Preparation method of selenium nanowires

A technology of selenium nanometer and selenium elemental substance, applied in the field of nanowires, can solve problems such as large-scale synthesis difficulties and complicated methods, and achieve the effects of mild reaction conditions, fine precipitated particles, and simple experimental devices and methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Dissolve 1.0g sodium selenite, 1.5ml concentrated hydrochloric acid and 3.0ml polyethylene glycol (average molecular weight 400) in deionized water to form 100ml aqueous solution;

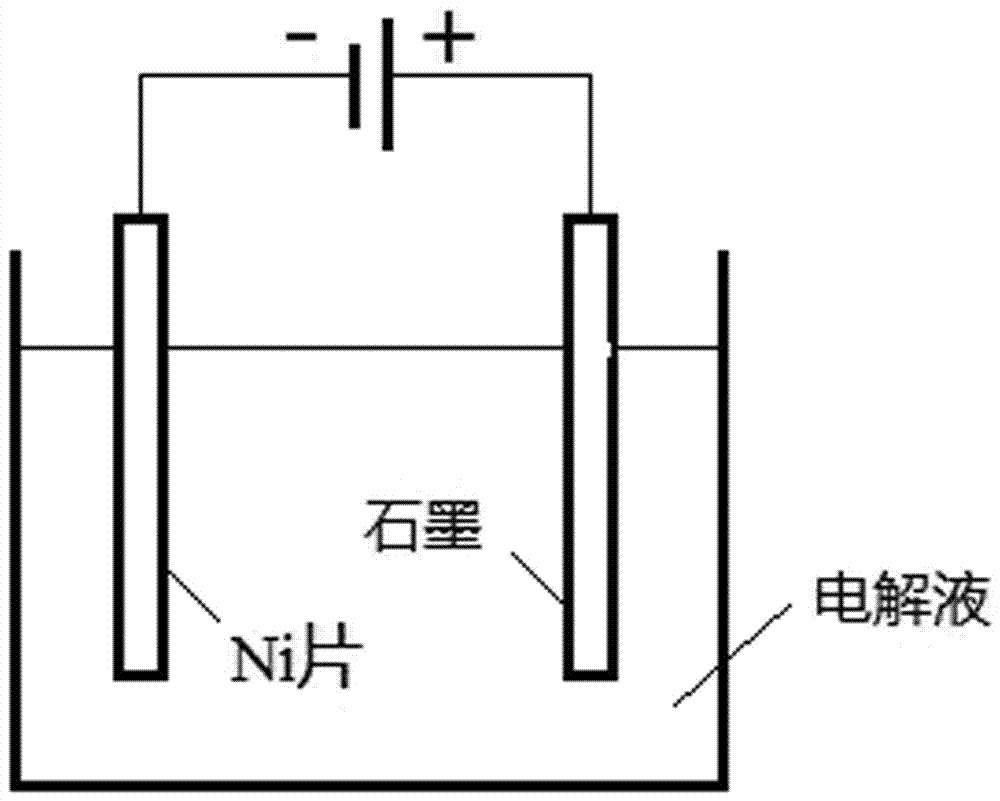

[0036] (2) A diaphragmless electrolytic cell is formed with a nickel sheet as the cathode and a graphite sheet as the anode, see figure 1 , figure 1 Schematic diagram of the structure of the electrolytic cell without diaphragm provided by the embodiment of the present invention;

[0037] (3) At room temperature, at 3mA / cm 2 Constant current electrolysis of the above aqueous solution for 3.5 hours at a current density of 10000 to obtain a brownish-red precipitate;

[0038] (4) The precipitate was washed successively with distilled water and absolute ethanol, and then placed in absolute ethanol for 24 hours to obtain selenium nanowires.

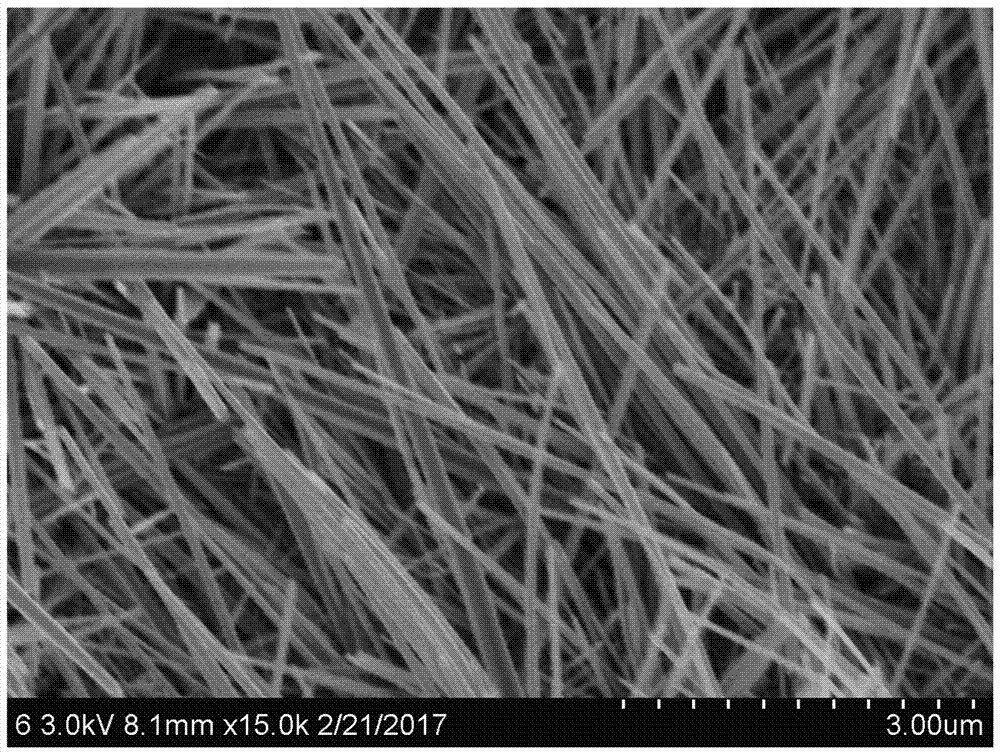

[0039] see figure 2 , figure 2 The scanning photo of the selenium nanowires prepared by the method provided by the present invention shows that th...

Embodiment 2

[0041] (1) Dissolve 1.0g sodium selenite, 1.5ml concentrated hydrochloric acid and 3.0ml polyethylene glycol (average molecular weight 400) in deionized water to form 100ml aqueous solution;

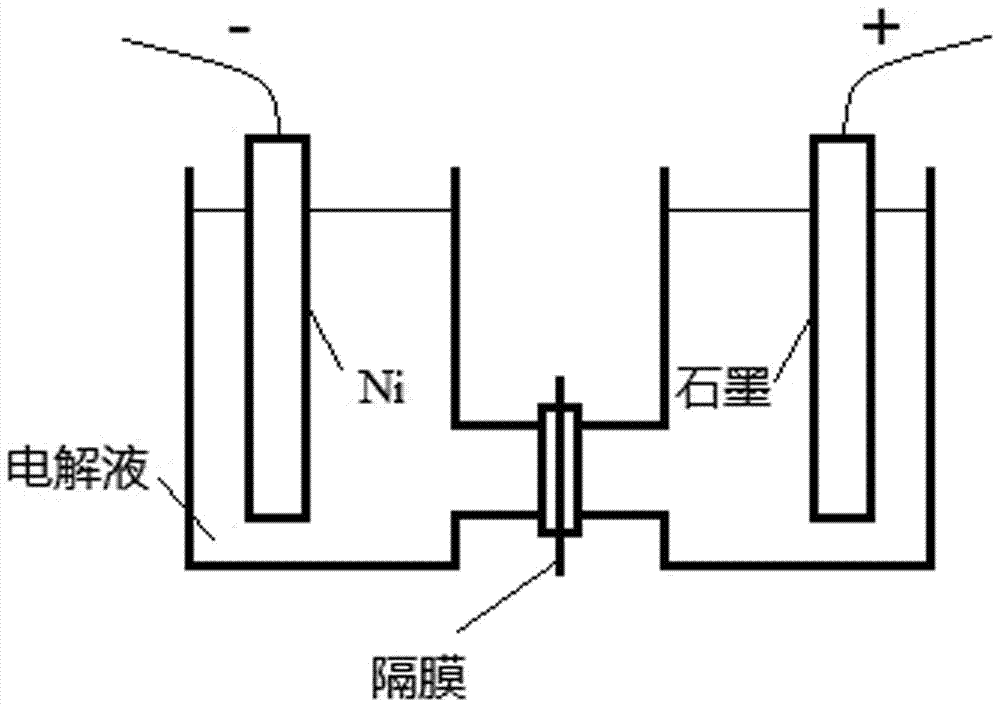

[0042] (2) The nickel sheet is used as the cathode, the graphite plate is used as the anode, and the cathode and anode are separated by a nafion membrane to form a diaphragm electrolytic cell, see image 3 , image 3 Schematic diagram of the membrane electrolytic cell structure provided for the embodiment of the present invention;

[0043] (3) At room temperature, at 3mA / cm 2 Constant current electrolysis of the above aqueous solution for 3.5 hours at a current density of 10000 to obtain a brownish-red precipitate;

[0044] (4) The precipitate was washed successively with distilled water and absolute ethanol, and then placed in absolute ethanol for 24 hours to obtain selenium nanowires.

[0045] The results show that the method provided by the invention has prepared selenium nanowires...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com