Preparation method of PbSxSe1-x ternary nanocrystal

A nanocrystal, selenium powder technology, applied in nanotechnology, chemical instruments and methods, non-metallic elements, etc., can solve the problems of solvent and surface ligand not being the same substance, serious solvent environmental pollution, and complicated operation process, etc. Simple, low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

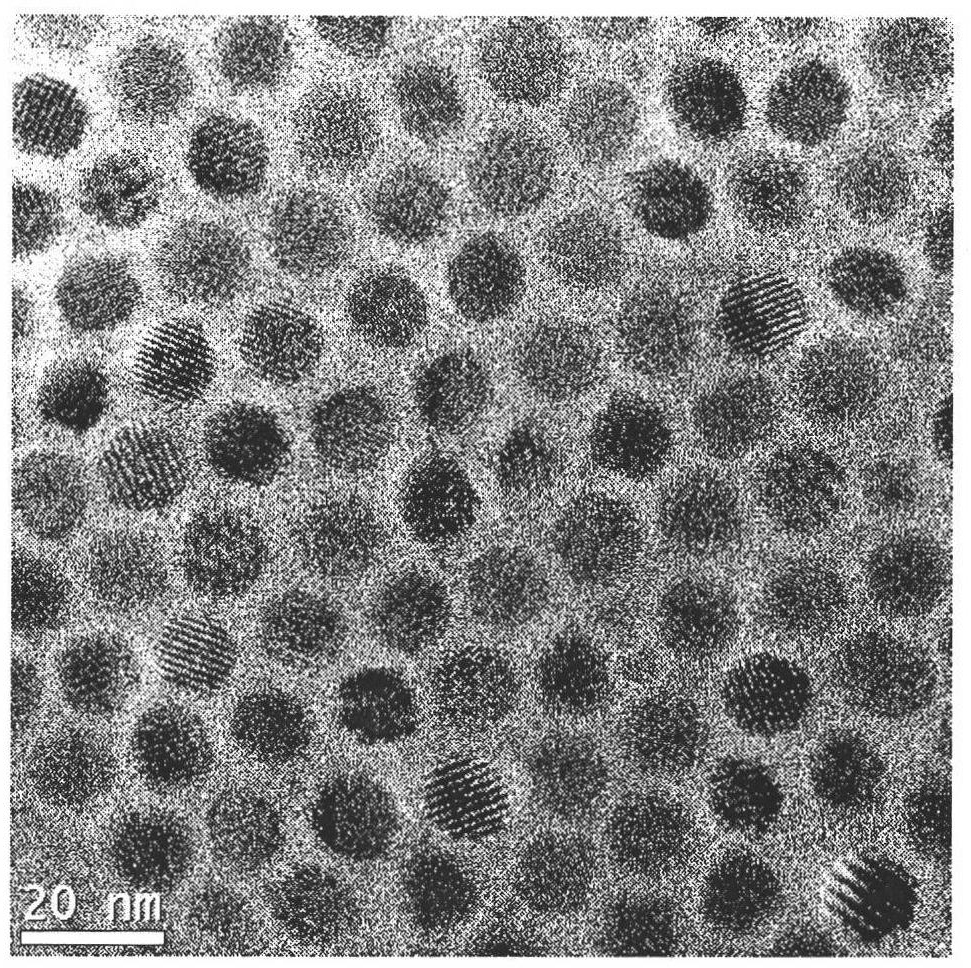

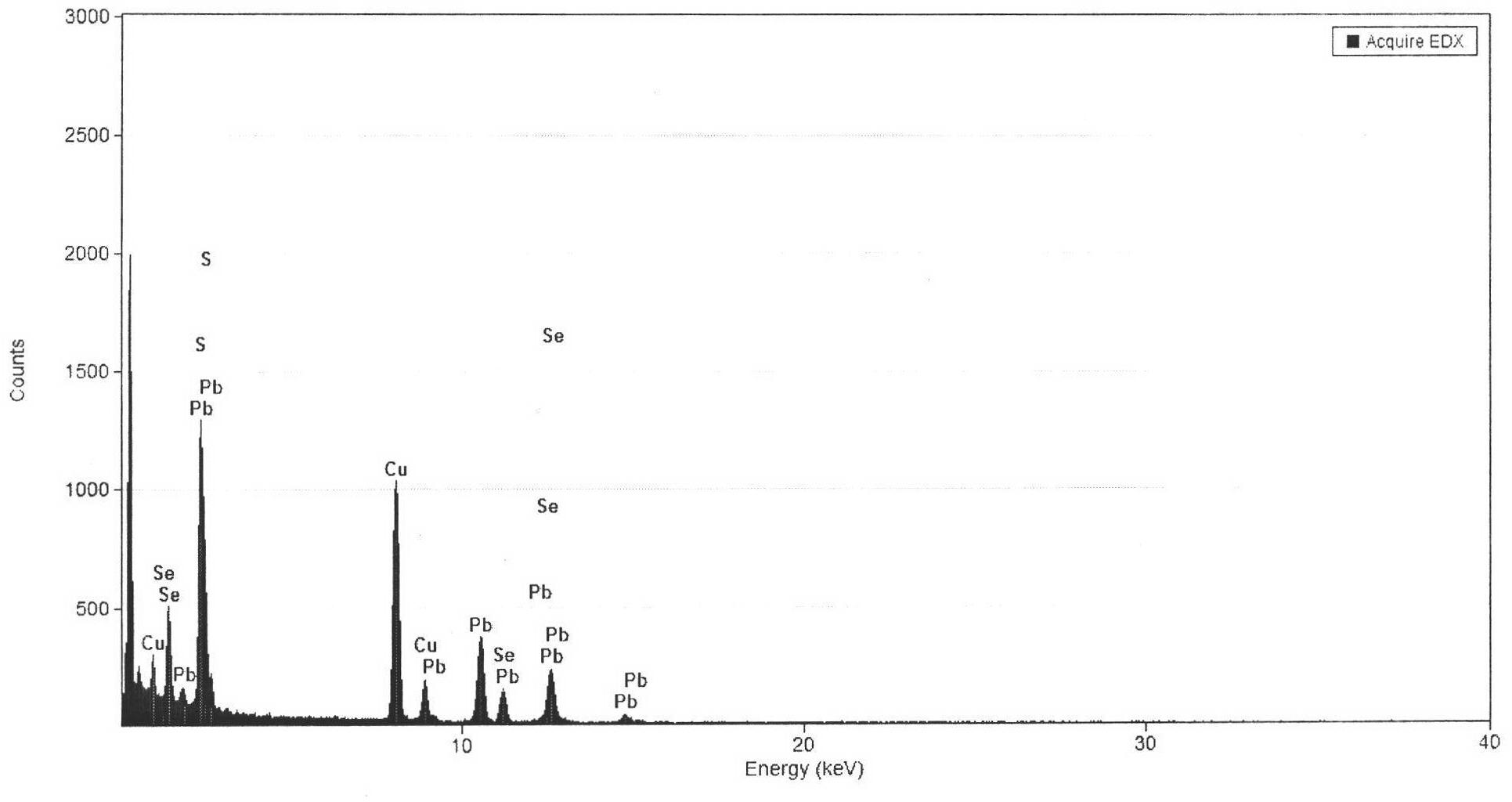

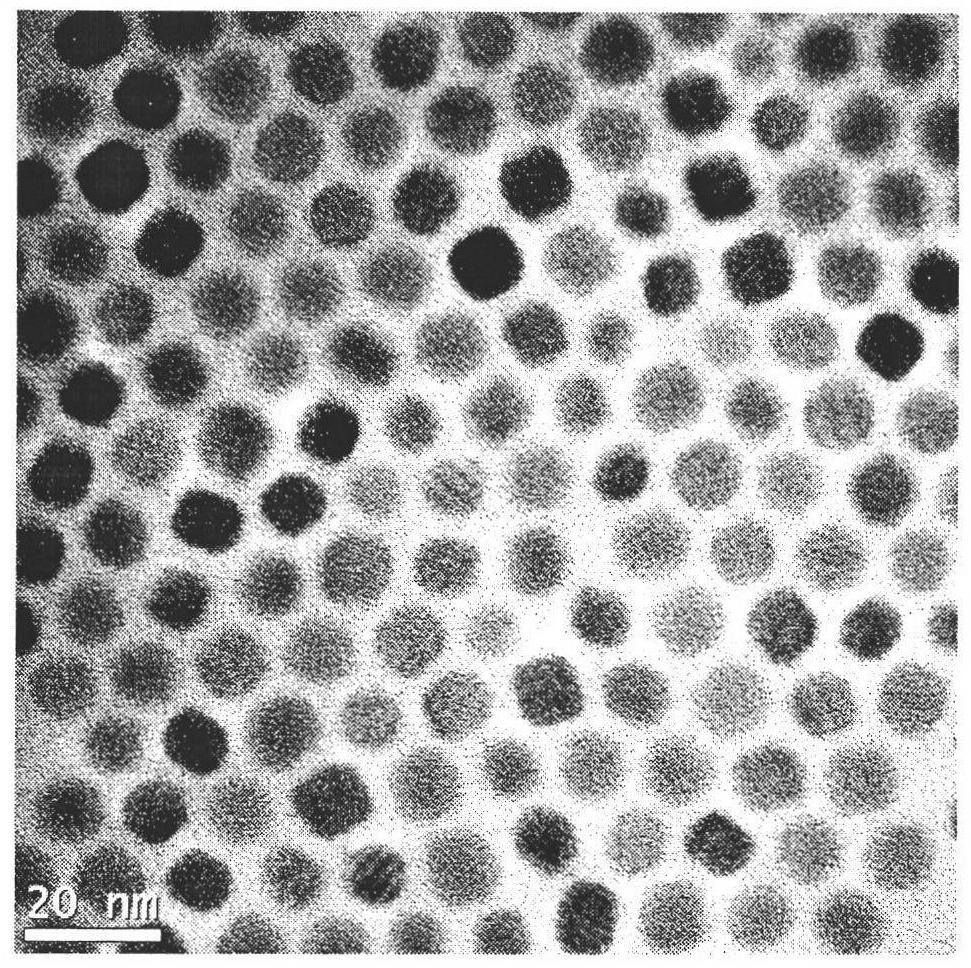

Image

Examples

Embodiment 1

[0034] The specific preparation steps of this embodiment are as follows:

[0035] a, at first, get 40 milligrams of selenium powders (0.5 millimoles) and 16 milligrams (0.5 millimoles) of sulfur powders and put into the two-necked flask that has cooling condition outside it, heating drives off air in the flask, fills with argon.

[0036] b. Inject 3 ml of oleylamine with a syringe and stir with a magnet.

[0037] c. Heat the above-mentioned (selenium powder+sulfur powder) amine mixed solution to 240°C with an oil bath, and the mixed solution slowly changes from a black suspension to a transparent light orange liquid, and keep this temperature for more than half an hour.

[0038] d. Next, put 280 mg of lead chloride into a 25 ml two-necked flask with condensed water, inject 5 ml of oleylamine with a syringe, stir with a magnet, and vacuumize for 15 minutes.

[0039] e. After heating the above-mentioned lead chloride mixed solution to 120° C. with an oil bath, pass in argon gas...

Embodiment 2

[0044] The specific preparation steps of this embodiment are as follows:

[0045] a, at first, get 55.3 milligrams of selenium powder (0.7 millimoles) and 9.6 milligrams of sulfur powders (0.3 millimoles) and put into the two-necked flask that has cooling condition outside it, get rid of air in the flask, charge into argon.

[0046] b. Inject 3 ml of oleylamine with a syringe and stir with a magnet.

[0047] c. Heat the above-mentioned selenium powder-sulfur mixed solution to 240° C. with an oil bath, and the mixed solution will slowly change from a black suspension to a transparent light orange liquid, and keep this temperature for more than half an hour.

[0048] d, secondly, get 280 milligrams of lead chloride and put it into a 25 milliliter two-necked flask with condensed water, inject 5 milliliters of oleylamine with a syringe, stir with a magnet, and vacuumize for half an hour.

[0049] e. After heating the above-mentioned lead chloride mixed solution to 120° C. with an...

Embodiment 3

[0054] The specific preparation steps of this embodiment are as follows:

[0055] a, at first, get 15.8 milligrams of selenium powders (0.2 millimoles) and 25.6 milligrams of sulfur powders (0.8 millimoles) and put into the two-necked flask that has cooling condition outside it, get rid of air in the flask, charge into argon.

[0056] b. Inject 3 ml of oleylamine with a syringe and stir with a magnet.

[0057] c. Heat the above-mentioned (selenium powder+sulfur powder) mixed solution to 240 DEG C with an oil bath, and the mixed solution slowly changes from a black suspension to a transparent light orange liquid, and keep this temperature for more than half an hour.

[0058] d, secondly, get 280 milligrams of lead chloride and put it into a 25 milliliter two-necked flask with condensed water, inject 5 milliliters of oleylamine with a syringe, stir with a magnet, and vacuumize for half an hour.

[0059] e. After heating the above-mentioned lead chloride mixed solution to 120° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com