Preparation method of MnO<2>/Ti<3>C<2>T<x>Mxene flexible supercapacitor electrode material

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as poor conductivity, limited energy density and durability, and achieve good conductivity, Effect of high energy density and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

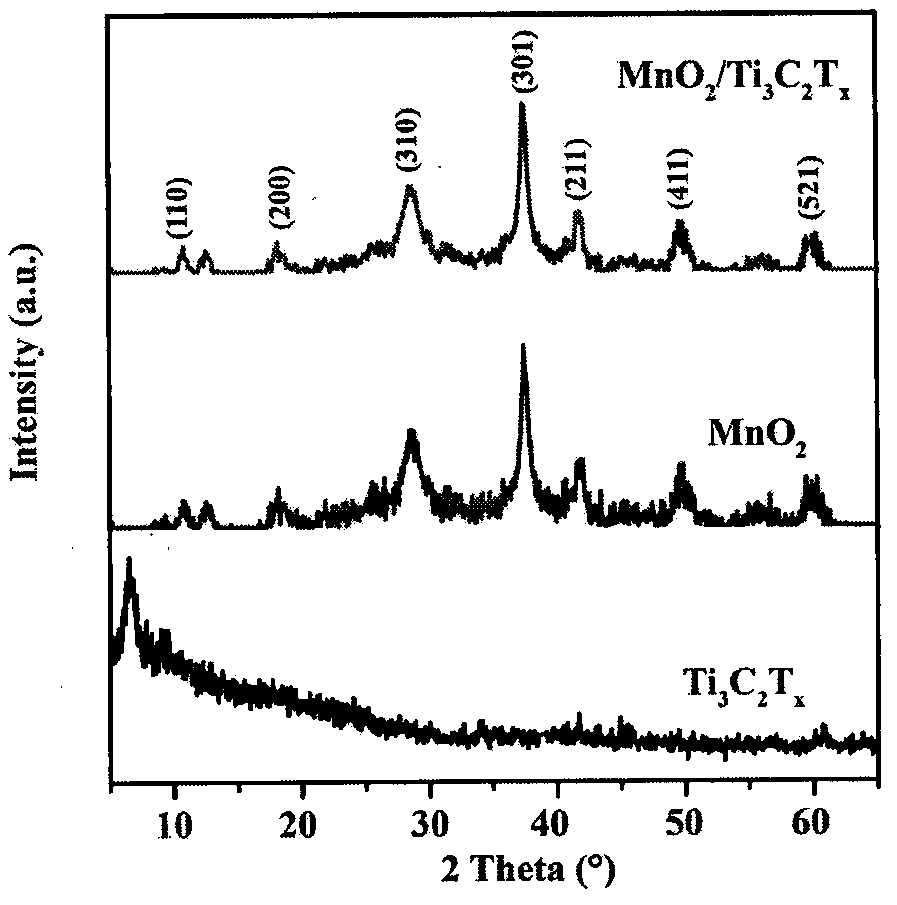

[0029] 1)Ti 3 C 2 T x Preparation of:

[0030] 1.1) Add 2g LiF to 20ml HCl and stir until clear to prepare corrosion solution.

[0031] 1.2) Add 2g Ti to the solution in step 1.1) 3 AlC 2 powder, the solution was heated to 40°C for 24 hours, then washed 5 times with deionized water, and centrifuged until the pH of the supernatant was about 6.

[0032] 1.3) The centrifuged solid in step 1.2) was vacuum-dried at 60°C for 12 hours to obtain Ti 3 C 2 Tx powder.

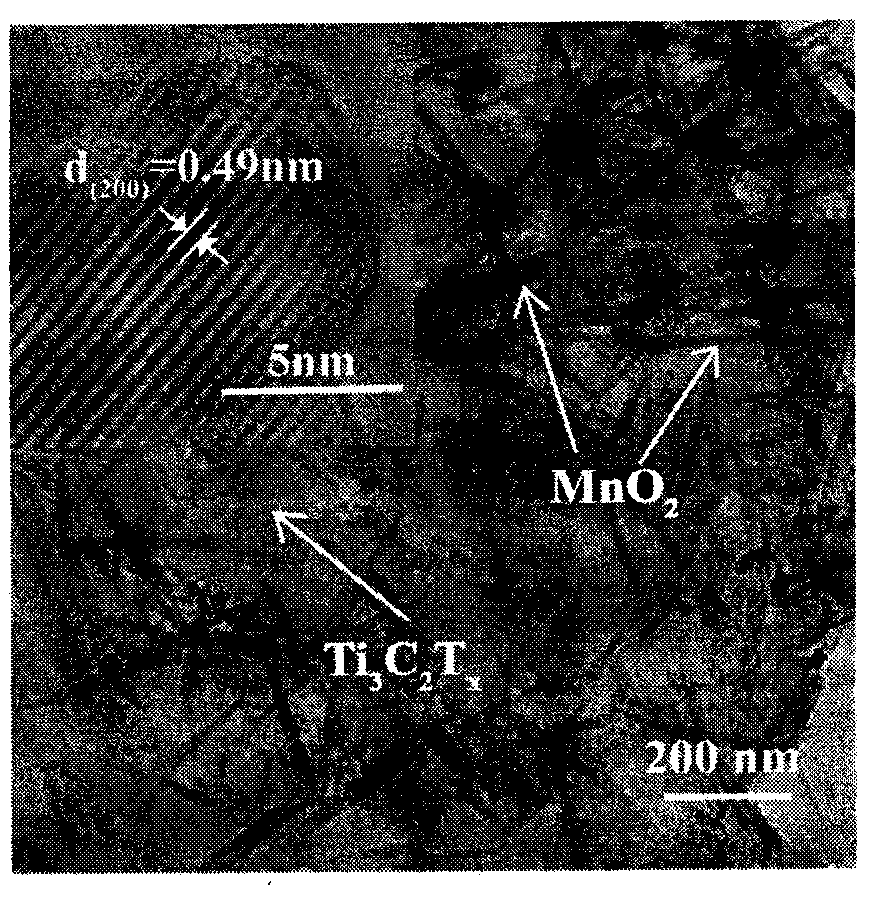

[0033] 2) MnO 2 / Ti 3 C 2 T x Preparation of composite materials:

[0034] 2.1) Weigh 0.36mmol MnCl 2 4H 2 O, 50 mg Ti from step 1) 3 C 2 T x , Disperse the two in 50ml of isopropanol, sonicate for 1-3h to obtain a stable suspension, stir and heat the suspension to 80-100°C.

[0035] 2.2) 0.24 mmol KMnO 4 Dissolve in 5ml deionized water to make the reacted MnO 2 and Ti 3 C 2 T x The theoretical mass ratio is 1.0; then quickly added to the suspension in step 2.1), condensed and refluxed for 20-40min,...

Embodiment 2

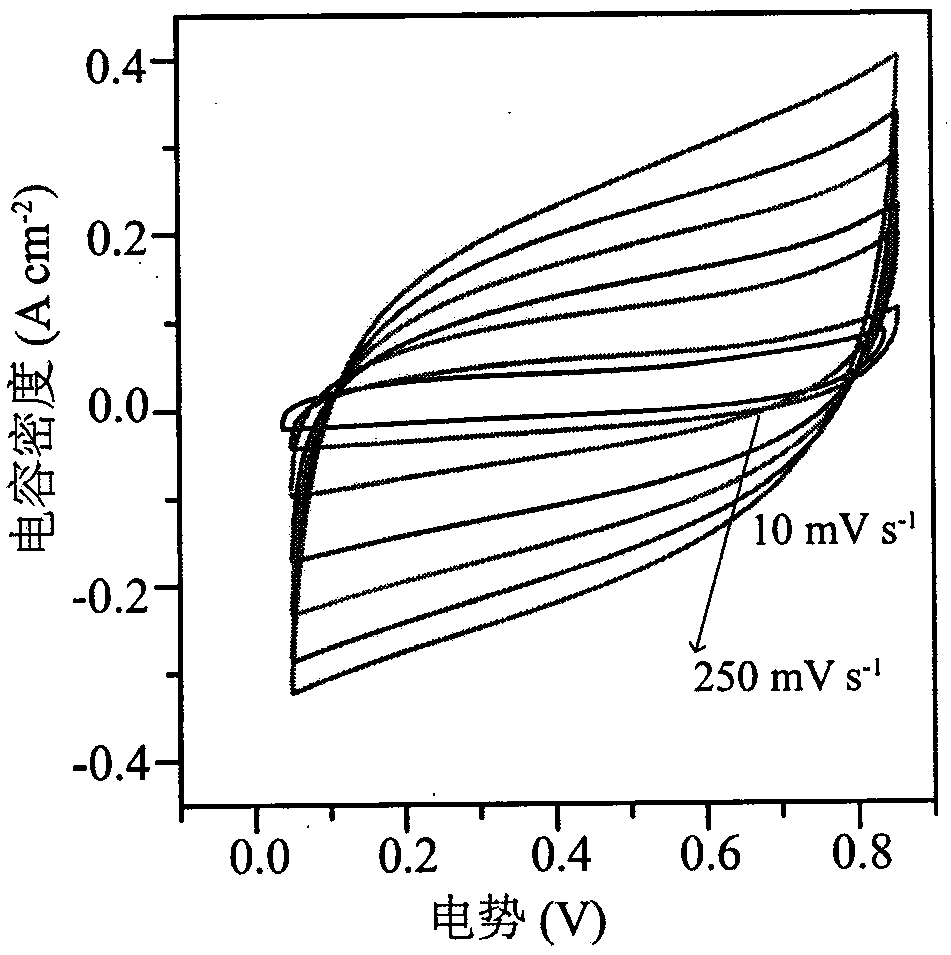

[0038] Change MnCl 2 4H 2 The amount of O is 0.086mmol, KMnO 4 The amount is 0.057mmol, so that the reacted MnO 2 and Ti 3 C 2 T x The theoretical mass ratio is 0.25; other conditions are the same as in Example 1, the obtained MnO 2 / Ti 3 C 2 T x The electrode material is made into a flexible supercapacitor for electrochemical performance measurement, and the measured specific capacitance is 8.5mF cm -2 .

Embodiment 3

[0040] Change MnCl 2 4H 2 The amount of O is 0.17mmol, KMnO 4 The amount is 0.12mmol, so that the MnO after the reaction 2 and Ti 3 C 2 T x The theoretical mass ratio is 0.5; other conditions are the same as in Example 1, the obtained MnO 2 / Ti 3 C 2 T x The electrode material was made into a flexible supercapacitor for electrochemical performance measurement, and the measured specific capacitance was 9.2mF cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com