A sulfur-modified mof-derived metal-doped porous carbon material and its preparation method and application

A technology of porous carbon material and metal doping, applied in the direction of fuel cell half-cells and secondary battery-type half-cells, fuel cell-type half-cells and primary battery-type half-cells, structural parts, etc., can solve Reduce catalyst selectivity, reduce energy utilization efficiency and stability of zinc-air batteries, etc., achieve high half-wave potential, high peak potential, and easy-to-control conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a sulfur-modified MOF-derived metal-doped porous carbon material, comprising the following steps: Preparation of CoCuZn-MOF(111) precursor

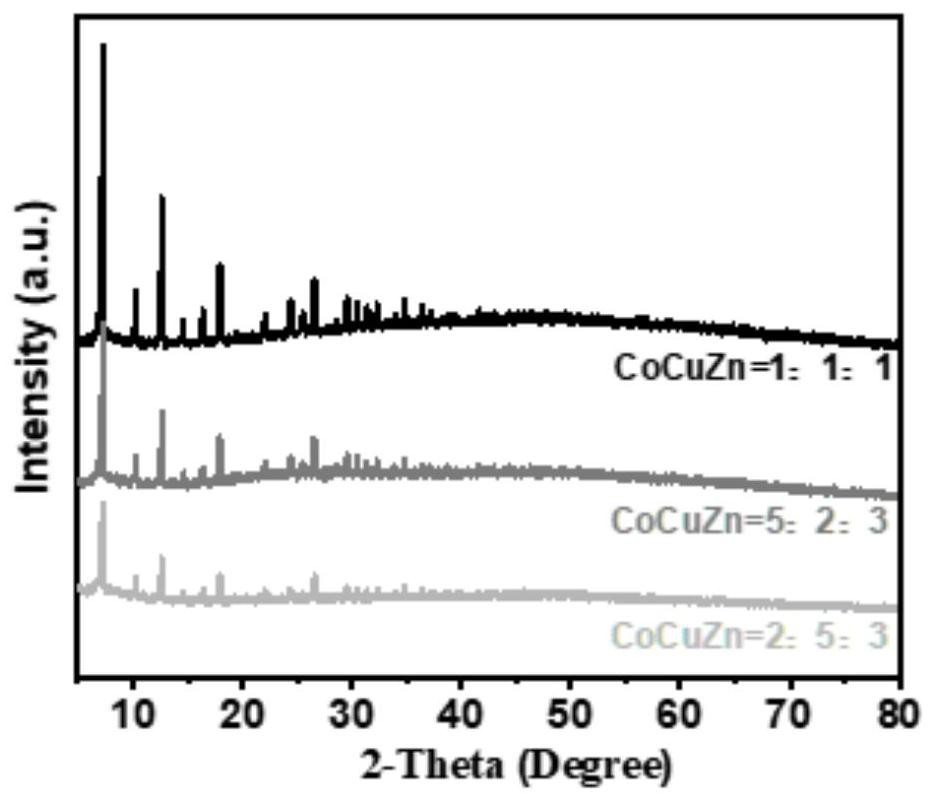

[0029] Prepare a mixed solution containing 0.1 mmol / L metal salt and 10 mmol / L 2-methylimidazole, and the metal salt is Co with a substance ratio of 1:1:1 2+ , Cu 2+ , Zn 2+ , where Co 2+ The substance ratio with 2-methylimidazole is 1:8; the reaction is carried out at 25°C for 24h. After the reaction, washed three times with deionized water, and dried in vacuum at 60 °C to obtain a cuboctahedral CoCuZn-MOF (111) precursor with uniform size. The XRD pattern is as follows figure 1 shown.

[0030] Cu-Co-N 4 (111) Preparation of composite materials

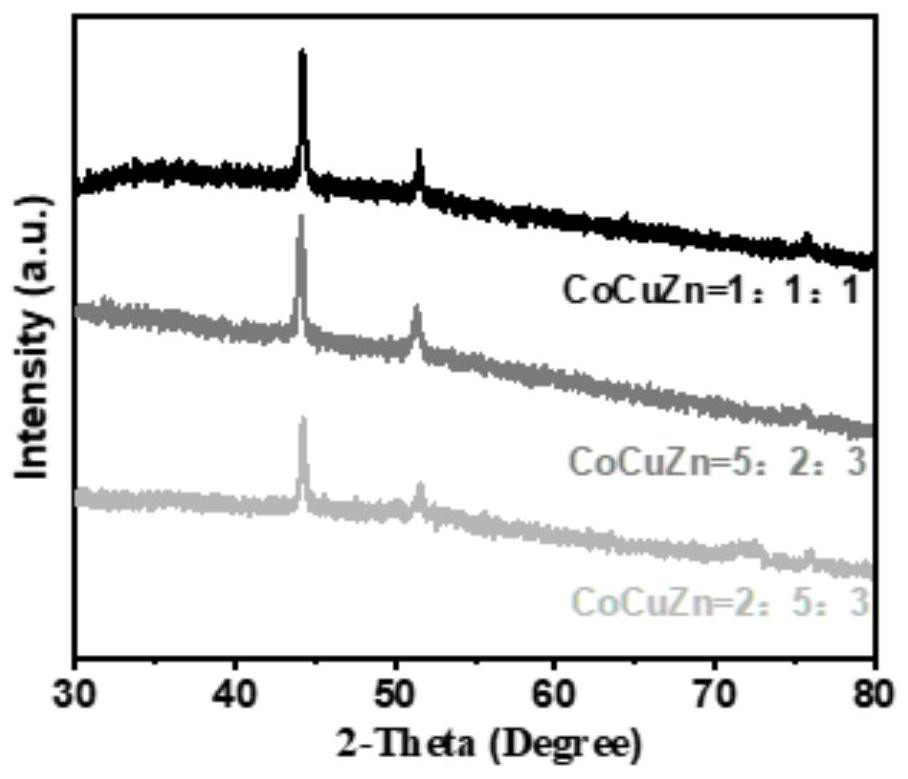

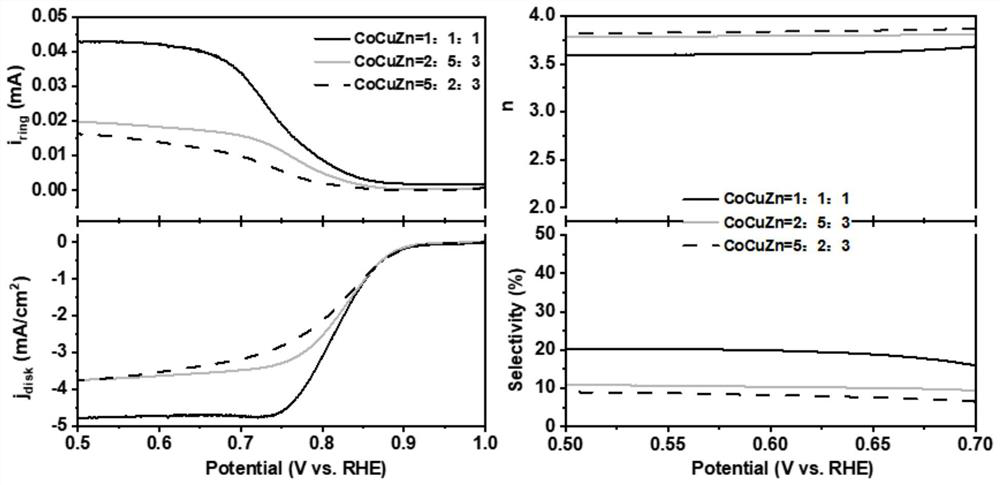

[0031] The CoCuZn-MOF (111) precursor obtained above is annealed at a temperature of 800 °C, a heating rate of 3 °C / min, and an annealing time of 3 h. During the high-temperature annealing process, Zn in the MOF will evaporate, thereby obtaining porous MOF-d...

Embodiment 2

[0037] A preparation method of a sulfur-modified MOF-derived metal-doped porous carbon material, comprising the following steps:

[0038] (1) Preparation of CoCuZn-MOF(253) precursor

[0039] Prepare a mixed solution containing 0.1 mmol / L metal salt and 10 mmol / L 2-methylimidazole, and the metal salt is Co with a substance ratio of 2:5:3. 2+ , Cu 2+ , Zn 2+ , where Co 2+ The material ratio with 2-methylimidazole was 1:8; the reaction was performed at 0 °C for 24 h. After the reaction, it was washed three times with deionized water and dried under vacuum at 60 °C to obtain a regular dodecahedral CoCuZn-MOF (253) precursor with uniform size. The XRD pattern is as follows figure 1 shown.

[0040] (2)Cu-Co-N 4 (253) Preparation of composite materials

[0041] The CoCuZn-MOF (253) precursor obtained above was annealed at a temperature of 700 °C, a heating rate of 1 °C / min, and an annealing time of 2 h. During the high-temperature annealing process, Zn in the MOF would evapor...

Embodiment 3

[0047] A preparation method of a sulfur-modified MOF-derived metal-doped porous carbon material, comprising the following steps:

[0048] (1) Preparation of CoCuZn-MOF(523) precursor

[0049] Prepare a mixed solution containing 0.1 mmol / L metal salt and 10 mmol / L 2-methylimidazole, the metal salt is Co with a substance ratio of 5:2:3 2+ , Cu 2+ , Zn 2+ , where Co 2+ The material ratio with 2-methylimidazole is 1:8; the reaction is carried out at 50°C for 12h. After the reaction, it was washed three times with deionized water and dried in vacuum at 60 °C to obtain a cuboctahedral CoCuZn-MOF (523) precursor with uniform size. The XRD pattern is as follows figure 1 shown.

[0050] (2)Cu-Co-N 4 (523) Preparation of composite materials

[0051] The CoCuZn-MOF (523) precursor obtained above is annealed at a temperature of 1000 °C, a heating rate of 5 °C / min, and an annealing time of 4 h. During the high temperature annealing process, Zn in the MOF will evaporate, thereby obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com