Preparation method of controllable multi-morphology microspheres

A technology of microspheres and morphology, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problems of limiting the application, introduction, and cumbersome preparation methods of microspheres, and achieve the effect of simple and flexible preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First, take two 50mL dry screw bottles and add the prepared 2% sodium alginate solution, and then add 2% ferric oxide nanoparticles to one of the bottles, and mix the two bottles of solutions evenly, respectively as a two-phase core shell The inner and outer phases of the microspheres. Take another receiving dish without a cover, add acetic acid aqueous solution containing 2% calcium chloride and 0.15% chitosan, and the solution depth exceeds 1cm, as a receiving bath for microspheres.

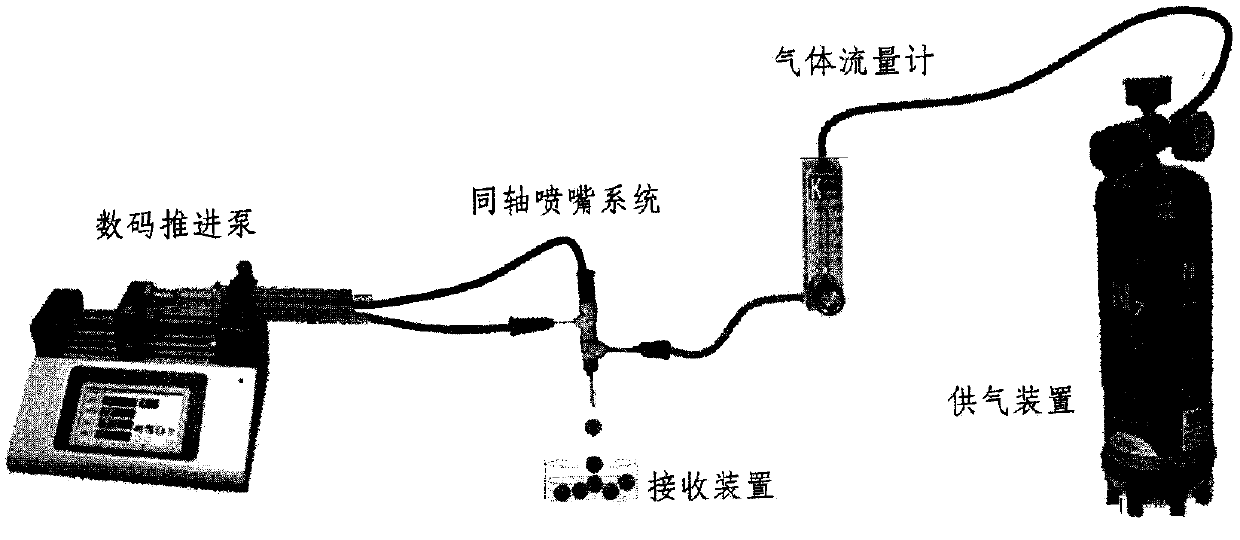

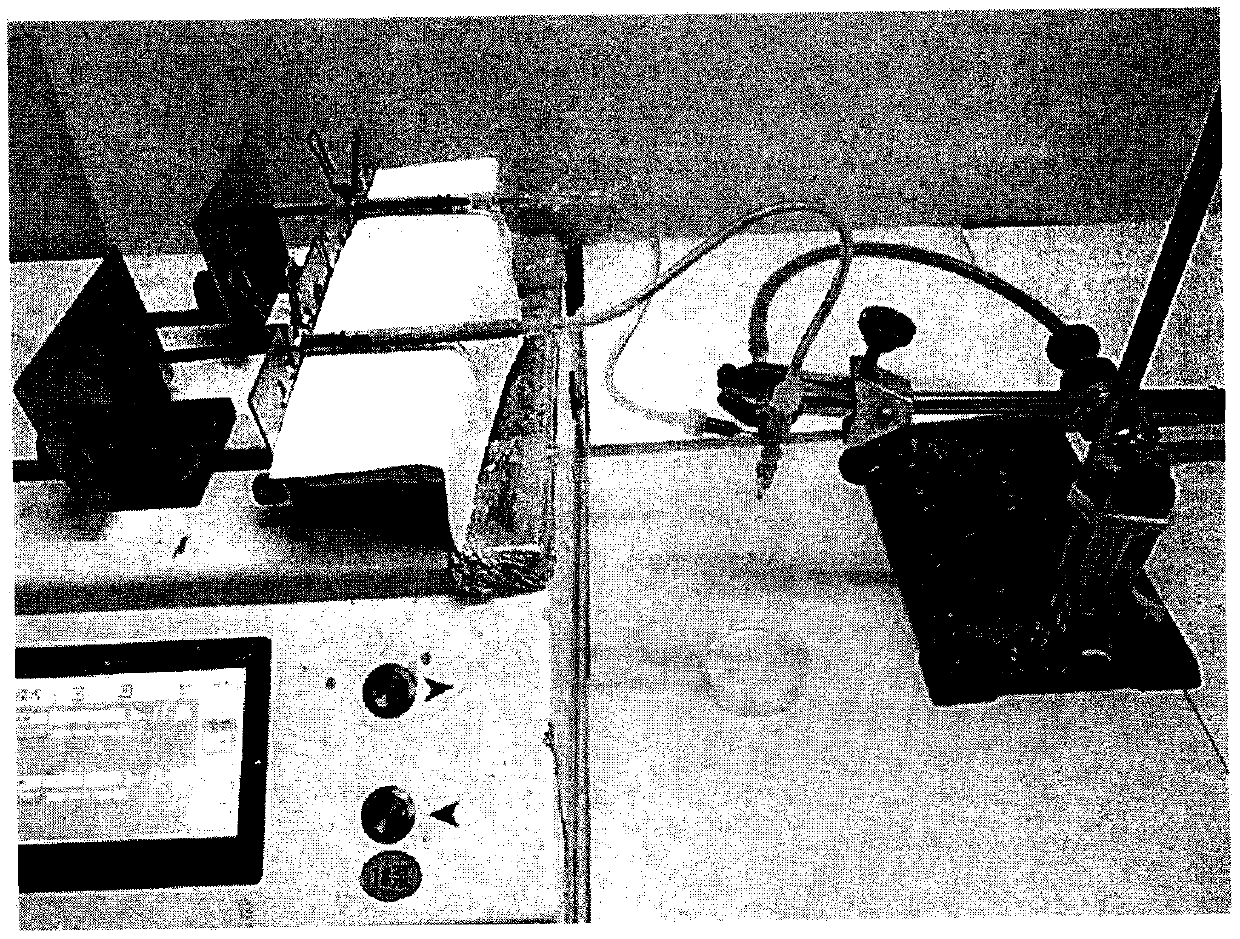

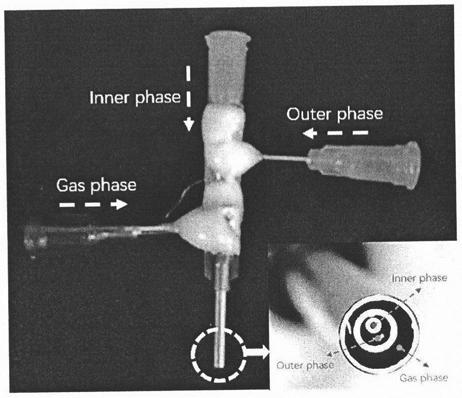

[0027] then follow figure 1 and figure 2 The device for gas-assisted preparation of microspheres was constructed as shown, according to image 3 Prepare a single-core-shell type coaxial nozzle system, add 2% sodium alginate solution containing 2% ferric oxide nanoparticles into the inner phase channel at a rate of 2mL / h, and add 0.5mL / h in the outer phase channel Add a sodium alginate solution that does not contain ferric oxide nanoparticles, and then pass nitrogen gas into the outer...

Embodiment 2

[0029] First, take two 50mL dry screw-top bottles and add the prepared 2% sodium alginate solution, and then add 0.5% iron ferric oxide nanoparticles to one of the bottles, and mix the two bottles of solutions evenly, respectively as a two-phase core-shell The inner and outer phases of the microspheres. Take another receiving dish without a cover, add an aqueous solution containing 2% calcium chloride and 0.15% chitosan, and the solution depth exceeds 1 cm, as a receiving bath for the microspheres.

[0030] then follow figure 1 and figure 2 The device for gas-assisted preparation of microspheres was constructed as shown, according to Figure 4 Prepare the surrounding multi-core-shell coaxial nozzle system, add sodium alginate solution containing 0.5% ferric oxide nanoparticles at a rate of 2mL / h in the inner phase channel, and add 0.5mL sodium alginate solution in the surrounding multi-outer phase channel. The sodium alginate solution that does not contain ferric oxide nan...

Embodiment 3

[0032] First, take three 50mL dry screw bottles and add the prepared 2% sodium alginate solution, then add 2% ferric oxide nanoparticles to one bottle, and add 0.8% iron ferric oxide nanoparticles to the other bottle , the last bottle does not add iron ferric oxide nanoparticles, and the solutions in the three bottles are uniformly mixed separately, as different phases of the core-shell microspheres. Take another receiving dish without a cover, add an aqueous solution containing 2% calcium chloride and 0.15% chitosan, and the solution depth exceeds 1 cm, as a receiving bath for the microspheres.

[0033] then follow figure 1 and figure 2 The device for gas-assisted preparation of microspheres was constructed as shown, according to image 3 Prepare a single core-shell type coaxial nozzle system, add sodium alginate solution containing 0.8% iron ferric oxide nanoparticles at a rate of 1mL / h in the inner phase channel, and add 0.5mL / h of sodium alginate solution in the outer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com