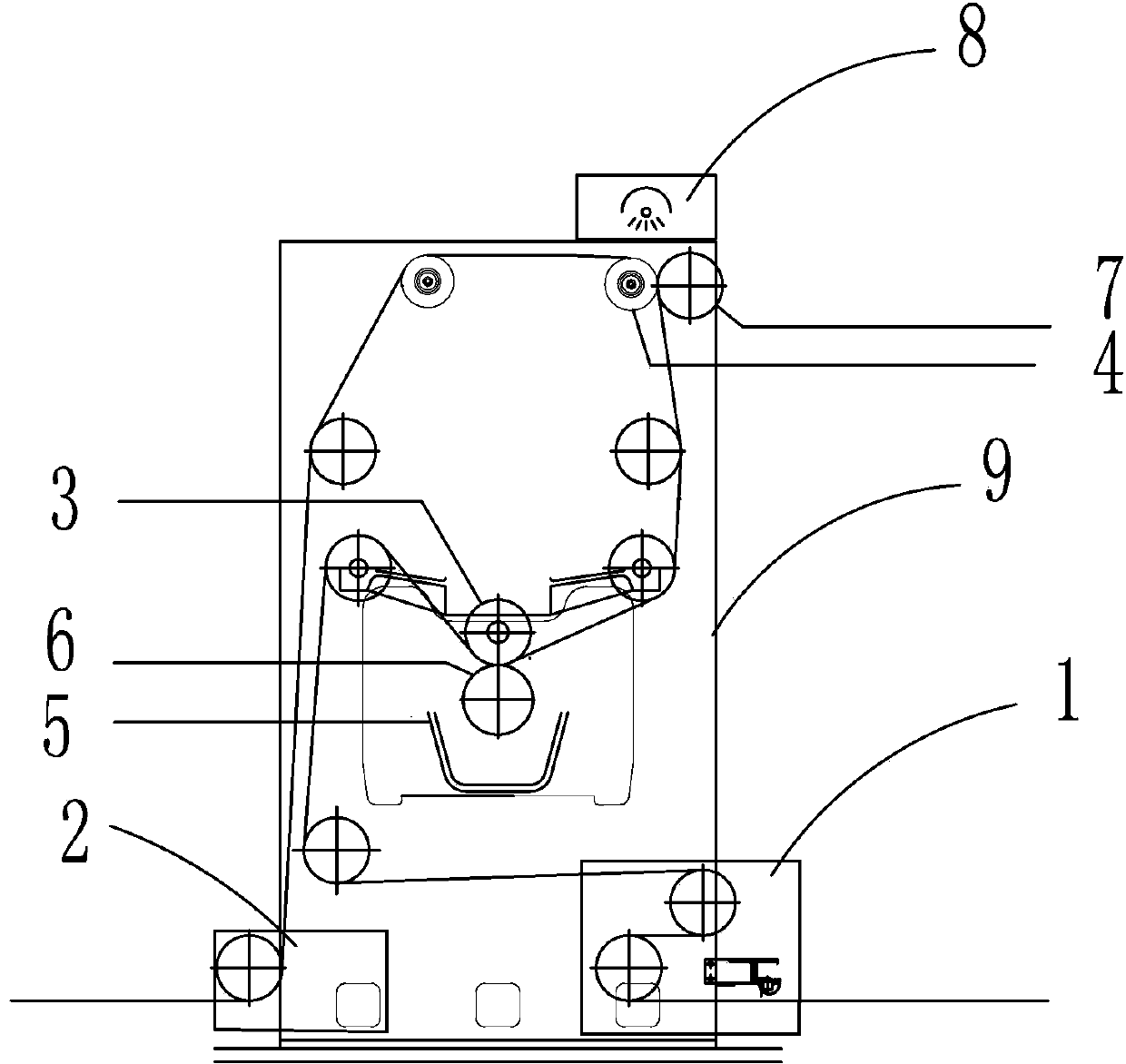

Laser pattern printing device

InactiveCN103395282AImprove work efficiencyDoes not require high temperature and pressureRotary pressesDrive wheelDevice form

The invention discloses a laser pattern printing device which comprises a rack. A paper tape transmission device formed by a plurality of driving wheels and used for transmitting a paper tape is arranged between a paper feeding device and a paper discharging device. The two driving wheels in the paper tape transmission device are a coating driving wheel and a coining driving wheel respectively. A container used for containing UV gloss oil is arranged below the coating driving wheel. A coating roll which coats the paper tape with the UV gloss oil evenly through the rotation of the coating roll to form a UV gloss oil layer is arranged inside the container. A laser pattern is arranged on the surface of a pattern coining roll. The pattern coining roll is used for coining the laser pattern on the UV gloss oil layer of the paper tape to form a laser pattern layer of the paper tape. A drying device used for drying a UV gloss oil pattern layer is arranged in the transmission direction of the coining driving wheel. By directly printing a laser anti-counterfeit pattern on the UV gloss oil layer, the laser pattern printing device improves production efficiency, lowers cost and enhances the anti-counterfeit property.

Owner:GUANGDONG NEW UVI PRINTING EQUIP & TECH CO LTD

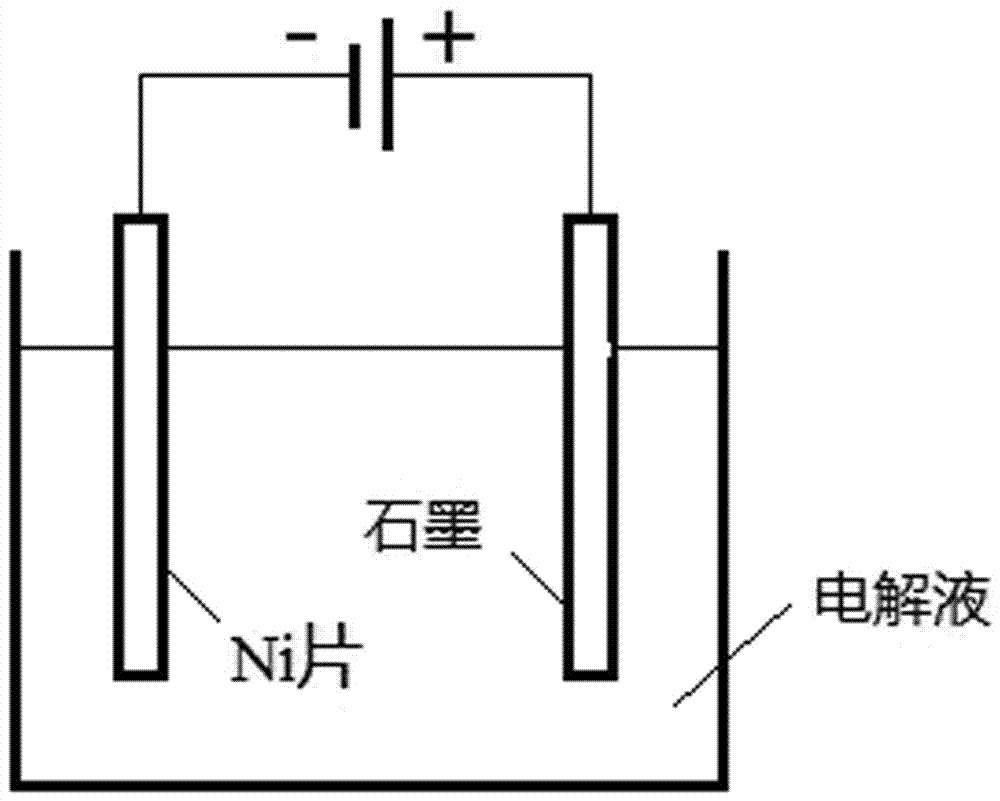

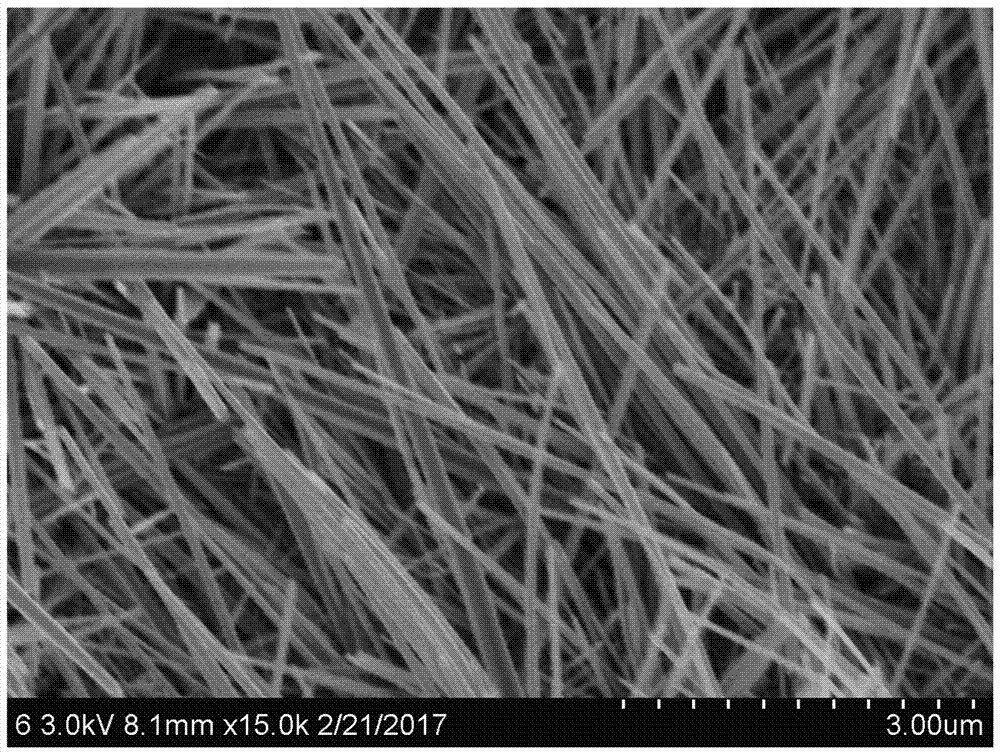

Preparation method of selenium nanowires

InactiveCN107099811AEasy to changeShorten the timeElectrolysis componentsNanotechnologyNanowireElectrolysis

The invention provides a preparation method of selenium nanowires, which includes the steps of: a) performing electrolysis with sodium selenite, polyethylene glycol and a hydrochloric acid water solution as an electrolyte to produce elementary selenium; b) washing the elementary selenium and allowing the elementary selenium to stand in anhydrous ethanol for aging the elementary selenium to produce the selenium nanowires. In the invention, with the sodium selenite, polyethylene glycol and hydrochloric acid water solution as the electrolyte for performing electrolysis, the sodium selenite is reduced on a negative pole into the elementary selenium, wherein the hydrochloric acid provides an acidic environment that is beneficial to the reduction reaction. The polyethylene glycol has dispersion effect, so that precipitate particles are fine, which is beneficial to follow-up crystal form transformation, thereby shortening the time of producing the selenium nanowires; after the elementary selenium is prepared, the elementary selenium is aged in the anhydrous ethanol, so that the elementary selenium is converted into the nanowires. A test result proves that the method can produce the selenium nanowires.

Owner:HEBEI NORMAL UNIV FOR NATTIES

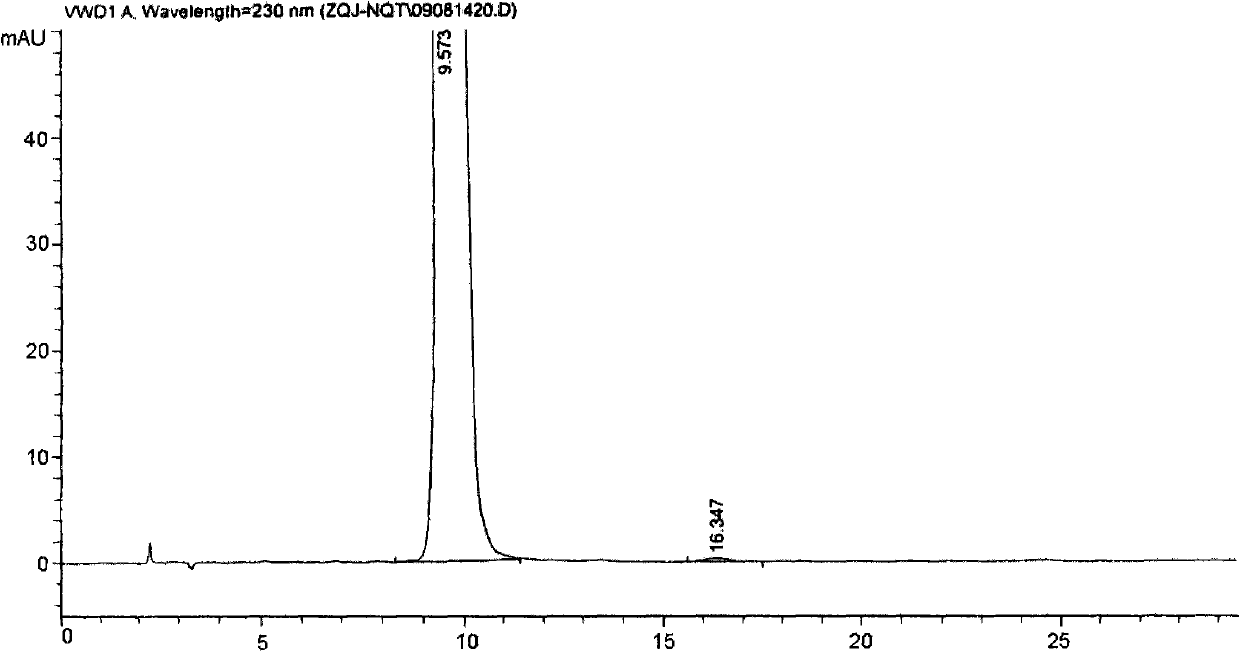

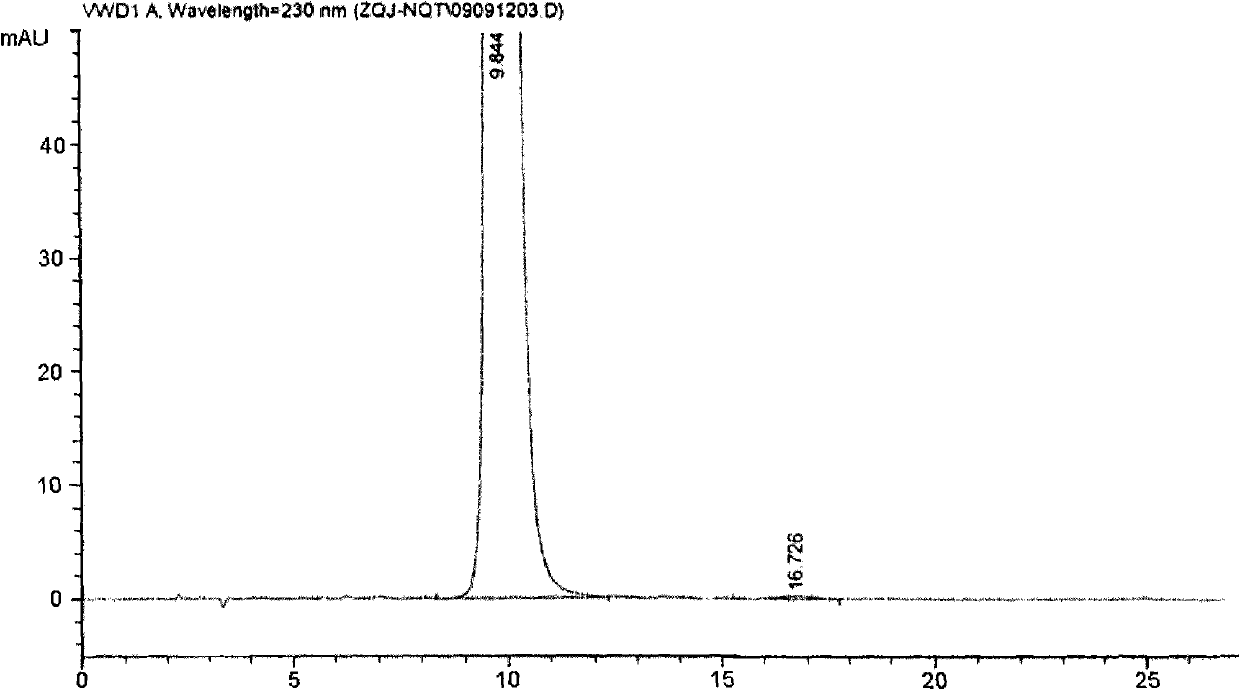

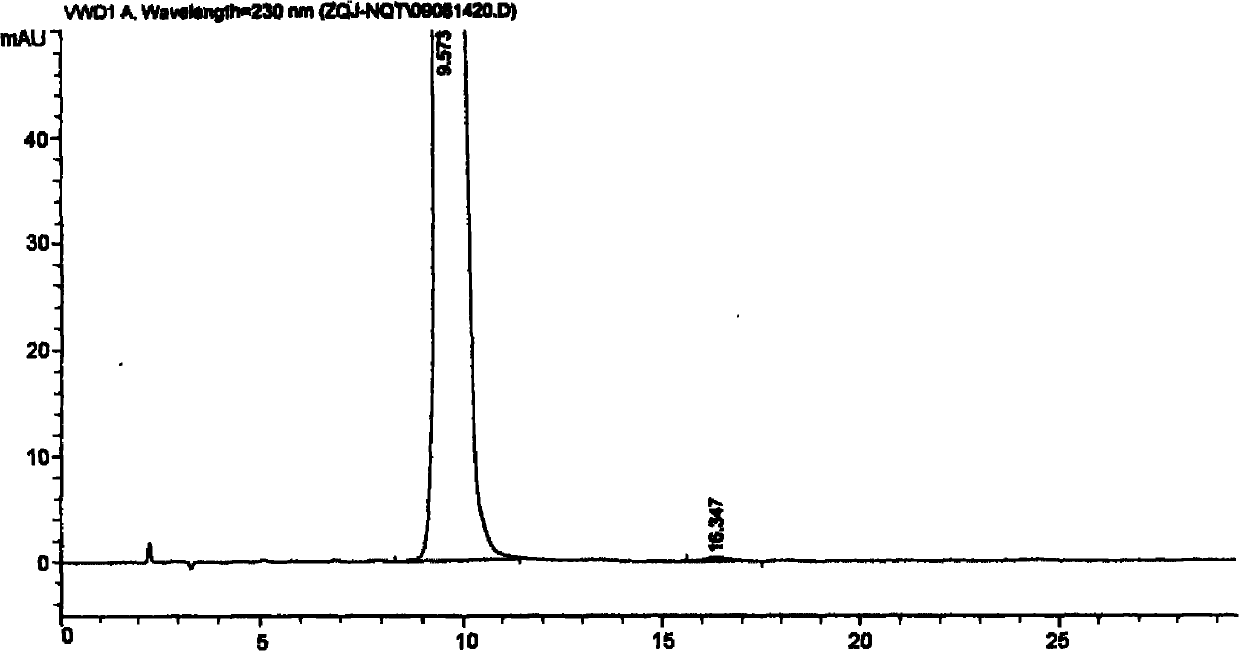

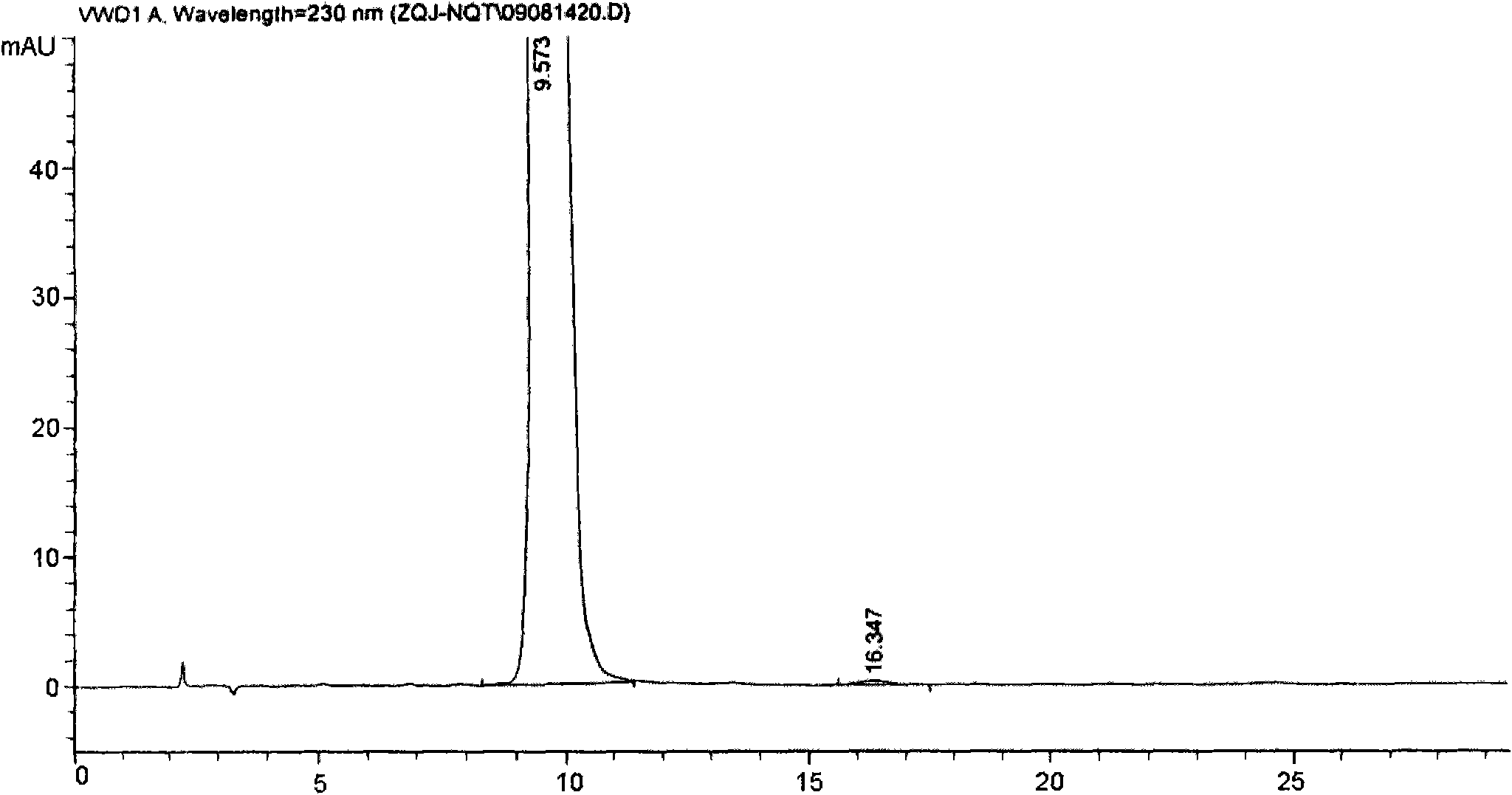

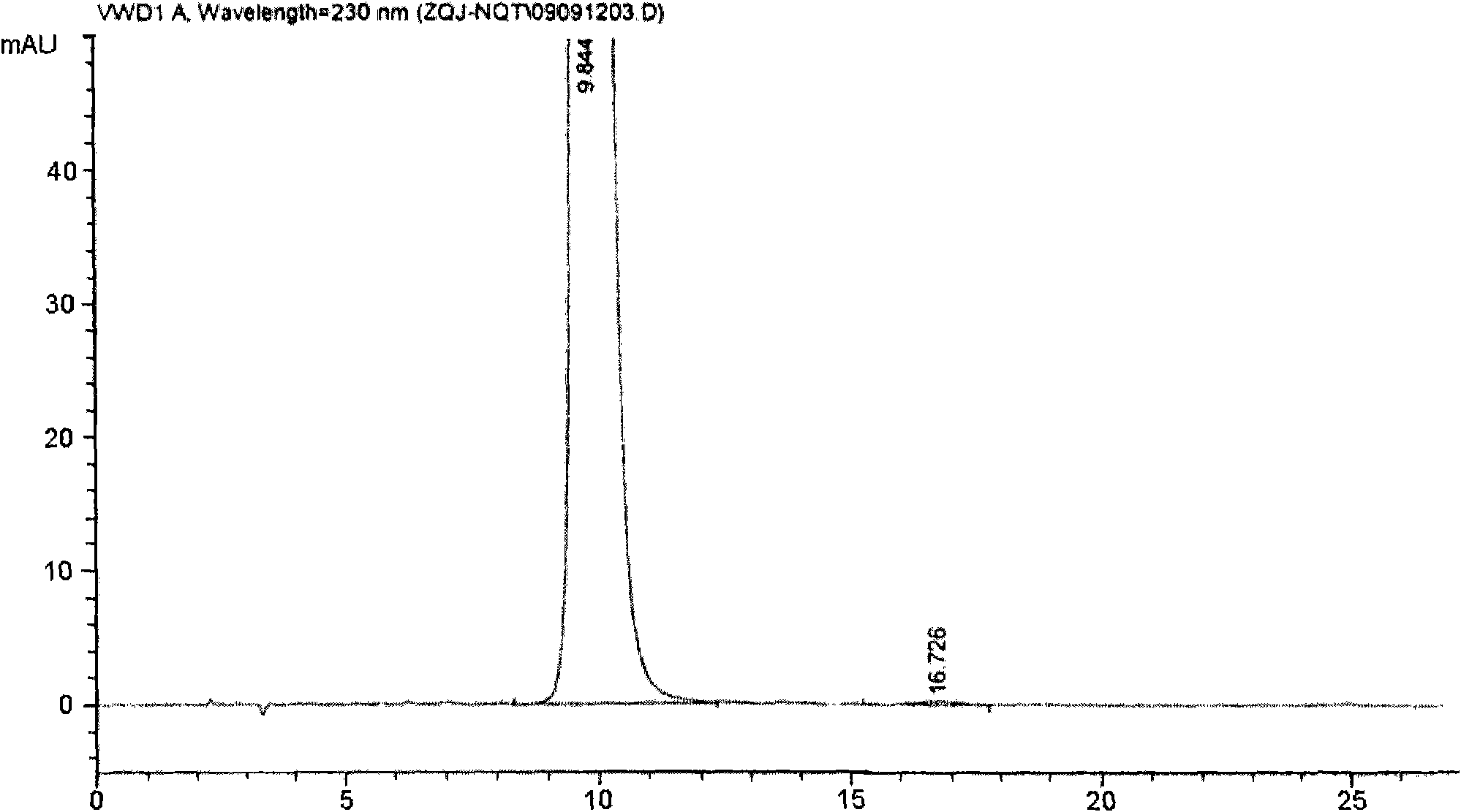

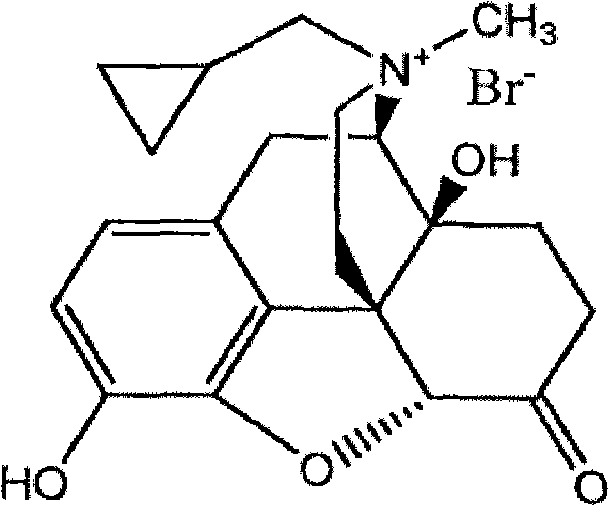

Refining method of methyhaaltrexone bromide

ActiveCN102558189AMild conditionsDoes not require high temperature and pressureOrganic chemistrySolventSilica gel

The invention provides a refining method of methyhaaltrexone bromide, belonging to the technical field of chemical drug synthesis. According to the refining method, the methyhaaltrexone bromide is separated and purified by inverse silica gel column chromatography, and the procedure of recrystallization on a methyhaaltrexone bromide product by a mixed solvent of methanol and water can be added before and after the inverse silica gel column chromatography. According to the refining method, the conditions are mild, the yield is high, the purity of refined products is high, and the generated product meet the requirement on purification of medical methyhaaltrexone bromide preparation, so that the method is applicable to industrialized mass production.

Owner:NEW FOUNDER HLDG DEV LLC +2

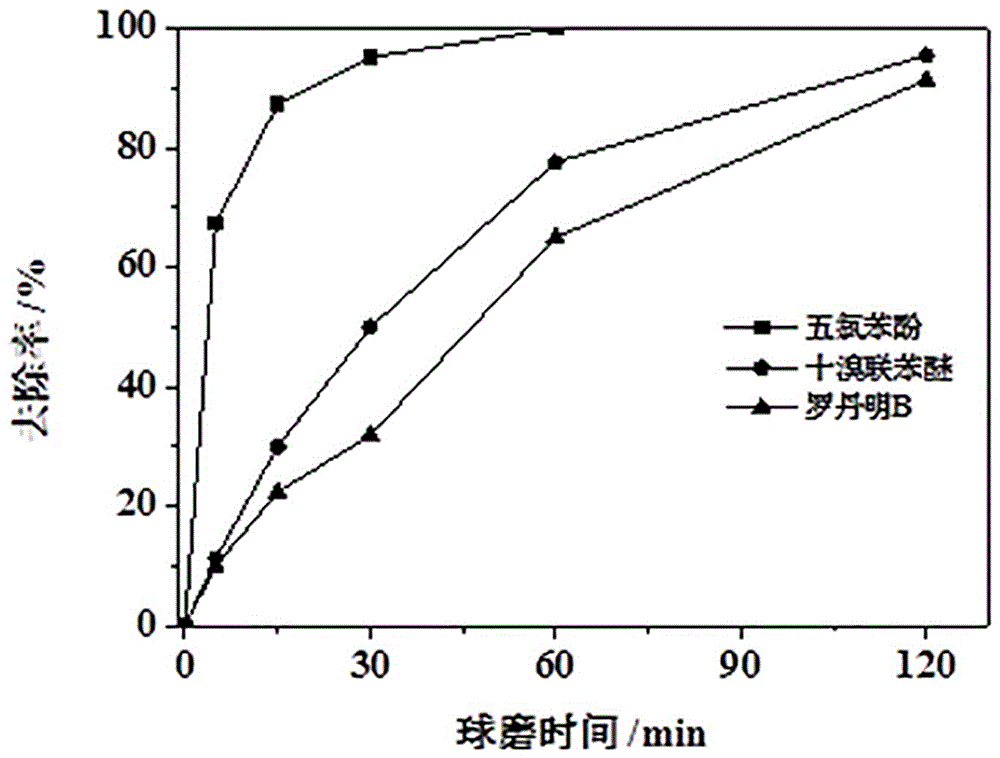

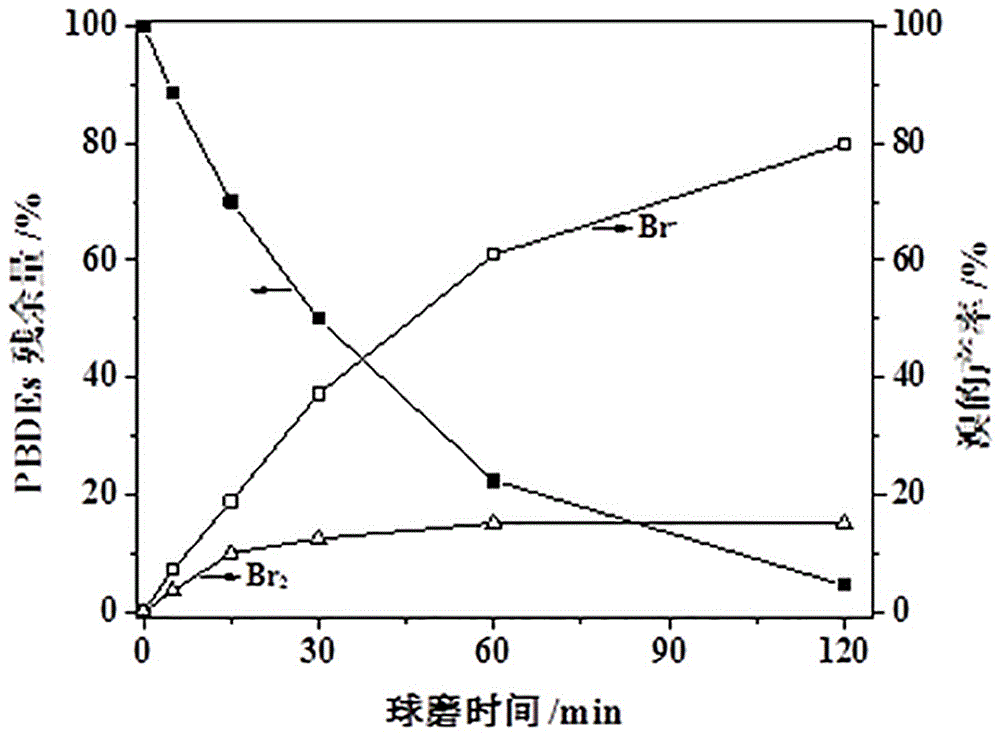

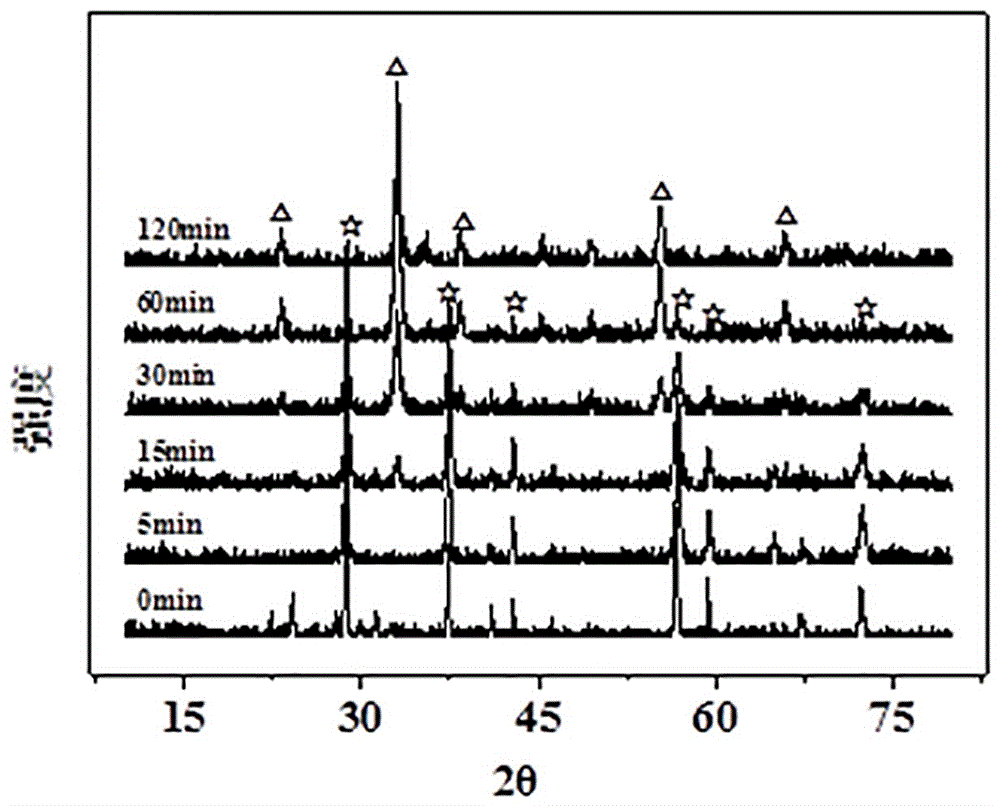

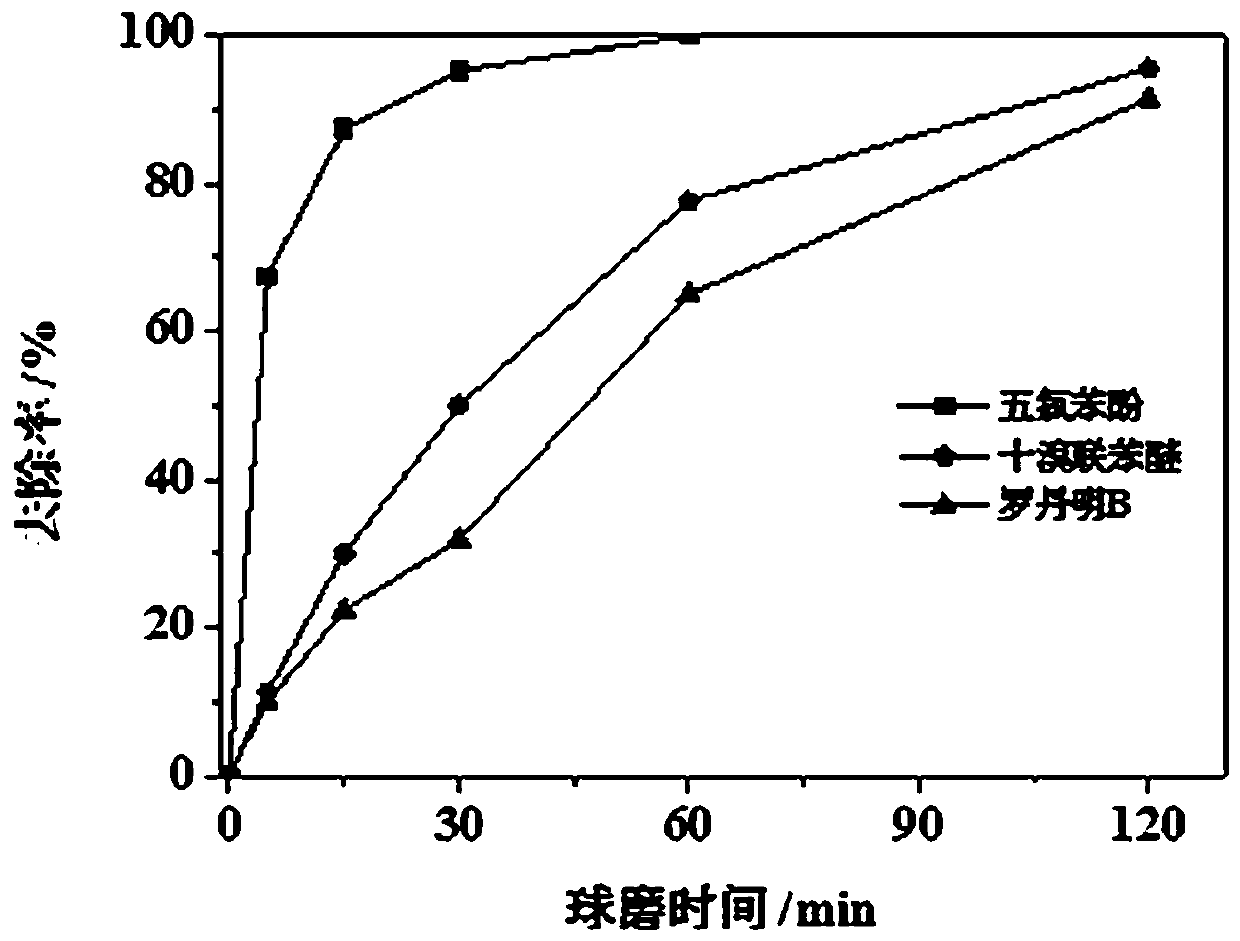

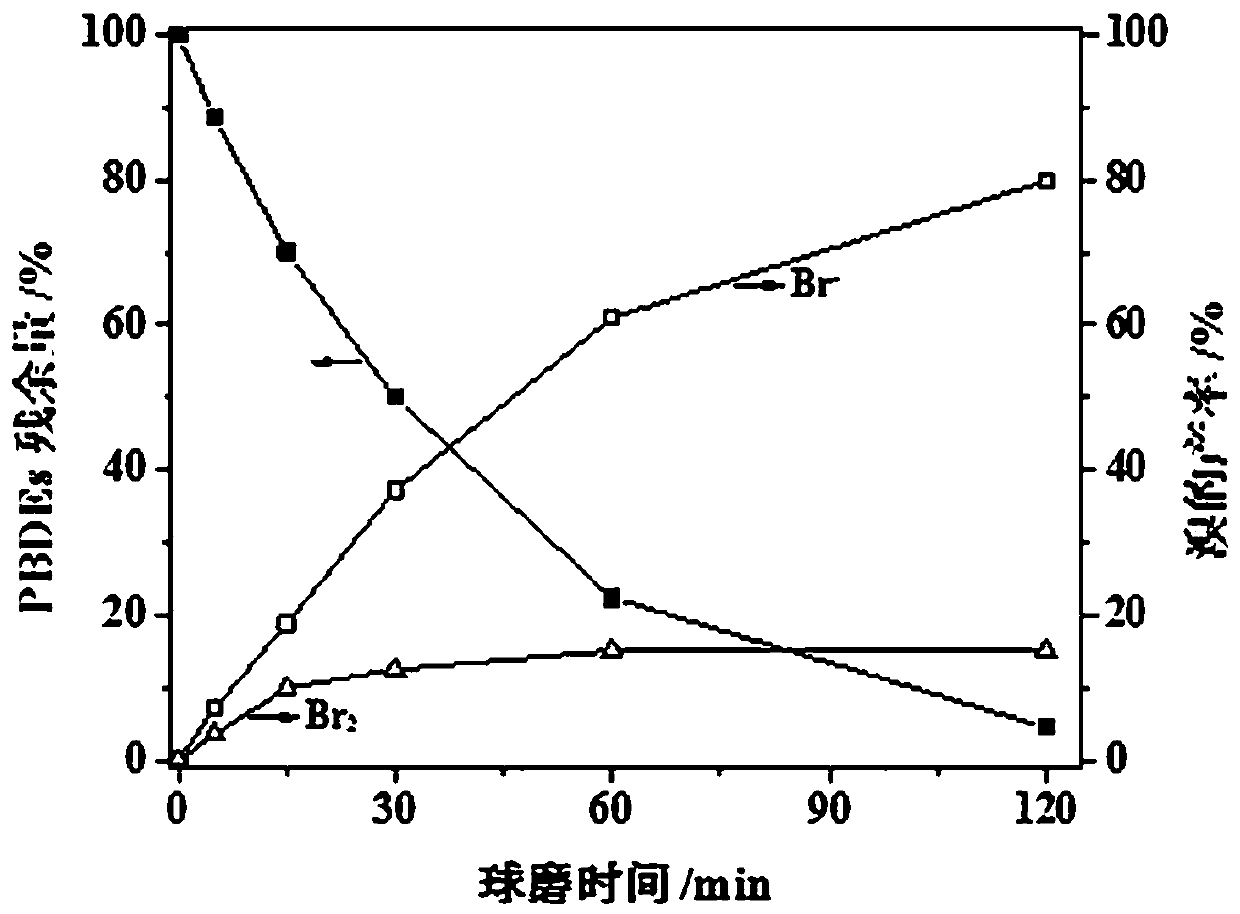

Method for treating organic solid waste through manganese dioxide, preparing manganic oxide and treating water pollutants through manganic oxide

ActiveCN106000554AAchieve degradationAchieve mineralizationWater contaminantsManganese oxides/hydroxidesSulfate radicalsPtru catalyst

The invention discloses a method for treating poisonous organic pollutant solid waste through ball milling mechanochemistry with manganese dioxide as an oxidant and reaction raw materials and preparing manganic oxide simultaneously and belongs to the technical field of waste treatment and new material preparation. According to the method, under the normal temperature and normal pressure, the organic solid waste and the manganese dioxide are put in a planetary ball milling reactor in a mixed mode, and oxidation reaction of the manganese dioxide and organic pollutants is reinforced by a mechanical force effect. On the one hand, fast degradation and deep mineralization of the organic pollutants are achieved; and on the other hand, reduction of the manganese dioxide is achieved, peroxymonosulfate can be activated by the manganic oxide, the reduzate of the manganese dioxide, and converted into sulfate radical anions, and then the poisonous organic pollutants in water are treated. The method has the following advantages that the treating process of the poisonous organic pollutant solid waste is simple, reaction conditions are mild, and oxidation and mineralization are thorough; and meanwhile, after reaction, the catalyst manganic oxide activating the peroxymonosulfate can be prepared by the oxidant used by treatment reaction.

Owner:HUAZHONG UNIV OF SCI & TECH +1

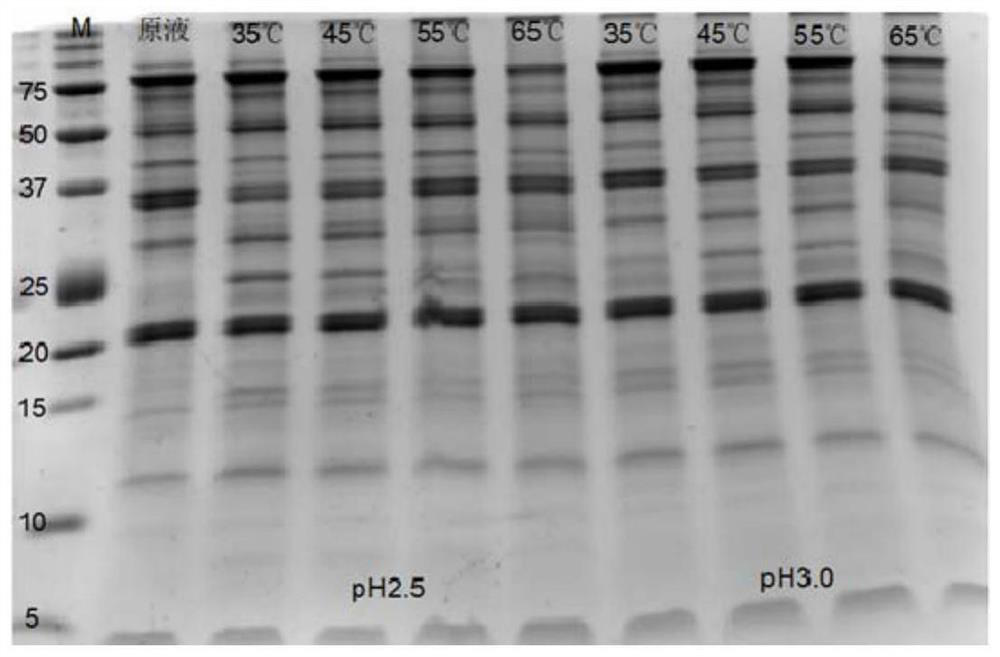

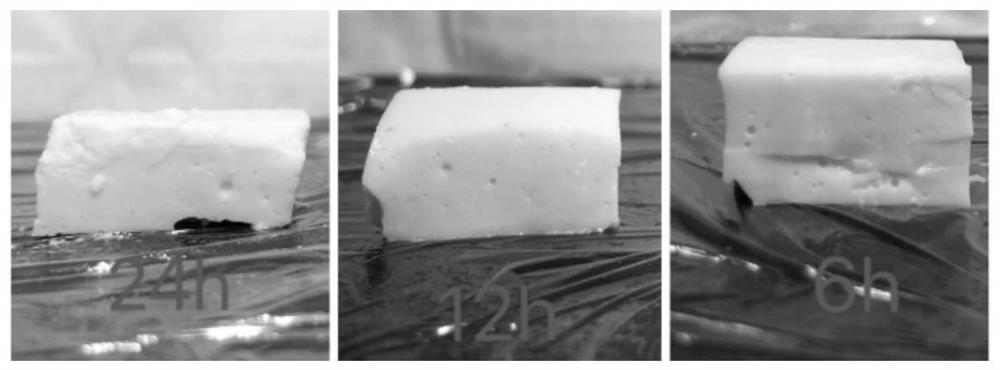

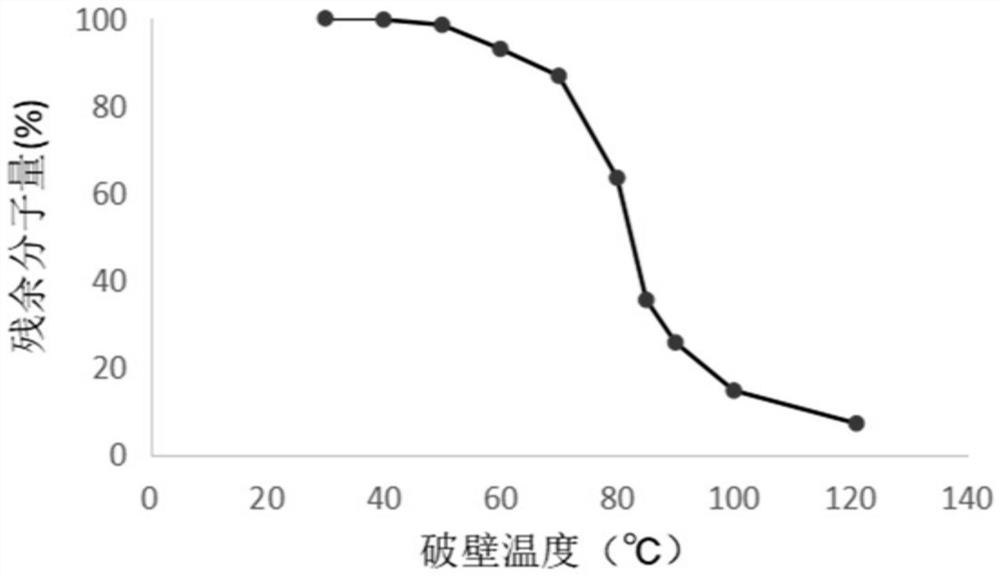

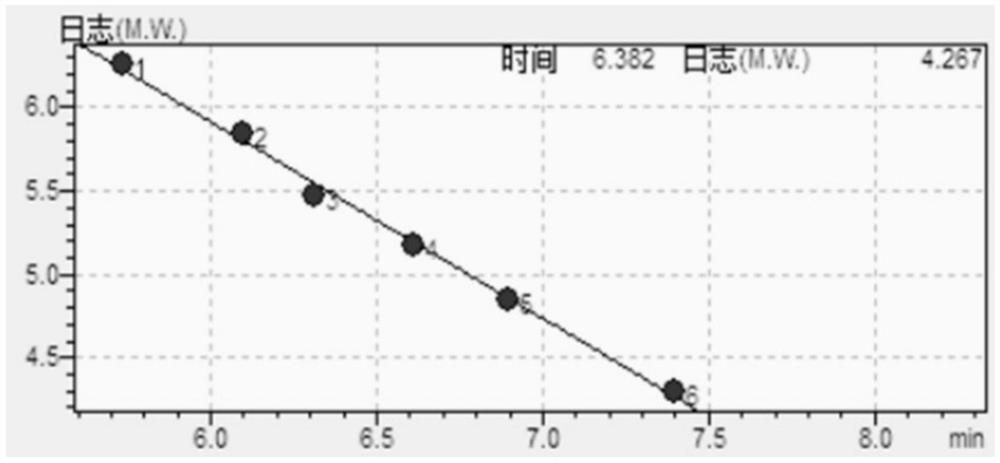

Method for preparing fiberized soybean protein gel under acidic condition

PendingCN113100325ADoes not require high temperature and pressureProtein composition from vegetable seedsProteins working-up by texturisingBiotechnologyProtein solution

The invention discloses a method for preparing fiberized soybean protein gel under an acidic condition, which belongs to the technical field of processing of vegetable protein. The fiberized soybean protein gel is finally obtained through preparation of a soybean aqueous extract, preparation of soybean protein liquid, preparation of a protein solution system and heat treatment. The fiberized soybean protein gel is prepared by utilizing the principle of protein molecule hydrolysis, polymerization and crosslinking under the acidic condition, can be used as a base material of artificial vegetarian meat or a substitute of animal protein, can effectively make up for the defects in the aspect of animal protein resources in China, and has great significance in the aspects of environmental protection, greenness and health.

Owner:JIANGNAN UNIV

A method of using manganese dioxide to treat organic solid phase waste and preparing manganese trioxide and using the product to treat pollutants in water

ActiveCN106000554BAchieve degradationLow costWater contaminantsManganese oxides/hydroxidesSulfate radicalsPtru catalyst

The invention discloses a method for treating poisonous organic pollutant solid waste through ball milling mechanochemistry with manganese dioxide as an oxidant and reaction raw materials and preparing manganic oxide simultaneously and belongs to the technical field of waste treatment and new material preparation. According to the method, under the normal temperature and normal pressure, the organic solid waste and the manganese dioxide are put in a planetary ball milling reactor in a mixed mode, and oxidation reaction of the manganese dioxide and organic pollutants is reinforced by a mechanical force effect. On the one hand, fast degradation and deep mineralization of the organic pollutants are achieved; and on the other hand, reduction of the manganese dioxide is achieved, peroxymonosulfate can be activated by the manganic oxide, the reduzate of the manganese dioxide, and converted into sulfate radical anions, and then the poisonous organic pollutants in water are treated. The method has the following advantages that the treating process of the poisonous organic pollutant solid waste is simple, reaction conditions are mild, and oxidation and mineralization are thorough; and meanwhile, after reaction, the catalyst manganic oxide activating the peroxymonosulfate can be prepared by the oxidant used by treatment reaction.

Owner:HUAZHONG UNIV OF SCI & TECH +1

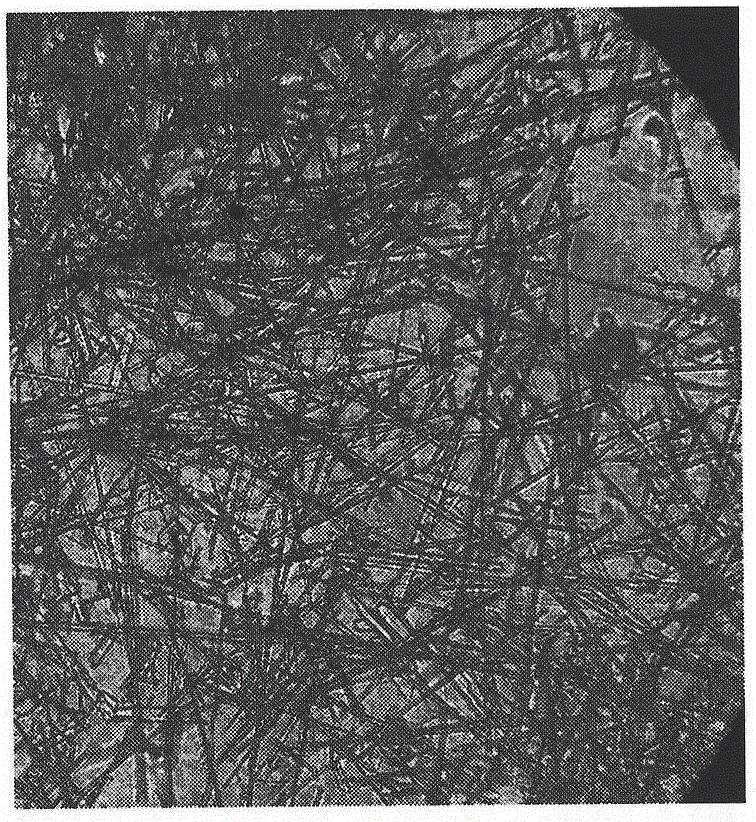

Method for producing natural fragrance smoked knitting wool

The present invention relates to the production process of natural fumigant knitting wool. Dyed knitting wool is mixed with treating solution containing natural perfume microcapsule and cross-linking agent in certain weight proportion and heated to the treating temperature of 40-50 deg.c for 12-18 min, so that the natural perfume microcapsule is adhered onto the knitting wool in the density as high as one million each square centimeter. During the clothes of the natural fumigant knitting wool is worn, the natural perfume microcapsules are broken gradually, and perform is released slowly and constantly.

Owner:王启发

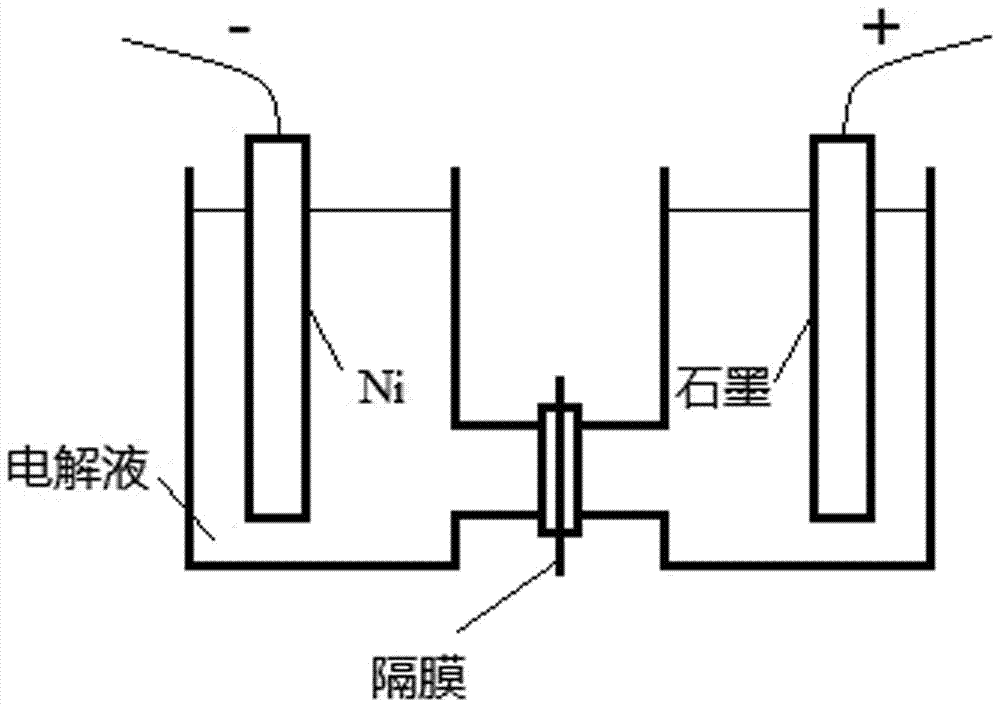

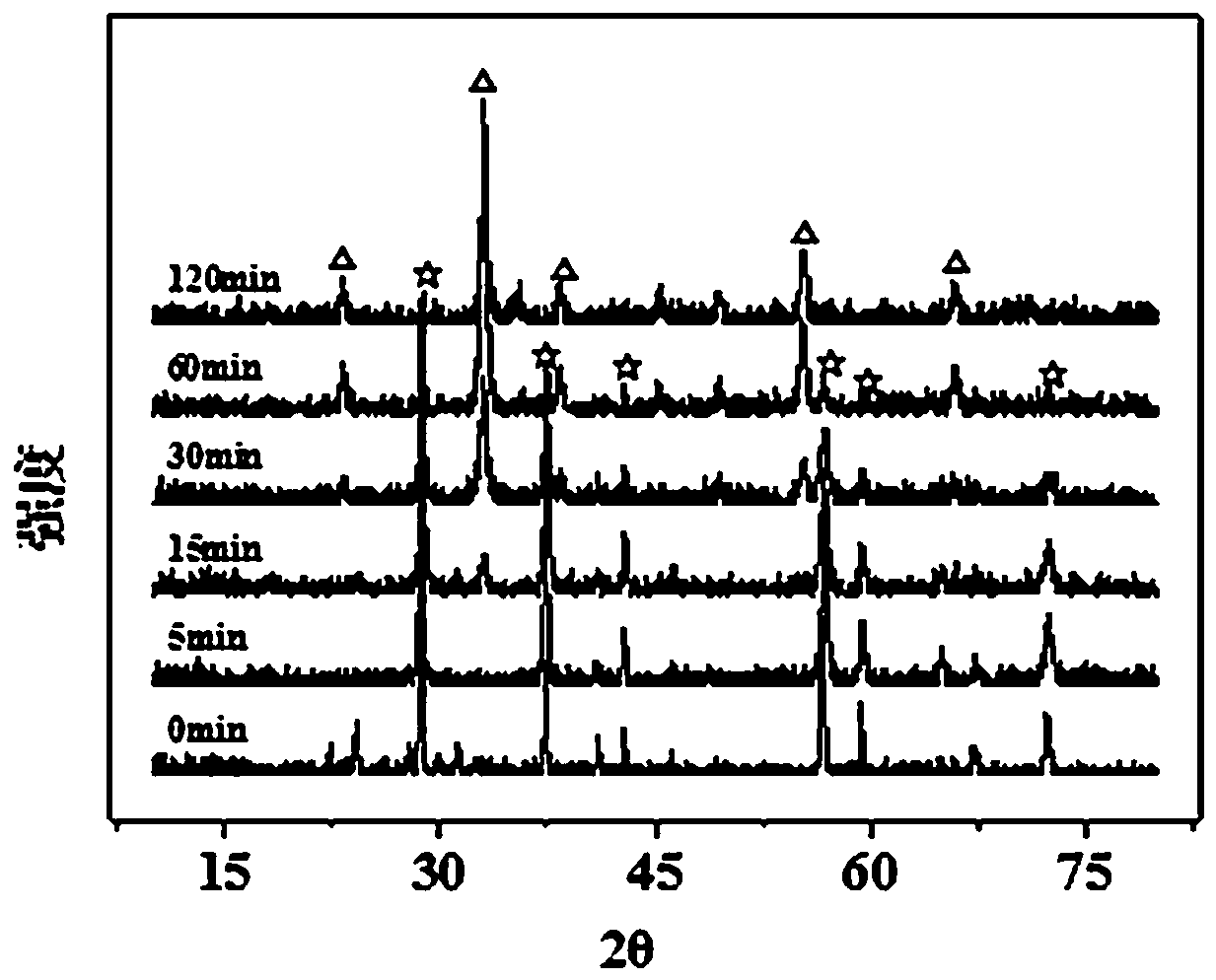

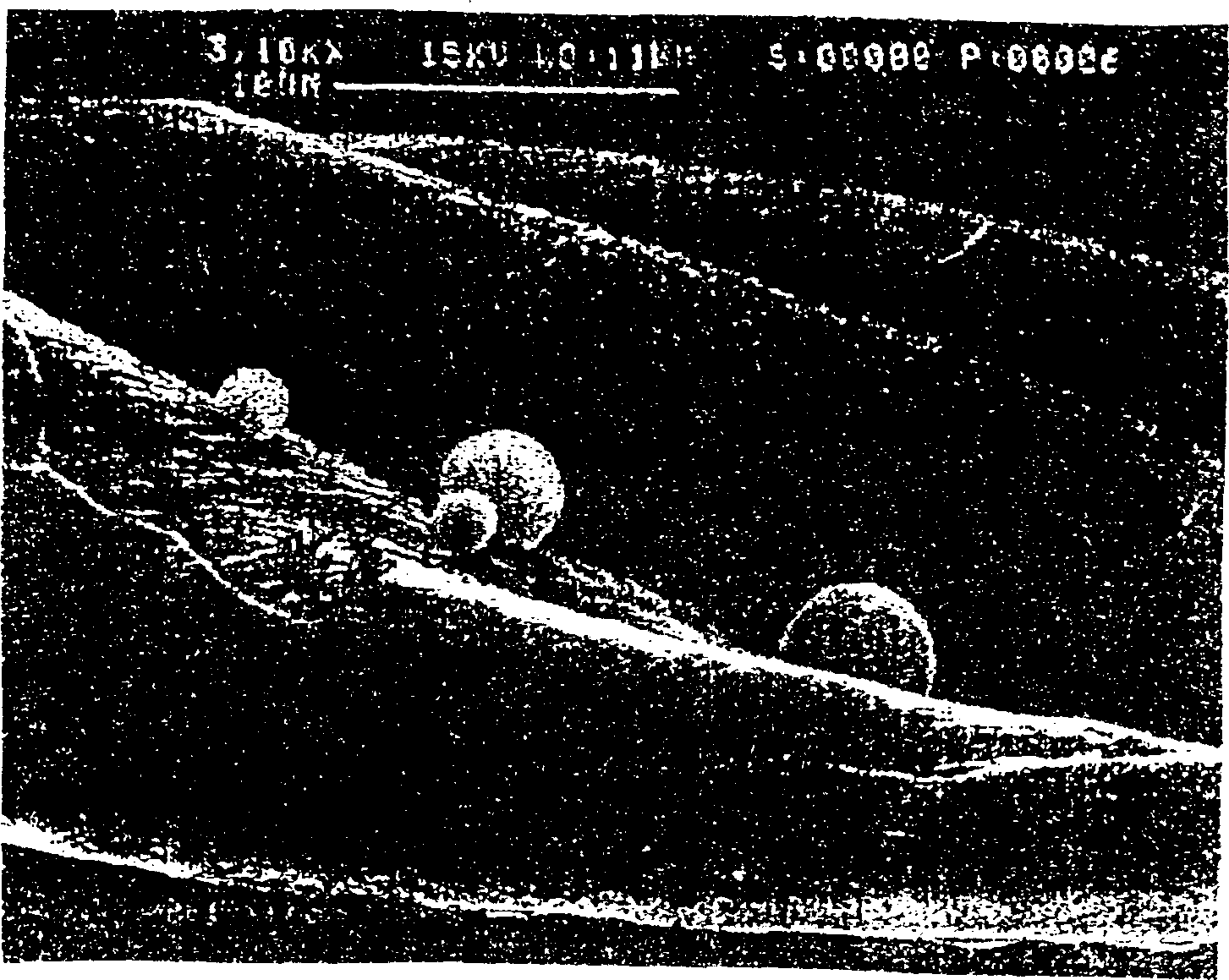

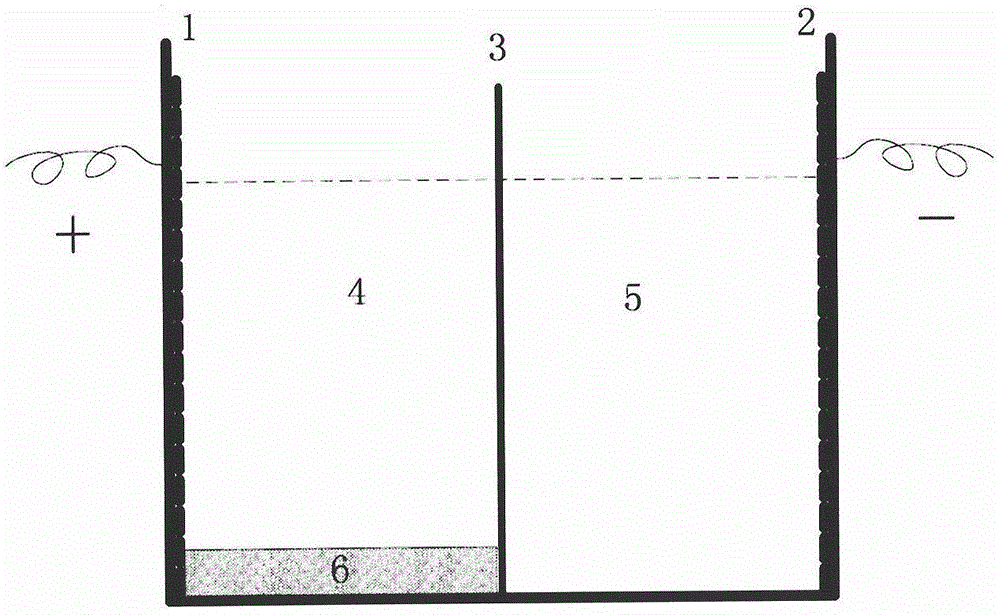

Preparation method of calcium sulfate whiskers

ActiveCN105568387ADoes not require high temperature and pressureRaw materials are easy to getPolycrystalline material growthFrom normal temperature solutionsHydrogenSulfate

The invention provides a preparation of calcium sulfate whiskers. The preparation method comprises the following steps of dividing a reaction vessel into a cathode chamber and an anode chamber by using an anion exchange membrane; adding a cathode plate to the cathode chamber; adding an anode plate to the anode chamber; adding a soluble sulfate water solution into the cathode chamber; adding a soluble calcium salt water solution into the anode chamber; switching on a direct-current power supply; obtaining needle-shaped calcium sulfate whiskers in the cathode chamber after regulating pH (Potential of Hydrogen) and applying voltage.

Owner:烟台远东精细化工有限公司

Preparation method of butynedioic acid

ActiveCN111377812ANo apparent environmental hazardReduce disposal volumePreparation from carboxylic acid saltsOrganic compound preparationPtru catalystPhysical chemistry

The invention discloses a preparation method of butynedioic acid. The method comprises the following steps of: (1) firstly, carrying out water-free and oxygen-free treatment on a closed reaction kettle; (2) putting calcium carbide, a solvent, a catalyst and an auxiliary agent into the reaction kettle, introducing carbon dioxide into the reaction kettle, and heating and pressurizing for reaction; (3) separating the reacted mixture obtained in the step (2) to obtain a liquid mixture, and adding a KOH solution into the liquid mixture; stirring to separate out a white precipitate; and dissolving the white precipitate in hot water, acidifying with concentrated sulfuric acid, cooling, separating out the white precipitate, and filtering to obtain the product. The synthesis method disclosed by theinvention is relatively environment-friendly and low in production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing organic acid by oxidative degradation of biomass and prepared organic acid

InactiveCN107827732ANot suitable for storageReduce energy consumptionOrganic compound preparationLignin derivativesWater bathsAcetic anhydride

The invention discloses a method for preparing organic acid by oxidative degradation of biomass and a prepared organic acid, which relate to the field of biomass reuse and solve the problems of high energy consumption, high cost, harsh reaction conditions, large residue amount and environment pollution existing in conventional biomass degradation and utilization methods. The method comprises the following steps: biomass and acetic anhydride are uniformly mixed according to a solid-liquid ratio of 1g:(5ml to 30ml) under magnetic stirring, and 30 percent of hydrogen peroxide is dripped by a constant-pressure drop funnel; the mixture is oxidized under the condition of 35 DEG C to 85 DEG C for 6 to 48 hours; filtration is performed to obtain an oxidized solution; the oxidized solution is driedby evaporation in water bath, so as to obtain residue; and the residue is separated by column chromatography, so that the organic acid is obtained. By oxidatively degrading an organic matter in the biomass under mild conditions, the chemical with high added value-the organic acid can be obtained, establishing a novel method for the application of biomass. The method has the advantages of low energy consumption, low cost, less residue and no environment pollution.

Owner:JILIN AGRI SCI & TECH COLLEGE

A preparation method of graphene quantum dots with controllable oxidation degree

ActiveCN104961126BHigh yieldLow priceMaterial nanotechnologyLuminescent compositionsInorganic saltsStrong acids

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

The synthetic method of 6-benzylphenanthridine compound

ActiveCN107235900BPost-processing is simpleSimple and fast operationOrganic chemistryPtru catalystCombinatorial chemistry

The invention discloses a synthetic method of 6-benzyl phenanthridine compounds. A reaction equation is as follows: formula (shown in the description), wherein R represents hydrogen, fluorine, chlorine, methyl, methoxyl or a naphthalene ring. The synthetic method has the beneficial effects that (1) the operation of the preparation process is simple and convenient, and the post-treatment of obtained products is easy; (2) high temperature and high pressure conditions are not required, and reaction conditions are mild; (3) a catalyst is not required, and the synthetic cost is lowered; (4) functional groups of a reaction substrate are high in tolerance, and the substrate is wide in range and easy to prepare; (5) an oxidant is cheap, easily available and relatively economic; (6) the reaction is efficient and high in yield; and (7) the synthetic method is pollution-free and environment-friendly.

Owner:WENZHOU UNIV

A kind of method for preparing acrolein

ActiveCN107915614BIncrease mass transfer rateReduce consumptionOrganic compound preparationCarbonyl compound preparationPtru catalystOrganosolv

The invention discloses a method for preparing acrolein. The method includes the steps: sufficiently and uniformly mixing catalysts, glycerin and water to prepare glycerin water catalysis reaction solution; adding low-pole organic solvents and Pickering emulsifying agents into the glycerin water catalysis reaction solution, and stirring and emulsifying mixture to prepare a Pickering emulsion reaction system; heating the Pickering emulsion reaction system to reach the reaction temperature, condensing and collecting acrolein generated by reaction, recycling the acrolein, and performing catalyticreaction on the recycled acrolein. The method has the advantages of low reaction temperature, high acrolein yield and good reaction selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

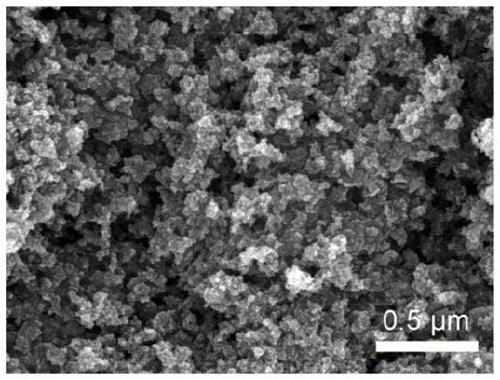

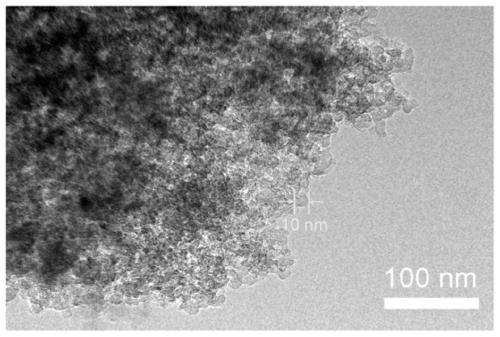

Preparation and application of biomass carbon nanosphere cluster material

InactiveCN111244477ARich varietyMild reaction conditionsFuel and secondary cellsCell electrodesBiomass carbonFuel cells

The invention relates to preparation and application of a biomass carbon nanosphere cluster material, and belongs to the technical field of biomass carbon materials / metal-air batteries. Renewable biomass is used as a raw material, the biomass carbon nanosphere cluster material with the open crack type pore structure is obtained by optimizing biomass carbonization steps and conditions, the raw materials are wide in variety, cheap and renewable, the preparation process is simple, the conditions are mild, and the preparation is suitable for industrial production; the biomass carbon nanosphere cluster material prepared by the invention has rich open crack type mesoporous and macroporous structures, can contain a large number of discharge products without being blocked, is beneficial to rapid conduction of oxygen and metal ions in the material, and has a wide application prospect in various metal-air batteries and fuel batteries.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Adsorbent for desulfurization of fuel oil, preparation method and application thereof

ActiveCN103041764BGood dispersionLarge particle sizeOther chemical processesHydrocarbon oils refiningNanoparticleSulfide

The invention discloses an adsorbent for desulfurization of fuel oil. The absorbent does not need any carriers, while only silver halide nanoparticles are used for absorbing and removing sulphides in the fuel oil under mild conditions. The adsorbent for desulfurization of the fuel oil adopts the silver halide nanoparticles.

Owner:NANJING TECH UNIV

Refining method of methyhaaltrexone bromide

InactiveCN102558189BMild conditionsDoes not require high temperature and pressureOrganic chemistrySolventSilica gel

Owner:NEW FOUNDER HLDG DEV LLC +2

Polycarbonate and polymethyl methacrylate lamination adhesive resin, preparation method and application thereof

The invention relates to polycarbonate and polymethyl methacrylate laminating adhesive resin, a preparation method and application thereof. The polycarbonate and polymethyl methacrylate laminating adhesive resin comprises a component A and a component B, wherein the component A is an NCO-terminated polyurethane prepolymer; the component B comprises hydroxyl acrylic resin, first polyol, transparentmicrospheres and an auxiliary agent; the molar ratio of isocyanate groups in the component A to hydroxyl groups in the component B is 0.9 to 1.3. The adhesive resin not only can be well adhered to polycarbonate and polymethyl methacrylate, but also can guarantee optical properties of an adhered laminated component.

Owner:CHINA BUILDING MATERIALS ACAD

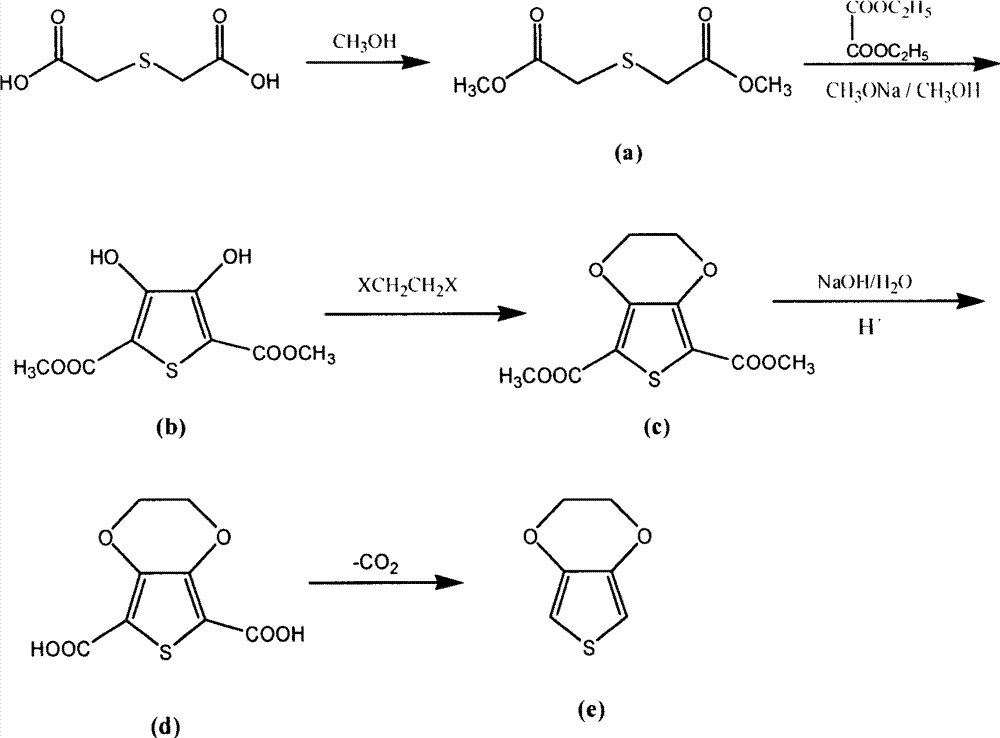

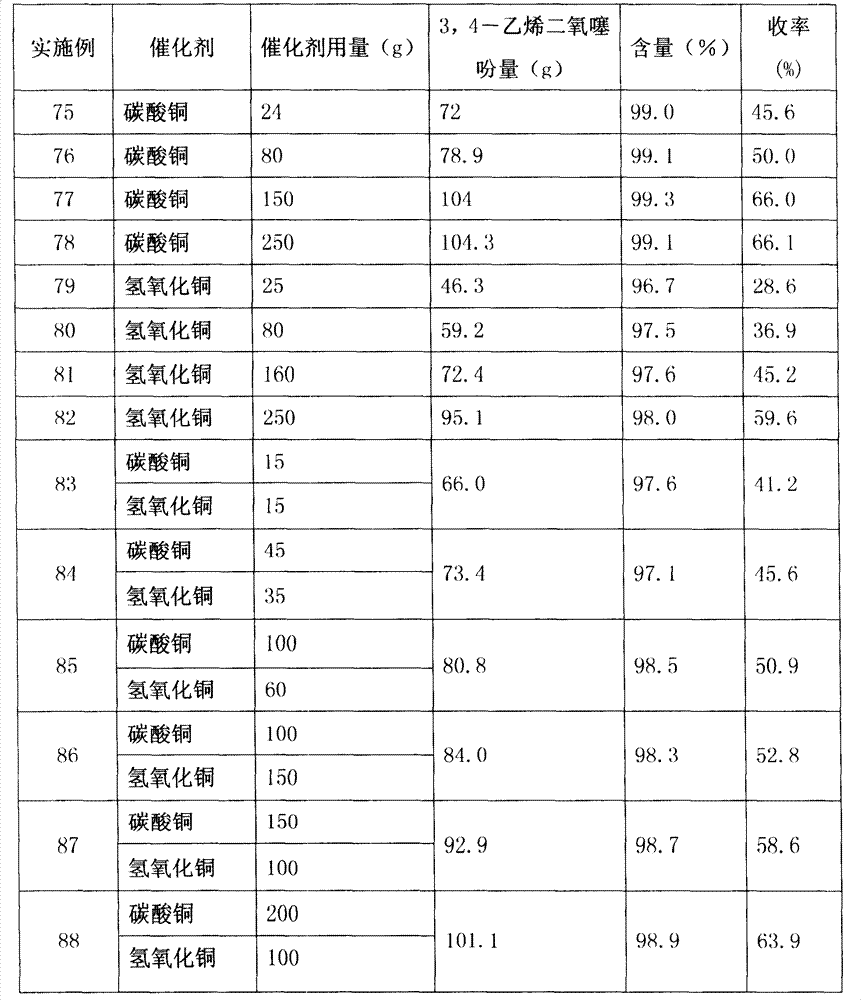

Preparation method of 3,4-ethene dioxythiophene

The invention discloses a preparing method of 3, 4-ethylene dioxide thiofuran (EDOT), which comprises the following steps: adopting reasonable processing line; choosing thiodiglycol as initial raw material; esterifying; condensing; Williamson; hydrolyzing; decarboxylating; getting the end product. This invention possesses simple craft, low cost and high receiving rate, which is fit for commercial product.

Owner:贝利科技(重庆)有限公司

High-purity extraction method of polyhydroxyalkanoate

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com