Vanadium-carbon-based catalyst for desulfurization and denitrification, preparation method and application thereof

A carbon-based catalyst, desulfurization and denitration technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of lax atmosphere control, uneven dispersion, low regeneration temperature, etc. The effect of uniform distribution, simple and flexible preparation method and stable activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

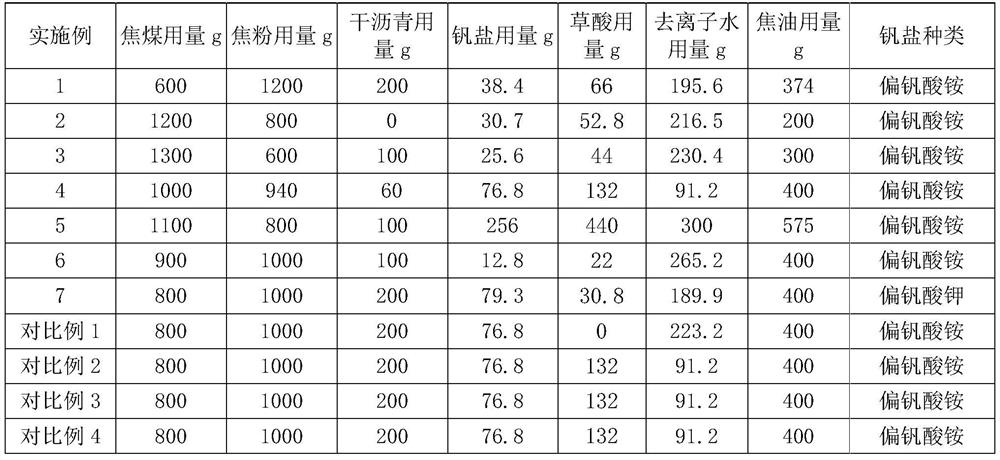

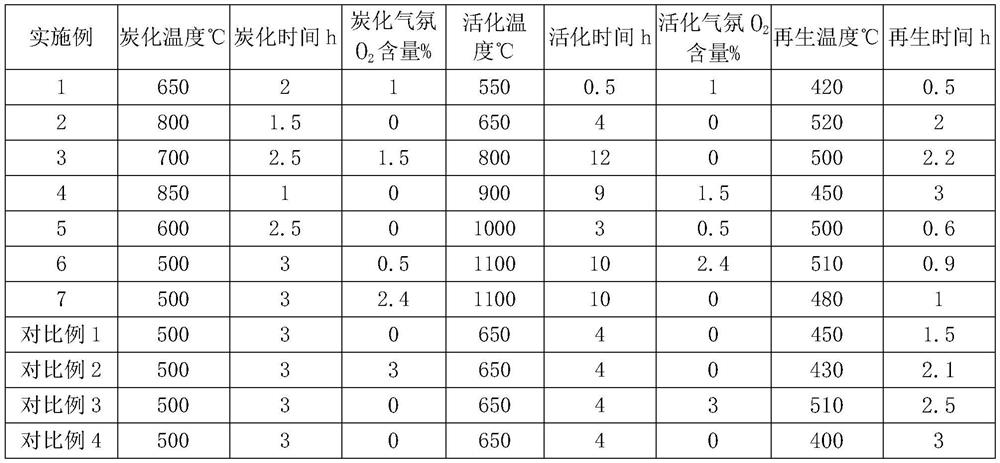

[0032] The technical solution of the present invention and its effects will be further described below through specific examples. The following examples are only used to illustrate the content of the present invention, and are not intended to limit the protection scope of the present invention. Applying the idea of the present invention to make simple changes to the present invention is within the scope of protection of the present invention.

[0033] The preparation method of the desulfurization and denitrification vanadium carbon-based catalyst of embodiment and comparative example is as follows:

[0034] (1) Preparation of coal powder: coking coal, coke powder, and dry asphalt are crushed, mixed and pulverized to a particle size of 200 mesh;

[0035] (2) Use ammonium metavanadate or potassium metavanadate, oxalic acid and deionized water to prepare a vanadium-containing complex solution;

[0036] (3) Manufacturing coal paste: Add the prepared coal powder, coal tar, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com