Airtight packaging structure of integrated thermoelectric refrigerator and preparation method thereof

A thermoelectric cooler and hermetic packaging technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of affecting the overall heat dissipation capacity of the device, reducing the heat dissipation effect of TEC, increasing the thermal resistance of the interface, etc., and achieving the convenience of circuit interconnection And airtight welding, improve heat resistance, reduce the effect of thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing an airtight packaging structure of an integrated thermoelectric cooler, the preparation method comprising the following steps:

[0030] Step 1: providing a three-dimensional ceramic substrate, and preparing a thermoelectric cooler on the three-dimensional ceramic substrate, so that the three-dimensional ceramic substrate and the thermoelectric cooler share a ceramic substrate.

[0031] Step 2, installing the chip in the cavity of the three-dimensional ceramic substrate, and using the packaging cover plate for hermetic packaging, thereby obtaining the hermetic packaging structure of the integrated thermoelectric cooler.

Embodiment 1

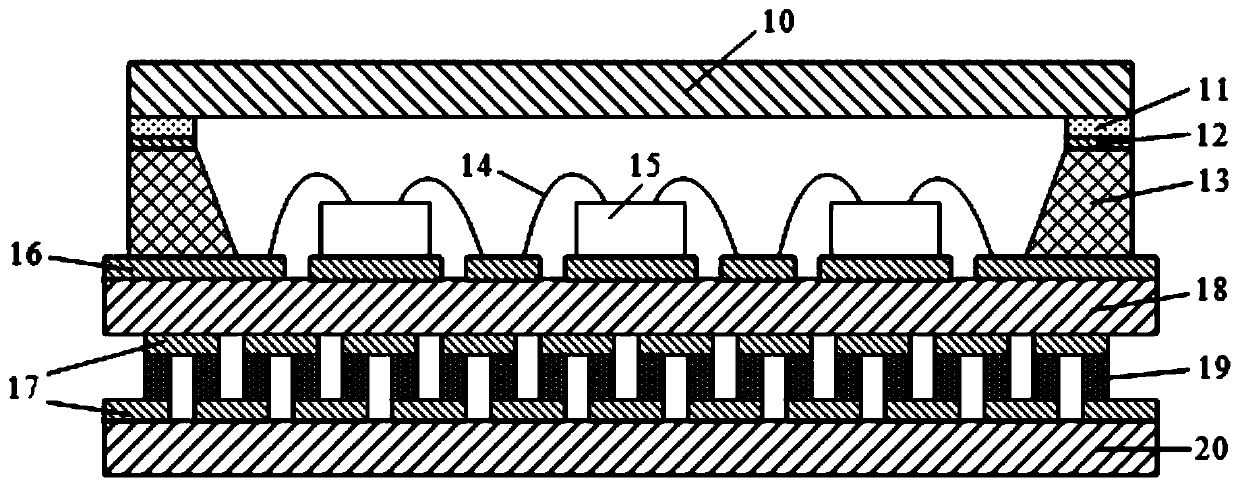

[0034] see figure 1 , the hermetic packaging structure of an integrated thermoelectric cooler provided in Embodiment 1 of the present invention, the hermetic packaging structure includes a packaging cover plate 10, a chip 15, a thermoelectric cooler and a three-dimensional ceramic substrate, and the thermoelectric cooler and the three-dimensional The ceramic substrates are connected, and the two share a ceramic substrate. The three-dimensional ceramic substrate is formed with a cavity, the chip 15 is disposed in the cavity, and the package cover 10 is connected to the three-dimensional ceramic substrate to package the chip 15 in the cavity.

[0035]In this embodiment, the ceramic substrate shared by the thermoelectric cooler and the three-dimensional ceramic substrate is the TEC upper substrate 18 . The TEC upper substrate 18 is directly bonded to the chip 15 . The thermoelectric cooler includes a TEC graphic layer 17, a PN type refrigeration element 19 and a TEC lower subst...

Embodiment 2

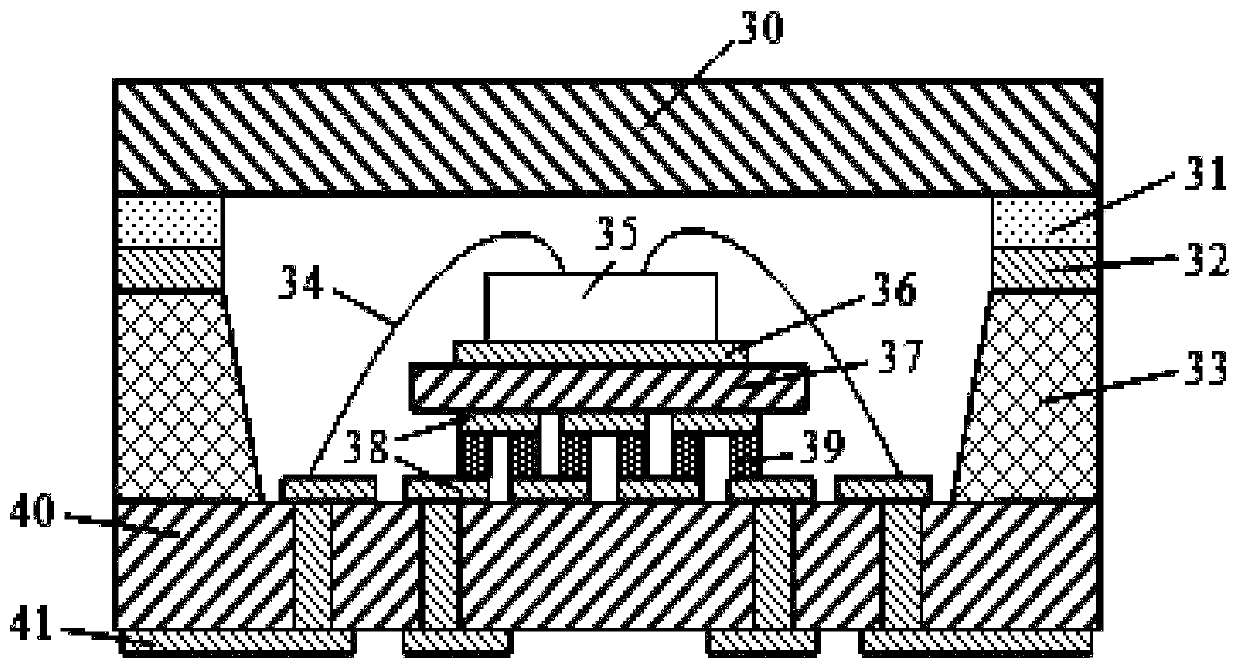

[0052] see figure 2 , the hermetic packaging structure of the integrated thermoelectric cooler provided by Embodiment 2 of the present invention, the hermetic packaging structure includes a packaging cover plate 30, a chip 35, a thermoelectric cooler and a three-dimensional ceramic substrate, and the thermoelectric cooler and the three-dimensional The ceramic substrates are connected, and the two share a ceramic substrate. The three-dimensional ceramic substrate is formed with a cavity, the chip 35 is disposed in the cavity, and the package cover 30 is connected to the three-dimensional ceramic substrate to package the chip 35 in the cavity.

[0053] In this embodiment, the ceramic substrate shared by the thermoelectric cooler and the three-dimensional ceramic substrate is the TEC lower substrate 40 . The thermoelectric cooler also includes a TEC upper substrate 37, two TEC graphic layers 38 and a plurality of PN type cooling elements 39, the TEC lower substrate 40 is in con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com