Preparation method of calcium sulfate whiskers

A calcium sulfate whisker and sulfate technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of high production cost and large equipment investment, and achieve simple equipment, simple operation, and mild operating conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of embodiment 1 calcium sulfate whiskers, comprises the following steps:

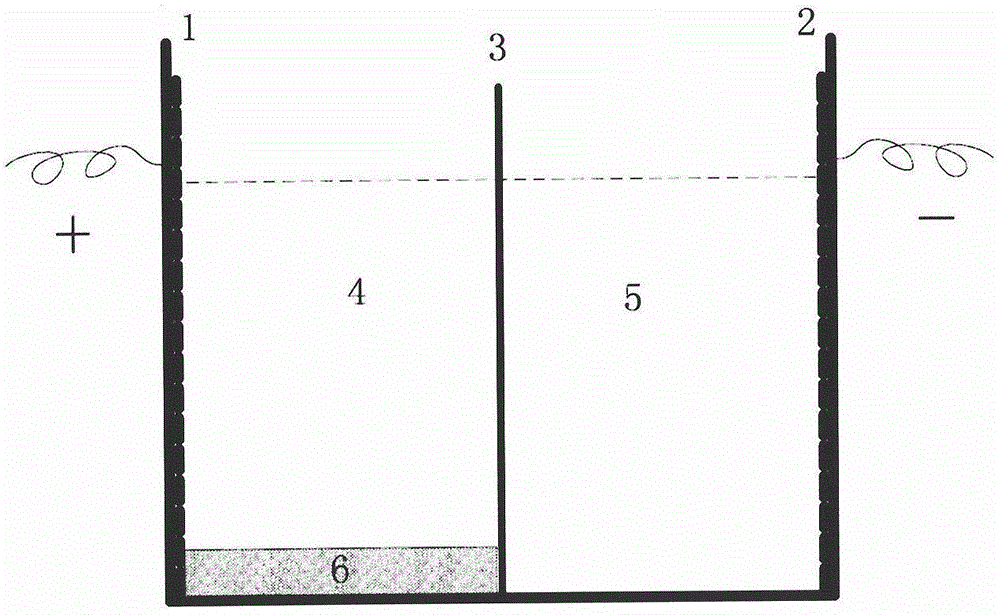

[0026] A. The reaction vessel is divided into two parts by an anion exchange membrane: the cathode chamber and the anode chamber.

[0027] B, add sodium sulfate aqueous solution in the cathode chamber, concentration 5% (mass); Add calcium chloride aqueous solution, concentration 2% (mass) in the anode chamber, both pole chambers all add stirring.

[0028] C. Turn on the DC power supply, the voltage is 4V, the current is 0.25A, and the pH is adjusted to 3,

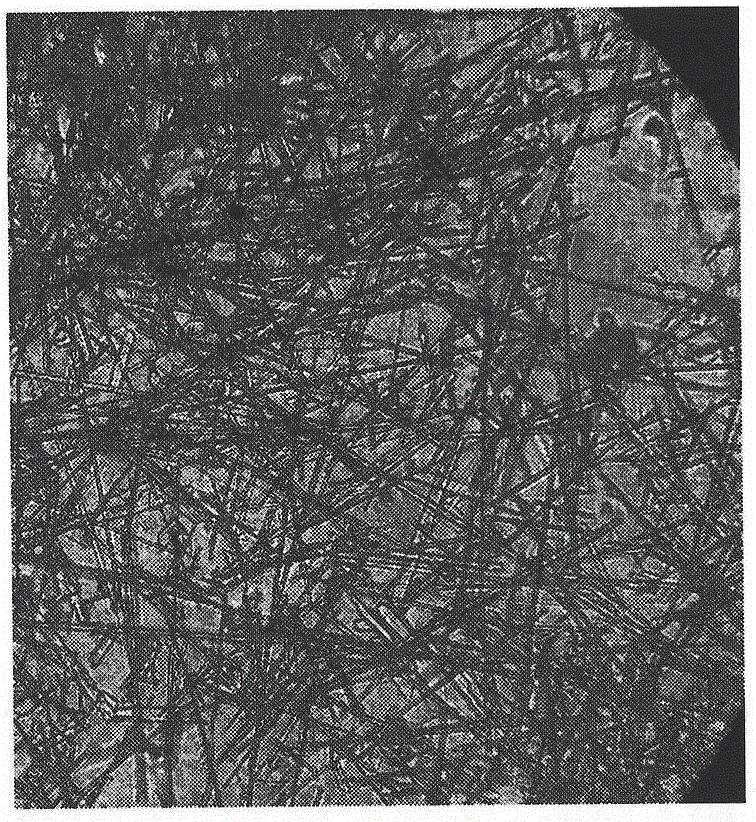

[0029] D. Acicular calcium sulfate whiskers were obtained in the cathode chamber after applying voltage for 2.5 hours.

[0030] E. Disconnect the DC power supply, continue to stir, and the whiskers continue to grow to obtain calcium sulfate whiskers with an aspect ratio greater than 100.

[0031] attached figure 1 It is a schematic process diagram of a preparation method of calcium sulfate whiskers. attached ...

Embodiment 2

[0032] A kind of preparation method of embodiment 2 calcium sulfate whiskers, the steps are as follows:

[0033] A. Use an anion exchange membrane to divide the reaction vessel into two parts: the cathode chamber and the anode chamber, the cathode chamber plus the cathode plate, and the anode chamber plus the anode plate;

[0034] B, add soluble sulfate aqueous solution (potassium sulfate, mass concentration 10%) in the cathode chamber, add soluble calcium salt solution (calcium nitrate, mass concentration 30%) in the anode chamber, both pole chambers all add stirring; For guaranteeing calcium sulfate crystal To ensure the consistency of the whiskers, calcium ions can be continuously added to the anode chamber, sulfate ions can be added to the cathode chamber, and stirring can be added to both the cathode chamber and the anode chamber.

[0035] C. Turn on the DC power supply and adjust the pH;

[0036] D. Acicular calcium sulfate whiskers are obtained in the cathode chamber a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com