Patents

Literature

36results about How to "The preparation method is simple and flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

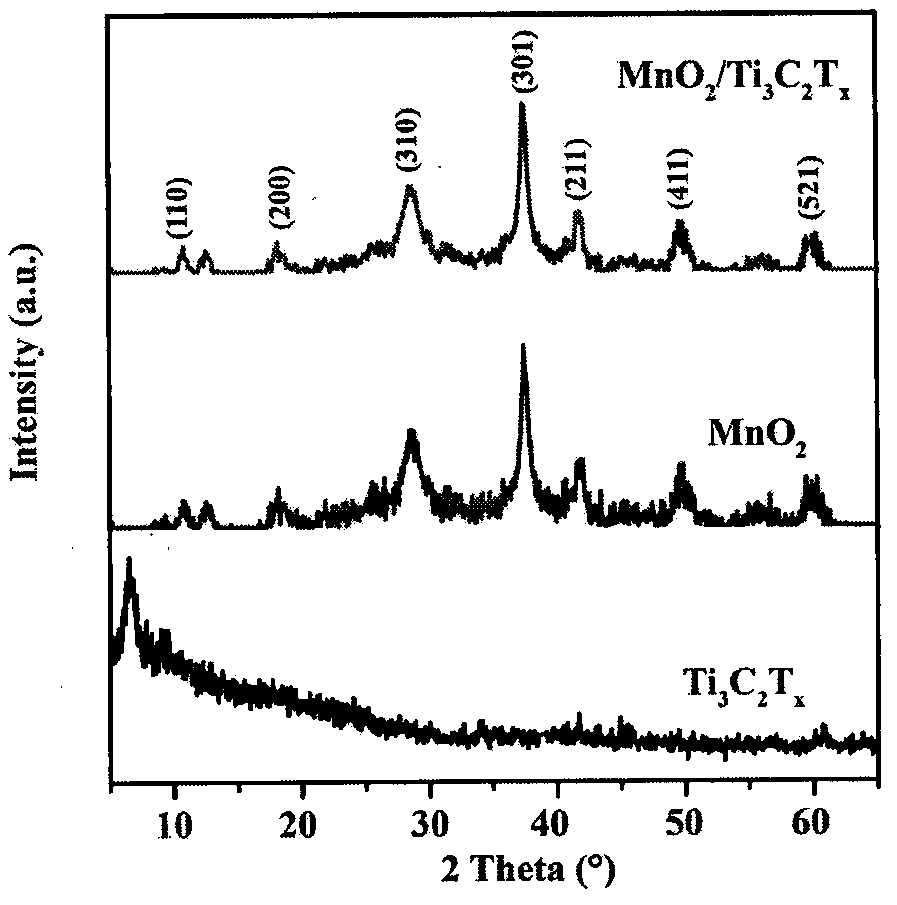

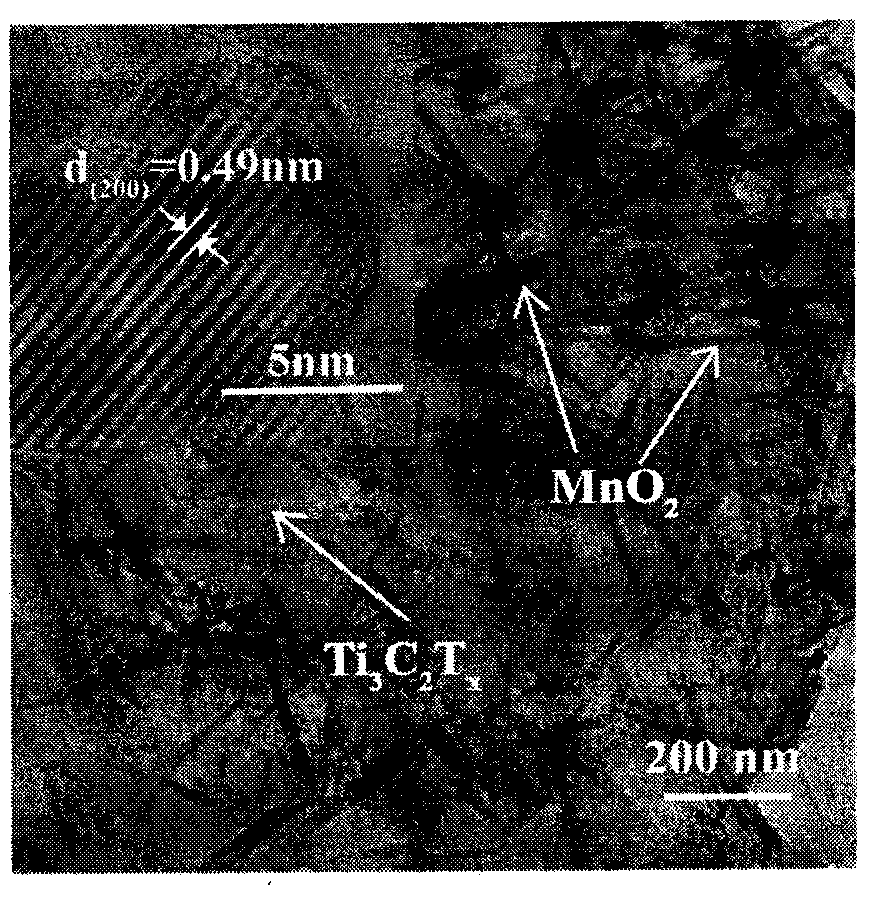

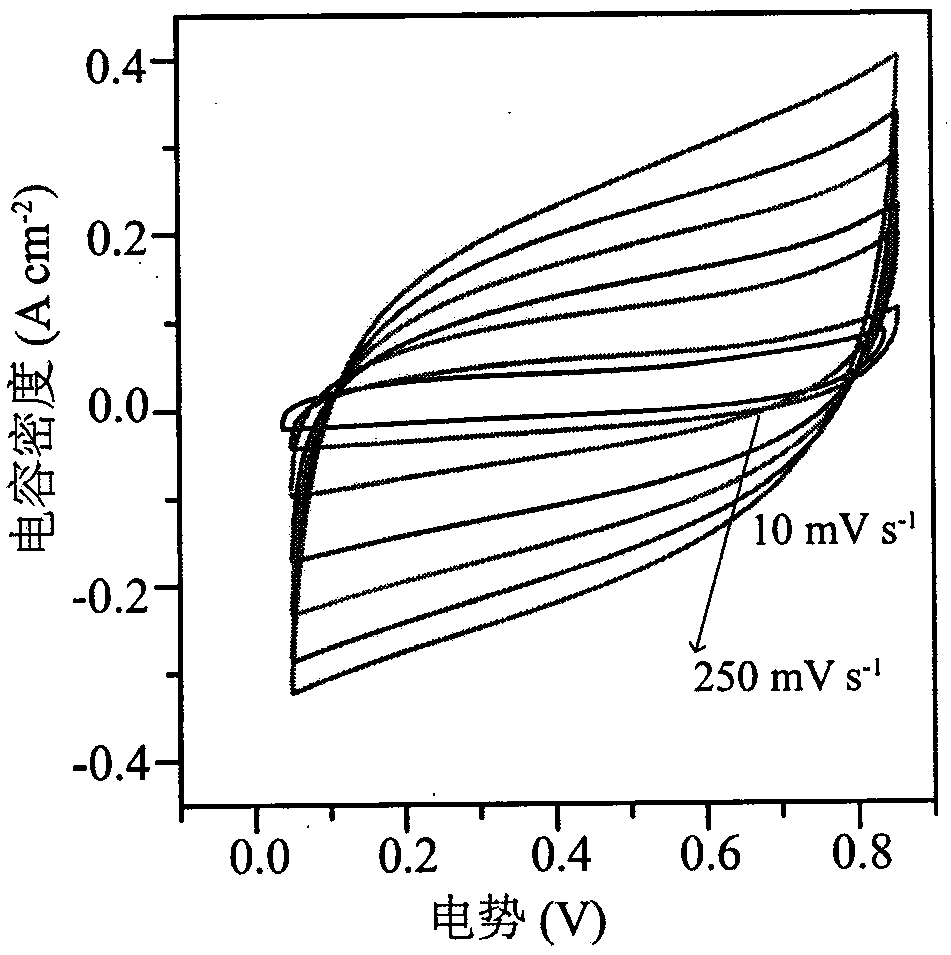

Preparation method of MnO<2>/Ti<3>C<2>T<x>Mxene flexible supercapacitor electrode material

PendingCN108807003AImprove conductivityImprove flexibilityMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHigh energy

Owner:重庆化工职业学院 +1

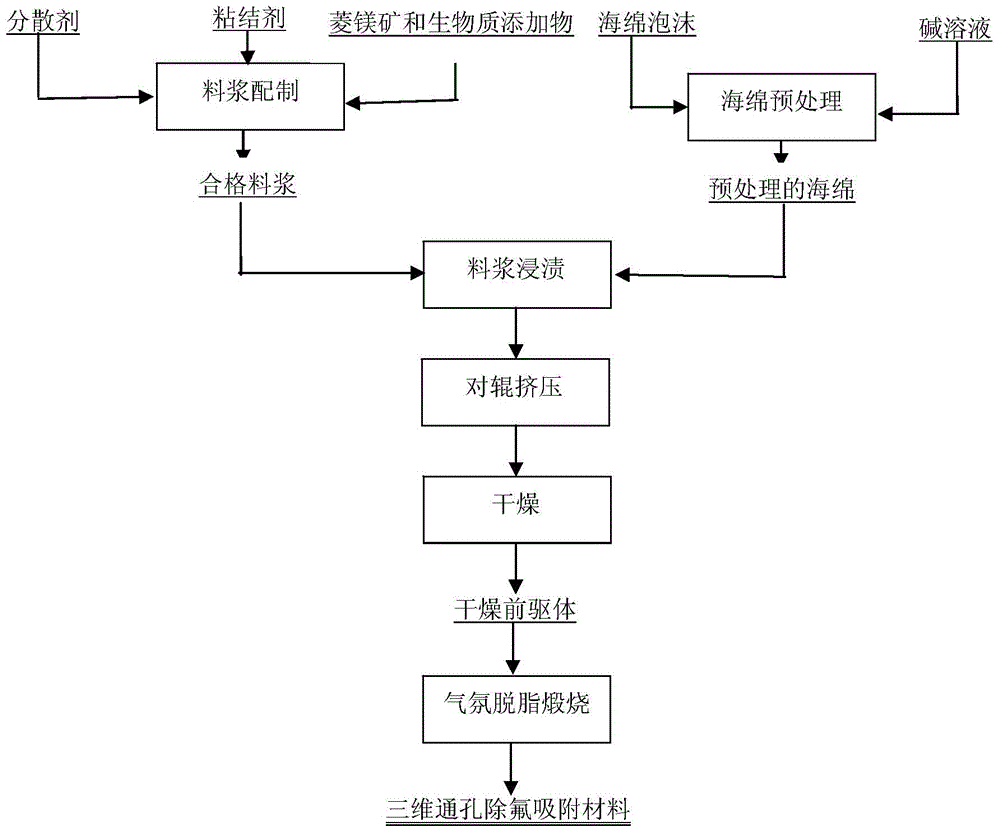

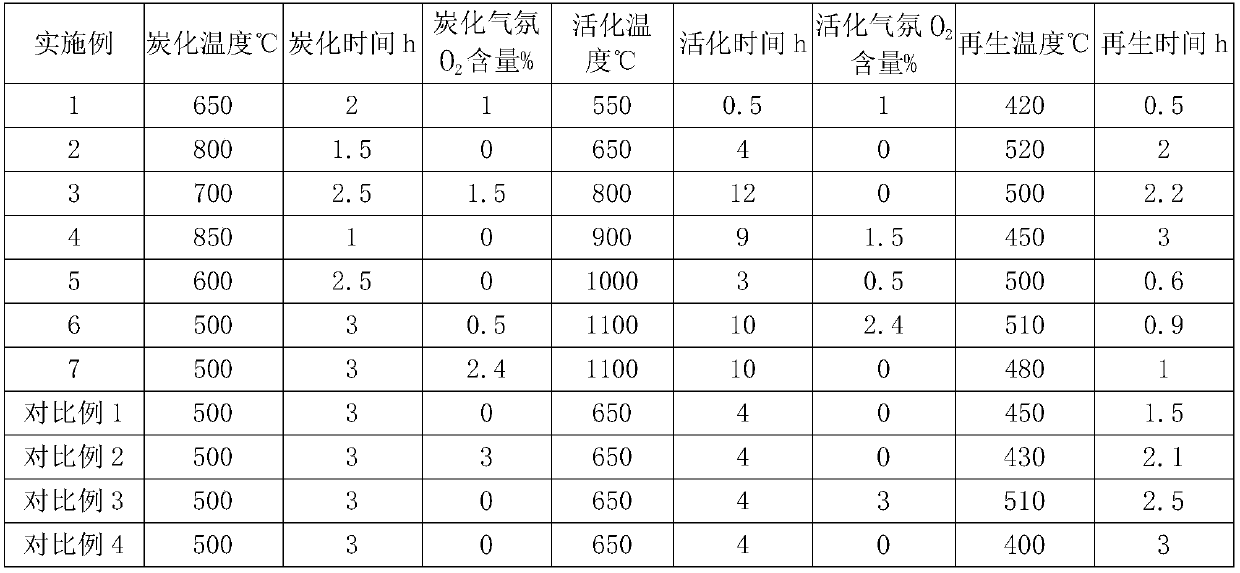

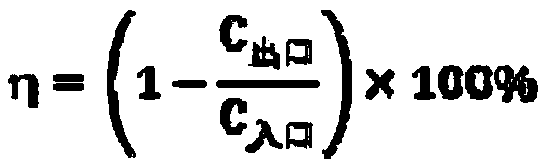

Preparation method of defluorination and adsorption material by taking magnesite as raw material

InactiveCN104874368ALarge specific surface areaOvercome the disadvantage of easy to produce large bed resistanceOther chemical processesWater contaminantsAdditive ingredientSlurry

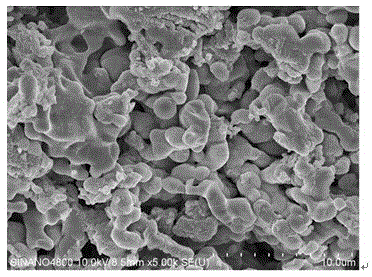

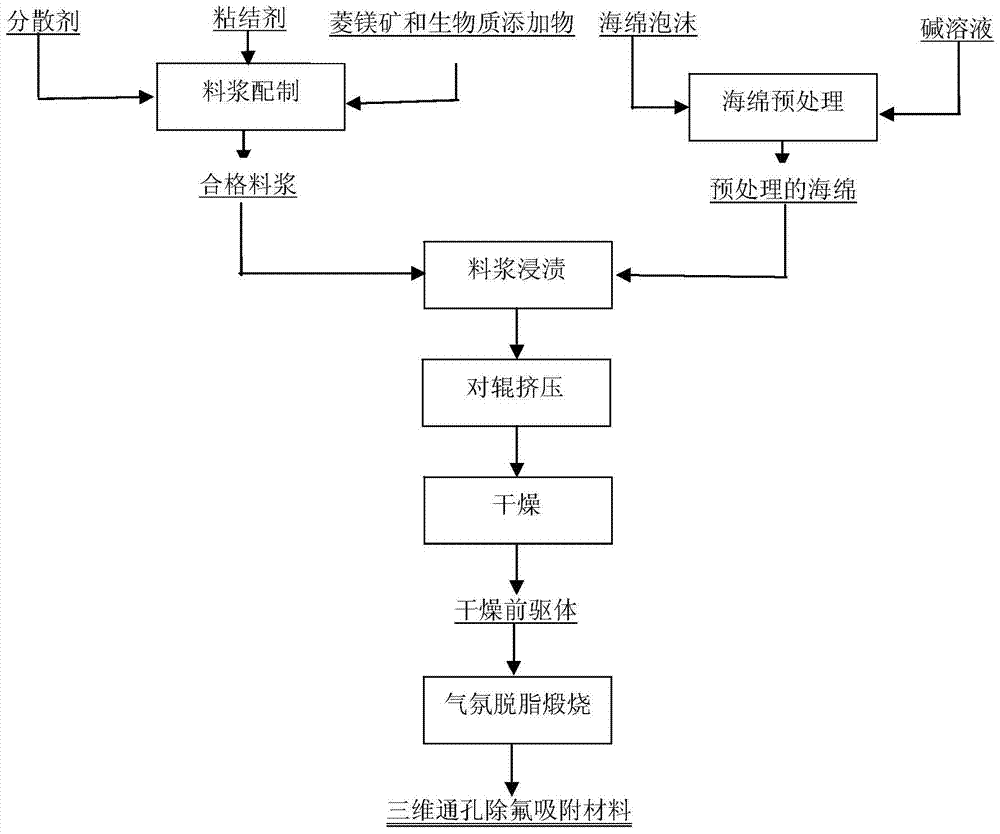

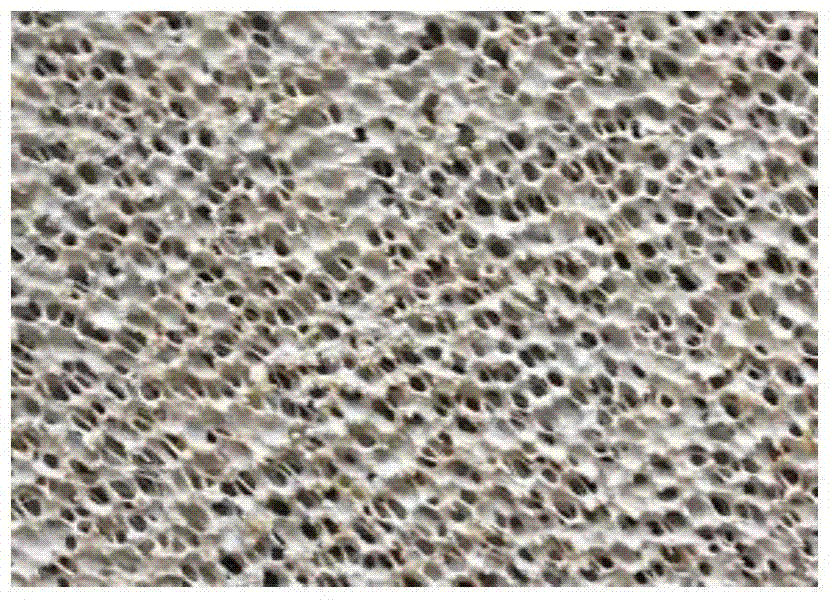

The invention provides a method for preparing a defluorination material with a three-dimensional through hole structure by taking magnesite as a raw material. The method comprises the following steps: mixing ground and sieved natural magnesite and a biomass additive at a certain ratio, and uniformly dispersing a solution containing a binding agent to form slurry; filling the slurry into through hole polyurethane sponge foams; and rolling, molding, drying, degreasing and calcining to obtain a defluorination adsorption material with the three-dimensional through hole structure. The defluorination adsorption material keeps a honeycomb pore structure of the polyurethane sponge foams, and a plurality of micro-pores, which are remained by volatilizing organic matters including the binding agent, polyurethane sponge and the like, are formed in the surface, so that the specific surface area is large. Furthermore, the material sufficiently utilizes characteristics of magnesium-rich ingredients of natural magnesite; degreasing and active calcining are carried out at the same time; and the adsorption material which takes active magnesium oxide as the main ingredient is obtained and can be widely applied to purification treatment of fluorine-containing sewage. The preparation method of the defluorination adsorption material is simple, the raw material cost and the equipment cost are low, the operation is easy and the industrial large-scale production is easy to realize.

Owner:北京绿洁美科技有限公司

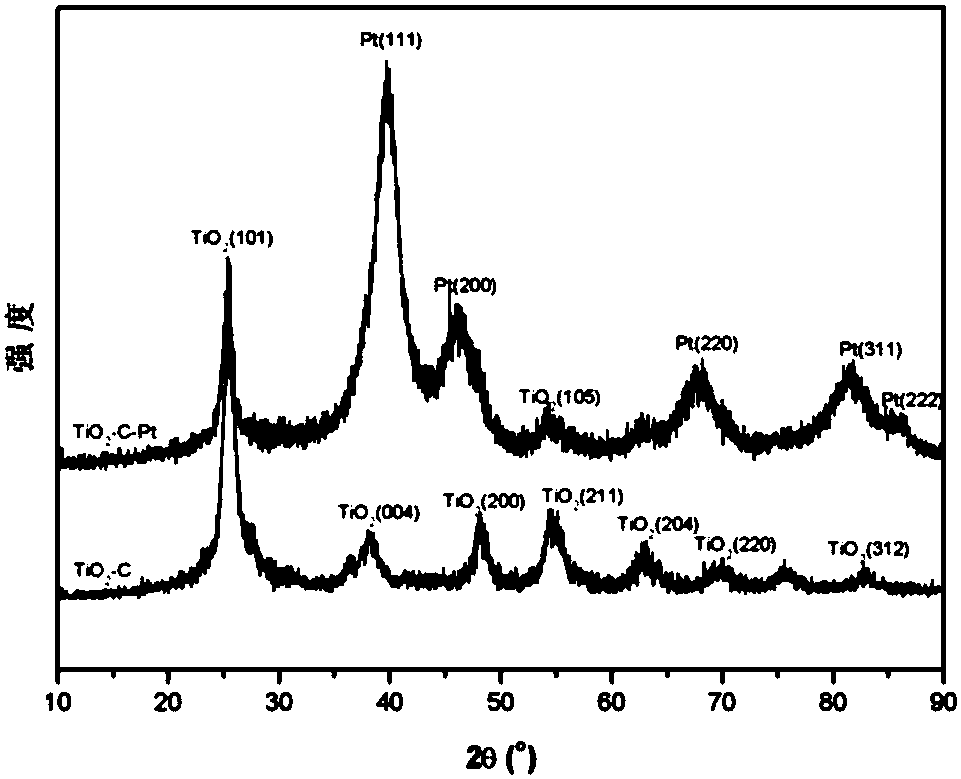

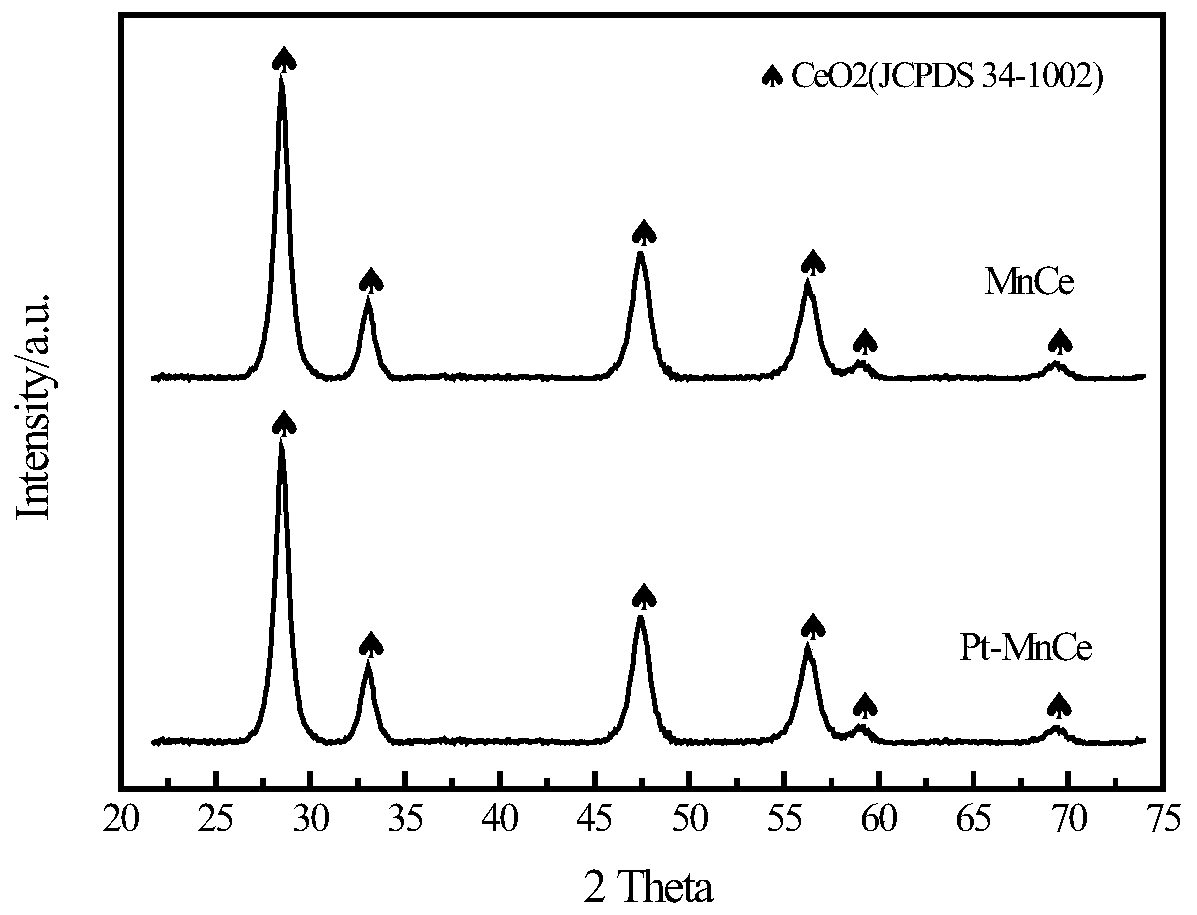

Composite material, catalyst using composite material as carrier, and preparation method and applications of catalyst

ActiveCN108160122ALarge specific surface areaHigh activityCatalyst carriersCell electrodesFiberDecomposition

The invention relates to a composite material, a catalyst using the composite material as a carrier, and a preparation method and applications of the catalyst, wherein particularly an electrocatalystN / MO2-C based on metal oxide-electric conduction material composite fiber / MO2-C and using the metal oxide-electric conduction material composite fiber / MO2-C as a carrier is prepared based on an electrospinning technology and a solution method. According to the present invention, the electrocatalyst carrier / MO2-C is metal oxide-electric conduction material composite fiber; the catalyst carrier canbe dispersed in the solution, and then Pt catalyst particles can be introduced through a reducing method, or a Pt salt precursor can be added to a spinning solution, and then the Pt-based electrocatalyst is prepared through a one-step method; through the addition of the electric conduction carbon material and the one-step low temperature treatment of the polymer nanometer fiber at the late stage,the loose porous structure of the prepared carrier is ensured while the electric conductivity of the carbon material to the carrier and the structural stability are ensured; and through the one-step low temperature treatment in the air or oxygen atmosphere, the oxidation of the metal precursor salt is ensured while the decomposition of the polymer precursor and the stable presence of the carbon material are ensured.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

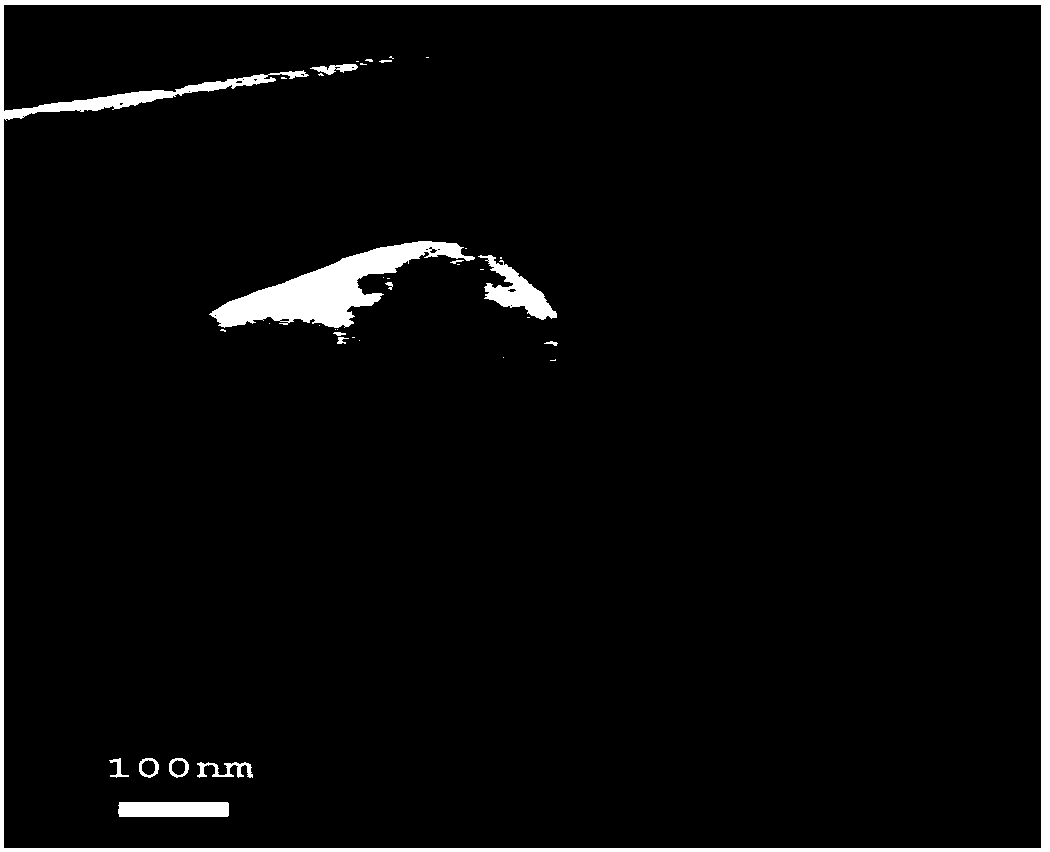

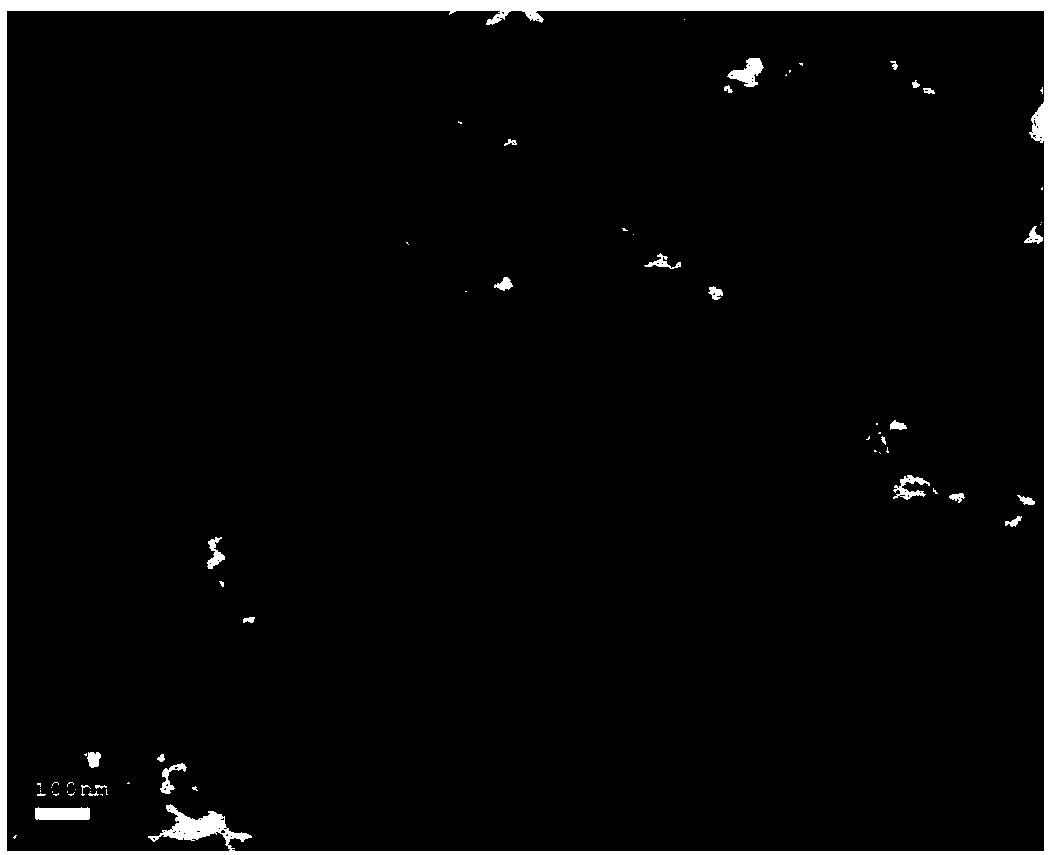

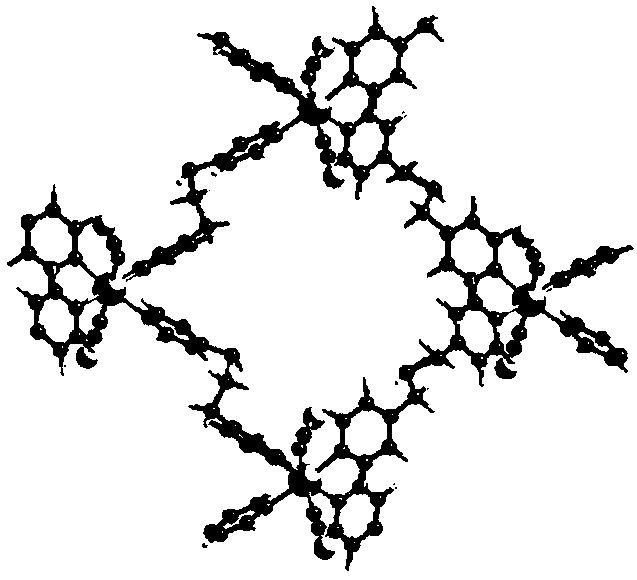

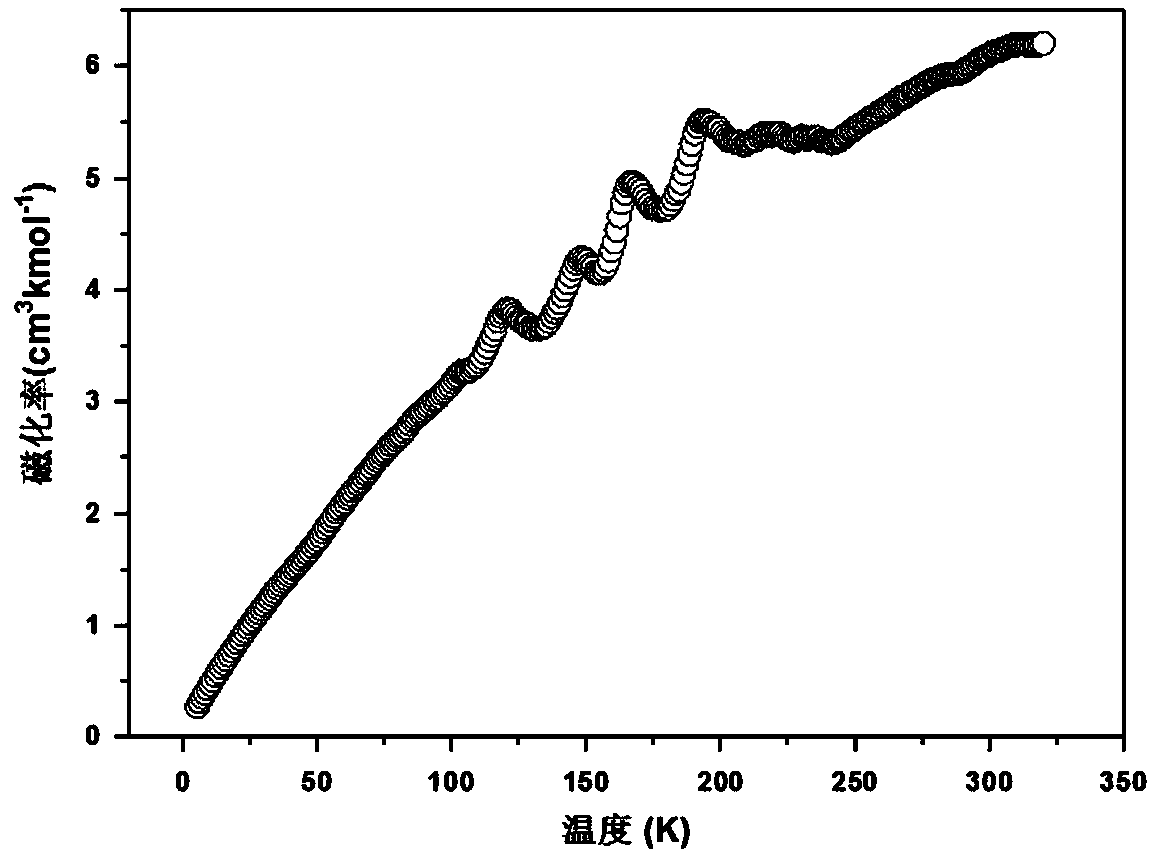

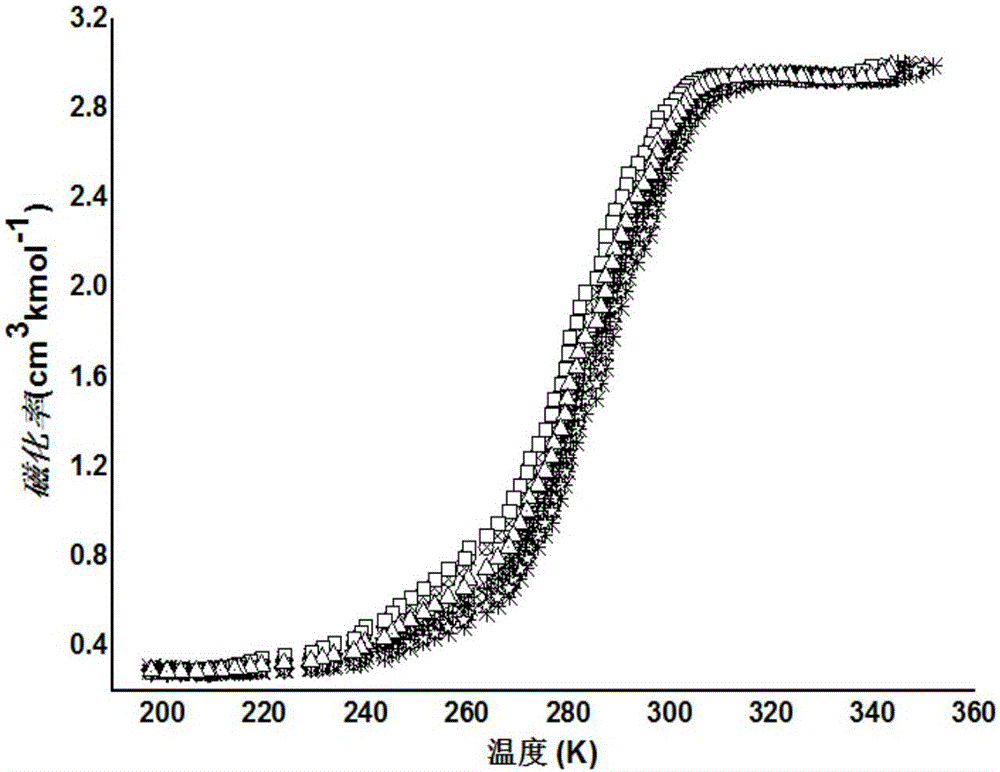

Ultra-thin two-dimensional spin-crossover nanometer material and preparation method and application thereof

InactiveCN108864206AGood dispersionImprove performanceIron group organic compounds without C-metal linkagesNanotechnologySolventMolecular switch

The invention discloses a preparation method of an ultra-thin two-dimensional spin-crossover nanometer material. The ultra-thin two-dimensional spin-crossover nanometer material is obtained by dispersing a three-dimensional van der waals complex in a solvent for ultrasonic exfoliation, wherein a structure formula of the three-dimensional van der waals complex is Fe(XCN)2(1,3-bis(4-pyridyl)propane)2, and X is selected from S or Se. The invention further discloses the ultra-thin two-dimensional spin-crossover nanometer material prepared through the preparation method and application in preparinga molecular electronic device used for information storage or a molecular switch or molecular display thereof. The thickness of the ultra-thin two-dimensional spin-crossover nanometer material is about 1-10 nm, and by means of the ultra-thin two-dimensional structure, multistep spin-crossover behaviour is achieved; the ultra-thin two-dimensional spin-crossover nanometer material is simple to prepare, good in dispersion and stable in performance and has huge application prospects in the molecular electronic device aspect of information storage, molecular switches, molecular display and the like.

Owner:SOUTHEAST UNIV

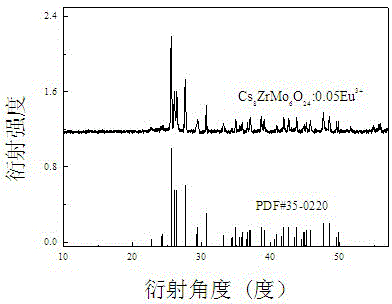

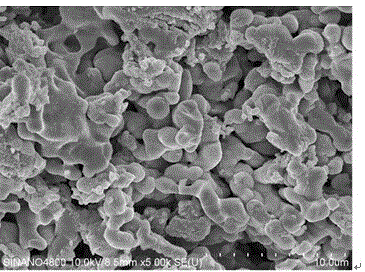

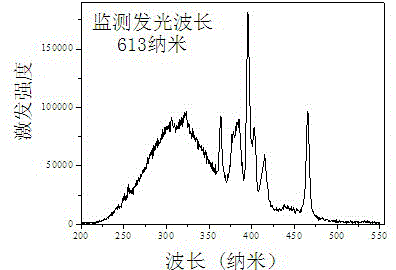

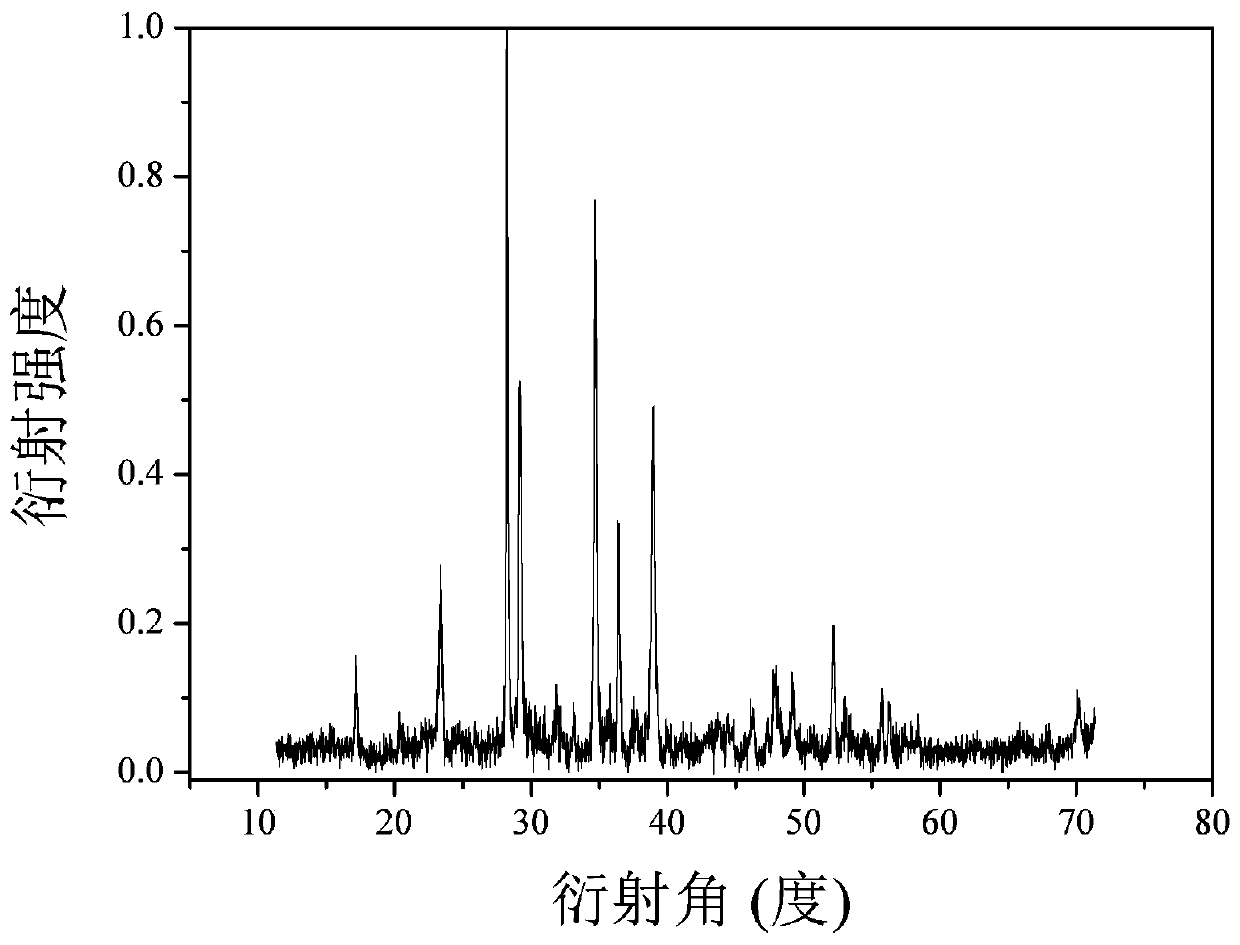

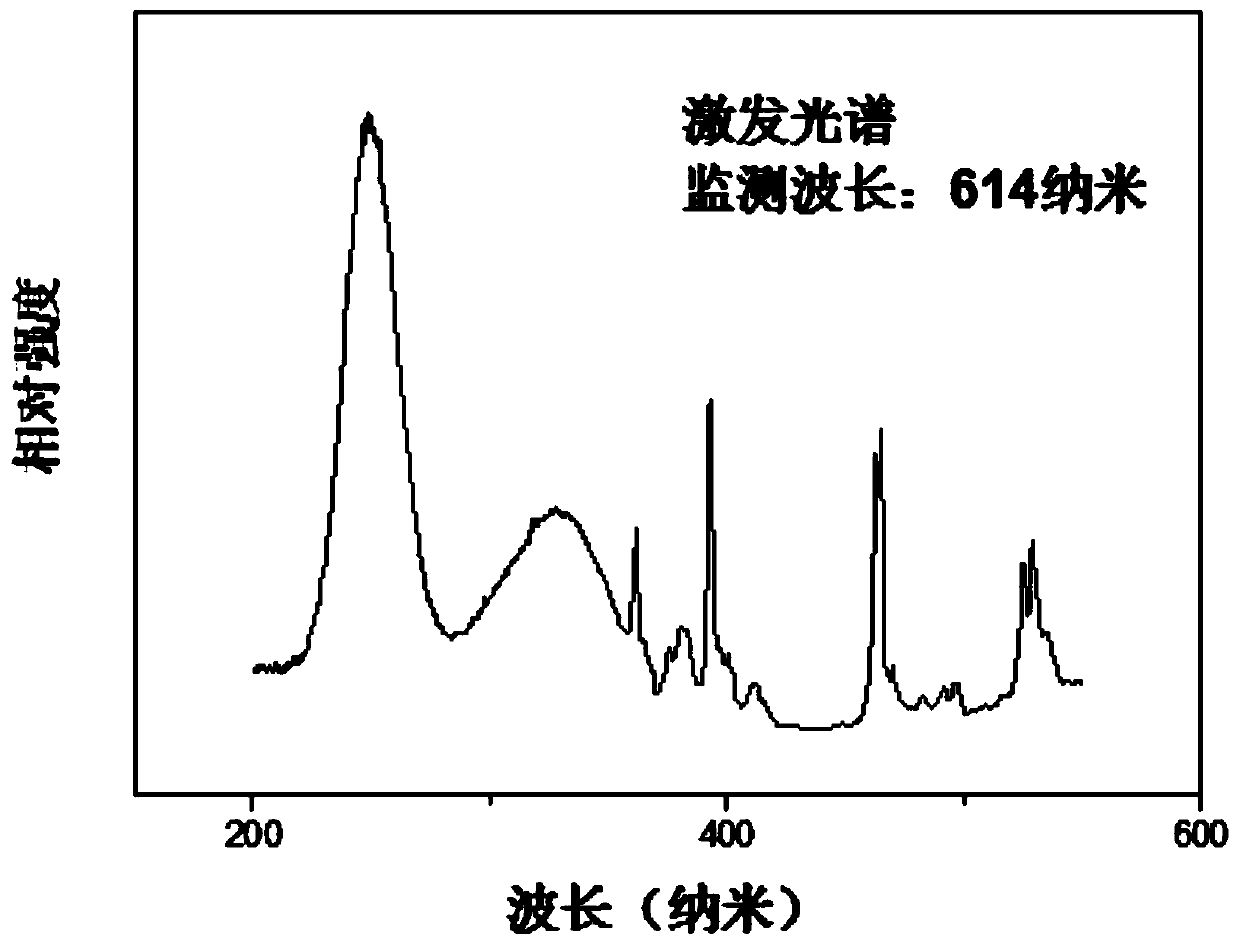

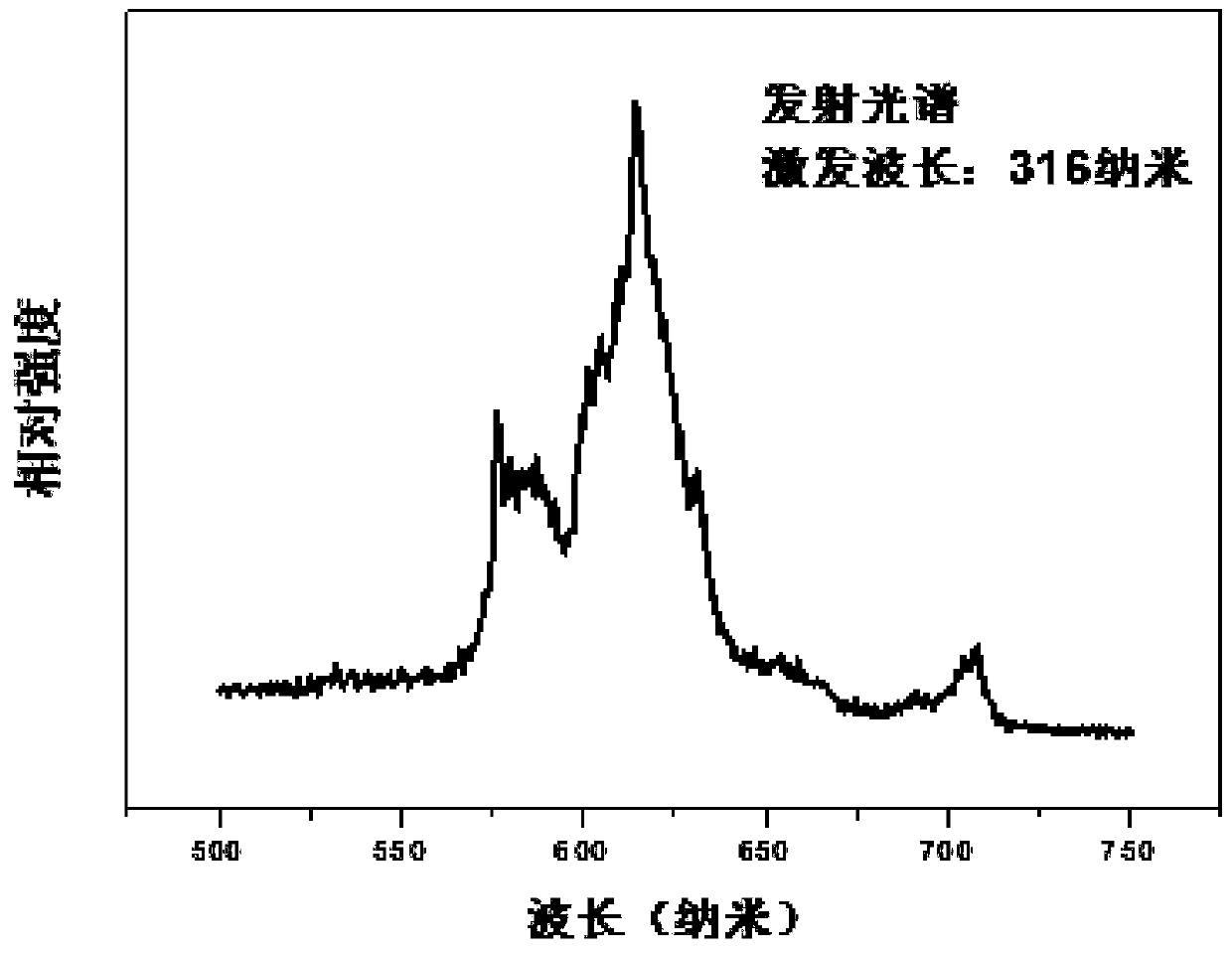

Molybdate-based red fluorescent powder and preparation method thereof

ActiveCN104312584AUniform particle sizeHigh crystallinityLuminescent compositionsChemical solutionDissolution

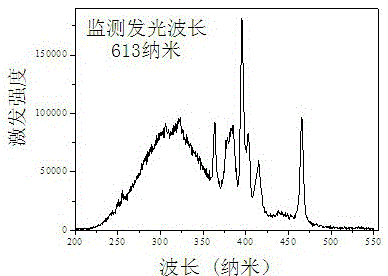

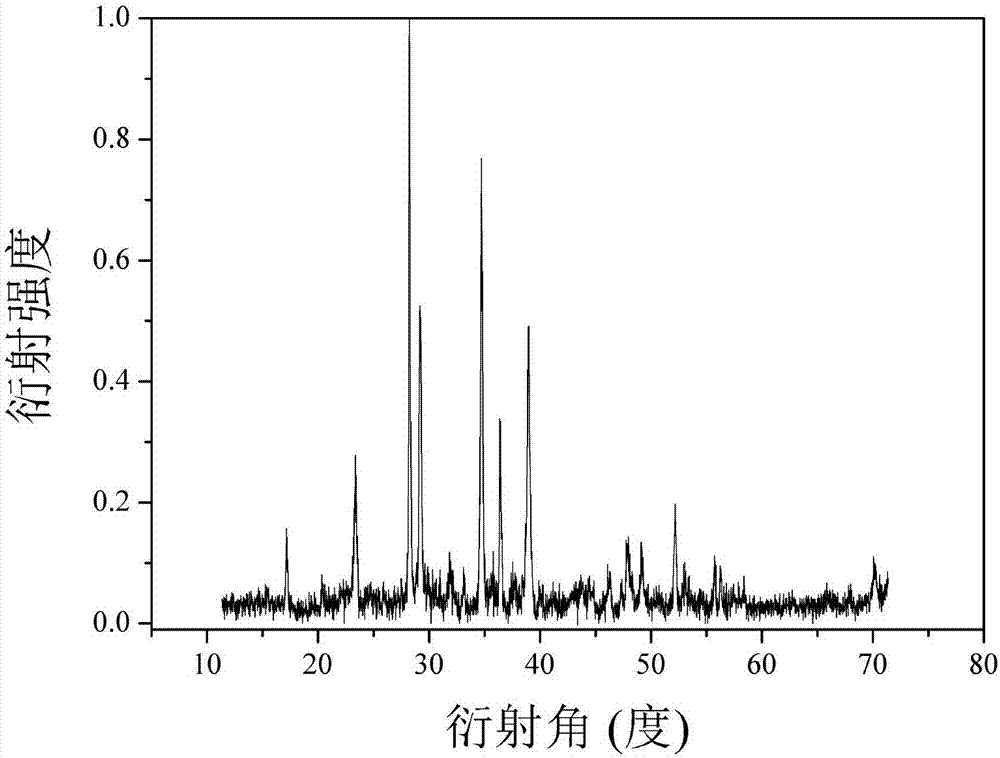

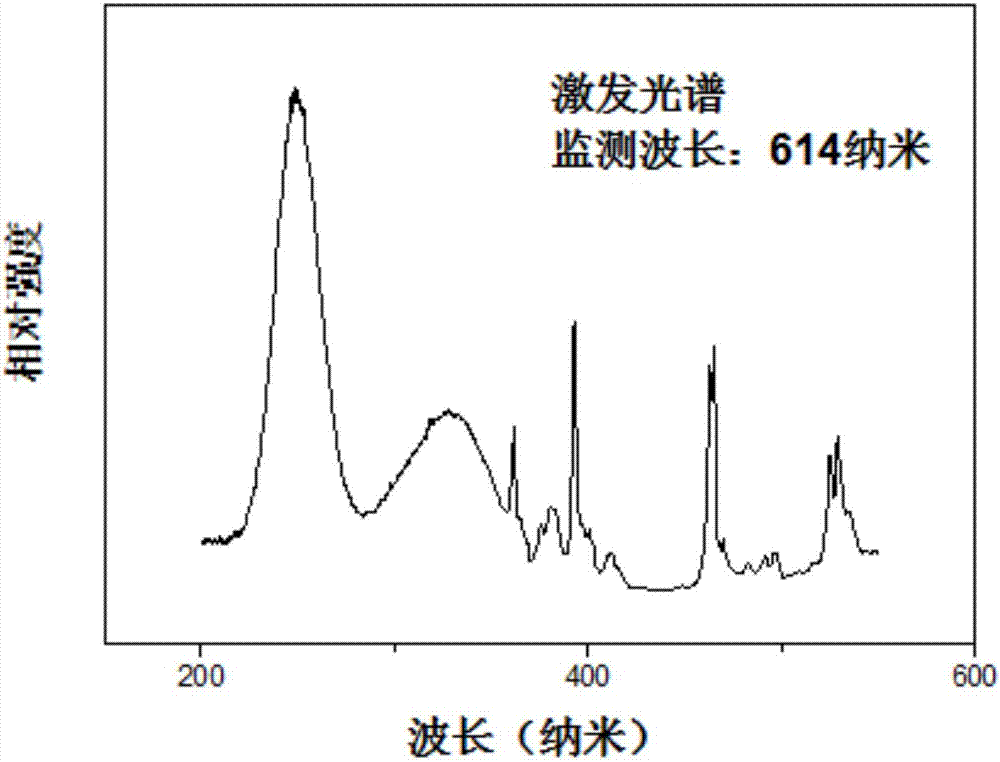

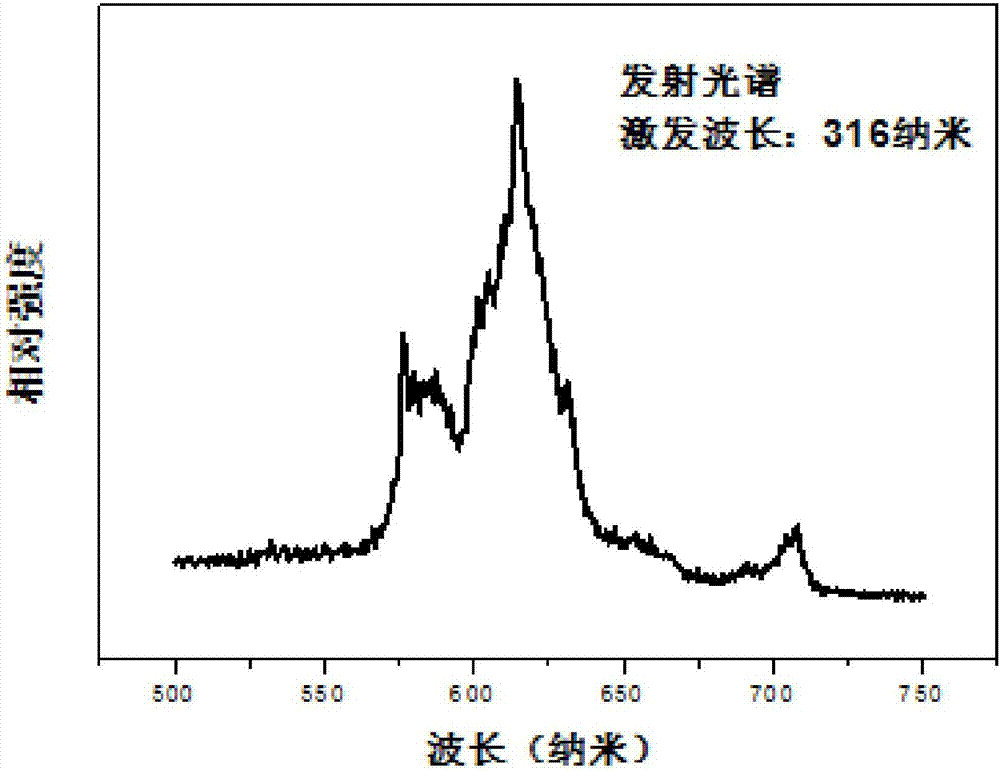

The invention discloses molybdate-based red fluorescent powder and a preparation method thereof. The molybdate-based red fluorescent powder has a chemical formula of M8ZrMo6O24: xEu<3+>, wherein an active ion is Eu<3+>, M represents one of alkali metal ions Cs<+>, Rb<+>, K<+> and Na<+>, x represents a mole percentage coefficient of Eu<3+> replacing M and x is greater than or equal to 0.0001 and is less than or equal to 0.1. The molybdate-based red fluorescent powder has uniform granularity, high luminescence efficiency, high degree of crystallization and high degree of pure red fluroescence color. The preparation method has simple and flexible processes, realizes mixing of compounds of elements required by red phosphor powder according to a ratio, high-temperature calcining or chemical solution dissolution and then calcination for material preparation, and adopts raw materials having abundant sources and low prices. The molybdate-based red fluorescent powder has strong excitability in a wavelength range of 370-410nm, has emission wavelength very same to that of a near ultraviolet LED chip, can emit bright red fluorescence under the excitation of near ultraviolet and has main emission wavelength of 614nm.

Owner:徐州博创建设发展集团有限公司

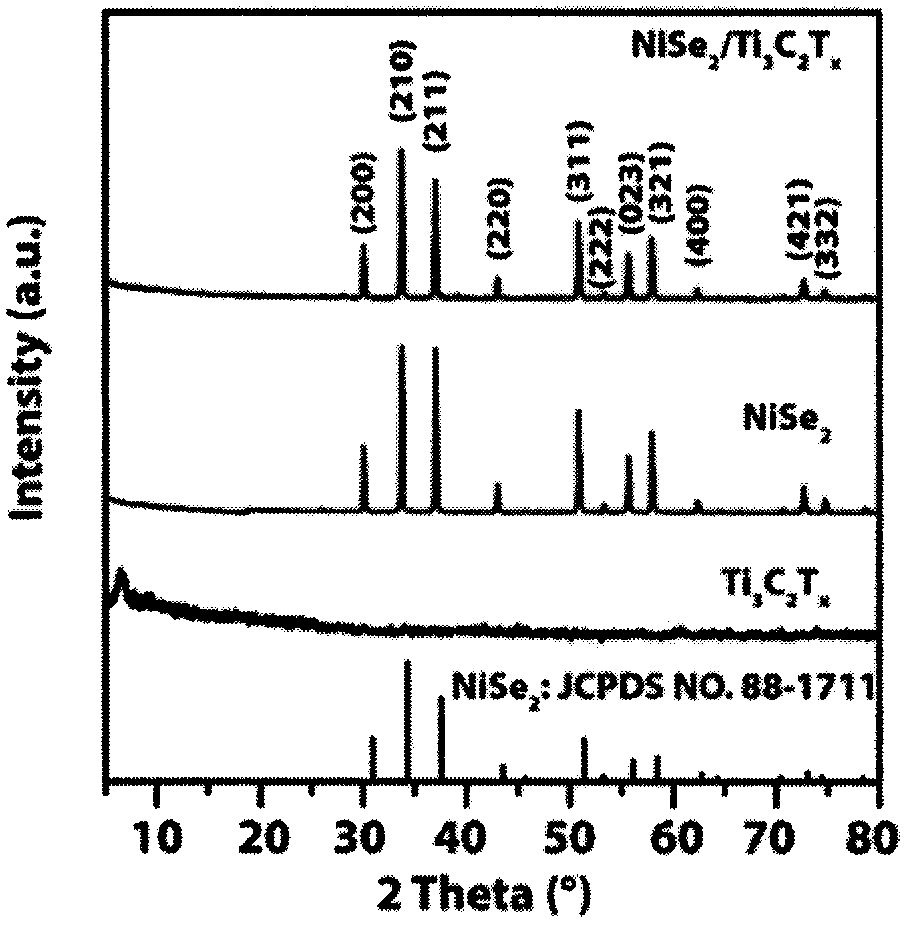

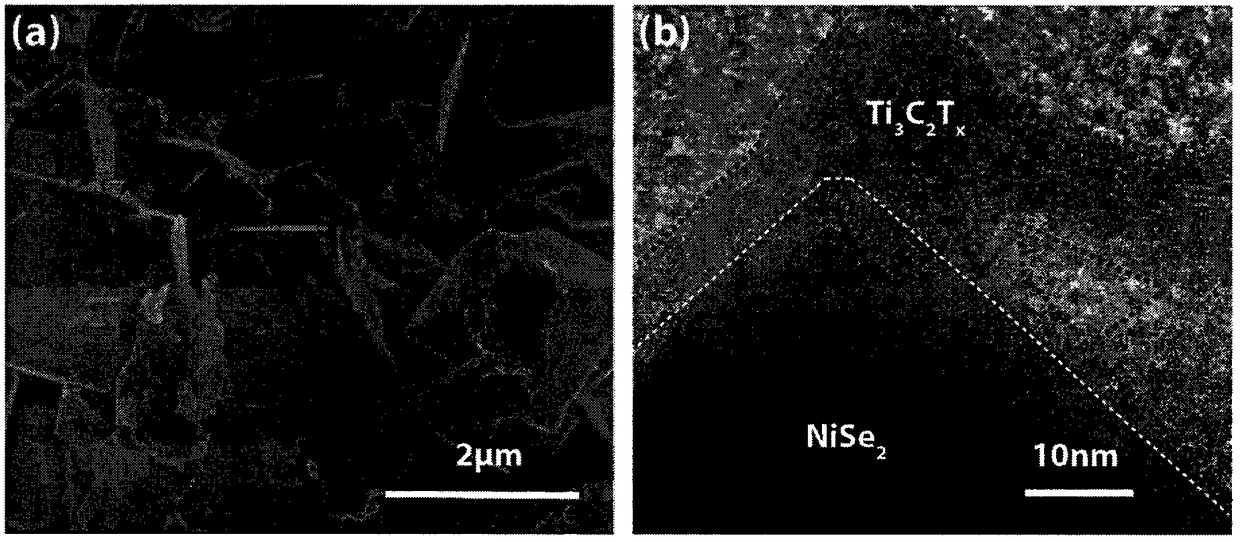

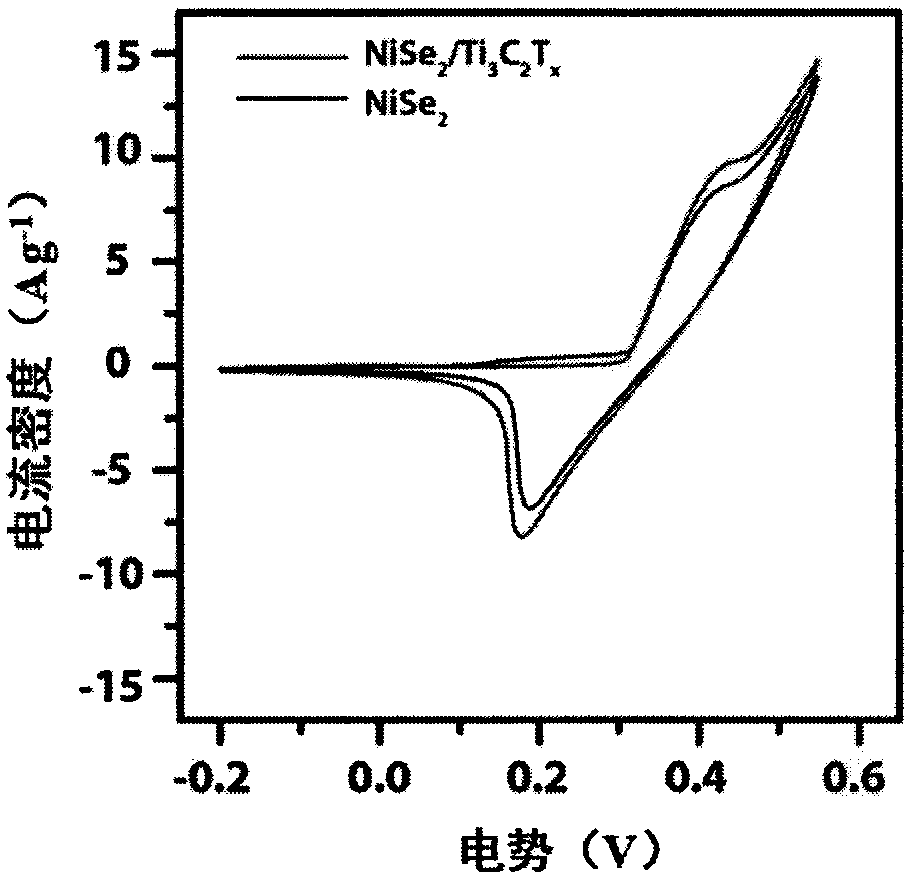

preparation method of NiSe2/Ti3C2Tx high-performance supercapacitor nanocomposite

ActiveCN109273281AImprove conductivityImprove electrochemical activityMaterial nanotechnologyHybrid capacitor electrodesSupercapacitorActive site

The invention relates to a preparation method of NiSe2 / Ti3C2Tx high-performance supercapacitor nano composite material, belonging to the technical field of energy storage materials. A supercapacitor electrode material with good electrochemical performance is prepare by combining NiSe2 and Ti3C2Tx. In particular to an etching solution of LiF and HCl, the Al layer of Ti3AlC2 is corroded, At that same time, Ti3C2Tx thin sheet is deposite on the NiSe2 particles, and finally, the electrode material of the supercapacitor is obtain by washing and drying. The Ti3C2Tx powder is mix with NiCl2 accordingto a certain molar ratio, and the reaction is carried out under the action of a chelating agent to generate NiSe2 nano particles. The invention utilizes NiSe2 material with high theoretical specificcapacitance, and aiming at its disadvantage of poor conductivity, hydrothermal method, Ti3C2Tx nanosheets with good electrical conductivity were compounded with NiSe2 particles, NiSe2 / Ti3C2Tx nanocomposites were obtained, which not only possessed better charge transfer and more active sites, but also improved the durability of NiSe2 / Ti3C2Tx nanocomposites, thus improving the performance of supercapacitors.

Owner:CHONGQING UNIV

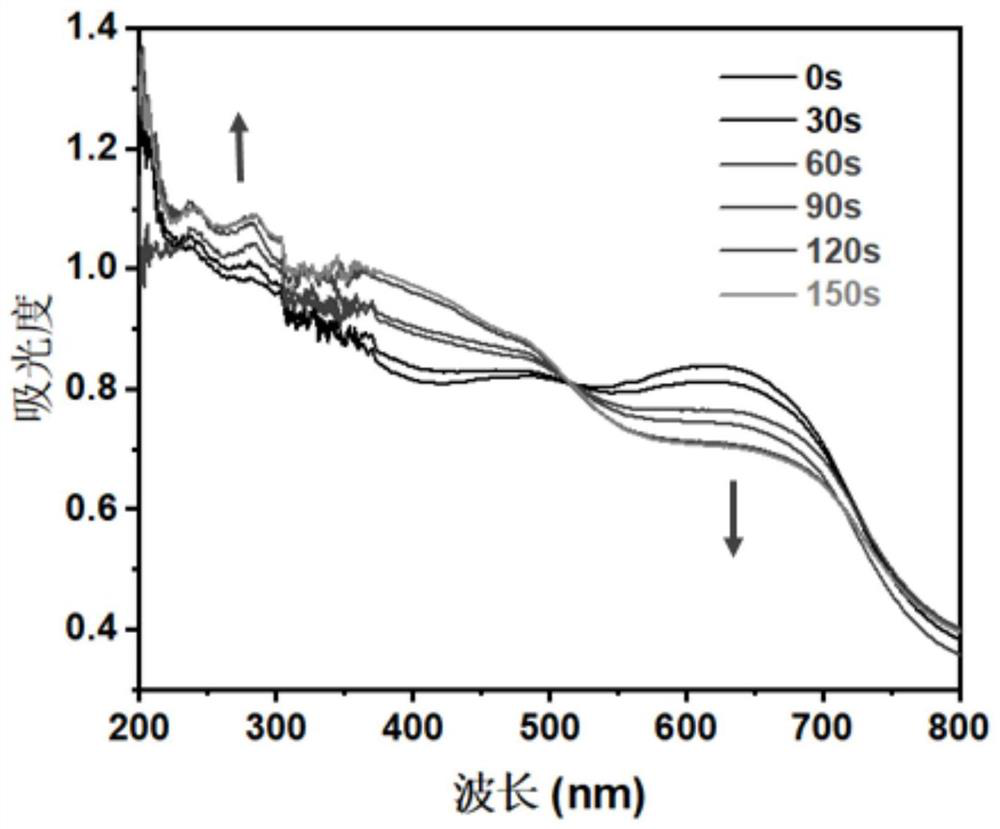

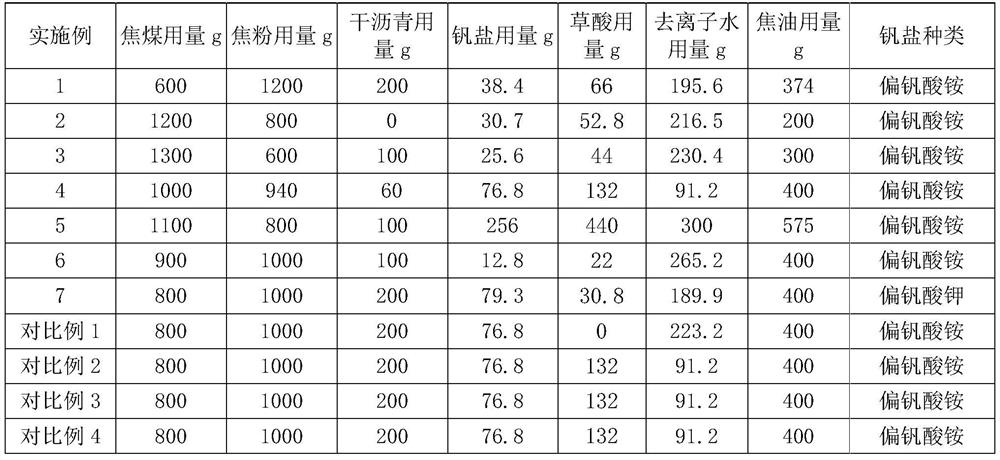

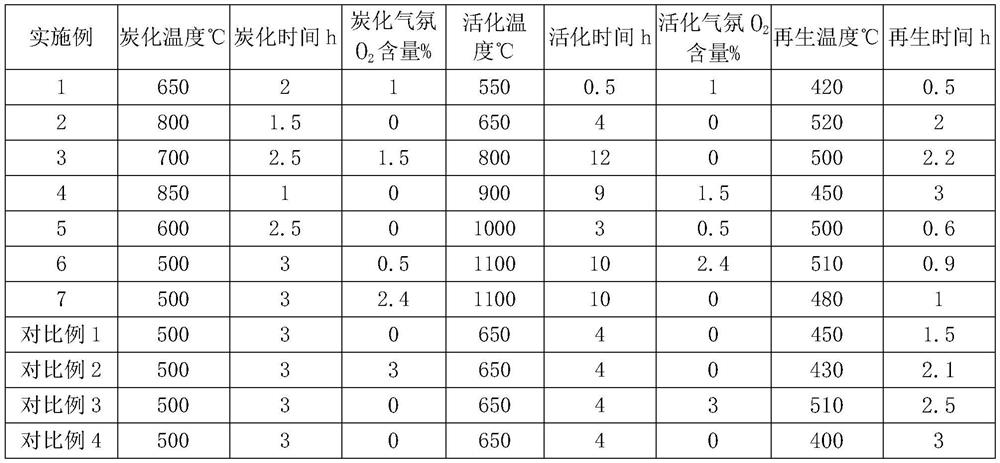

Vanadium-carbon-based catalyst for desulfurization and denitrification as well as preparation method and application of vanadium-carbon-based catalyst

ActiveCN109589965AImprove solubilityIncreased dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurActive component

The invention discloses a vanadium-carbon-based catalyst for desulfurization and denitrification comprising a carbon material and vanadium serving as an active component, wherein measured by V2O5, vanadium accounts for 0.5%-10% of the weight of the catalyst, and the balance is the carbon material. The vanadium-carbon-based catalyst has the advantages that the preparation method is simple and convenient, the active component is uniformly distributed, and the sulfur capacity and denitrification activity are remarkably improved with a regeneration process.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Refractory material lining body for steel ladle and preparation method of refractory material lining body

The invention discloses a refractory material lining body for a steel ladle and a preparation method of the refractory material lining body. The refractory material lining body comprises a working lining and a permanent lining. The working lining is located on the inner side of the permanent lining, the working lining is made of a heavy calcium hexaluminate material to be used for resisting the high temperature, and the permanent lining adopts a medium-heavy or light calcium hexaluminate material to be used for conducting heat preservation and thermal insulation. The working lining and the permanent lining can be manufactured by adopting the methods of in-situ casting, a prefabricated member or a refractory brick. According to the refractory material lining body for the steel ladle, the problem that the steel ladle refractory material causes impurities in molten steel can be solved, no impurity can be led into the molten steel in the using process, meanwhile the impurities in steel canbe captured, and the molten steel can be purified and the quality is improved.

Owner:UNIV OF SCI & TECH BEIJING +1

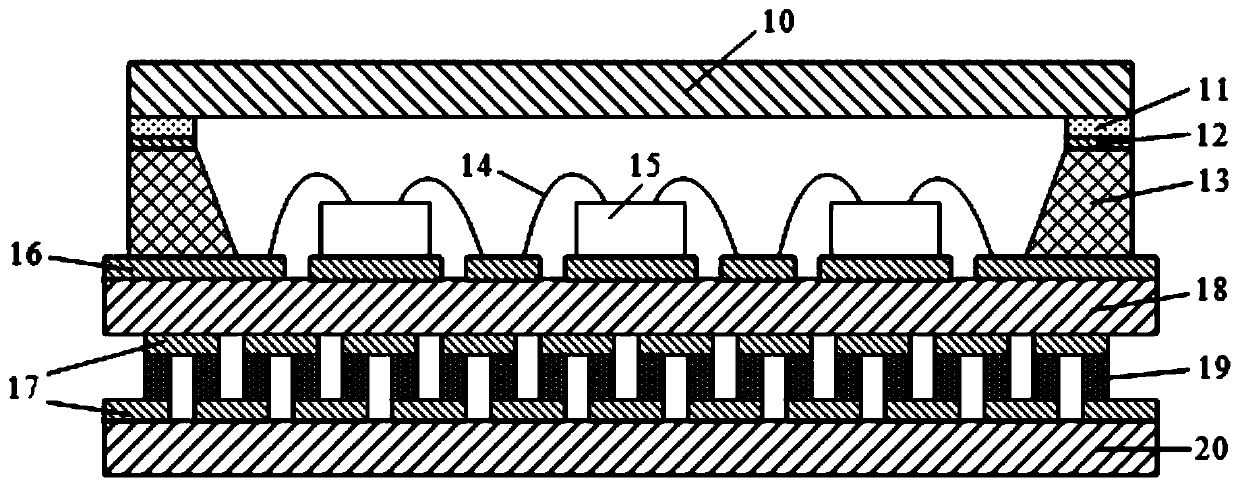

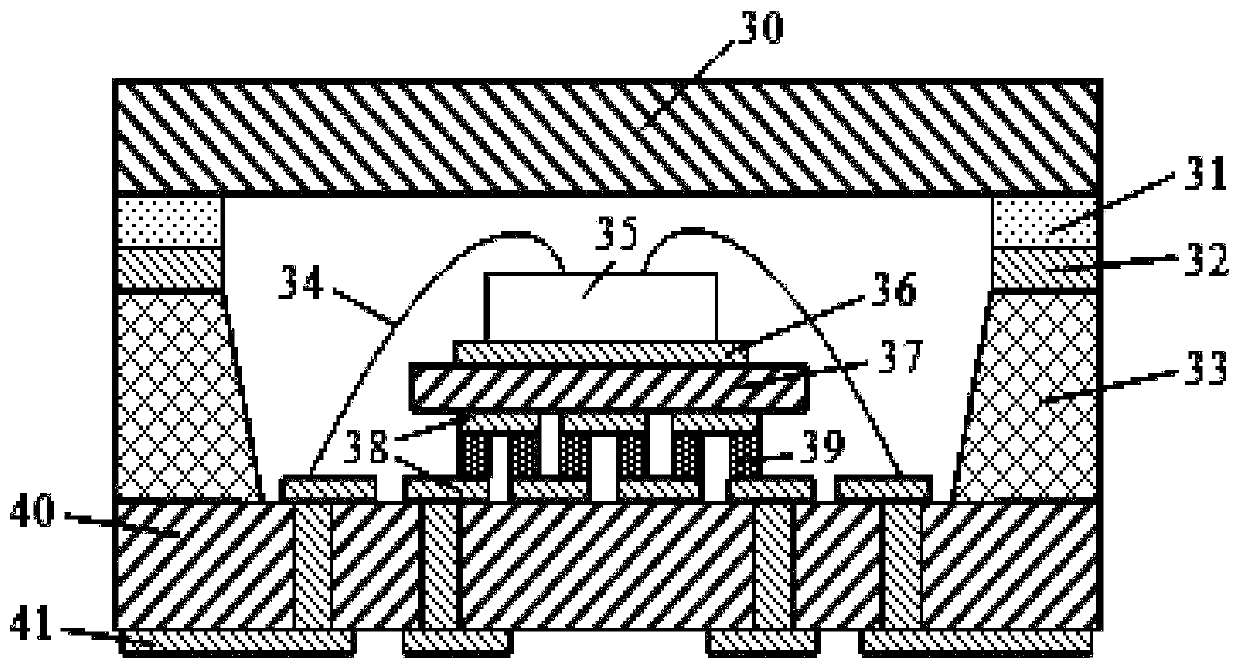

Airtight packaging structure of integrated thermoelectric refrigerator and preparation method thereof

ActiveCN111403376AImprove cooling effectReduce soldering interfaceSemiconductor/solid-state device detailsSolid-state devicesCeramic substrateComposite material

The invention belongs to the related technical field of microelectronic packaging, and discloses an airtight packaging structure of an integrated thermoelectric refrigerator and a preparation method thereof. The airtight packaging structure of the integrated thermoelectric refrigerator comprises a packaging cover plate, a chip, the thermoelectric refrigerator and a three-dimensional ceramic substrate, a cavity is formed in the three-dimensional ceramic substrate, the chip is arranged in the cavity, and the packaging cover plate is in airtight connection with the three-dimensional ceramic substrate so as to package the chip in the cavity; the three-dimensional ceramic substrate is connected with the thermoelectric refrigerator, and the three-dimensional ceramic substrate and the thermoelectric refrigerator share one ceramic substrate, so that the heat dissipation refrigerator and the three-dimensional ceramic substrate are combined to form an airtight packaging structure. According to the airtight packaging structure, the three-dimensional DPC ceramic substrate is used, and interconnection between the inside and the outside of the cavity is realized by utilizing the cavity structureand the vertical interconnection characteristic of the three-dimensional DPC ceramic substrate; the three-dimensional DPC ceramic substrate is used as a ceramic substrate of the TEC, that is, the thermoelectric refrigerator and the three-dimensional ceramic substrate share the ceramic substrate, so that one layer of ceramic substrate and one layer of welding interface are reduced, the heat dissipation capability of the device is improved, the thermal resistance can be reduced, and the packaging integration degree is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

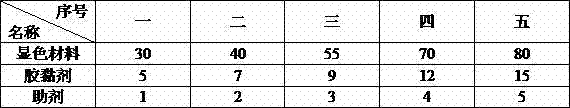

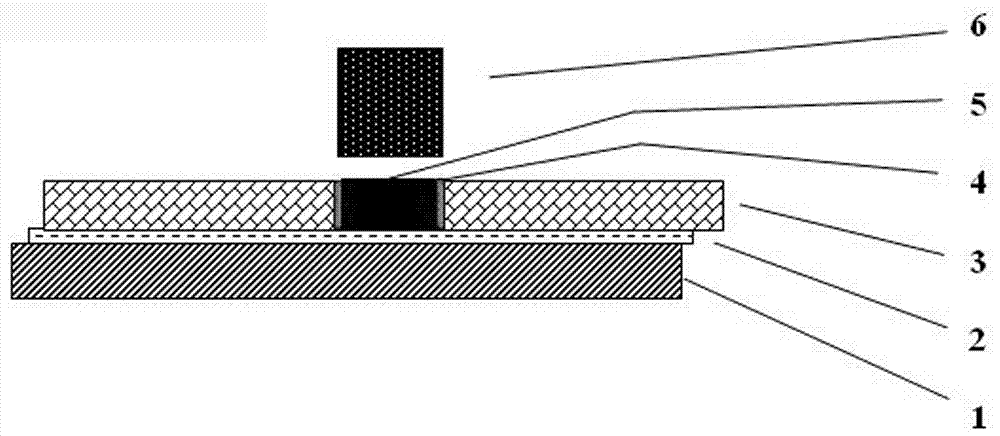

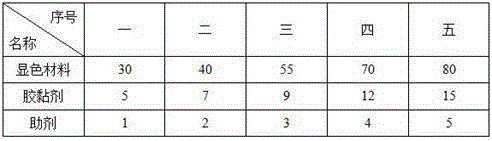

Anti-fake carbonless copy paper and preparation method thereof

ActiveCN103572659AThe preparation method is simple and flexibleEasy production controlNon-fibrous pulp additionCoatings with pigmentsAdhesivePulp and paper industry

The invention belongs to the technical field of carbonless copy paper processing. The anti-fake carbonless copy paper is prepared by scraping or scratching back and forth within a small area with hard materials such as fingernails and plastic cards which are common in life instead of special conditions and tools to show patterns, characters, symbols or lines with different colors so as to achieve the anti-fake purpose of simple identification and common identification. The anti-fake carbonless copy paper comprises body paper, a carbonless copy paper coating and an anti-fake coating layer expressing information with invisible images and texts, wherein the carbonless copy paper coating contains a microcapsule with different colors; the anti-fake coating layer comprises a developing material, an adhesive and an auxiliary; the invisible images and texts are formed by coating the anti-fake coating layer on the body paper or the carbonless copy paper coating according to a special shape. The invention also provides a preparation method of the anti-fake carbonless copy paper.

Owner:GUANGDONG GUANHAO HIGH TECH

Anti-fake ticket thermo-sensitive paper and preparing method thereof

ActiveCN106904014AThe preparation method is simple and flexibleEasy production controlCoatings with pigmentsCoatingsInvoicePulp and paper industry

The invention discloses anti-fake ticket thermo-sensitive paper suitable for the fields of entrance tickets, license plates, invoices and special labels. The anti-fake ticket thermo-sensitive paper has the developing function of common thermo-sensitive paper, in addition, after a color development device conducts developing, the black interior and red edge developing anti-fake function is achieved, the large developing area shows the black character pattern, and the edge of the black character pattern shows red. Accordingly, the common anti-fake ticket thermo-sensitive paper easy to distinguish is provided, and the forging behavior of the thermo-sensitive paper can be cracked down in the special field.

Owner:上海固尔建工贸有限公司

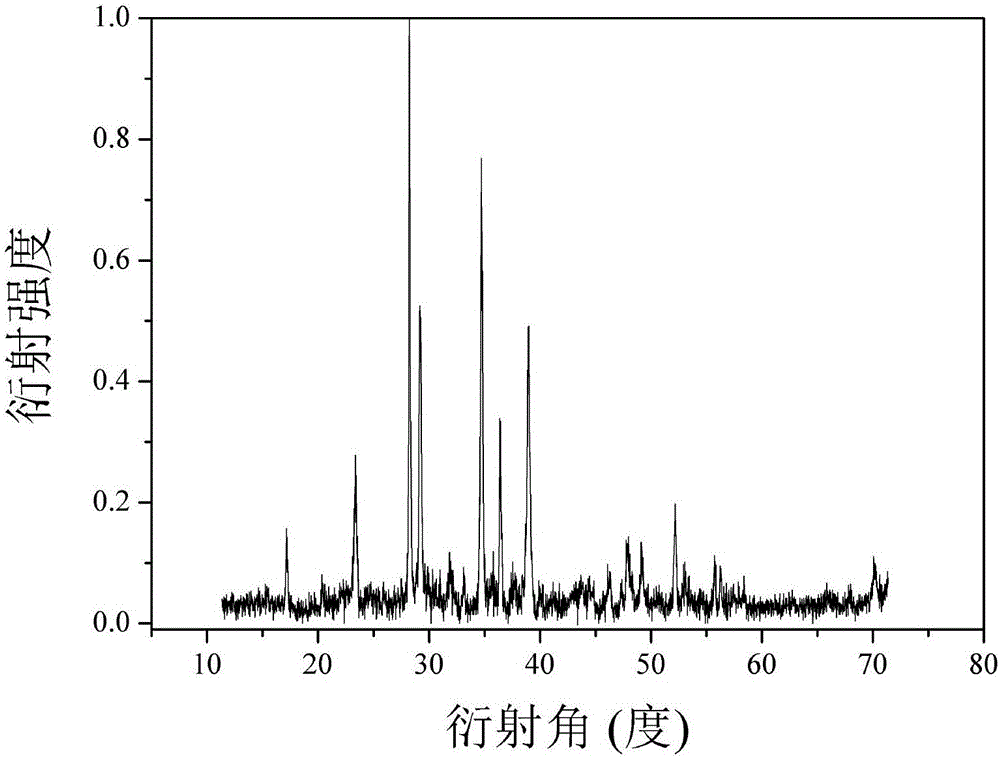

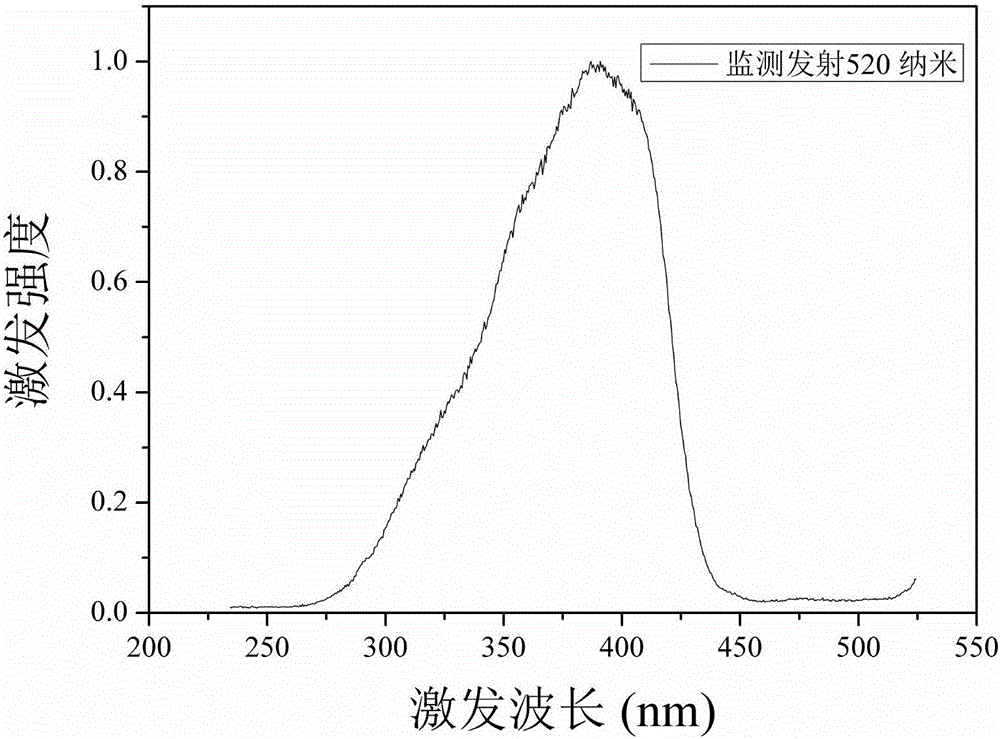

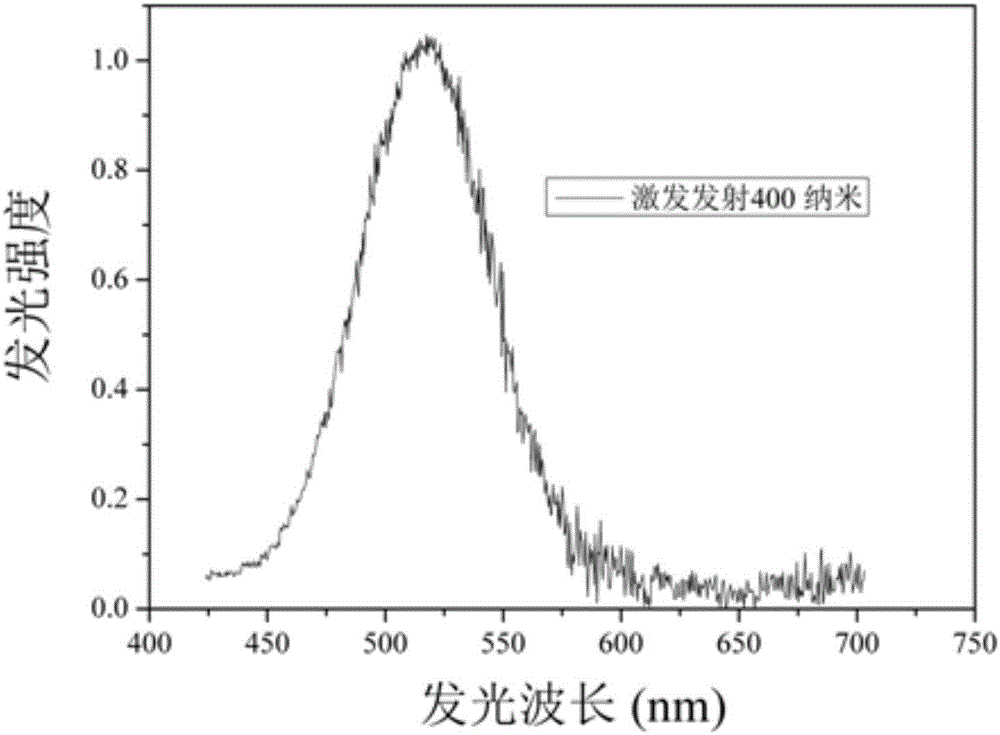

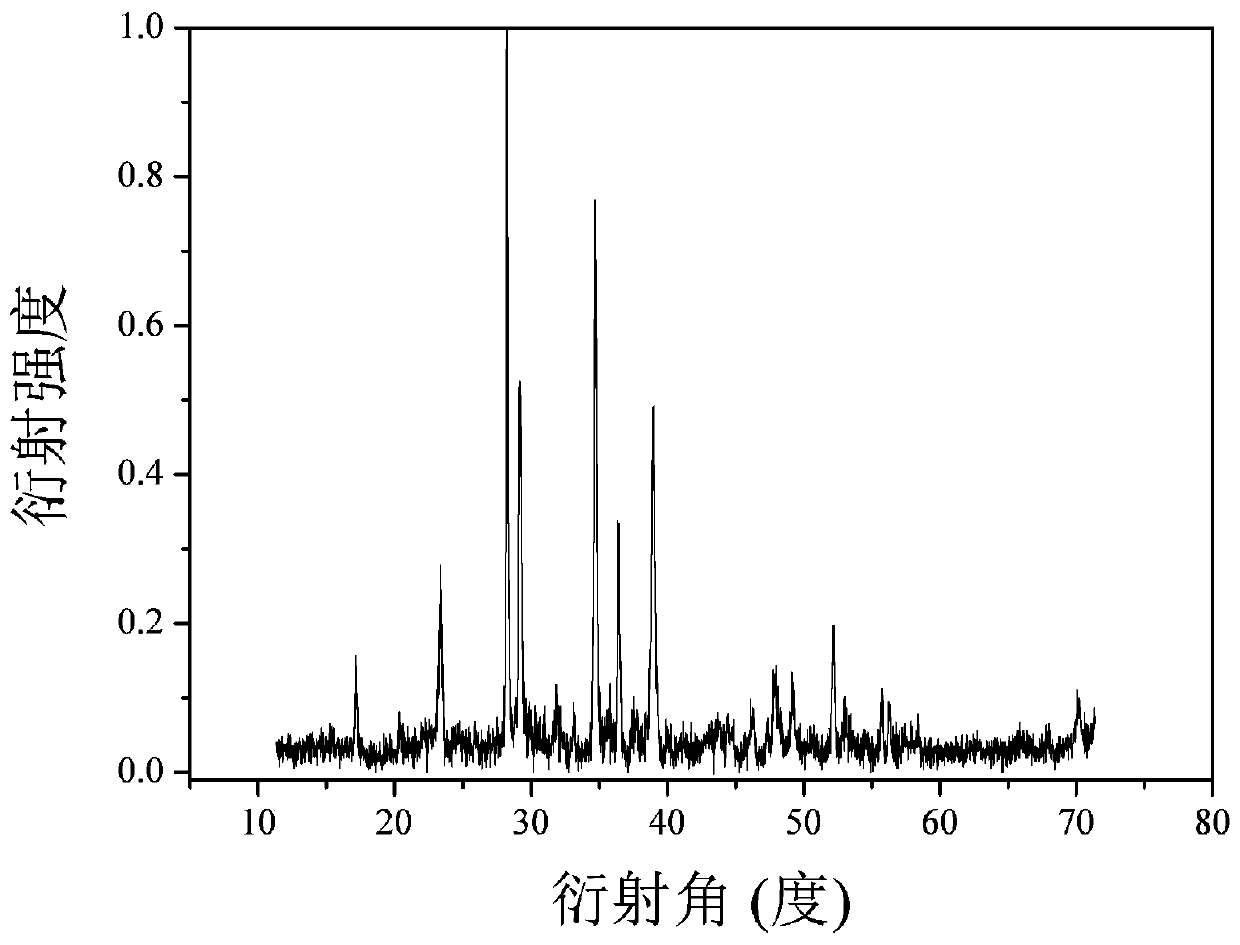

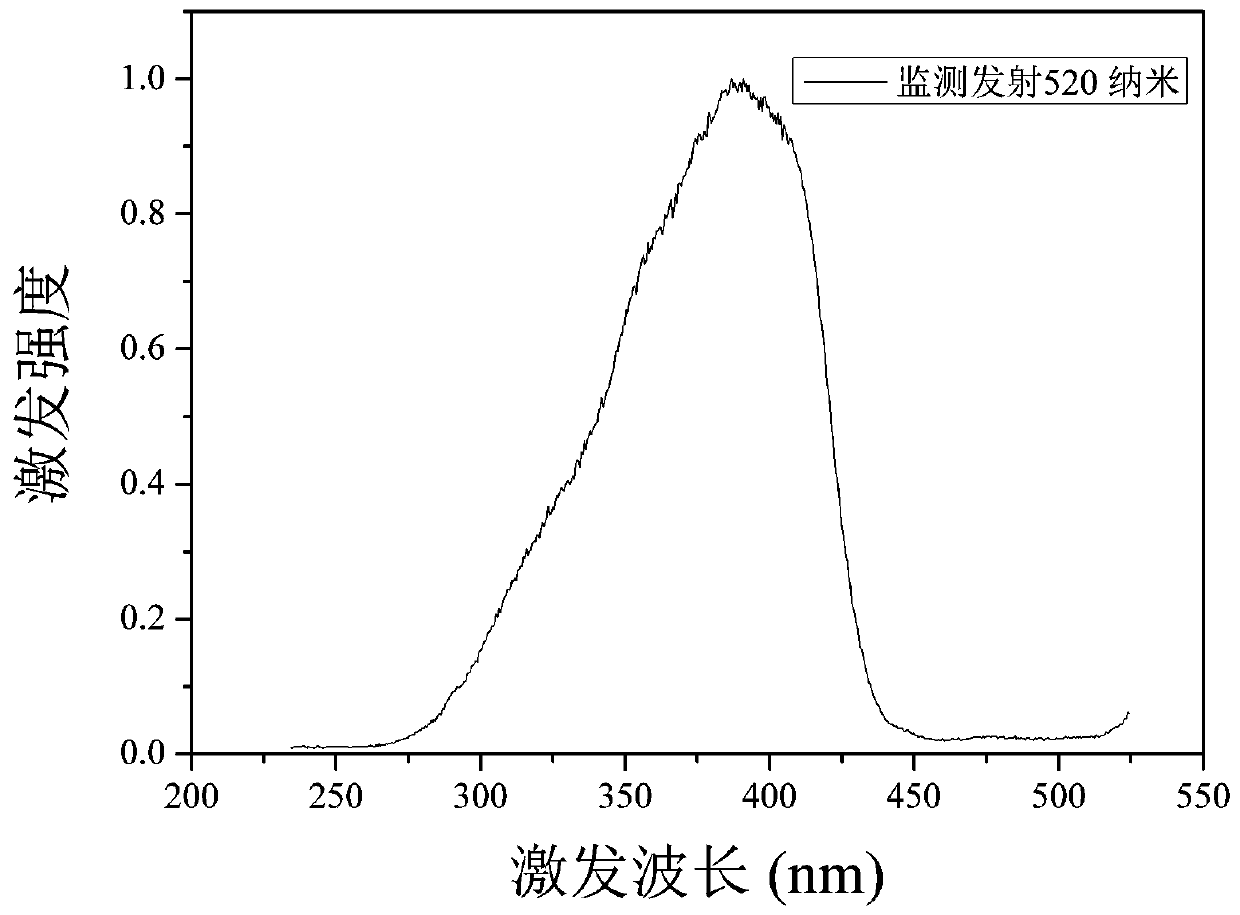

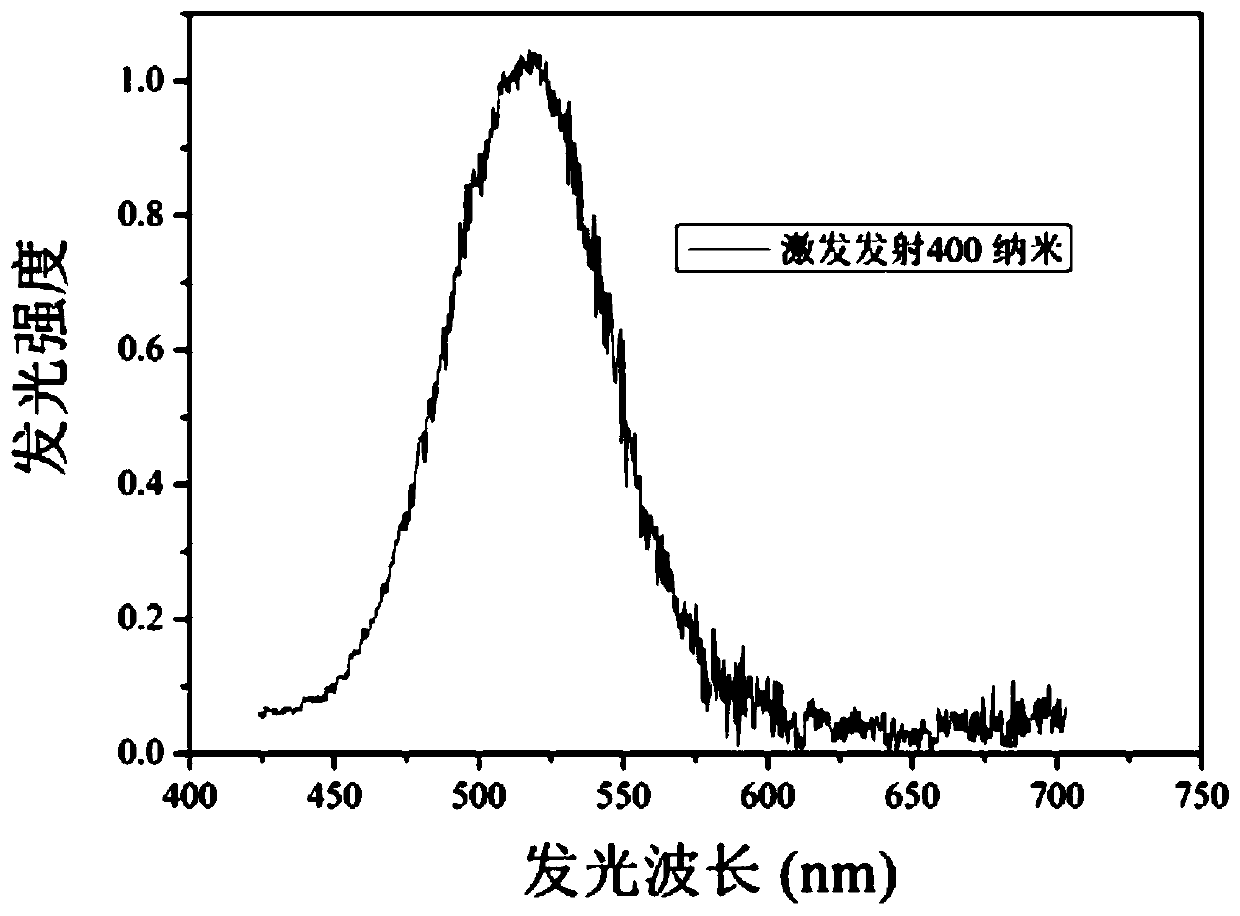

Ultraviolet /near ultraviolet light excited green emitting phosphor and preparation method thereof

ActiveCN106833643ASmall particlesEvenly distributedRare earth metal compoundsLuminescent compositionsChemical synthesisLuminous intensity

The invention discloses ultraviolet / near ultraviolet light excited green emitting phosphor and a preparation method thereof. The green emitting phosphor has a chemical formula of Ba10-10xEu10xAl2O13, wherein the excited ion is a europium ion Eu<2+>, x is a molar ratio at an Eu<2+> doped Ba<2+> site, and x is more than or equal to 0.0001 and less than or equal to 0.25. The green emitting phosphor prepared by the invention has the advantages of wide excitation wavelength, particle dispersion uniformity, excellent heat stability and physical and chemical stability, avoidance from acting with packaging materials, semiconductor chips and the like and the like, is easily and efficiently excited by light in the ultraviolet / near ultraviolet band (300-420nm) and is high in luminous intensity, high in luminous efficiency and pure in fluorescent color; during preparation, compounds containing elements needed for synthesis of luminous materials are mixed according to a ratio, the green emitting phosphor is prepared by a high temperature solid state method or a chemical synthesis method, repeated calcination preparations are needed, and the preparation method is simple in process, easy to operate, rich in raw material source and low in production cost.

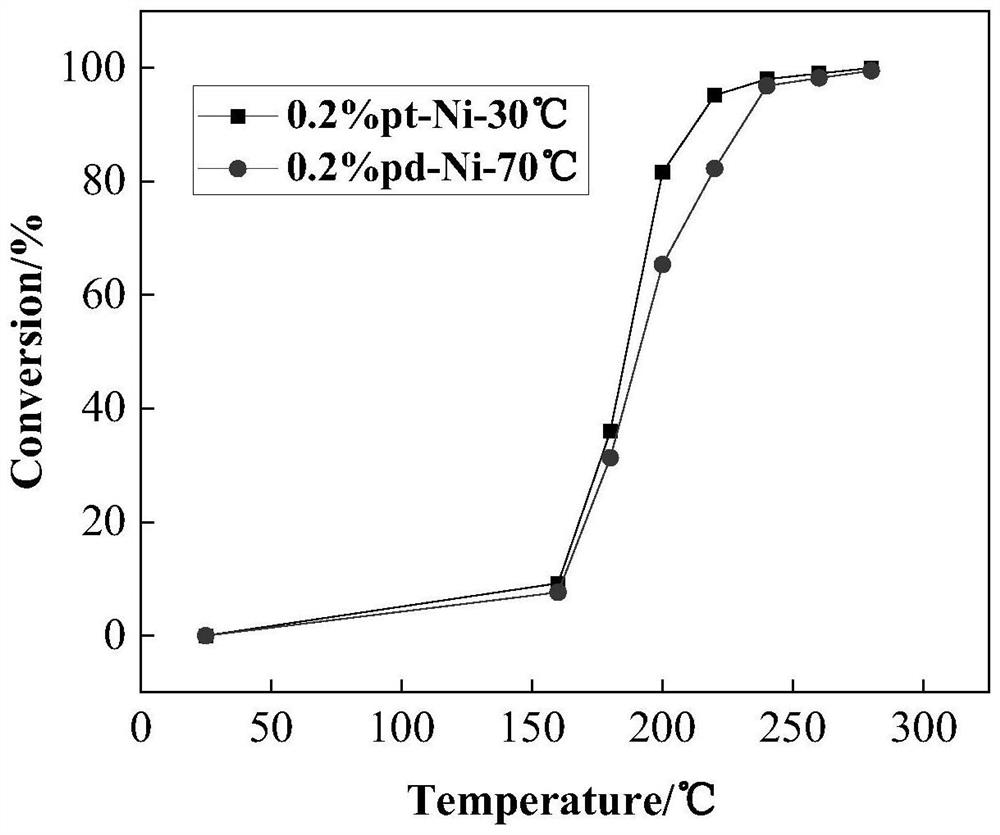

VOCs catalytic combustion monolithic metal foam catalyst and preparation and application thereof

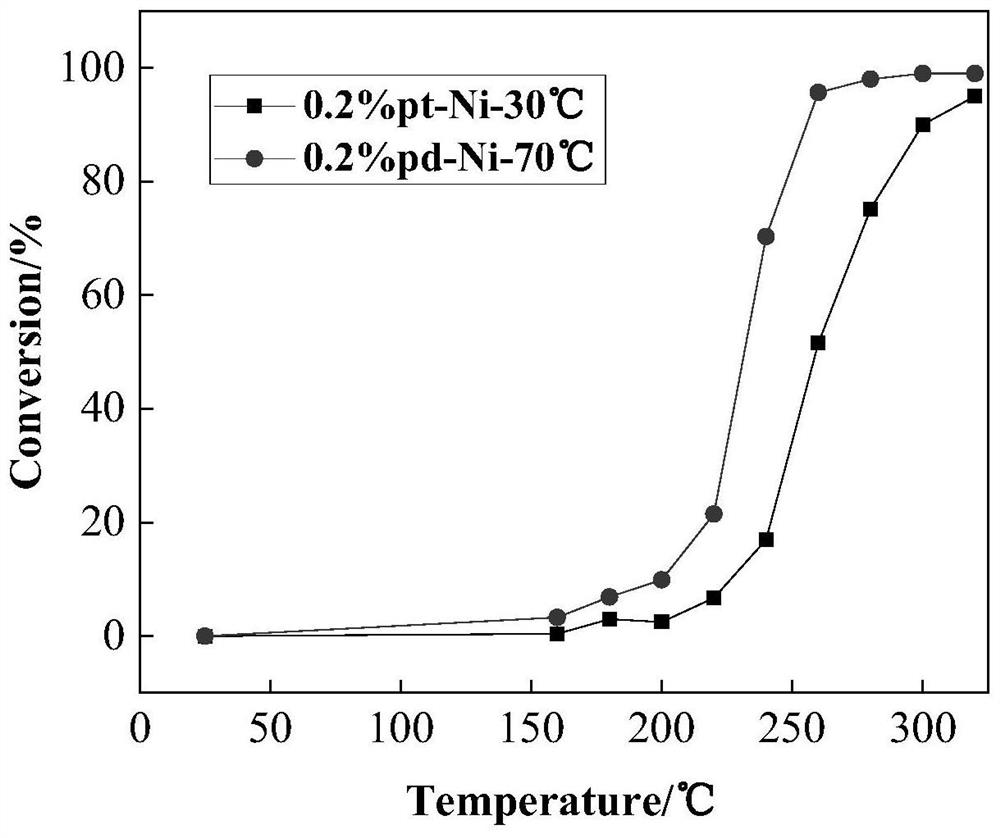

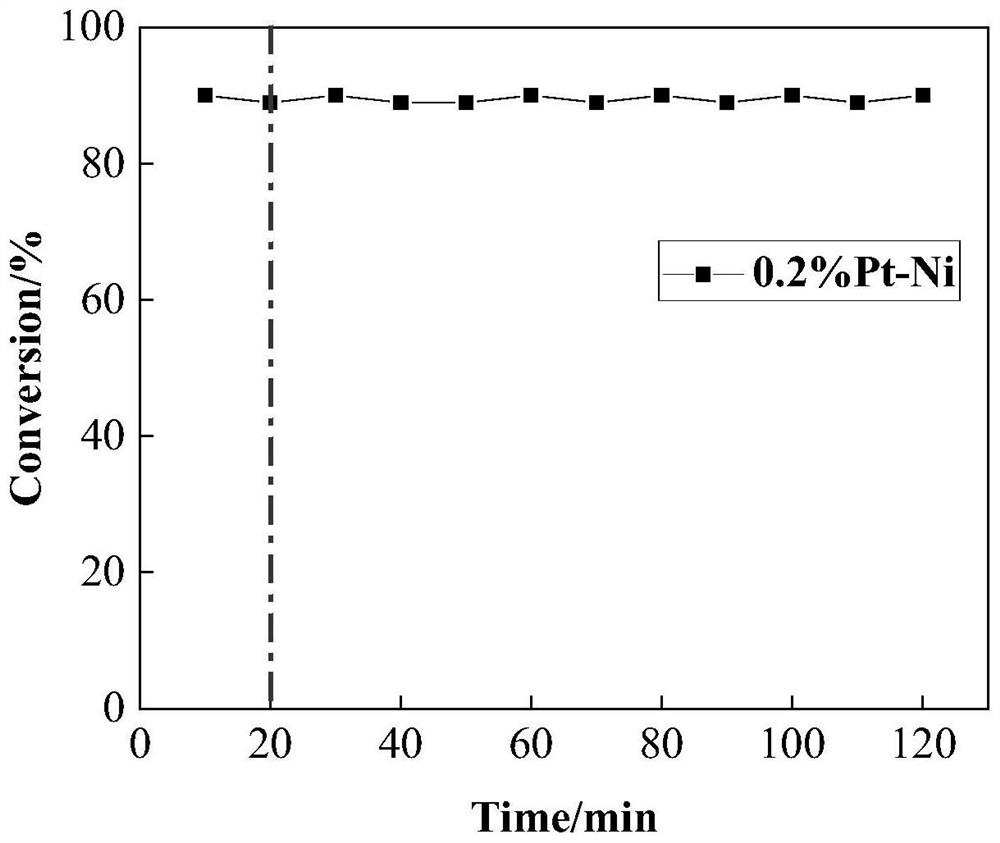

PendingCN112044448AThe preparation method is simple and flexibleStrong thermal shock resistance and stabilityCatalyst activation/preparationIncinerator apparatusIon exchangeNoble metal

The invention provides a noble metal monolithic catalyst which takes foamed nickel as a carrier and Pt or Pd as an active component, and the mass loading capacity of the active component is 0.1-1%. The catalyst is prepared by an ion exchange method, and the reaction temperature is 20-90 DEG C; the preparation method of the noble metal integral foam nickel catalyst is simple and flexible, and the noble metal integral foam nickel catalyst has excellent activity in catalytic combustion of VOCs, and has excellent water resistance, thermal shock resistance and very high stability.

Owner:ZHEJIANG UNIV OF TECH

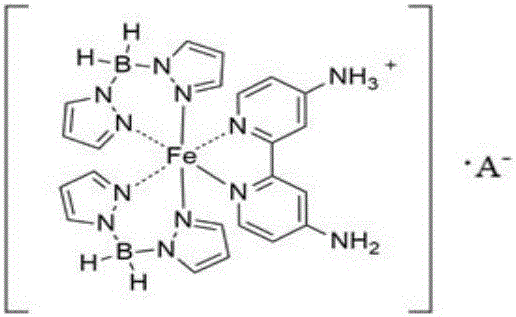

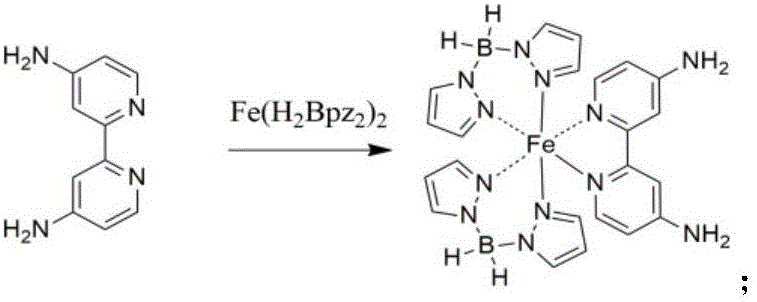

Proton-regulated spin-crossover complex and preparation method and application thereof

InactiveCN106279296ASimple structureImprove performanceIron group organic compounds without C-metal linkagesChemical structureProton

The invention discloses a proton-regulated spin-crossover complex and a preparation method and application thereof. The proton-regulated spin-crossover complex consists of a mononuclear ferrous compound [Fe( H2Bpz2 )2( bipy-NH2 )] containing amino functional groups and an inorganic monoacid, the chemical structural formula is as follows: (img file=DDA0001073756450000011.TIF wi=496 he=334 / ), wherein A is Cl, Br, I, NO<3>, BF<4>, ClO<4>, PF<6> and SbF<6>. The spin-crossover complex disclosed by the invention realizes a proton-regulated spin-crossover behavior within a normal temperature range under the effect of different inorganic monoacids. The proton-regulated spin-crossover complex is easy to synthesis, is high in yield, has sable properties, and has an enormous application prospect in terms of information storage and molecular electronic devices such as molecular switches and molecular display.

Owner:SOUTHEAST UNIV

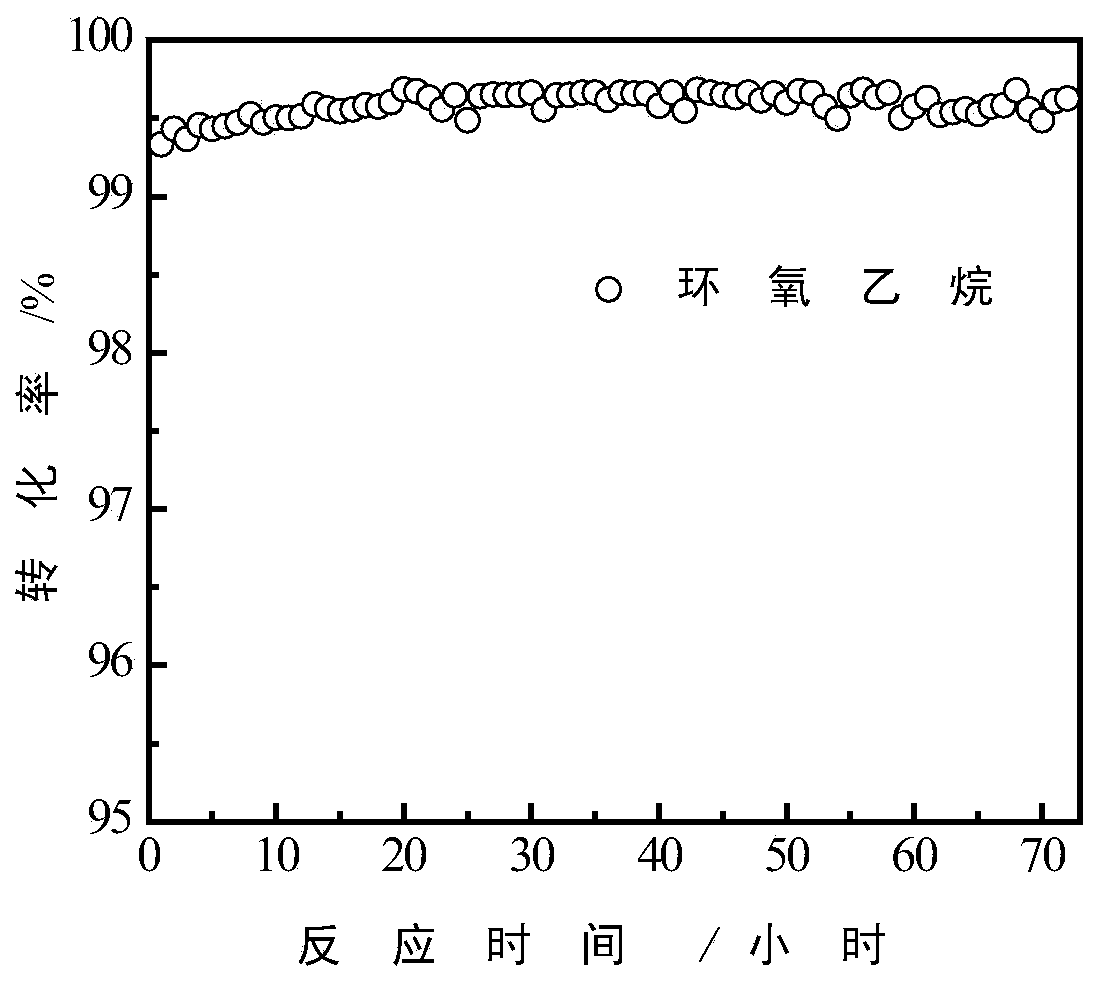

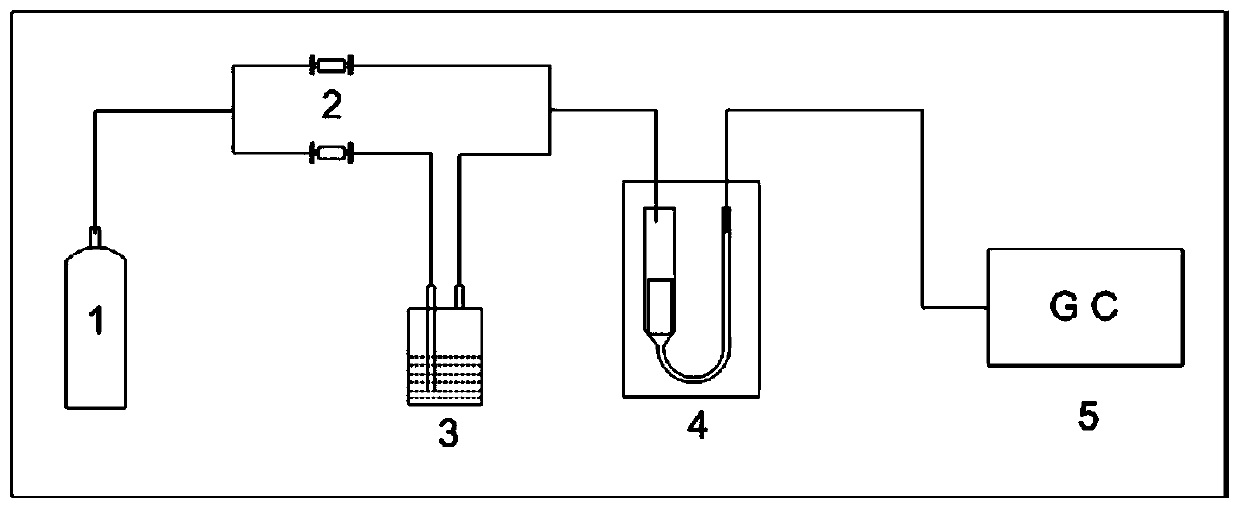

Ethylene oxide combustion catalyst with double active sites and production and application of ethylene oxide combustion catalyst with double active sites

InactiveCN110743545AThe preparation method is simple and flexibleGood activity at low temperatureIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystEthylene oxide

The invention discloses an ethylene oxide combustion catalyst with double active sites and production and application of the ethylene oxide combustion catalyst with the double active sites. Accordingto the catalyst with the double active sites, cordierite is used as a carrier, noble metal and compound metal are used as active components respectively, the noble metal is one of Pt, Pd and Au, massloading of the noble metal is 0.1-0.7%, the compound metal is obtained by mixing any two of Co, Zn, Cu, Ce, Ni and Mn according to a mass ratio ranging from 1:1 to 1:10, and total mass loading of thecompound metal is 3-10%. According to the ethylene oxide combustion catalyst with the double active sites and production and application of the ethylene oxide combustion catalyst with the double active sites, the catalyst with the double active sites is produced by means of an impregnation method, a production method is simple and flexible, the catalyst shows excellent low-temperature activity incatalytic combustion of ethylene oxide, T50=142 DEGC, and T90=147 DEG C. The activity of the ethylene oxide combustion catalyst with the double active sites is reduced by 80 DEG C or more compared with that of an industrialized catalyst on the current market.

Owner:ZHEJIANG UNIV OF TECH

A sulfur-modified mof-derived metal-doped porous carbon material and its preparation method and application

ActiveCN113540472BLow priceThe preparation method is simple and flexibleFuel and primary cellsFuel and secondary cellsPorous carbonZinc–air battery

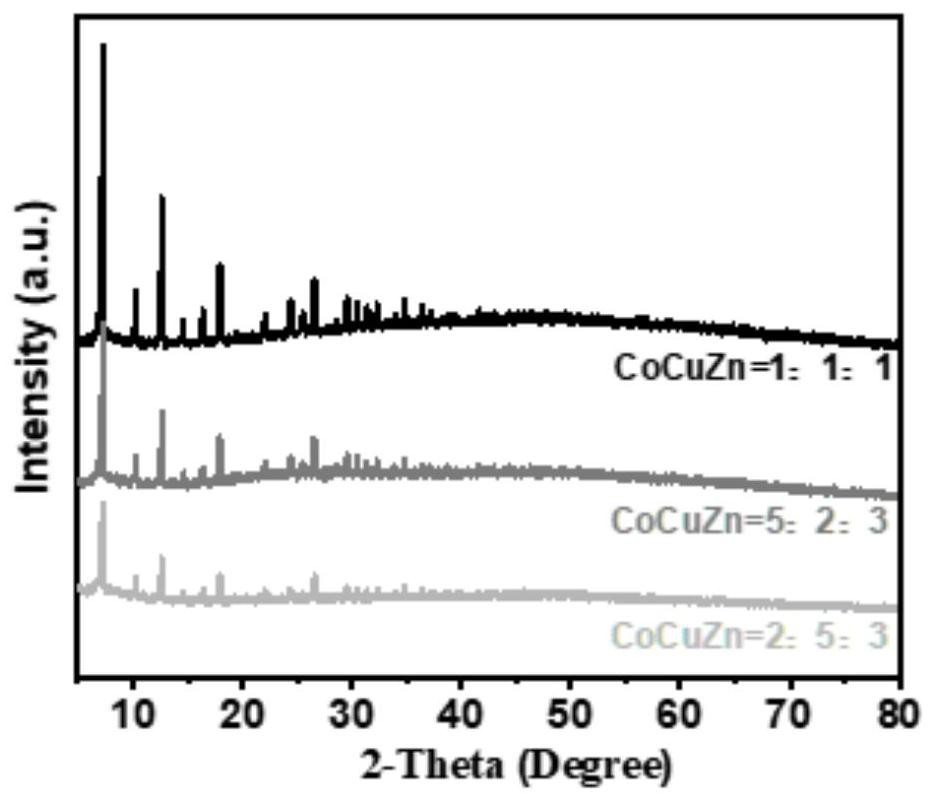

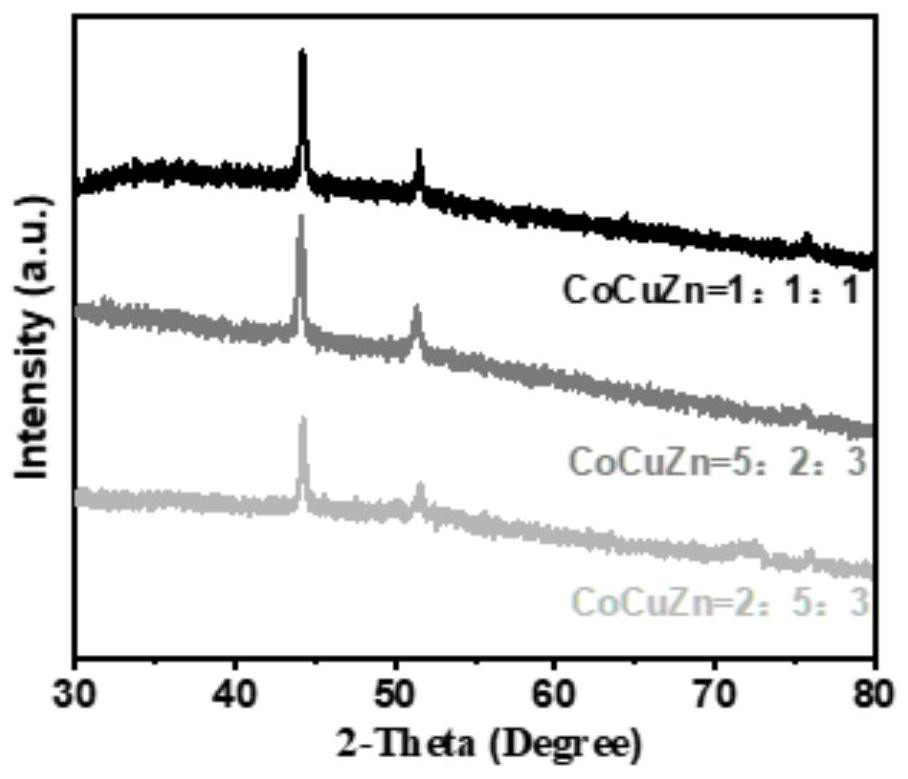

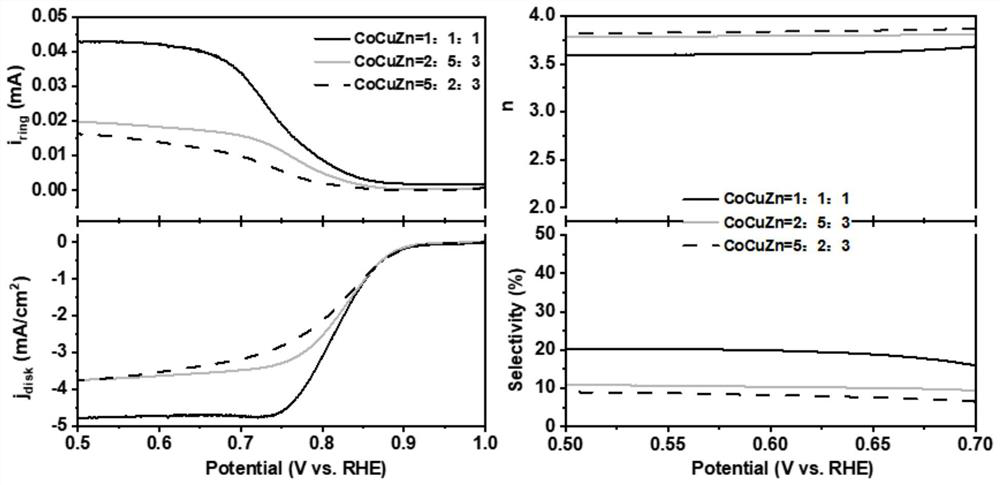

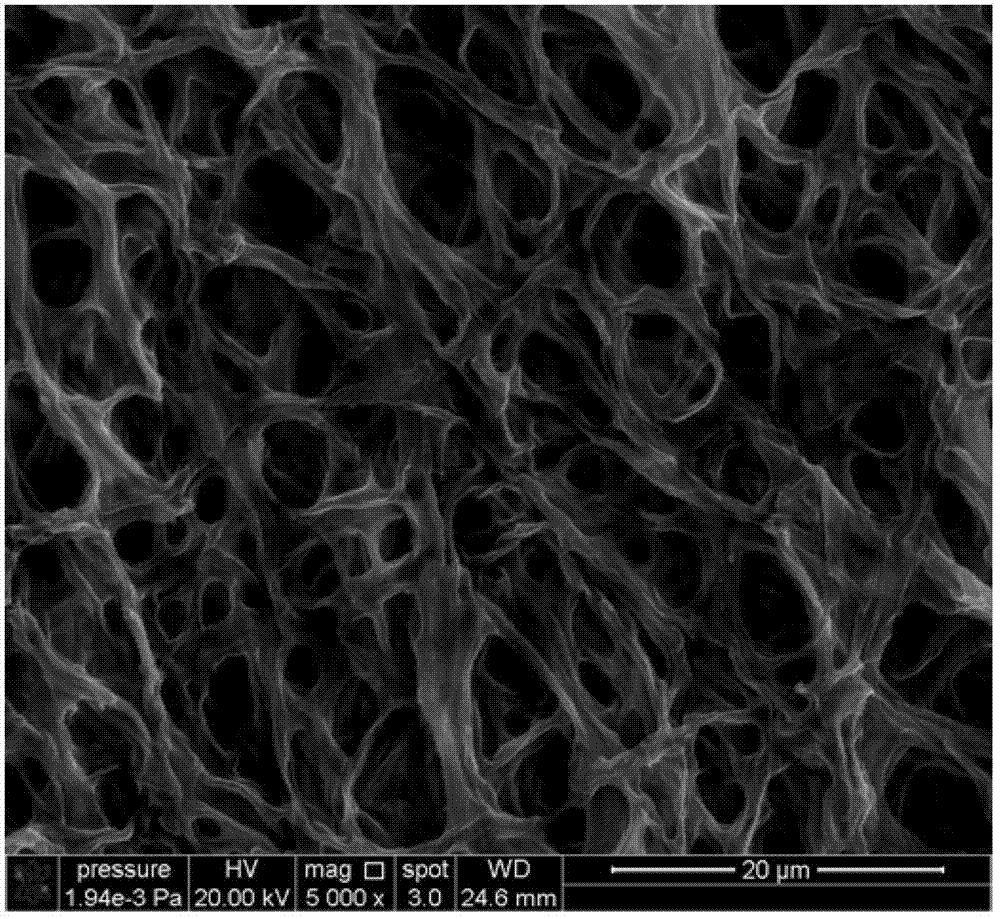

The invention relates to the technical field of composite electrode materials, and for traditional MOF-derived metal-doped porous carbon materials, there are 2e ‑ The problem of ORR reaction is to provide a sulfur-modified MOF-derived metal-doped porous carbon material and a preparation method thereof. First, a mixed solution containing a metal salt and 2-methylimidazole is prepared, and the metal ions of the metal salt include Co 2+ , Cu 2+ , Zn 2+ , reacted to obtain CoCuZn-MOF precursor; then annealed to obtain Cu-Co-N 4 Derived carbon-based composite material, that is, MOF-derived metal-doped porous carbon material; followed by vulcanization treatment to introduce sulfur. The method is easy to obtain raw materials, simple to operate, has no special requirements for equipment, and is easy to industrialize. The present invention also provides the application of the sulfur-modified MOF-derived metal-doped porous carbon material in a zinc-air battery.

Owner:ZHEJIANG UNIV OF TECH

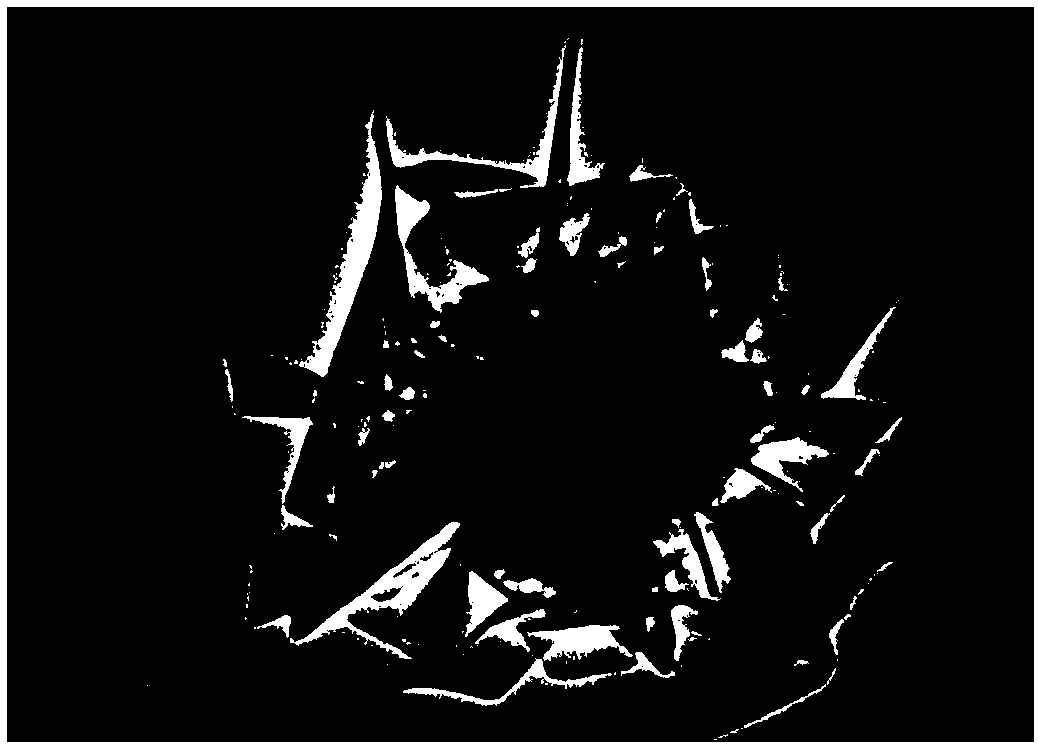

Preparation method of multi-component porous visible-light-induced photocatalyst with hierarchical structure

InactiveCN103143400BThe preparation method is simple and flexibleLow costPhysical/chemical process catalystsOxide matrixBiological materials

The invention discloses a preparation method of a multi-component porous visible-light-induced photocatalyst with a hierarchical structure. The preparation method comprises the following steps: pre-treating a natural biological material having a three-dimensional porous structure to take the natural biological material as a template; preparing a metal oxide nanometer material having a three-dimensional porous hierarchical structure through the template to take the metal oxide nanometer material as a matrix; and depositing a composite semiconductor nanometer material on the metal oxide matrix to finally prepare a composite nanometer material having a multi-component porous hierarchical structure. According to the method disclosed by the invention, the biological materials having three-dimensional hierarchical structures can be extensively selected as the template, the process is simple and flexible, the cost is low, and the composite nanometer material can be obtained by regulating and controlling the technological parameters and different template structures, and the like. The composite material prepared by the invention can be used as a visible-light-induced photocatalyst, and the composite material can quickly and effectively degrade organic pollutants under the irradiation of visible light, so that the composite material has an important application prospect in such fields as environmental protection, etc.

Owner:SHANGHAI JIAOTONG UNIV

Composite material and catalyst supported by composite material and its preparation and application

ActiveCN108160122BLarge specific surface areaHigh activityCatalyst carriersCell electrodesFiberPtru catalyst

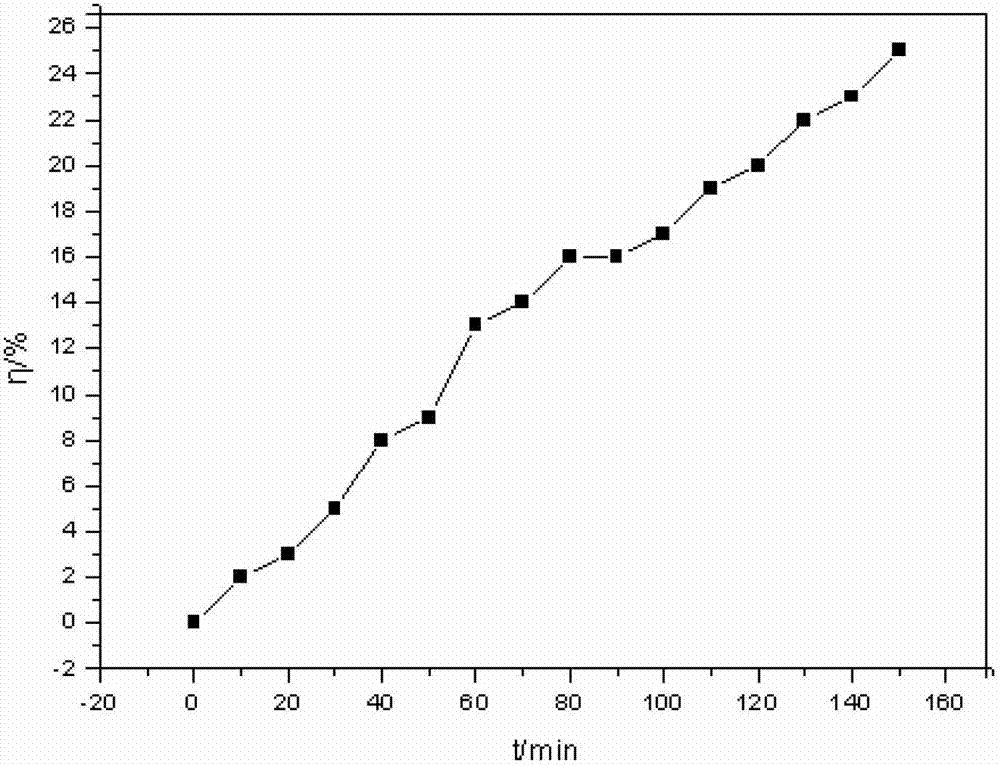

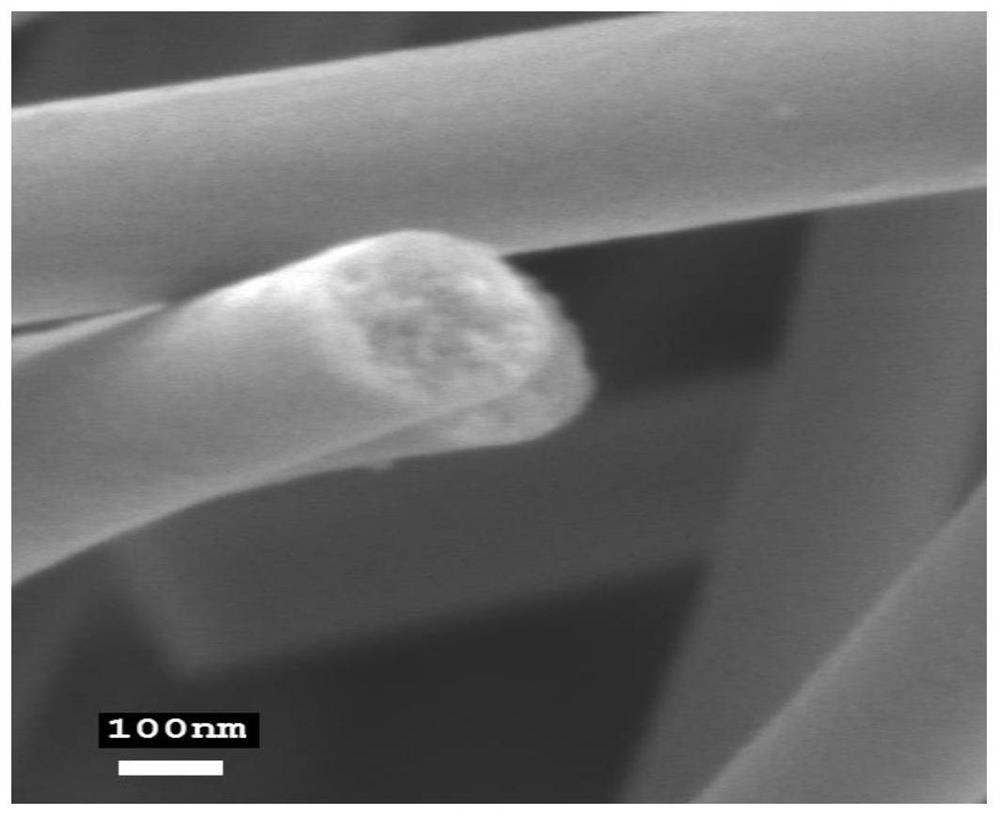

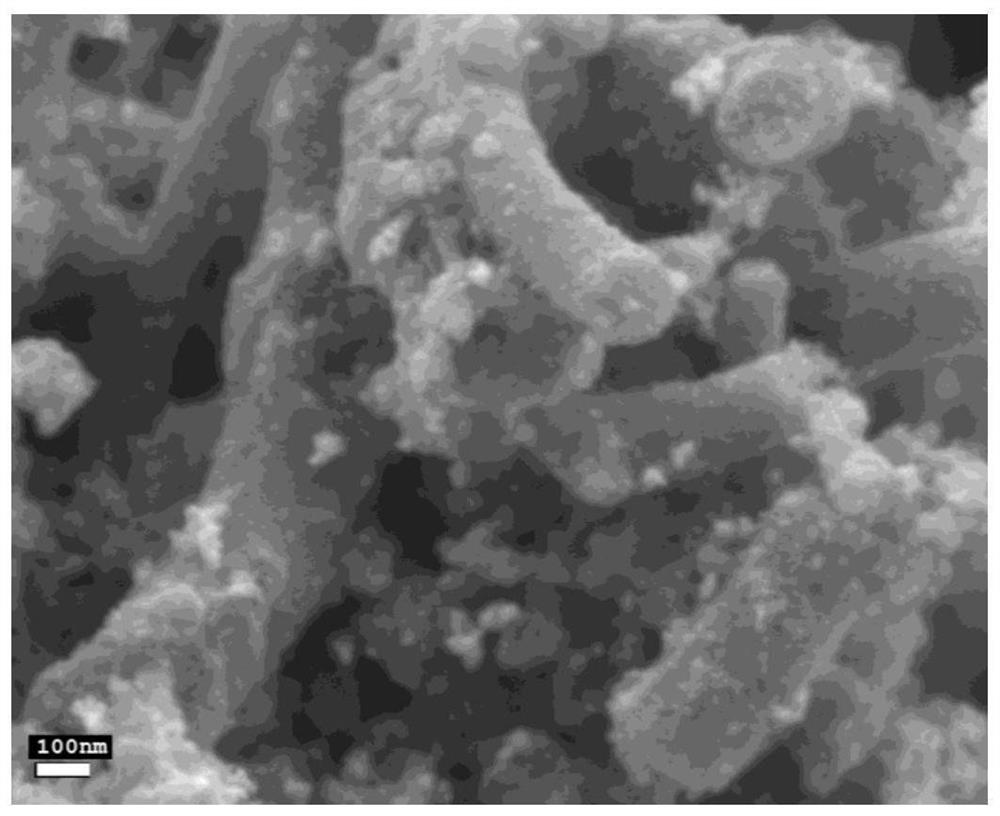

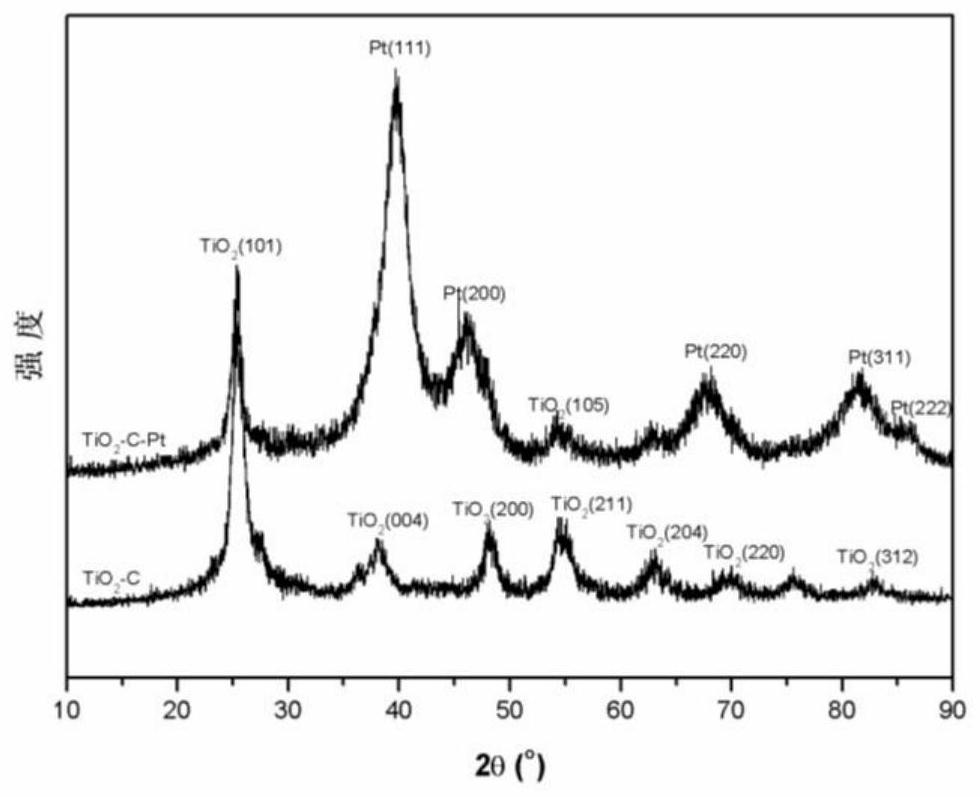

The invention relates to a composite material and a catalyst with the composite material as a carrier and its preparation and application. Specifically, it is based on electrospinning technology and solution method to prepare composite fiber / MO based on metal oxide-conductive material. 2 ‑C and its electrocatalyst N / MO as a carrier 2 -C. Its electrocatalyst carrier / MO 2 ‑C is a metal oxide‑conductive carbon material composite fiber. The introduction of the catalyst Pt can be done by dispersing the catalyst carrier into the solution and then introducing the Pt catalyst particles by reduction method, or by adding a Pt salt precursor to the spinning solution, and then a one-step method Preparation of Pt-based electrocatalysts. Through the addition of conductive carbon materials and the one-step low-temperature treatment of polymer nanofibers in the later stage, the present invention not only ensures the loose porous structure of the prepared carrier, but also ensures the conductivity and structural stability of the carbon material in the carrier. In addition, air or The one-step low-temperature treatment under an oxygen atmosphere not only ensures the oxidation of the metal precursor salt, but also ensures the decomposition of the polymer precursor and the stable existence of the carbon material.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Three-dimensional spin-crossover gel material as well as preparation method and application thereof

The invention discloses a three-dimensional spin-crossover gel material as well as a preparation method and application thereof. The gel material comprises PVDF, PEG, a two-dimensional spin crossover complex and lanthanide doped up-conversion nanoparticles, the two-dimensional spin crossover complex is [Fe(1, 3-bpp) 2 (NCS) 2]2, the mass percent of [Fe (1, 3-bpp) 2 (NCS)2] 2 to PVDF is 0.375%-6%, and the mass percent of up-conversion nanoparticles to PVDF is 0.075%-1.2%; and the mass ratio of the PEG to the PVDF is (0.2-1): (1-4). The three-dimensional spin-crossover gel material realizes a molecular spin-crossover behavior triggered by near-infrared light at normal temperature and normal pressure, is simple to prepare and stable in performance, and has a huge application prospect in the aspects of molecular electronic devices such as information storage, molecular switches and molecular display.

Owner:SOUTHEAST UNIV

A kind of three-dimensional spin cross gel material and preparation method and application

ActiveCN113354841BImprove performanceAchieving multi-step spin-crossover behaviorMolecular switchUpconversion nanoparticle

Owner:SOUTHEAST UNIV

Vanadium-carbon-based catalyst for desulfurization and denitrification, preparation method and application thereof

ActiveCN109589965BThe preparation method is simple and flexibleUniform distribution of active ingredientsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

A vanadium carbon-based catalyst for desulfurization and denitrification includes carbon material, active component vanadium, wherein vanadium, represented by V 2 o 5 Calculated, accounting for 0.5%-10% by weight of the catalyst, the rest is carbon materials. The invention has the advantages of simple preparation method, uniform distribution of active components, and remarkable improvement of sulfur capacity and denitrification activity along with the regeneration process.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of controllable multi-morphology microspheres

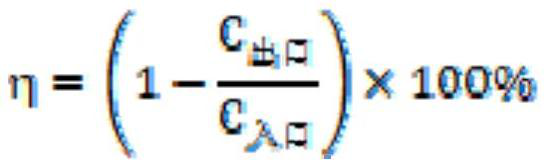

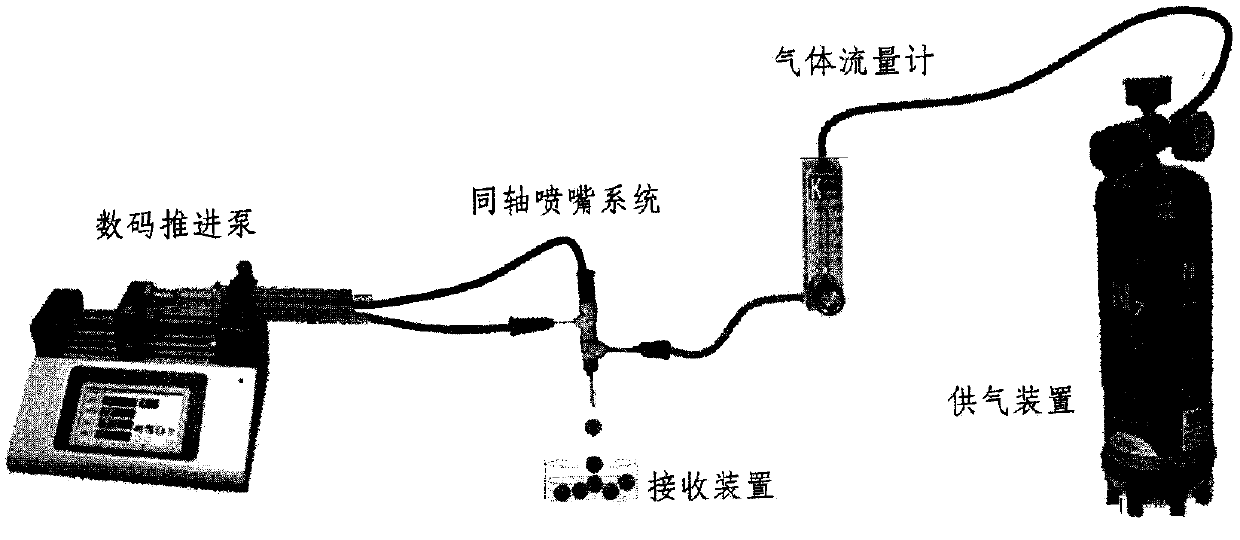

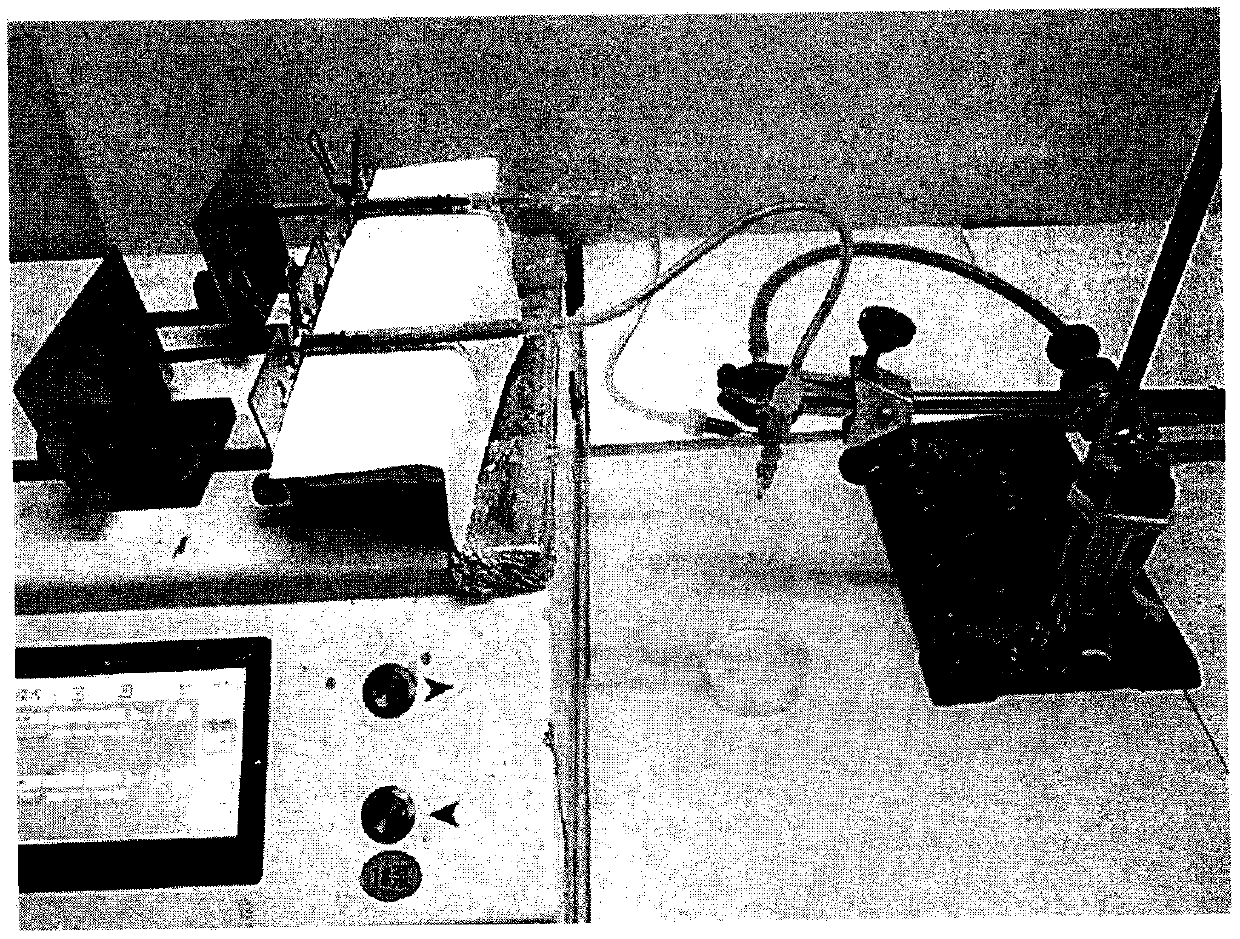

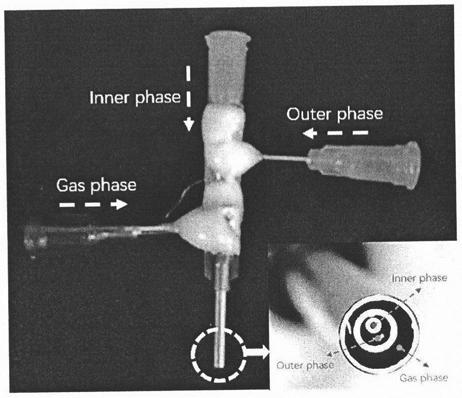

InactiveCN111589386AThe preparation method is simple and flexibleNo complex pre-processing steps requiredMicroballoon preparationMicrocapsule preparationMicrosphereBiocompatibility

The invention discloses a preparation method of controllable multi-morphology microspheres. The method has the advantages of favorable biocompatibility and simplicity, and can be used for preparing the microspheres with complex morphologies in one step. The microspheres with corresponding complex morphologies are obtained through a gas-assisted microsphere preparation device, two types of coaxialnozzle systems are taken as examples, microspheres with three different types of morphologies are displayed, and microspheres with controllable morphologies are obtained by adjusting multiple parameters. The whole preparation method is simple, easy to operate and environmentally friendly, the microspheres of various complex morphologies can be prepared, the microsphere material has broad spectrumand high flexibility, and important reference is provided for preparation of the microspheres of various morphologies.

Owner:NANJING FORESTRY UNIV

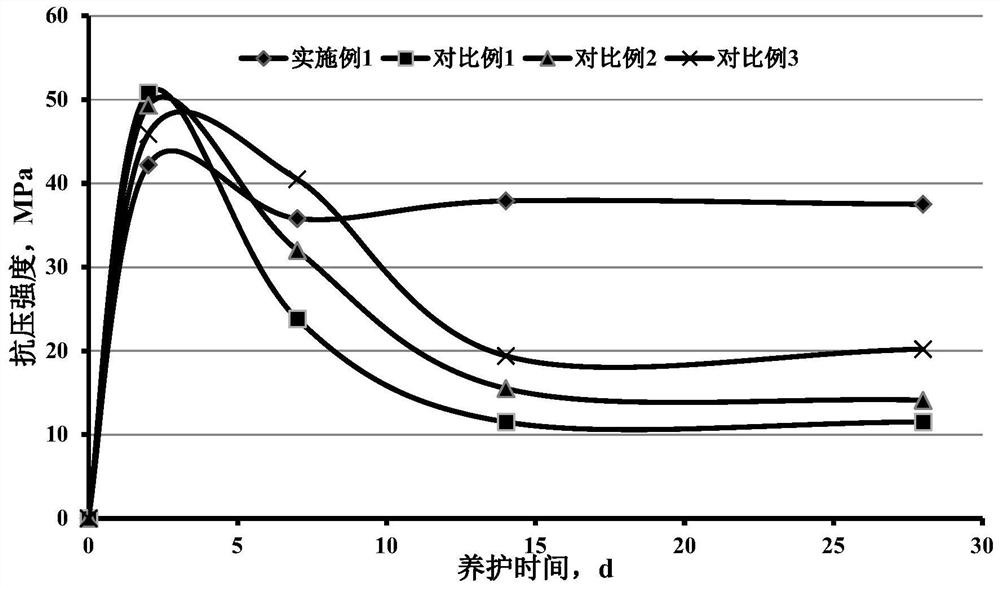

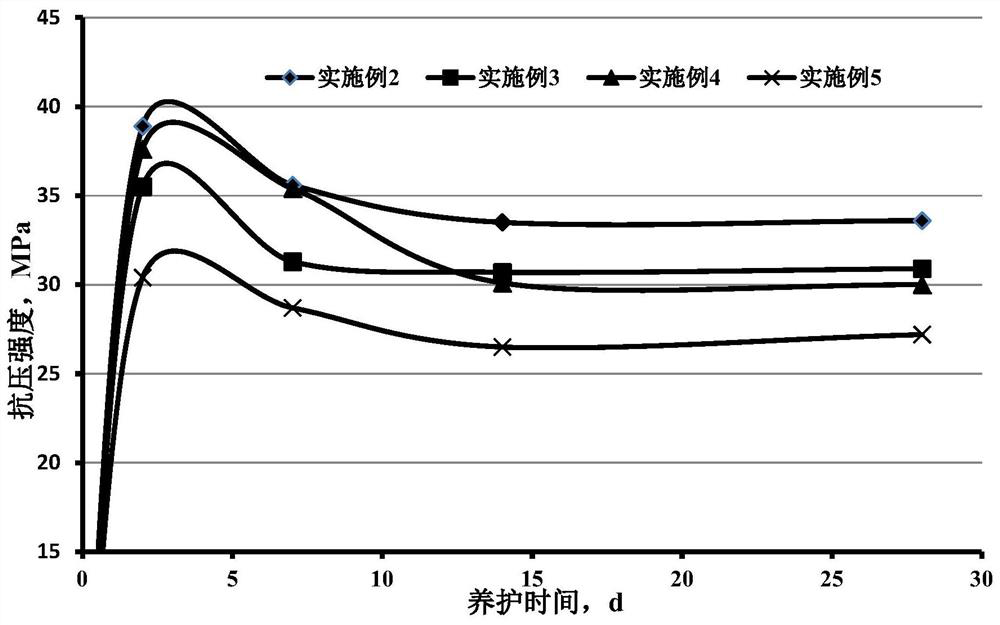

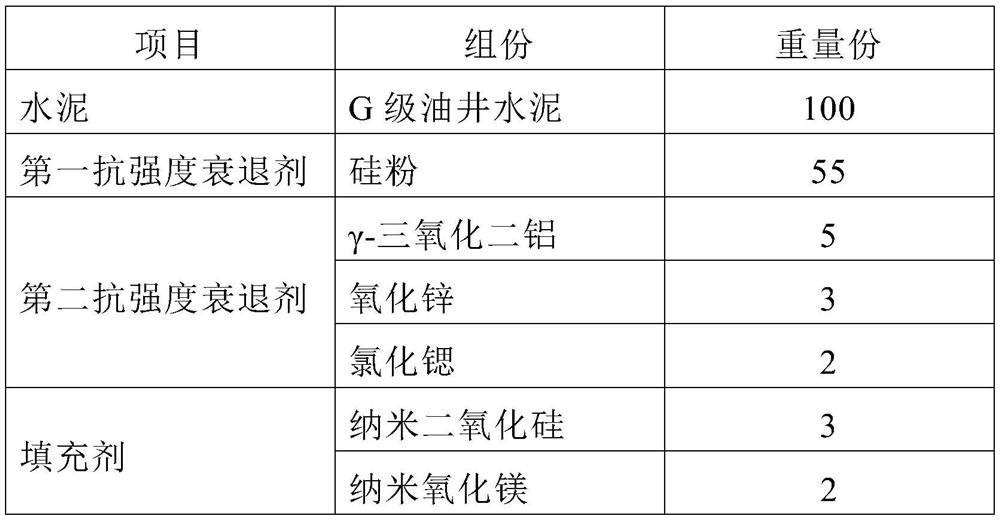

A cementing cement for ultra-high temperature deep wells and its preparation method and application

ActiveCN110563428BExtend your lifeImprove thermal stabilityDrilling compositionZinc hydroxideAluminium hydroxide

Owner:PETROCHINA CO LTD

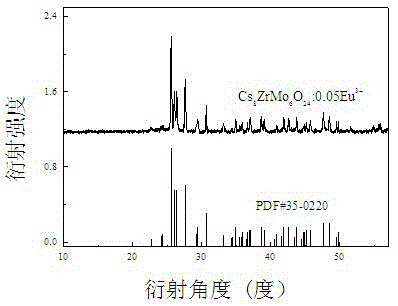

A kind of molybdate-based red fluorescent powder and preparation method thereof

ActiveCN104312584BUniform particle sizeHigh crystallinityLuminescent compositionsChemical solutionDissolution

The invention discloses molybdate-based red fluorescent powder and a preparation method thereof. The molybdate-based red fluorescent powder has a chemical formula of M8ZrMo6O24: xEu<3+>, wherein an active ion is Eu<3+>, M represents one of alkali metal ions Cs<+>, Rb<+>, K<+> and Na<+>, x represents a mole percentage coefficient of Eu<3+> replacing M and x is greater than or equal to 0.0001 and is less than or equal to 0.1. The molybdate-based red fluorescent powder has uniform granularity, high luminescence efficiency, high degree of crystallization and high degree of pure red fluroescence color. The preparation method has simple and flexible processes, realizes mixing of compounds of elements required by red phosphor powder according to a ratio, high-temperature calcining or chemical solution dissolution and then calcination for material preparation, and adopts raw materials having abundant sources and low prices. The molybdate-based red fluorescent powder has strong excitability in a wavelength range of 370-410nm, has emission wavelength very same to that of a near ultraviolet LED chip, can emit bright red fluorescence under the excitation of near ultraviolet and has main emission wavelength of 614nm.

Owner:徐州博创建设发展集团有限公司

A kind of preparation method of fluorine removal adsorption material based on magnesite

InactiveCN104874368BLarge specific surface areaOvercome the disadvantage of easy to produce large bed resistanceOther chemical processesWater contaminantsAdditive ingredientSlurry

The invention provides a method for preparing a defluorination material with a three-dimensional through hole structure by taking magnesite as a raw material. The method comprises the following steps: mixing ground and sieved natural magnesite and a biomass additive at a certain ratio, and uniformly dispersing a solution containing a binding agent to form slurry; filling the slurry into through hole polyurethane sponge foams; and rolling, molding, drying, degreasing and calcining to obtain a defluorination adsorption material with the three-dimensional through hole structure. The defluorination adsorption material keeps a honeycomb pore structure of the polyurethane sponge foams, and a plurality of micro-pores, which are remained by volatilizing organic matters including the binding agent, polyurethane sponge and the like, are formed in the surface, so that the specific surface area is large. Furthermore, the material sufficiently utilizes characteristics of magnesium-rich ingredients of natural magnesite; degreasing and active calcining are carried out at the same time; and the adsorption material which takes active magnesium oxide as the main ingredient is obtained and can be widely applied to purification treatment of fluorine-containing sewage. The preparation method of the defluorination adsorption material is simple, the raw material cost and the equipment cost are low, the operation is easy and the industrial large-scale production is easy to realize.

Owner:北京绿洁美科技有限公司

Aluminate red fluorescent powder being suitable for excitation from near ultraviolet to blue light and preparation method thereof

ActiveCN106947474ASmall particlesEvenly distributedLuminescent compositionsChemical synthesisLuminous intensity

The invention discloses an aluminate red fluorescent powder being suitable for excitation from near ultraviolet to blue light and a preparation method thereof. The chemical formula of the fluorescent powder is Ba<10-10x>Eu<10x>Al2O13, wherein Eu<3+> is an exciting ion and x is the molar ratio of Eu<3+> doping Ba<2+>, 0.0001 <= x <= 0.25. The fluorescent powder is wide in excitation wavelength, is uniform in particle dispersion, has excellent thermal stability and physical and chemical stability, and is not reacted with a packaging material and a semiconductor chip and the like. The fluorescent powder is easy to excite by light in the wave band from near ultraviolet to blue light (220-475 nm), is high in luminous intensity and luminous efficiency and has pure fluorescence chroma. During preparation, compounds, which contain elements required in synthesis of the luminescent material, are mixed according to ratio, wherein a high-temperature solid phase method or a chemical synthesis method are employed to prepare the fluorescent powder in a multi-time calcination manner. The preparation method is simple and is easy to carry out, is abundant in source of raw materials, and is low in production cost.

Owner:XUZHOU NORMAL UNIVERSITY

A kind of anti-counterfeit carbonless copy paper and its preparation method

ActiveCN103572659BThe preparation method is simple and flexibleEasy production controlNon-fibrous pulp additionCoatings with pigmentsAdhesivePulp and paper industry

The invention belongs to the technical field of carbonless copy paper processing. The anti-fake carbonless copy paper is prepared by scraping or scratching back and forth within a small area with hard materials such as fingernails and plastic cards which are common in life instead of special conditions and tools to show patterns, characters, symbols or lines with different colors so as to achieve the anti-fake purpose of simple identification and common identification. The anti-fake carbonless copy paper comprises body paper, a carbonless copy paper coating and an anti-fake coating layer expressing information with invisible images and texts, wherein the carbonless copy paper coating contains a microcapsule with different colors; the anti-fake coating layer comprises a developing material, an adhesive and an auxiliary; the invisible images and texts are formed by coating the anti-fake coating layer on the body paper or the carbonless copy paper coating according to a special shape. The invention also provides a preparation method of the anti-fake carbonless copy paper.

Owner:GUANGDONG GUANHAO HIGH TECH

Sulfur-encapsulated controlled-release potassium fertilizer and manufacturing method thereof

The invention provides a sulfur-coated controlled-release potassium fertilizer and a manufacturing method thereof. The sulfur-coated controlled-release potassium fertilizer comprises potassium fertilizer granules, wherein the surface of each of the potassium fertilizer granules is sequentially coated with sulfur and a wax mask from inside to outside. The sulfur-coated controlled-release potassium fertilizer comprises the following components in parts by weight: 80-90 parts of potassium fertilizer granules, 8-17 parts of sulfur and 1-3 parts of wax composition. The sulfur-coated controlled-release potassium fertilizer is not limited by the shape of a coating raw material; and the used coating material is environment-friendly and excellent in controlled release property. The invention also discloses a preparation method of the sulfur-coated controlled-release potassium fertilizer, which comprises the following steps: (1) preheating potassium fertilizer granules to 60-90 DEG C, and coating with molten sulfur; and (2) coating the surfaces of the granules obtained in the step (1) with a molten wax composition, and cooling to obtain the sulfur-coated controlled-release potassium fertilizer. The preparation method is simple, easy to implement and convenient to realize industrial production.

Owner:DALIAN HANFENG GRP

Aluminate red phosphor suitable for excitation from near ultraviolet to blue light and preparation method thereof

ActiveCN106947474BSmall particlesEvenly distributedLuminescent compositionsChemical synthesisLuminous intensity

The invention discloses an aluminate red fluorescent powder suitable for near-ultraviolet to blue light excitation and a preparation method thereof. The chemical formula is Ba 10‑10x Eu 10x al 2 o 13 , where the active ion is europium ion Eu 3+ , x is Eu 3+ Doping Ba 2+ The molar ratio of bits, 0.0001≤x≤0.25. The fluorescent powder prepared by the present invention has the advantages of wide excitation wavelength, uniform particle dispersion, excellent thermal stability and physical and chemical stability, no interaction with packaging materials, semiconductor chips, etc., and is easily absorbed by near-ultraviolet to blue light (220-475m ) band of light is excited efficiently, with high luminous intensity, high luminous efficiency, and pure fluorescent chromaticity; during preparation, the compounds containing the elements required for the synthesis of luminescent materials are mixed in proportion, prepared by high-temperature solid-phase method or chemical synthesis method, and calcined multiple times The preparation process is simple, easy to operate, rich in raw material sources, and low in production cost.

Owner:XUZHOU NORMAL UNIVERSITY

A kind of green fluorescent powder excited by ultraviolet/near ultraviolet light and preparation method thereof

ActiveCN106833643BSmall particlesEvenly distributedRare earth metal compoundsLuminescent compositionsChemical synthesisLuminous intensity

The invention discloses a green fluorescent powder excited by ultraviolet / near ultraviolet light and a preparation method thereof. The chemical formula is Ba 10‑ 10x Eu 10x Al 2 o 13 , where the active ion is europium ion Eu 2+ , x is Eu 2+ Doping Ba 2+ The molar ratio of bits, 0.0001≤x≤0.25. The phosphor powder prepared by the present invention has the advantages of wide excitation wavelength, uniform particle dispersion, excellent thermal stability and physical and chemical stability, no interaction with packaging materials, semiconductor chips, etc., and is easily absorbed by ultraviolet-near ultraviolet (300-420nm) High-efficiency excitation of light in the wavelength band, high luminous intensity, high luminous efficiency, and pure fluorescence chromaticity; during preparation, the compounds containing the elements required for the synthesis of luminescent materials are mixed in proportion, prepared by high-temperature solid-phase method or chemical synthesis method, and prepared by multiple calcinations , the process is simple, easy to operate, the source of raw materials is abundant, and the production cost is low.

Owner:XUZHOU NORMAL UNIVERSITY

Popular searches

Raw materials are cheap and easy to get Does not require high temperature and pressure Improve electrochemical performance Improve mechanical properties Improve cycle stability Increase energy density Low raw material cost Reduce equipment costs Easy to operate Easy to achieve industrial mass production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com