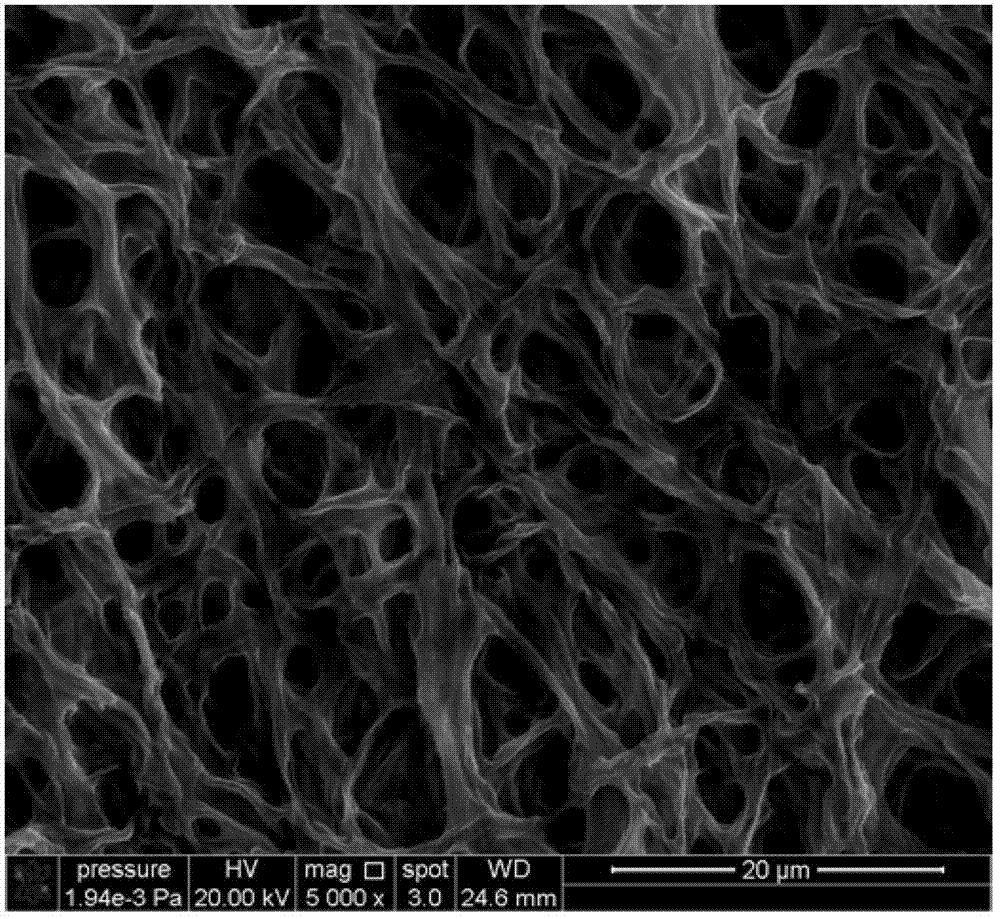

Preparation method of multi-component porous visible-light-induced photocatalyst with hierarchical structure

A hierarchical structure, visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of excellent photocatalytic performance, low cost, simple and flexible preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

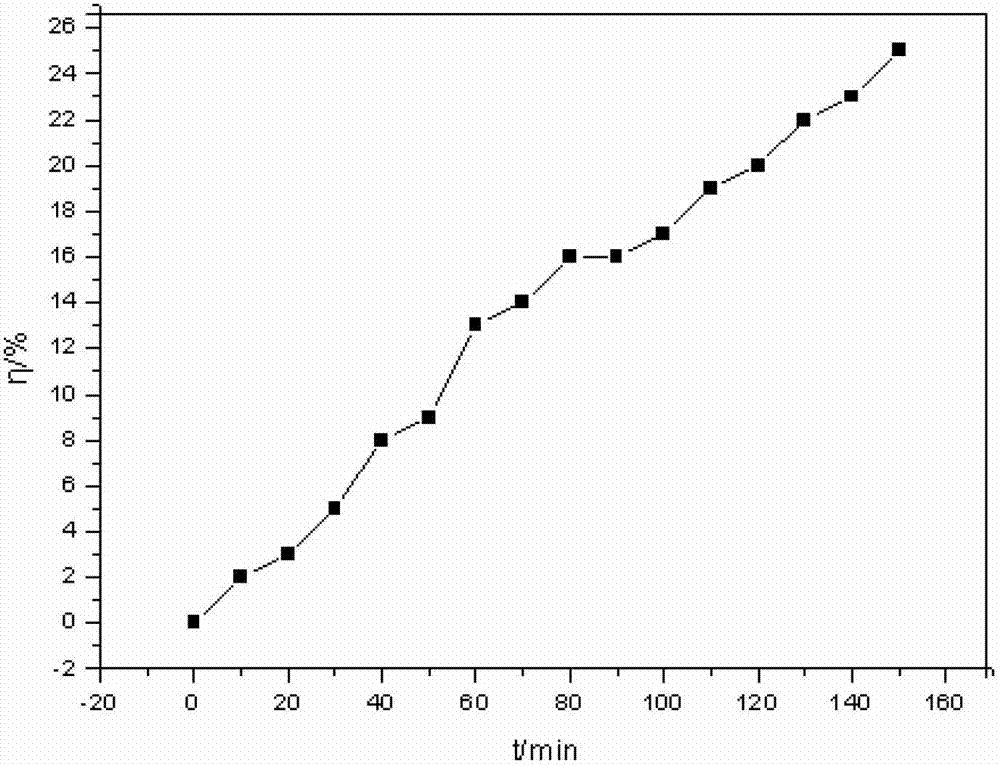

Embodiment 1

[0029] Wash the shells of commercially available eggs and peel off the egg membranes. Wash the egg membrane, dry it, and save it for future use. Then immerse the egg membrane in a solution mixed with tetra-n-butyl titanate, absolute ethanol, and concentrated hydrochloric acid in a ratio of 12:3:1. After soaking for 10 hours, take it out, wash it with absolute alcohol first, and then wash it with deionized water. After natural drying, put it in an oxidation furnace for calcination, and increase the temperature from room temperature to 500 °C at a rate of 36 ° C / min. °C for 90 min and then cooled to room temperature with the furnace to obtain a titanium dioxide matrix. To 0.03mol / L CdCl 2 Add concentrated ammonia water drop by drop until the solution turns from white turbidity to clear again to obtain the cadmium salt impregnation precursor. Put the matrix material into the cadmium salt impregnation precursor solution and soak it for 4.5h, take it out, wash it with deionized ...

Embodiment 2

[0032] Wash the shells of commercially available eggs and peel off the egg membranes. Wash the egg membrane, dry it, and save it for future use. Dip the egg membrane into a solution mixed with tetra-n-butyl titanate, absolute ethanol, and concentrated hydrochloric acid in a ratio of 12:3:1. Take it out after soaking for 10 hours, wash it with absolute alcohol first, then wash it with deionized water, after natural drying, put it in an oxidation furnace for calcination treatment, and raise the temperature from room temperature to 800 °C at a rate of 36 ° C / min °C for 90 min and then cooled to room temperature with the furnace to obtain a titanium dioxide matrix. To 0.03mol / L CdCl 2 Add concentrated ammonia water drop by drop until the solution turns from white turbidity to clear again to obtain the cadmium salt impregnation precursor. Put the matrix material into the cadmium salt impregnation precursor solution and soak it for 4.5h, take it out, wash it with deionized water,...

Embodiment 3

[0034] Wash the shells of commercially available eggs and peel off the egg membranes. Wash the egg membrane, dry it, and save it for future use. Dip the egg membrane into a solution mixed with tetra-n-butyl titanate, absolute ethanol, and concentrated hydrochloric acid in a ratio of 12:3:1. After soaking for 10 hours, take it out, wash it with absolute alcohol first, and then wash it with deionized water. After natural drying, put it in an oxidation furnace for calcination, and increase the temperature from room temperature to 500 at a rate of 18°C / min. °C for 90 min and then cooled to room temperature with the furnace to obtain a titanium dioxide matrix. To 0.03mol / L CdCl 2 Add concentrated ammonia water drop by drop until the solution turns from white turbidity to clear again to obtain the cadmium salt impregnation precursor. Put the matrix material into the cadmium salt impregnation precursor solution and soak it for 4.5h, take it out, wash it with deionized water, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com