High-purity extraction method of polyhydroxyalkanoate

A technology of polyhydroxyalkanoate and bacteria, which is applied in the field of bioengineering technology and biochemical industry, can solve the problems of difficult to meet the requirements of the application market, molecular weight loss, etc., and achieve the effect of industrial application of green production, high molecular weight and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Determination of polyhydroxyalkanoate content (refer to the literature Unsterile and continuous production of polyhydroxybutyrate by Halomonas TD01, Tan D, et al, Bioresource Technology, 2011, 102(17): 8130-8136):

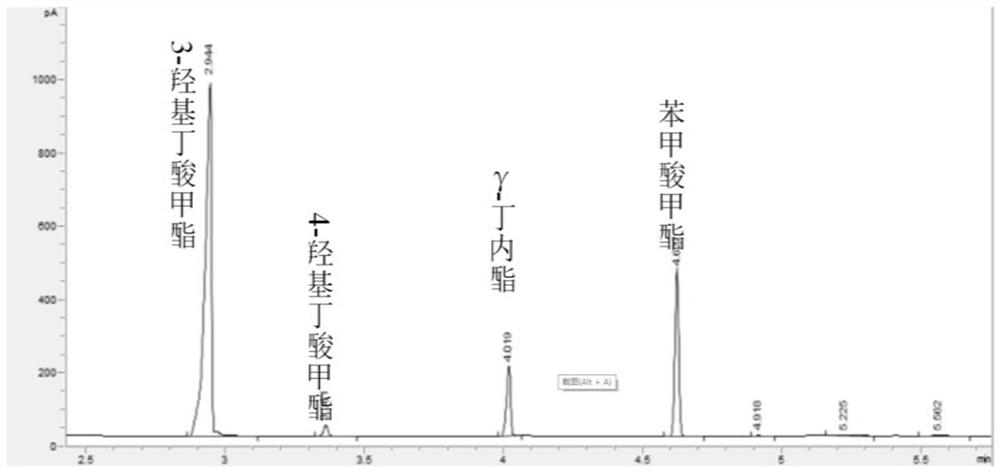

[0073] According to the different monomer components of the samples, PHB and butyrolactone were selected as the external standard, and benzoic acid was used as the internal standard. The standard sample and the sample form a monomer through acid hydrolysis, and esterify with methanol to generate the corresponding methyl ester, which is then detected by gas chromatography, such as the sum of the content of P34HB, 3HB and 4HB (see attached figure 1 ).

[0074] GPC method for determining the molecular weight of polyhydroxyalkanoate:

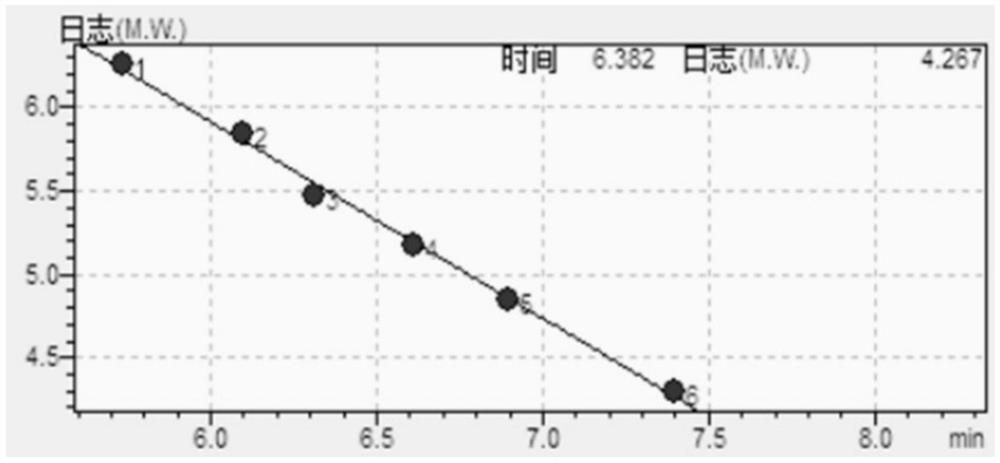

[0075] Polystyrenes with different molecular weights (20000Da~1800000Da) were used as standard products, and prepared into solutions with a concentration of 1mg / mL with chloroform to make a standard curve. The mobile phase was c...

Embodiment 2

[0078] The influence of embodiment 2 solid-liquid separation mode and number of times on PHA content

[0079]Take 200mL of fermentation liquid of halophilic bacteria in a tank, centrifuge at 8000rpm for 10min, wash with water for different times, and freeze-dry the obtained bacterial pellet for 48 hours to detect the PHA content. The results showed that the effect of breaking the wall was the best after centrifuging once to completely remove the supernatant before breaking the wall. Although excessive washing times can remove some soluble impurities and slightly improve product purity, it consumes a large amount of washing water, which is not conducive to industrial applications.

[0080] Further, by simulating an industrial disc centrifuge, take 200 mL of fermentation broth, centrifuge at 8000 rpm for 10 minutes, remove 65% of the supernatant, and mix the remaining part to form an industrial centrifugation. Add 0.5% of the purification aid sorbitol, pH9.5, and treat at 90°C ...

Embodiment 3

[0083] The influence of embodiment 3 wall breaking temperature and time on PHA content

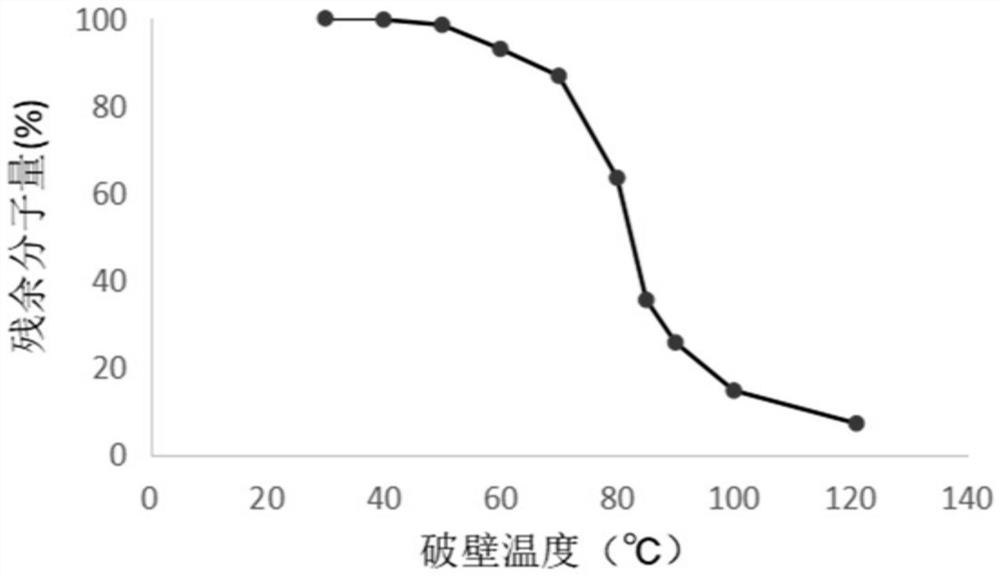

[0084] Select the same batch of fermentation liquid in the tank to break the wall under the premise of other conditions unchanged (washing 3 times, 200g / L cell concentration, breaking pH 10.0, treatment time 120min, etc.), but design different broken walls Temperature, to study the effect of temperature on PHA content. The molecular weight test results show that the molecular weight remains unchanged when the temperature is lower than 40°C, and the molecular weight of the PHA finished product decreases rapidly as the wall breaking temperature continues to increase (see attached figure 2 ).

[0085] The GC test results of samples with different breaking temperatures show that when the temperature is too high, the PHA content of the finished product will decrease instead, indicating that too high a temperature will cause irreversible denaturation and precipitation of impurities such as pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com