A kind of anti-counterfeit carbonless copy paper and its preparation method

A technology for carbonless copy paper and coating layer, which is applied in papermaking, textile and papermaking, pulp raw material addition process and other directions, can solve the problems of easy imitation and high cost of anti-counterfeiting carbonless copy paper, and achieves easy production control, simple and flexible preparation method, and identification. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in combination with specific embodiments.

[0020] An anti-counterfeiting carbonless copy paper of the present invention comprises base paper, a coating of carbonless copying paper and an anti-counterfeiting coating layer expressing information in the form of invisible graphics and texts. The coating layer includes color-developing materials, adhesives and auxiliary agents, and the invisible graphic is to process the anti-counterfeiting coating layer on the base paper or carbonless copy paper coating in a specific shape through coating.

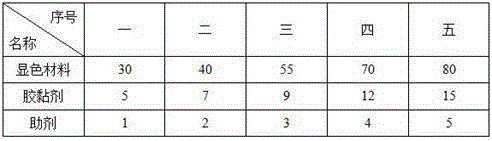

[0021] In this embodiment, the proportion of the anti-counterfeiting paint layer is: 30-80 parts of color-developing material, 5-15 parts of adhesive, and 1-5 parts of auxiliary agent. For example see the table below:

[0022]

[0023] In this embodiment, the color-developing material is activated clay, p-aryl phenol resin, zinc salicylate or zinc salt modified phenoli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com