Patents

Literature

119 results about "Coaxial nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

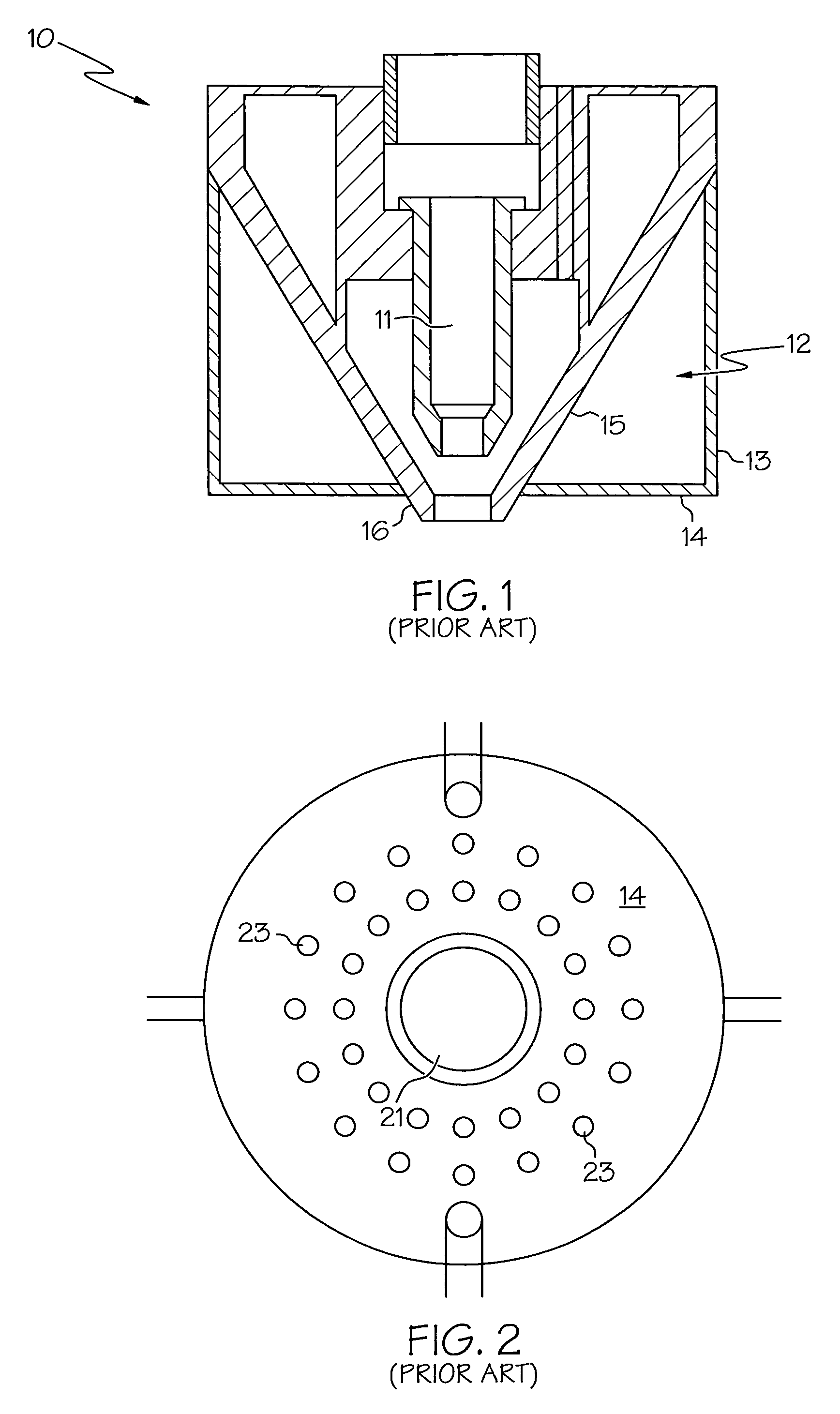

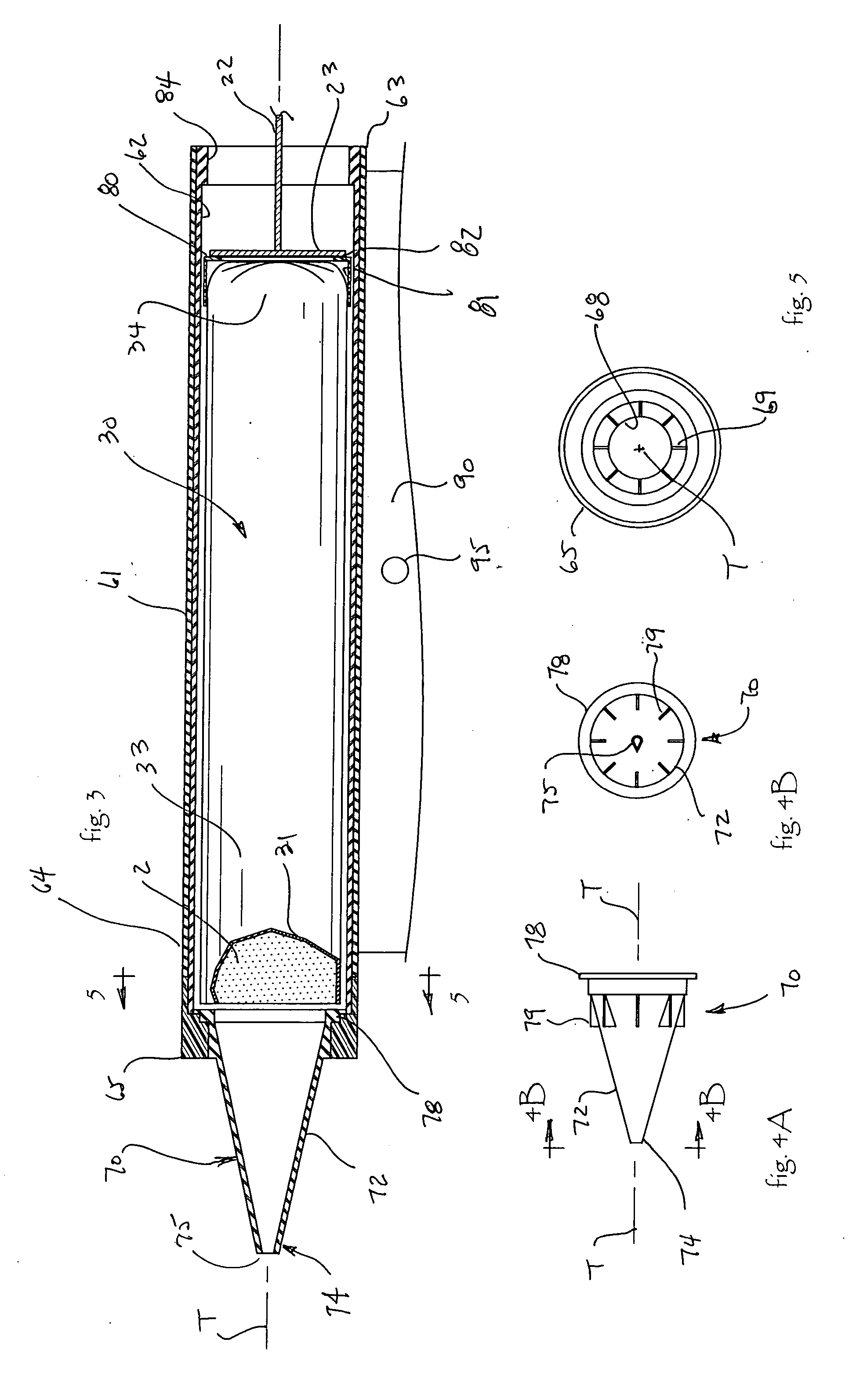

Coaxial nozzle design for laser cladding/welding process

InactiveUS20050056628A1Reliably-symmetric powder flowLong-term useLaser beam welding apparatusLaser NozzleShielding gas

A laser nozzle for use in a laser powder fusion (LPF) welding process provides longer service life and ease of maintenance. Eliminating the use of laser nozzle inserts, the laser nozzle uses an inner tip that is less subject to damage from the welding process. The laser beam travels down an open central passage to exit out the inner tip in focused alignment with a conical powder flow stream ending in a point generally coincident with the laser beam. The powder supply travels through a passage that is generally coaxial to the central laser passage. A circumscribing passage for inert shielding gas or the like is coincidentally coaxial with both the laser powder flow channel and the central laser channel. Coolant is circulated through a main body portion of the nozzle in order to keep the entire assembly cool. Both the laser and the flow of powder may be adjusted according to operating preferences. A porous shielding cover prevents ejecta and other materials from entering into the shielding gas flow channel. The entire assembly is easily constructed from readily available materials and is easily disassembled for cleaning. Reassembly is also easily achieved in order to enable rapid refurbishment and reconstitution of an optimal LPF welding nozzle.

Owner:HONEYWELL INT INC

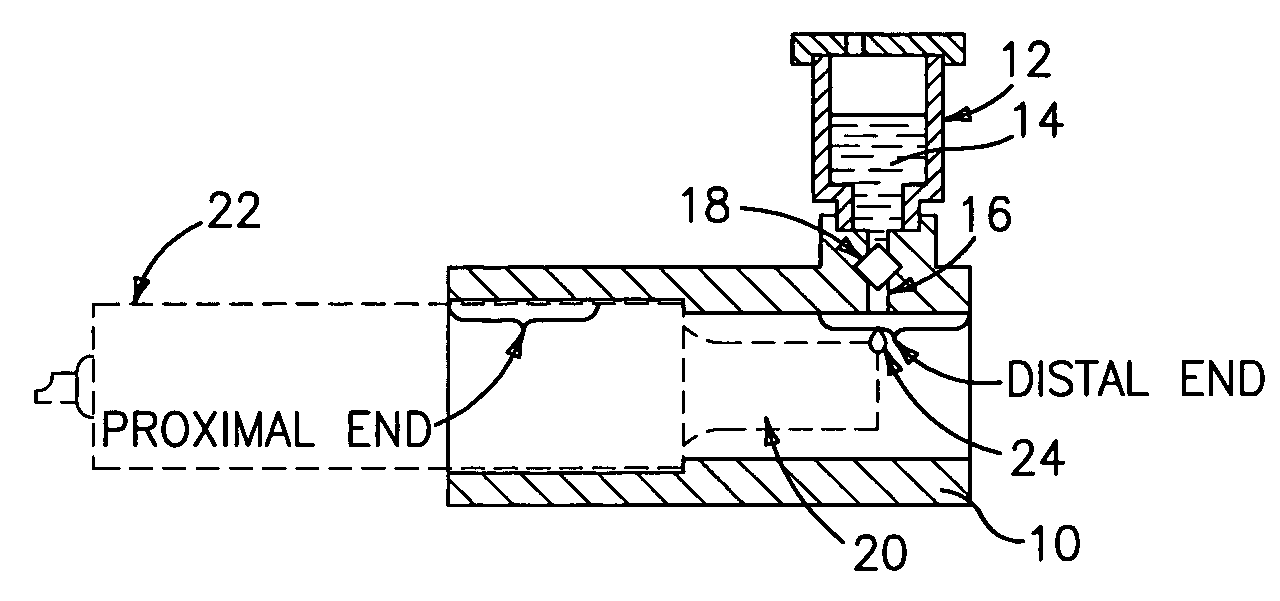

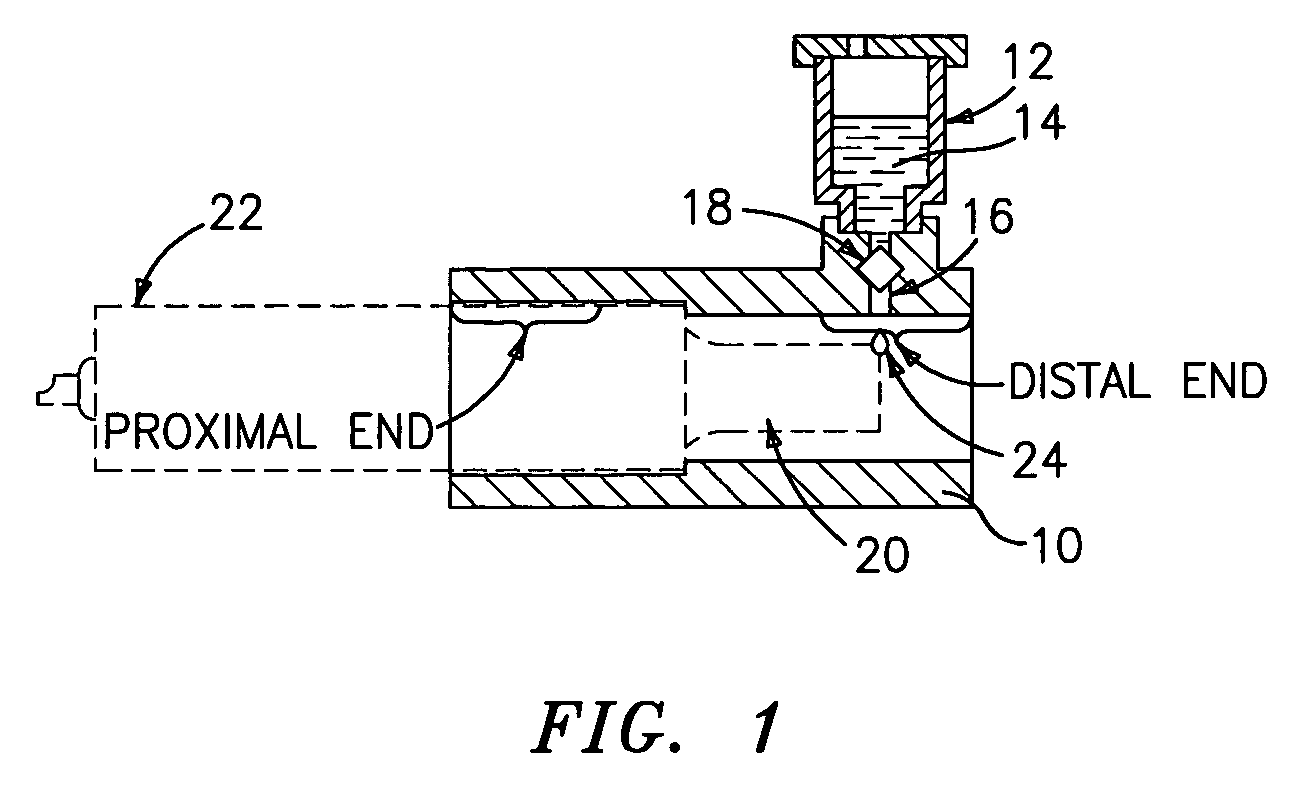

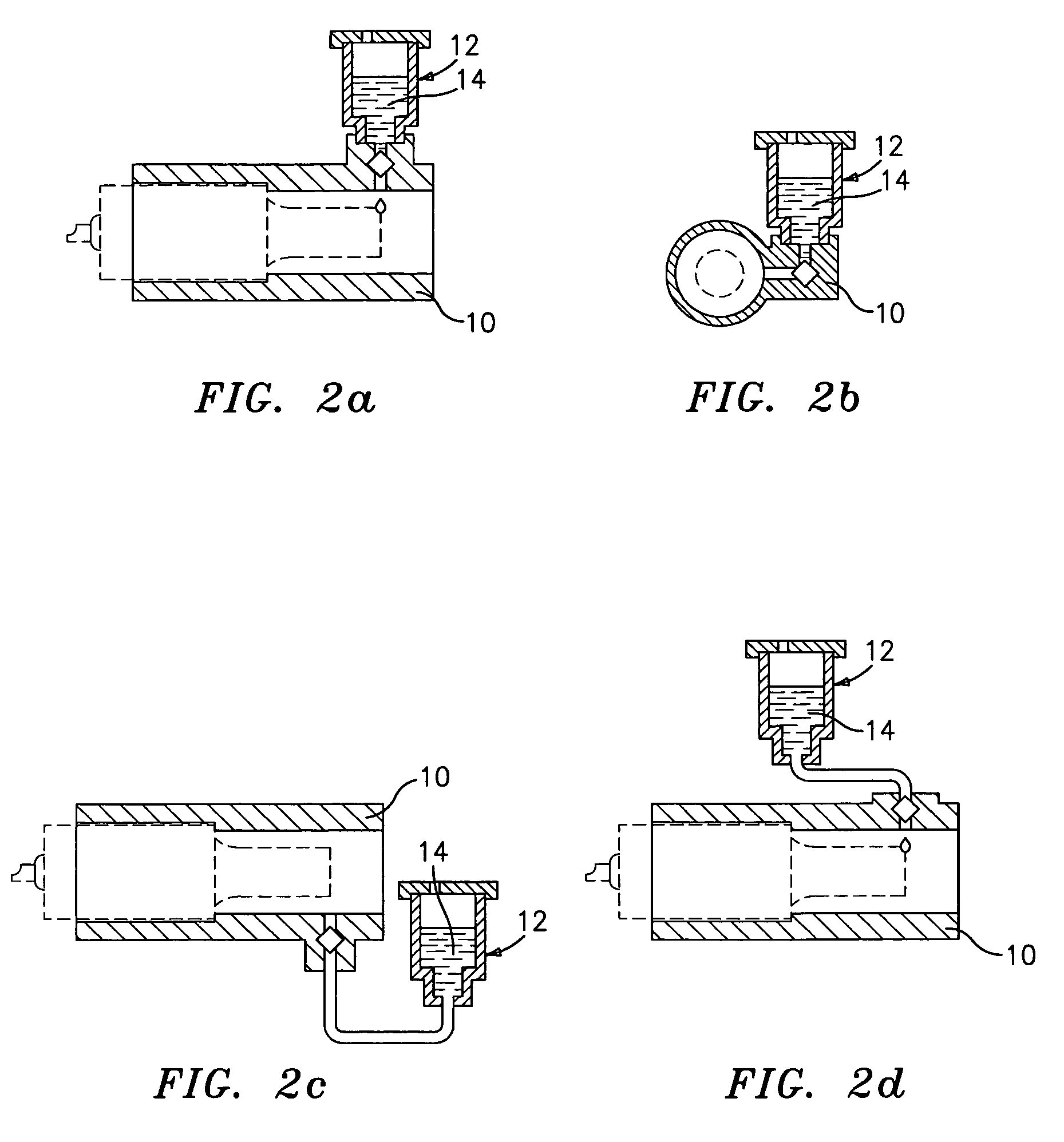

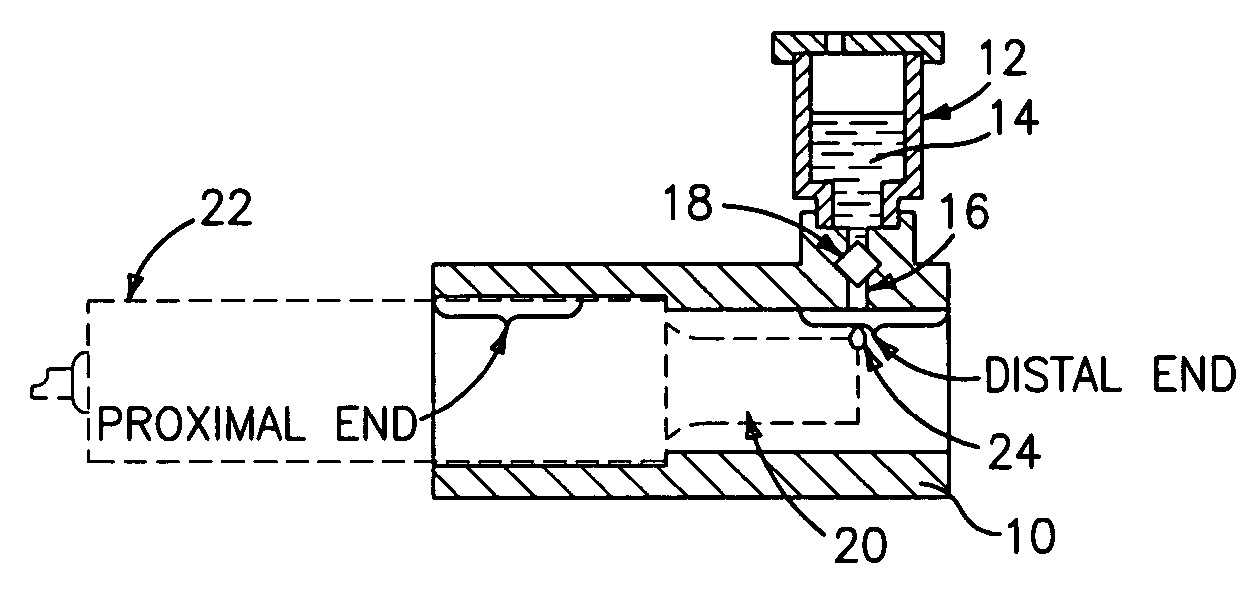

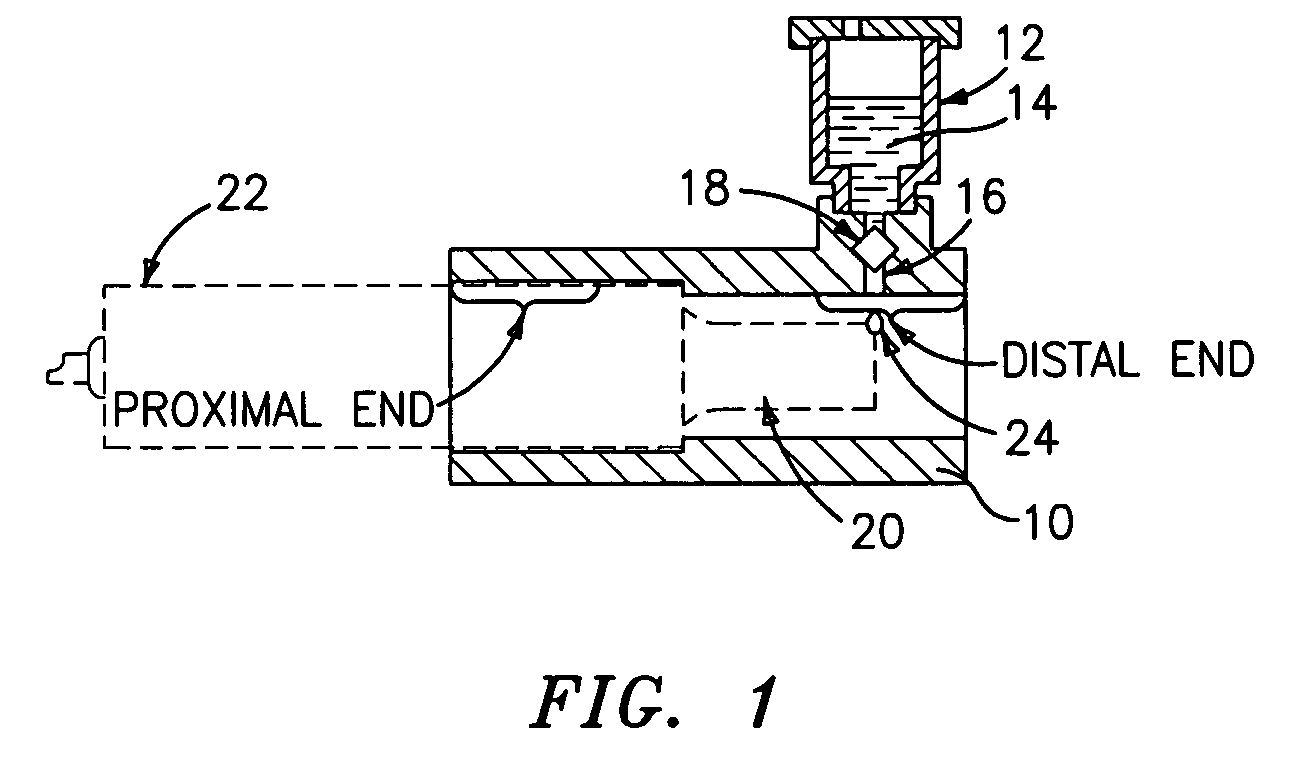

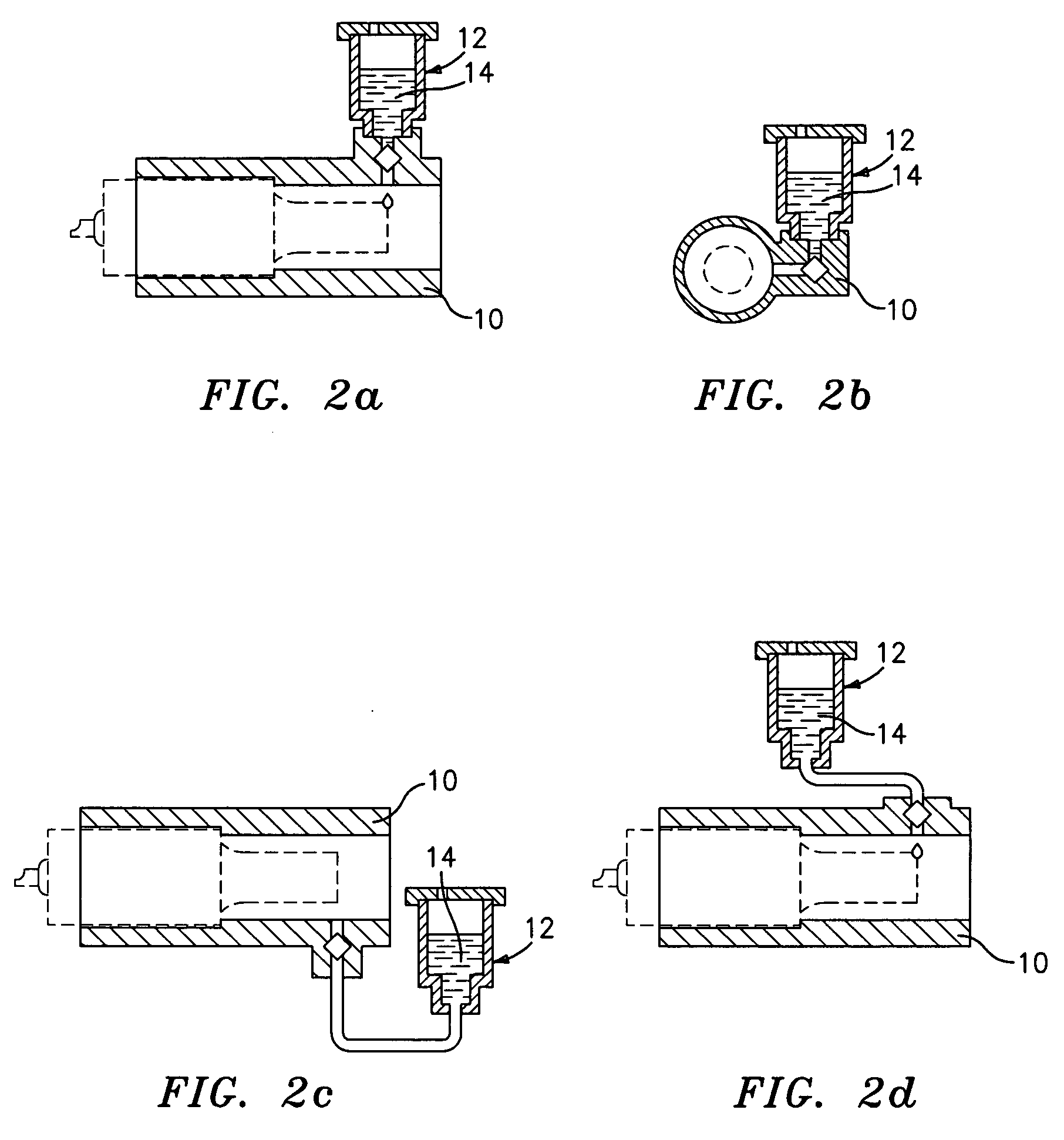

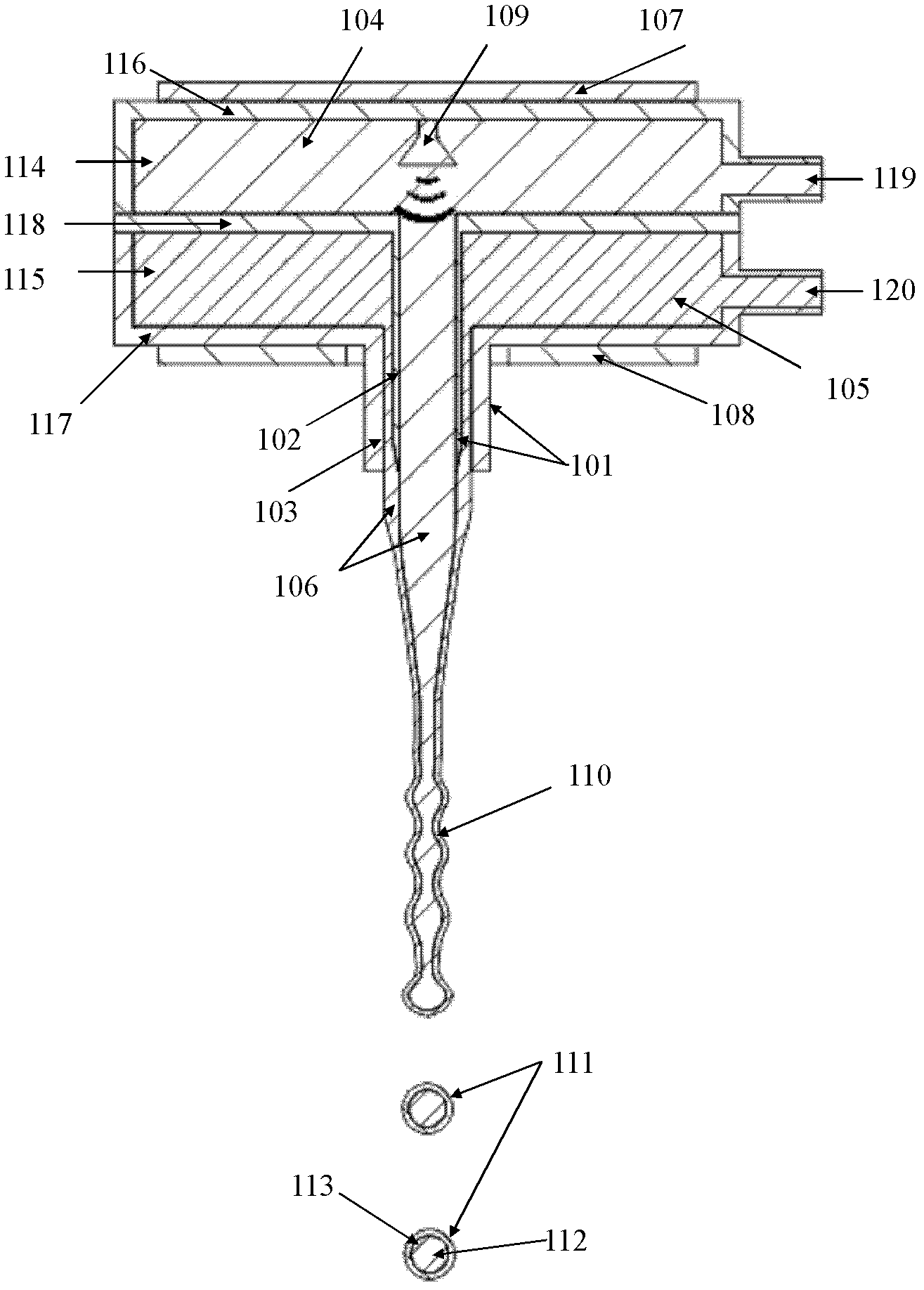

Nozzle for ultrasound wound treatment

A nozzle for ultrasound wound treatment comprising a main body with proximal and distal ends, a reservoir and valve. The proximal end of the nozzle being removably attached to an ultrasound transducer. The distal end of the nozzle being marginally close and coaxial to the free distal end of the ultrasound transducer. The body of the nozzle connected with liquid reservoir, which holds the wound treatment solution and delivers same to the free end of ultrasound tip directly or through a tube. The nozzle is provided with valve for controlling flow rate of wound treatment solution. The nozzle can mix different liquids or a liquid with a gas and deliver same to the wound surface.The nozzle can also be provided with trigger system for one hand use. The present invention is a device, using ultrasonic waves to create, direct and deliver liquid treatment spray to a wound surface.

Owner:SANUWAVE HEALTH INC

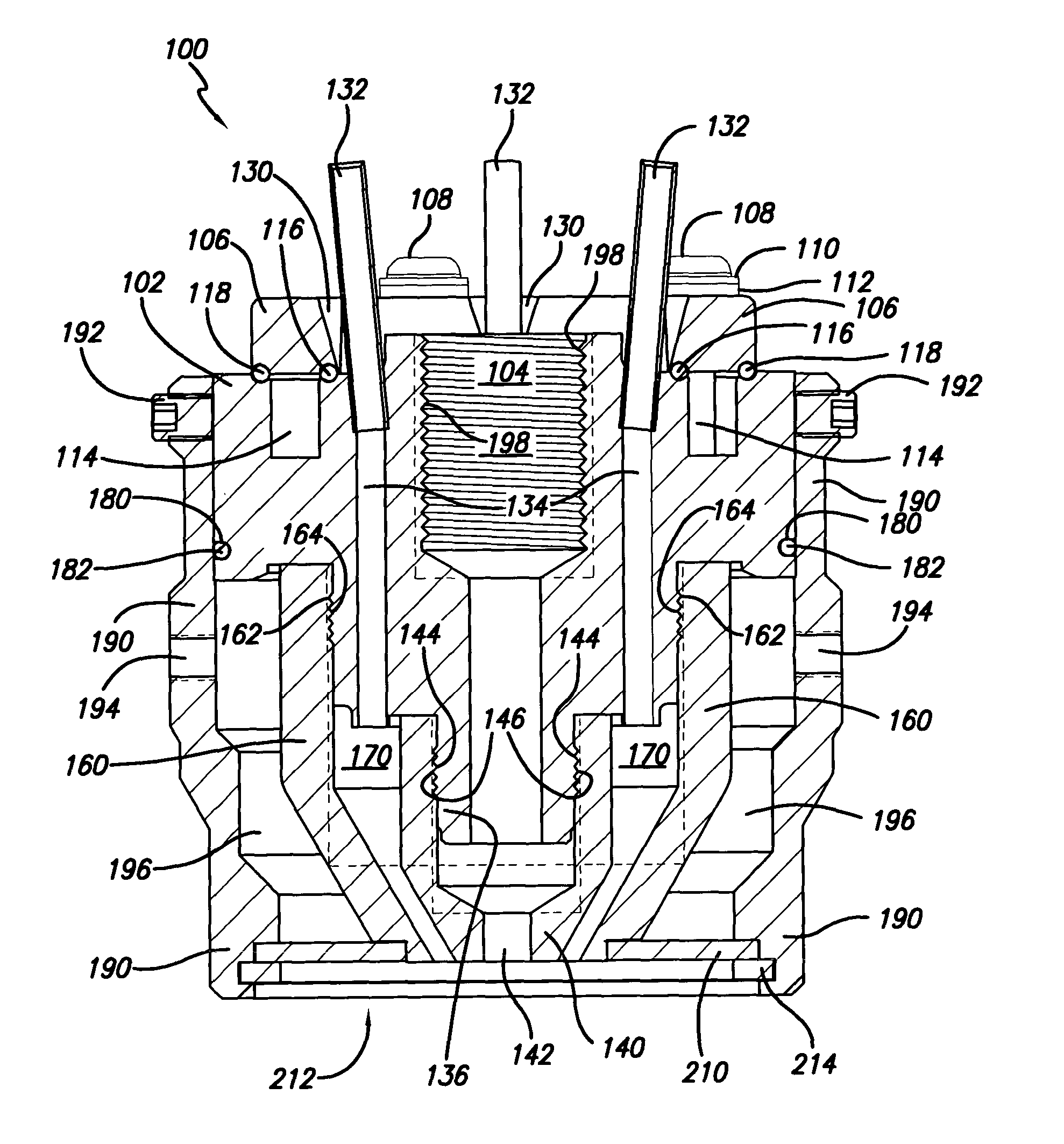

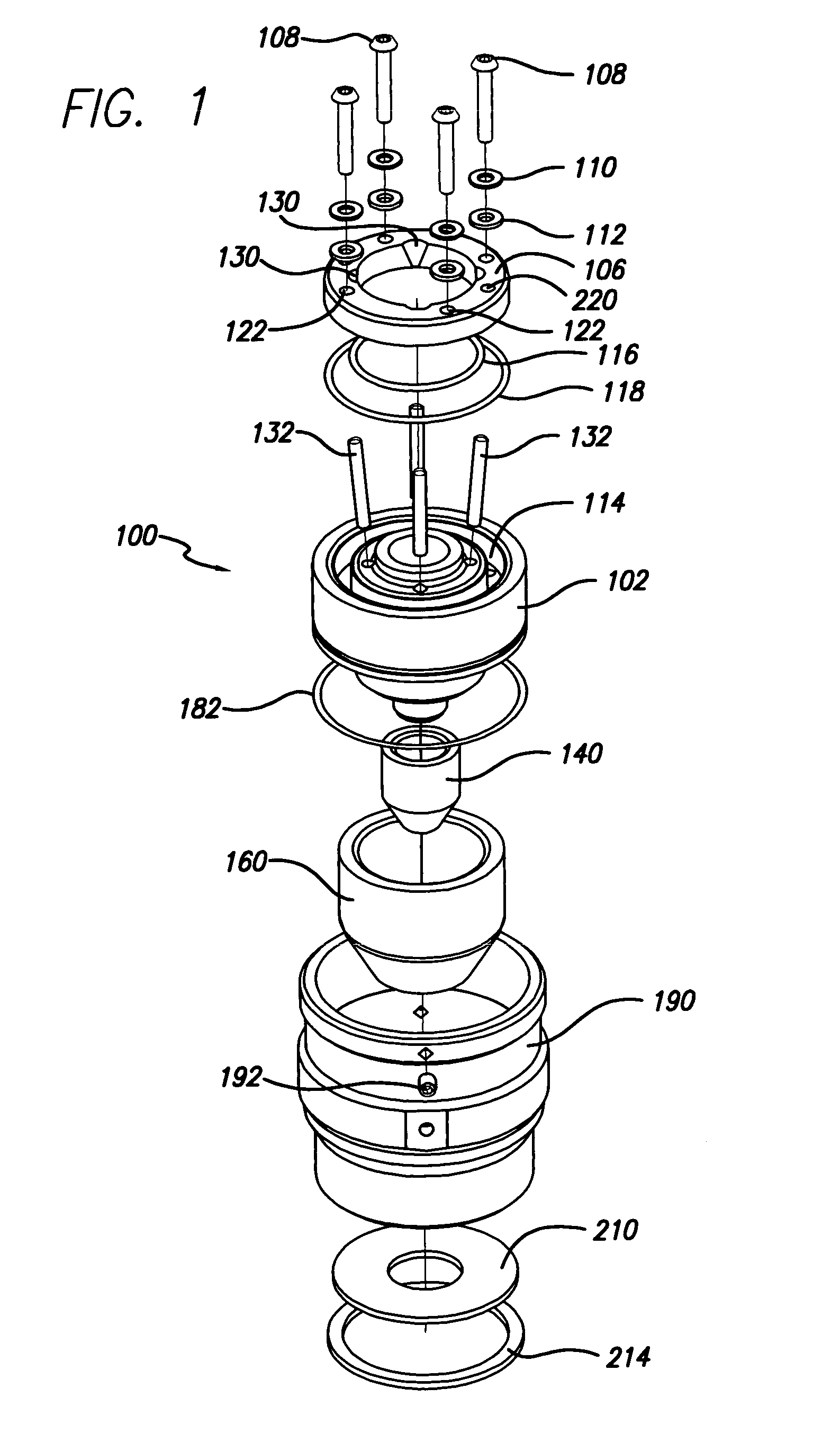

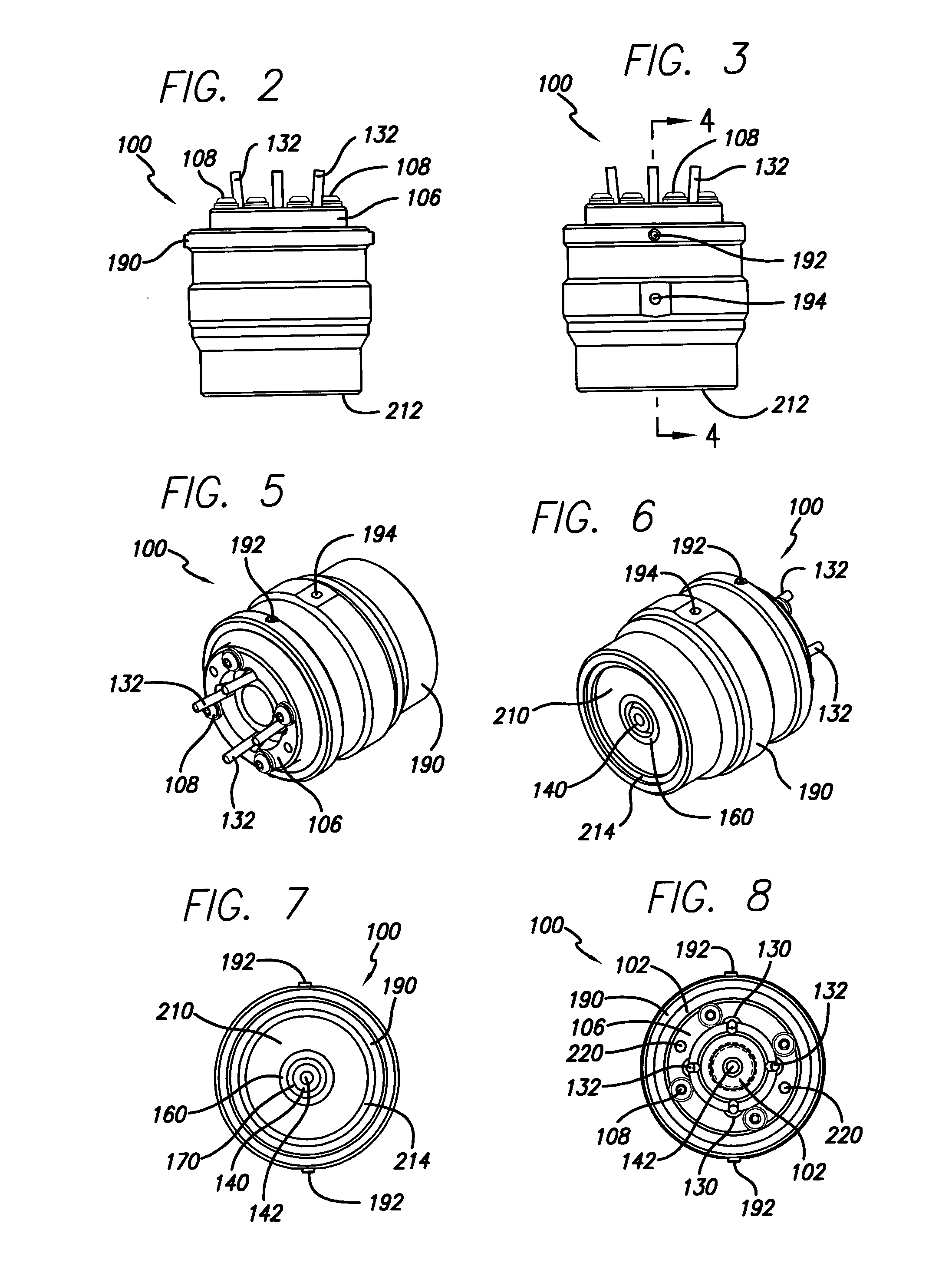

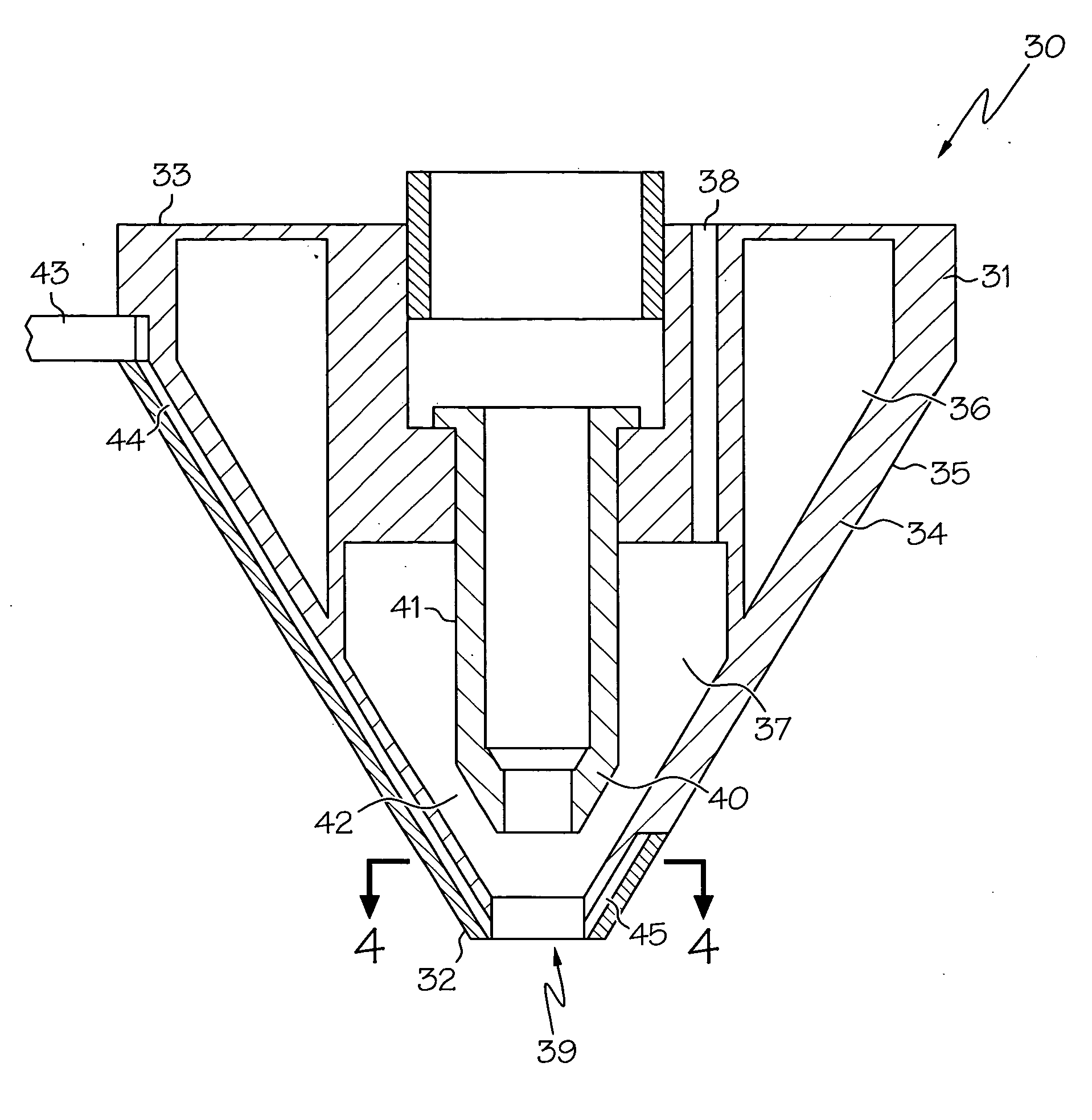

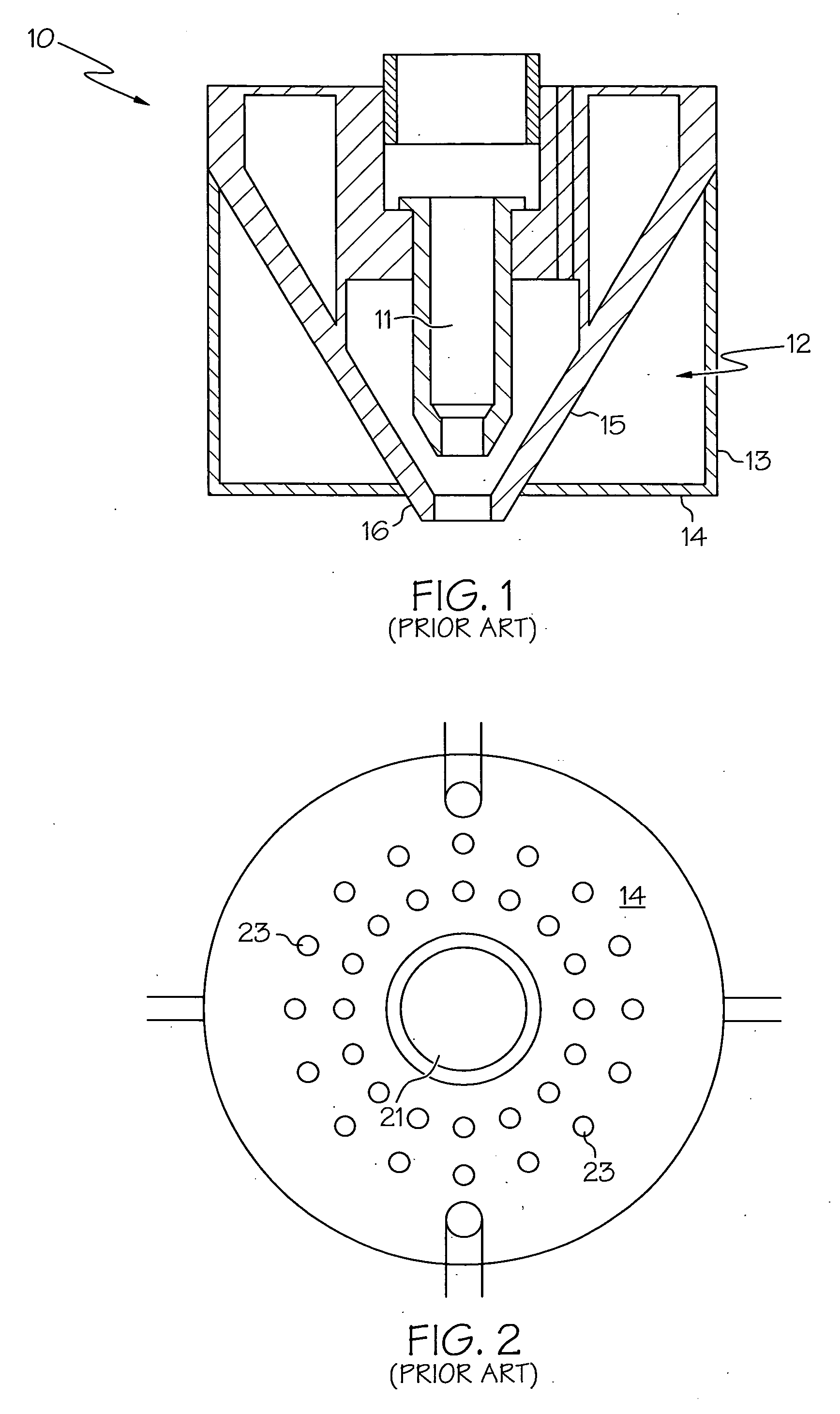

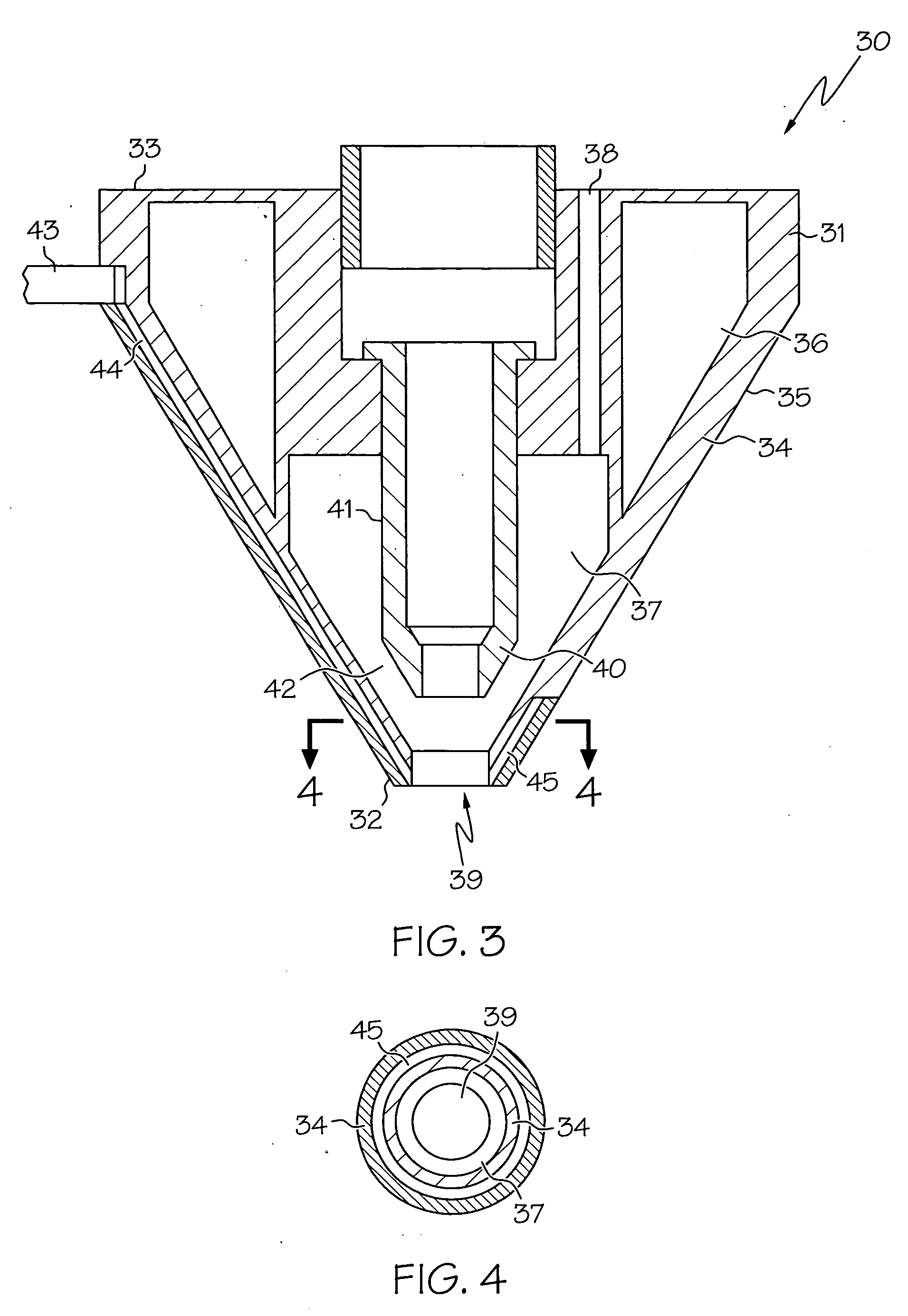

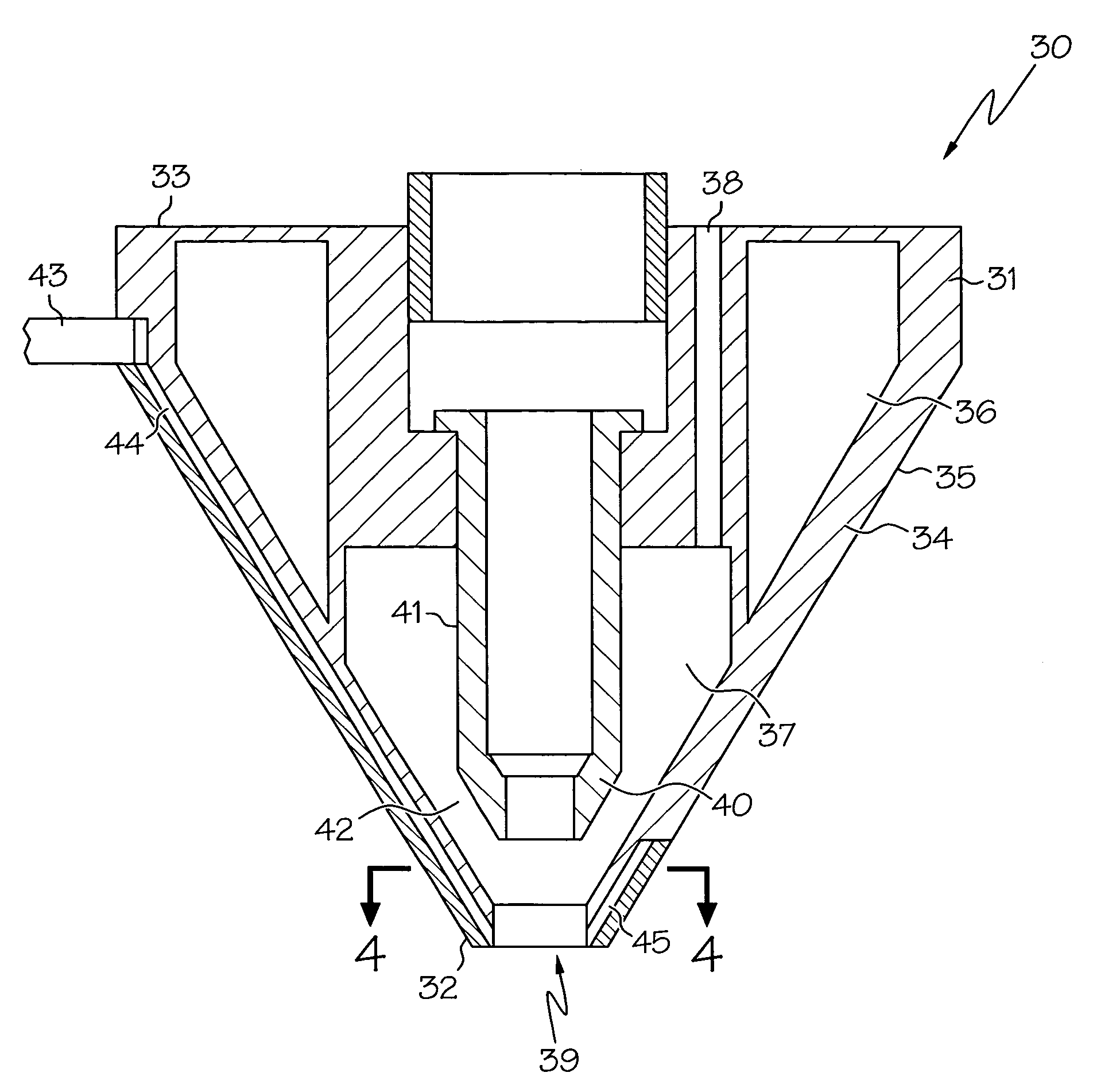

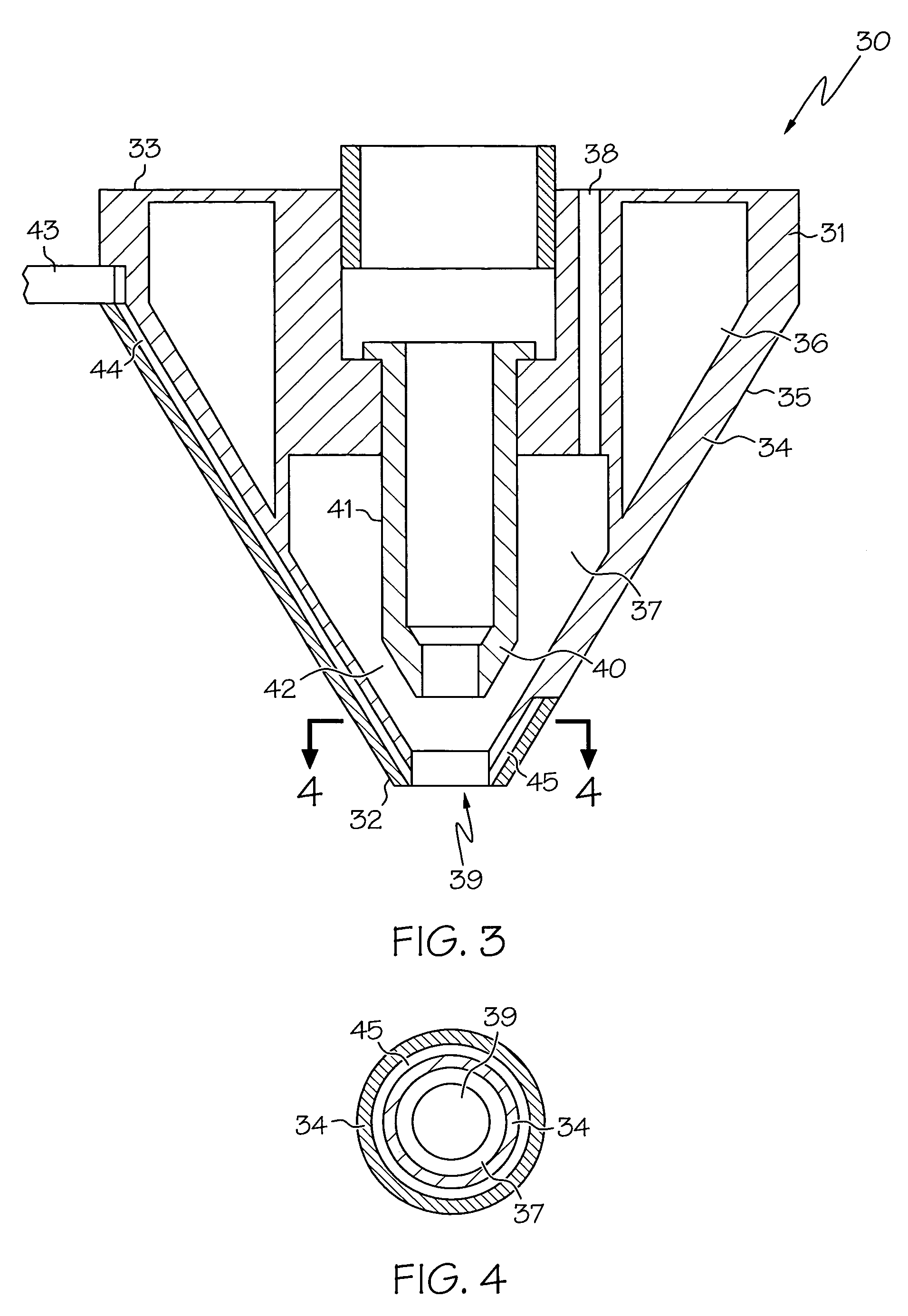

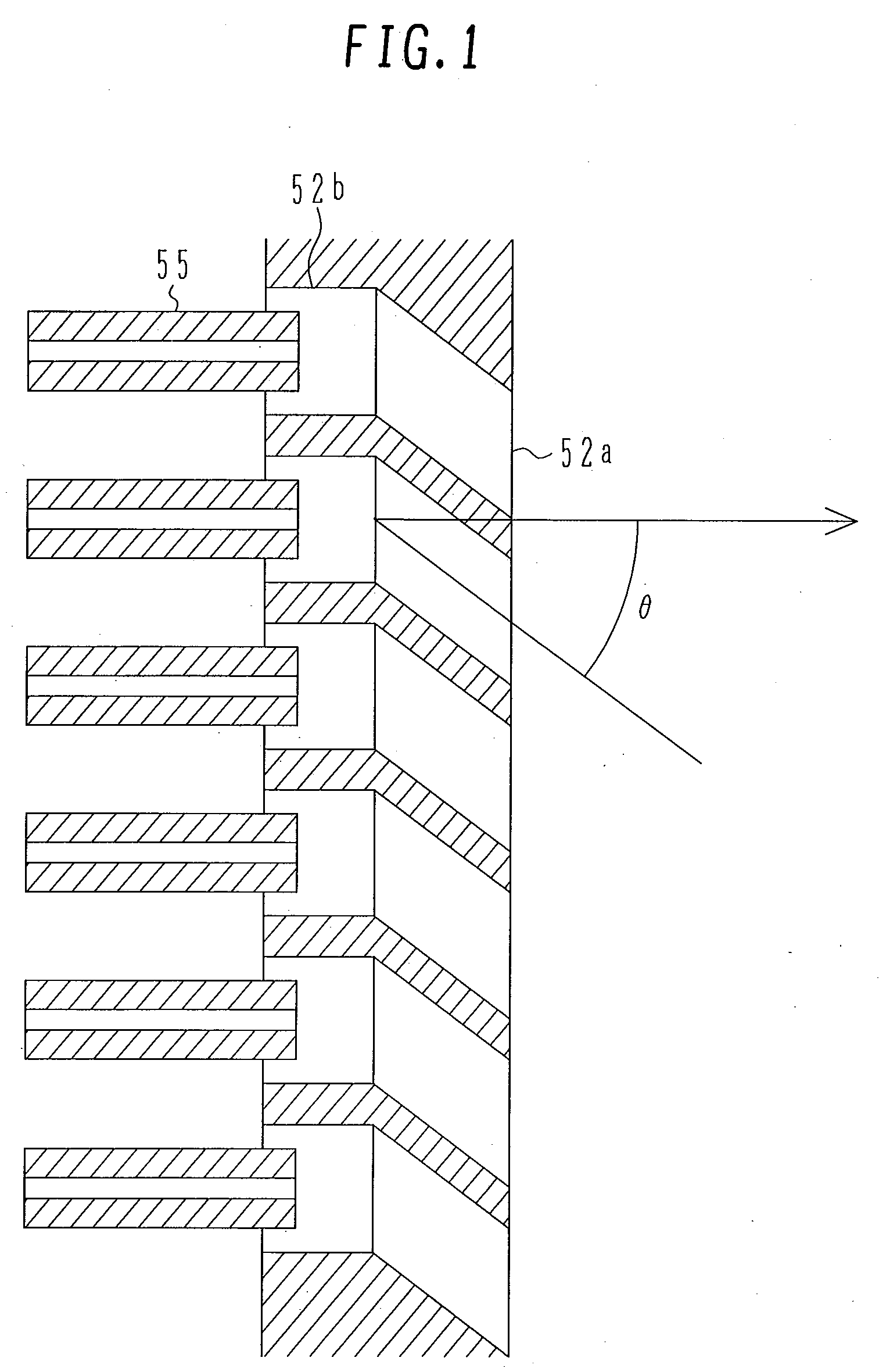

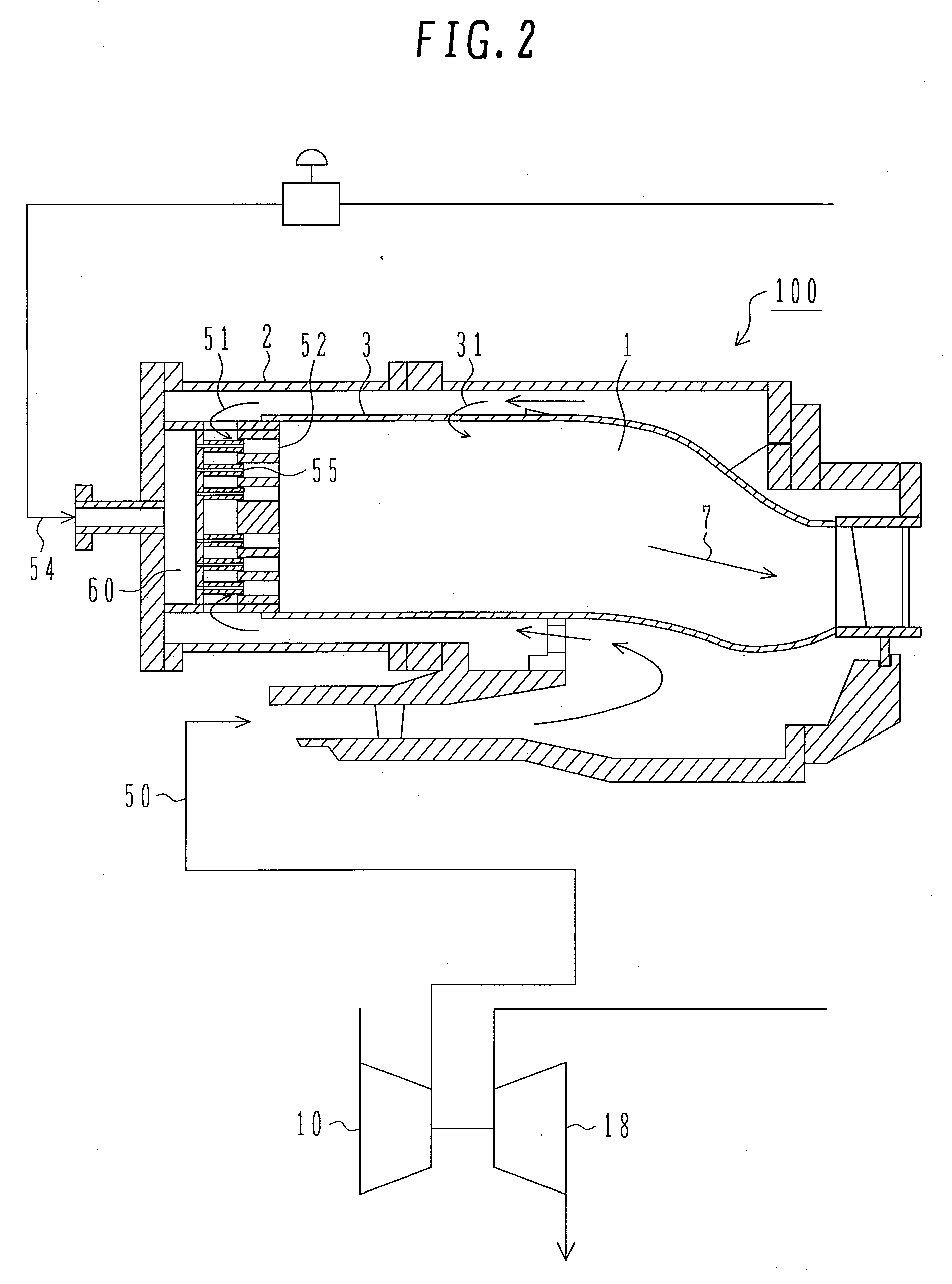

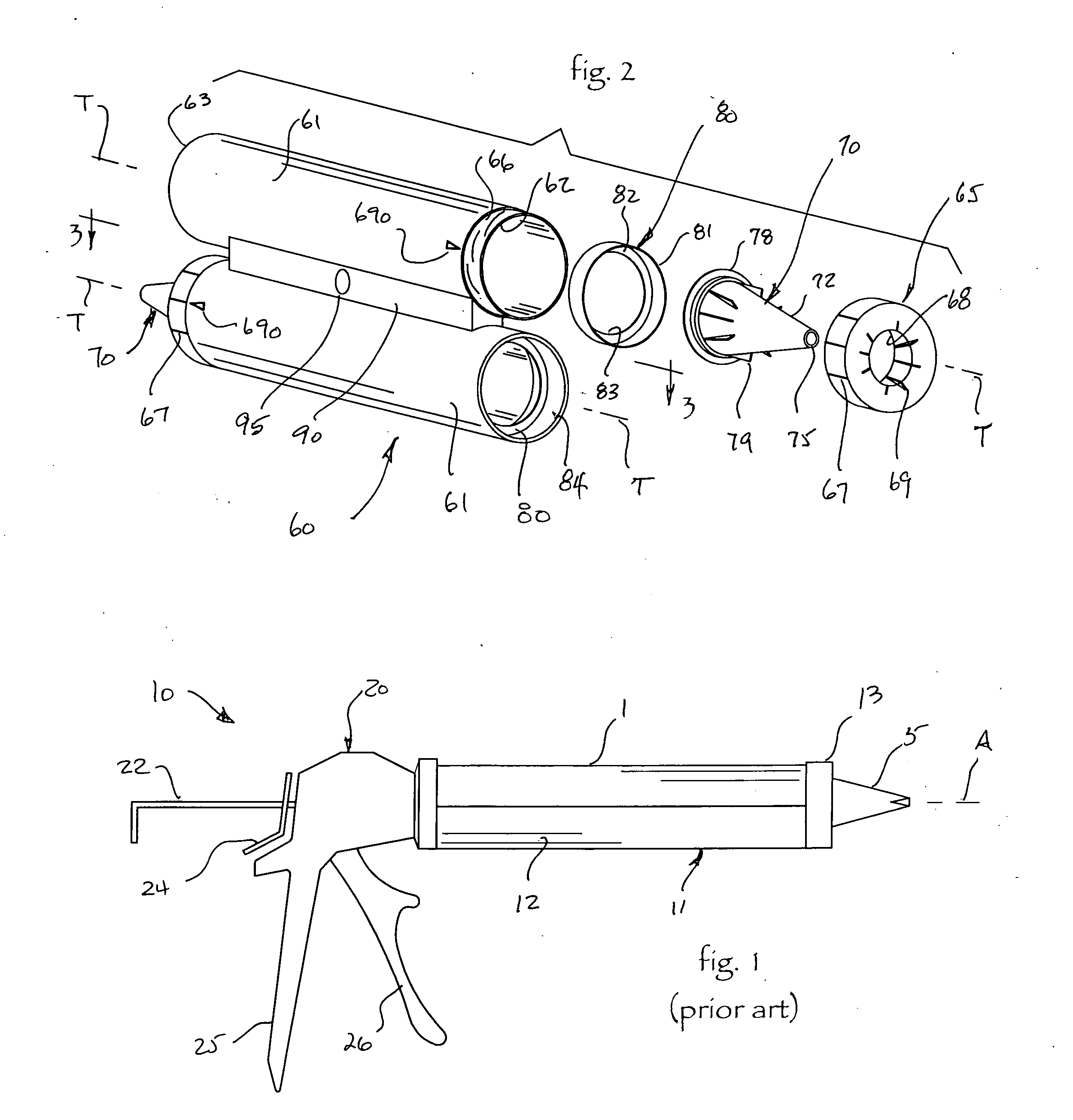

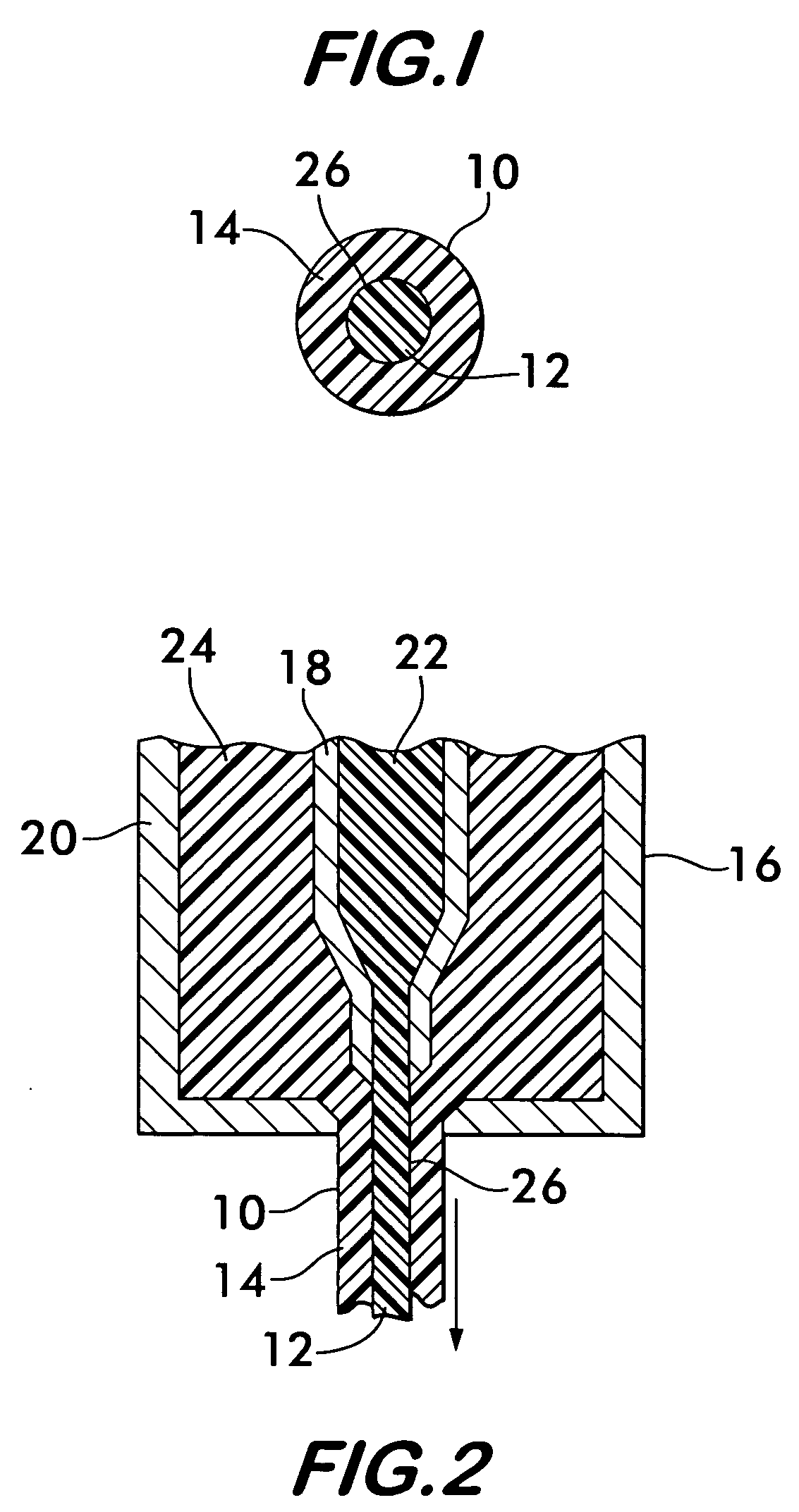

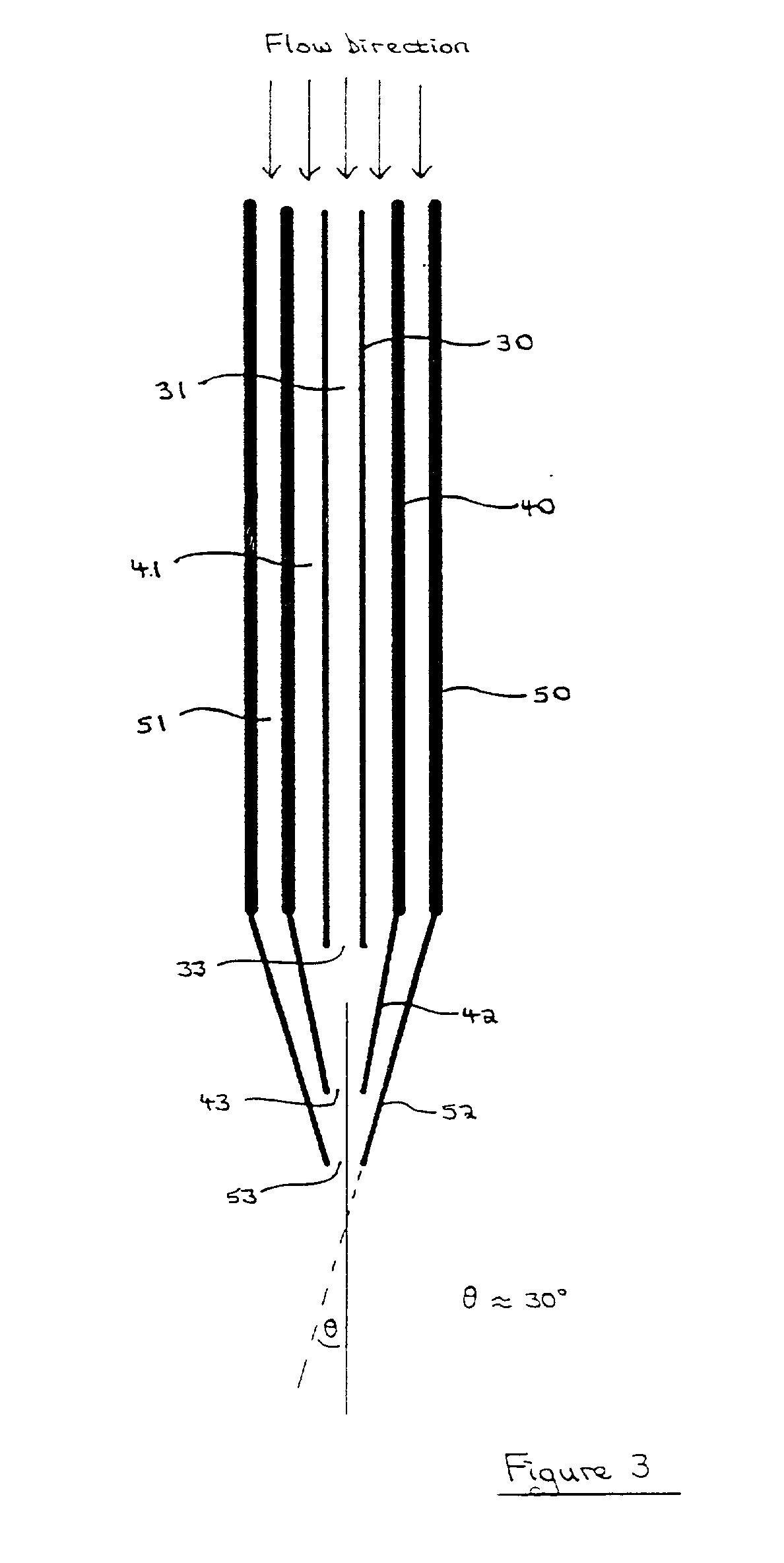

Compact coaxial nozzle for laser cladding

The present invention provides a compact coaxial nozzle useful in laser welding operations where the welding piece has a restricted or confined geometry. The nozzle is generally conical in shape, terminating in a relatively small tip. The nozzle includes a central laser discharge opening. The conical shape allows movement of the nozzle in confined areas. The nozzle includes a cooling jacket for proving coolant to the nozzle. The nozzle also includes a powder mixing chamber that provides good mixing of powdered filler material with a coaxial discharge around the laser. Finally, the nozzle further provides for inert gas to pass from an upper inlet, through passageways, out of a ring discharge. The ring discharge is also coaxially disposed around the central laser. Further the ring discharge provides mixing of the inert gas in order to minimize turbulent flow problems associated with restrictor plates.

Owner:HONEYWELL INT INC

Compact coaxial nozzle for laser cladding

InactiveUS7259353B2Quality improvementUse performanceLaser beam welding apparatusFilling materialsEngineering

The present invention provides a compact coaxial nozzle useful in laser welding operations where the welding piece has a restricted or confined geometry. The nozzle is generally conical in shape, terminating in a relatively small tip. The nozzle includes a central laser discharge opening. The conical shape allows movement of the nozzle in confined areas. The nozzle includes a cooling jacket for proving coolant to the nozzle. The nozzle also includes a powder mixing chamber that provides good mixing of powdered filler material with a coaxial discharge around the laser. Finally, the nozzle further provides for inert gas to pass from an upper inlet, through passageways, out of a ring discharge. The ring discharge is also coaxially disposed around the central laser. Further the ring discharge provides mixing of the inert gas in order to minimize turbulent flow problems associated with restrictor plates.

Owner:HONEYWELL INT INC

Nozzle for ultrasound wound treatment

A nozzle for ultrasound wound treatment comprising a main body with proximal and distal ends, a reservoir and valve. The proximal end of the nozzle being removably attached to an ultrasound transducer. The distal end of the nozzle being marginally close and coaxial to the free distal end of the ultrasound transducer. The body of the nozzle connected with liquid reservoir, which holds the wound treatment solution and delivers same to the free end of ultrasound tip directly or through a tube. The nozzle is provided with valve for controlling flow rate of wound treatment solution. The nozzle can mix different liquids or a liquid with a gas and deliver same to the wound surface. The nozzle can also be provided with trigger system for one hand use. The present invention is a device, using ultrasonic waves to create, direct and deliver liquid treatment spray to a wound surface.

Owner:CELLERATION INC

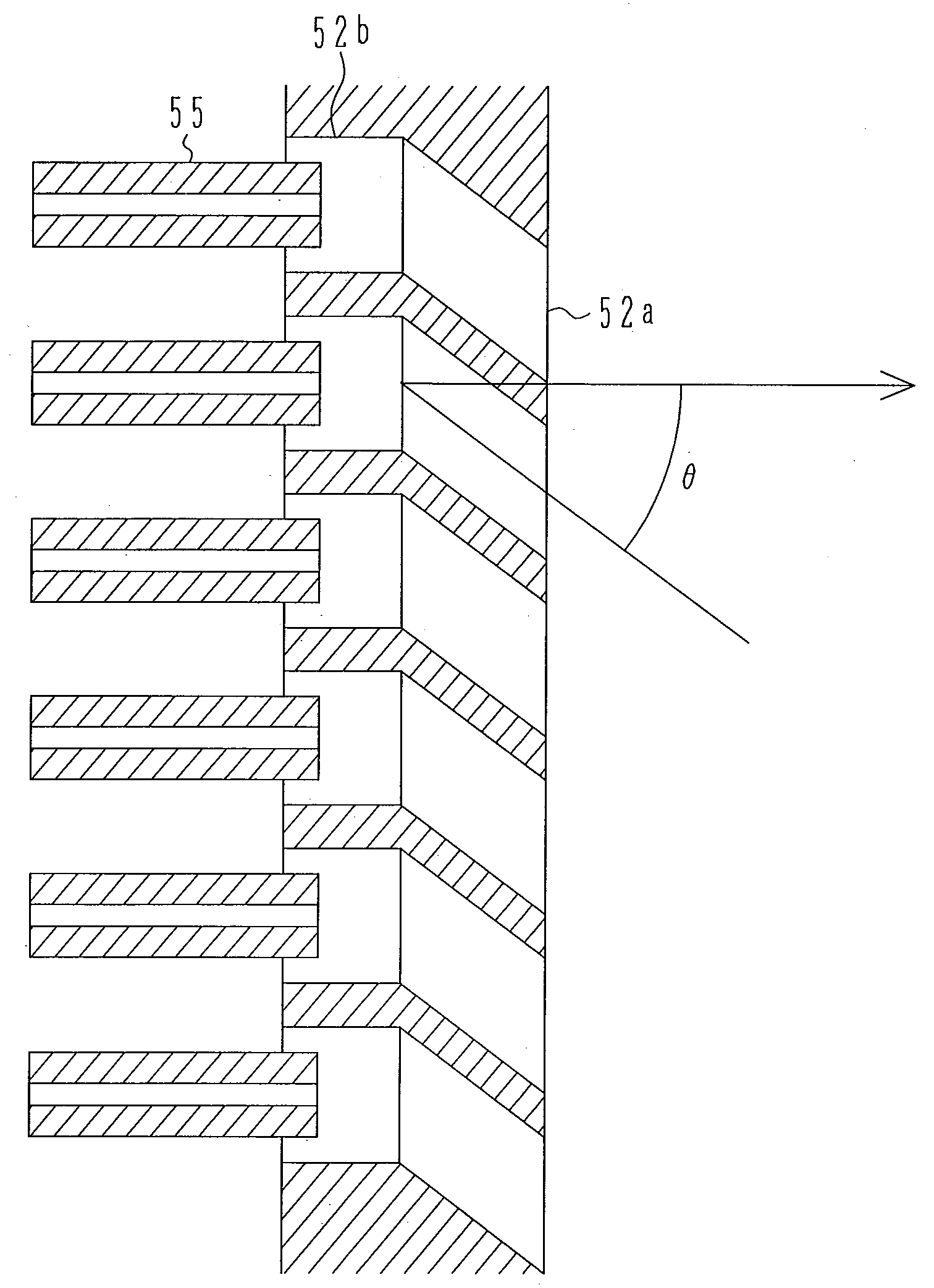

Gas turbine combustor and method for supplying fuel to the same

InactiveUS20090293484A1Reduce NOxContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberCombustor

A fuel flow path and a flow path of air for combustion are disposed coaxially to create a coaxial jet such that a fuel flow is embraced by an air flow. A large number of such fuel flow paths and air flow paths are arranged in a wall surface of a combustion chamber to create coaxial nozzle jets. Some of the flow paths of air for combustion are arranged inclinedly so as to create rotation for the stabilization of combustion and straight portions not having an inclination angle are added respectively to upstream ends of such inclined air flow paths. Fuel is jetted toward or within the straight portions.

Owner:HITACHI LTD

Laser welding seam coaxial blowing protection device and application method

ActiveCN105772942ASimple structureImprove protectionLaser beam welding apparatusWeld seamEngineering

The invention relates to the technical field of laser welding, and discloses a laser welding seam coaxial blowing protection device and an application method. The protection device comprises a coaxial nozzle, an annular gas hood, a lower cavity, an upper cavity, first air inlet nozzles and second air inlet nozzles; the upper cavity, the lower cavity, the annular gas hood and the coaxial nozzle are sequentially and coaxially mounted fixedly; a boss end of the lower cavity is arranged in a through hole of the annular gas hood; the coaxial nozzle is arranged in the boss end of the lower cavity, and an annular gas seam communicated with a gas groove is formed between the coaxial nozzle and an interlayer end; the protection device is applied to a welding device, the protection device and laser are coaxially arranged, a laser beam sent out by a welding head passes through the protection device firstly and then acts on a workpiece to be welded, the protection device is additionally arranged in the welding device, and reliability of welding of the workpiece to be welded can be ensured; and in the welding process of the workpiece to be welded, air can be exhausted, welding seam oxidation caused by air involving can be prevented, and the high-temperature welding seam can be subject to delay protection.

Owner:HANS LASER TECH IND GRP CO LTD

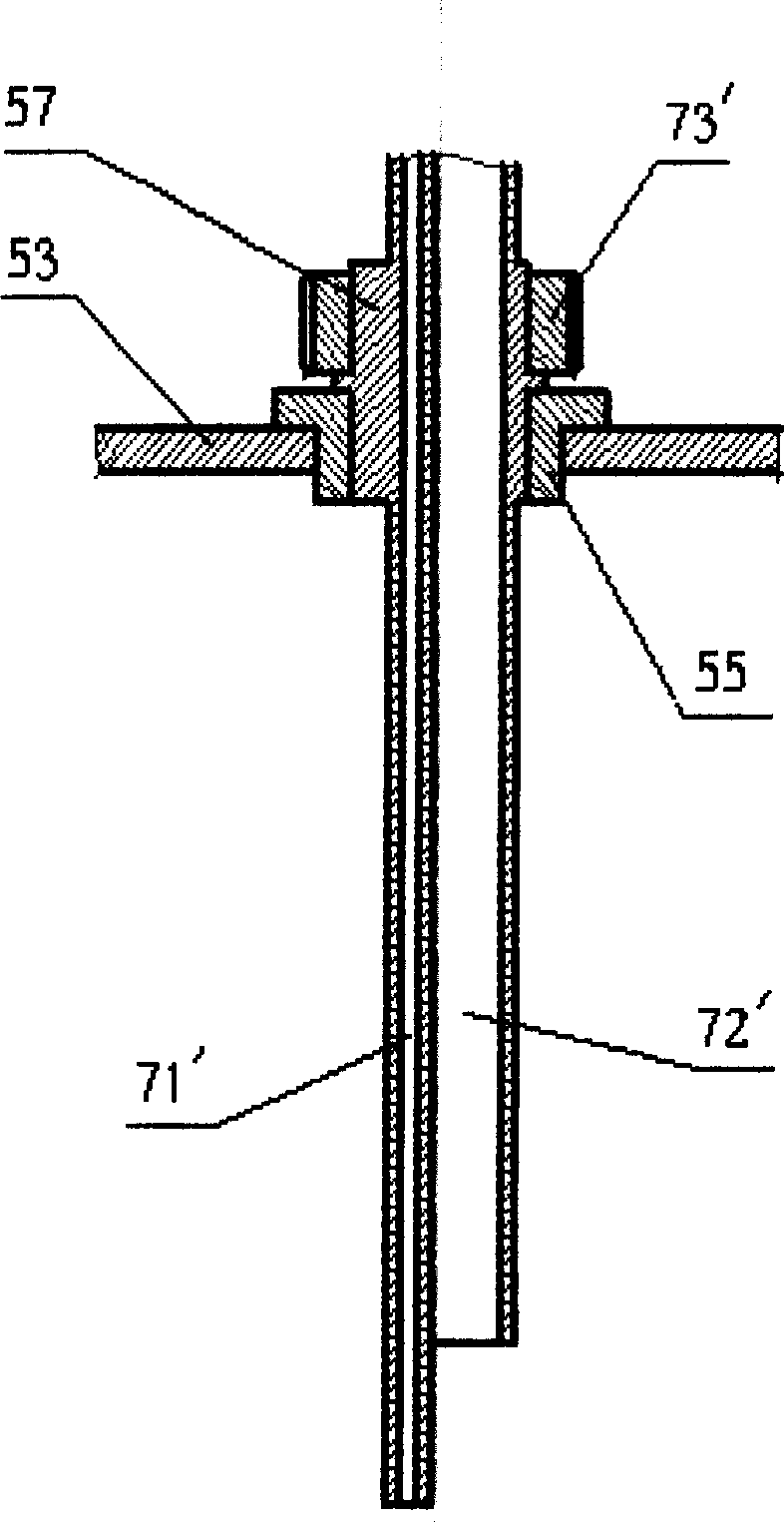

Coaxial nozzle for electrofluid spray printing

ActiveCN103911678AMake up for the defect of insufficient control precisionMeet structural needsFilament/thread formingEngineeringCoaxial nozzle

The invention discloses a coaxial nozzle for electrofluid spray printing. The coaxial nozzle comprises an outer nozzle and an inner nozzle. An axle hole is formed in the bottom of the outer nozzle and is connected with a connecting seat in a sleeved manner, an axial stepped hole is formed in the connecting seat, a base of the inner nozzle is sleeved in the stepped hole, a centring support is sleeved in the inner barrel, close to one side of the spout, of the outer nozzle, one end of an inner spraying needle is fixed on the base of the inner nozzle while the other end of the same penetrates a positioning through hole of the centring support to be fixed, a piezoelectric ceramic driver is connected to the outer wall of the connecting seat in a sleeved manner and is fixedly connected with an outer spraying barrel. The relative height of the inner nozzle and the outer nozzle can be precisely adjusted through the piezoelectric ceramic driving device, relative flow rate of different fluid in the inner and outer layers can be precisely controlled, the structural thickness of each 'shell' layer of coaxial spinning can be more precisely controlled, and coaxial centring precision of the inner and outer nozzles can be improved by the arrangement of the centring support.

Owner:HUAZHONG UNIV OF SCI & TECH

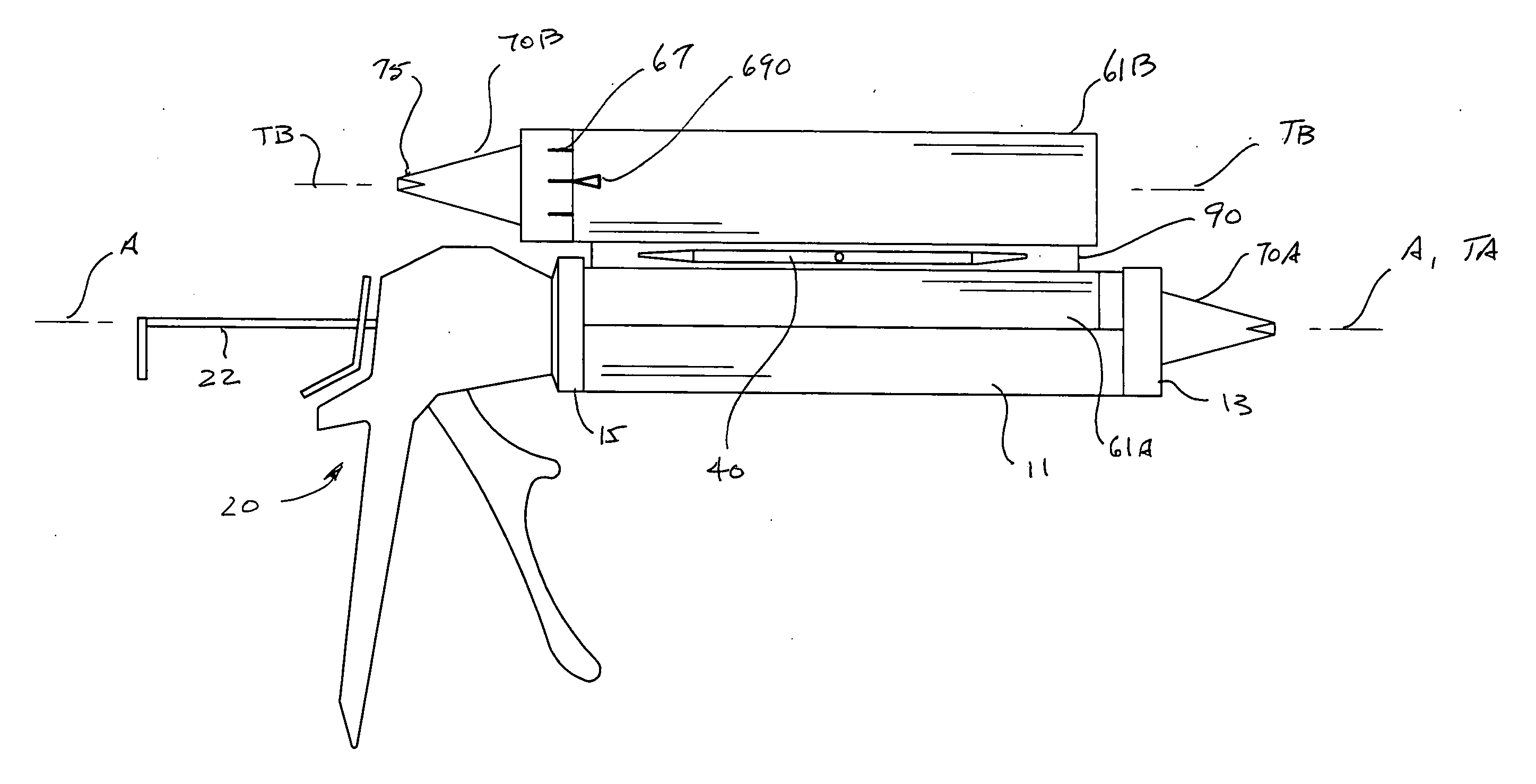

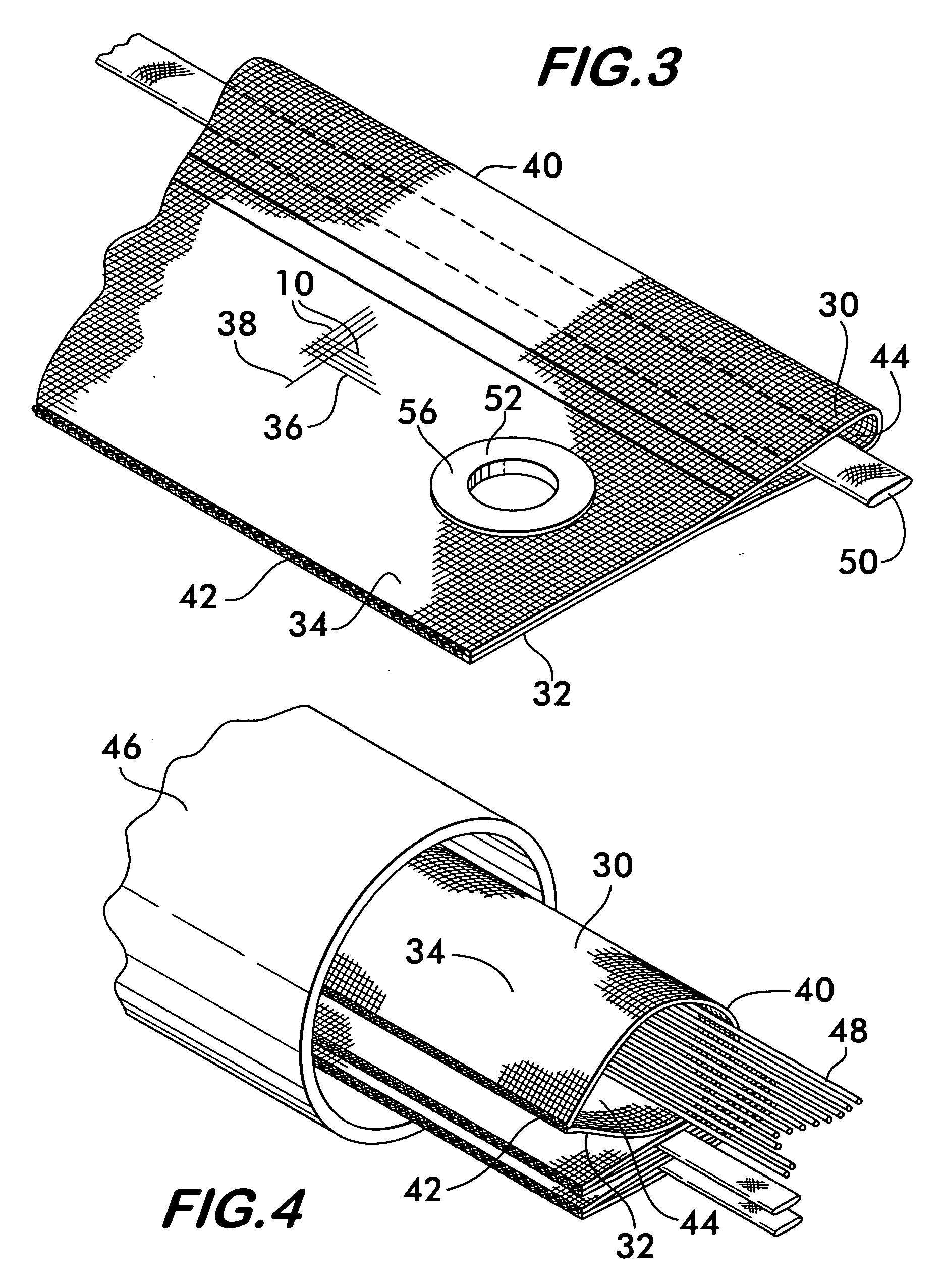

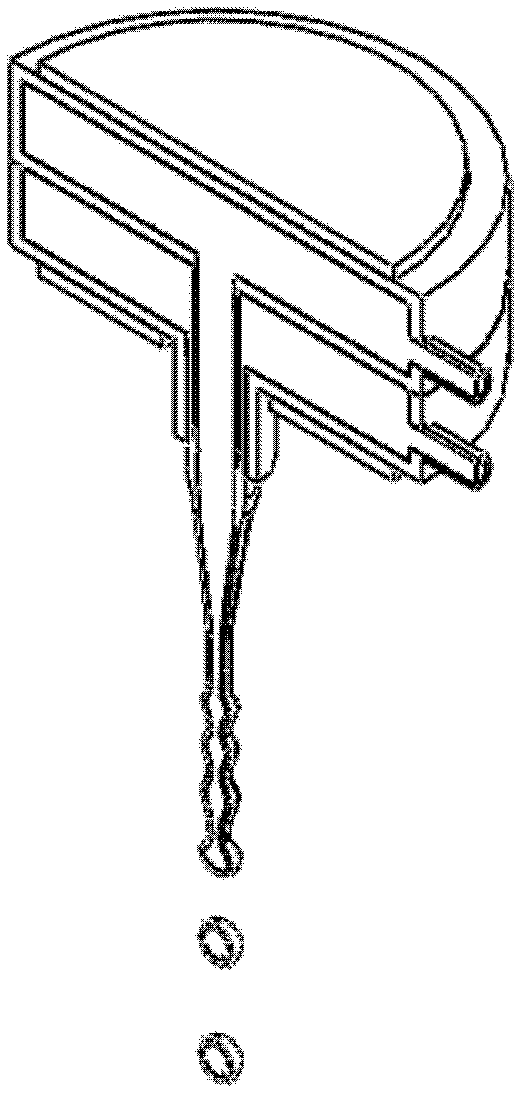

Double barrel caulking gun caddy

InactiveUS20070114248A1Fast loadingEasy to replace the refillOpening closed containersBottle/container closureFilling materialsEngineering

A caulking gun barrel system fits into caulking guns designed for pre-filled cartridges. The caddy system utilizes soft-sided recharge packs of fill material ordinarily designed for more expensive caulking machines with built-in barrels. The caddy system includes at least one tubular barrel having a removable cap for providing access to the barrel interior for insertion of a recharge pack. A shuttle disposed within the tube articulates between ends of the tube and interfaces between the soft-sided refill pack and the caulking gun piston. Built into the removable cap is an elongate, coaxial nozzle for distributing the fill material. In a preferred embodiment, two such barrels are coupled together by a spine adapted to hold them in linear alignment. After inserting into each barrel a recharge pack opened at one end, a user inserts one of the barrels into a caulking gun and employs its plunger and piston to force fill material out the nozzle. When that recharge pack is spent, the user reverses the barrels to use the other recharge pack in like manner. The system holds the barrels oriented in opposite directions to minimize interference by the spare barrel with use of the caulking gun. The backbone also may include means on its side for holding a smoothing tool commonly employed by users to smooth a bead of the fill material after it has been distributed from the nozzle.

Owner:KOVAC KAREN S

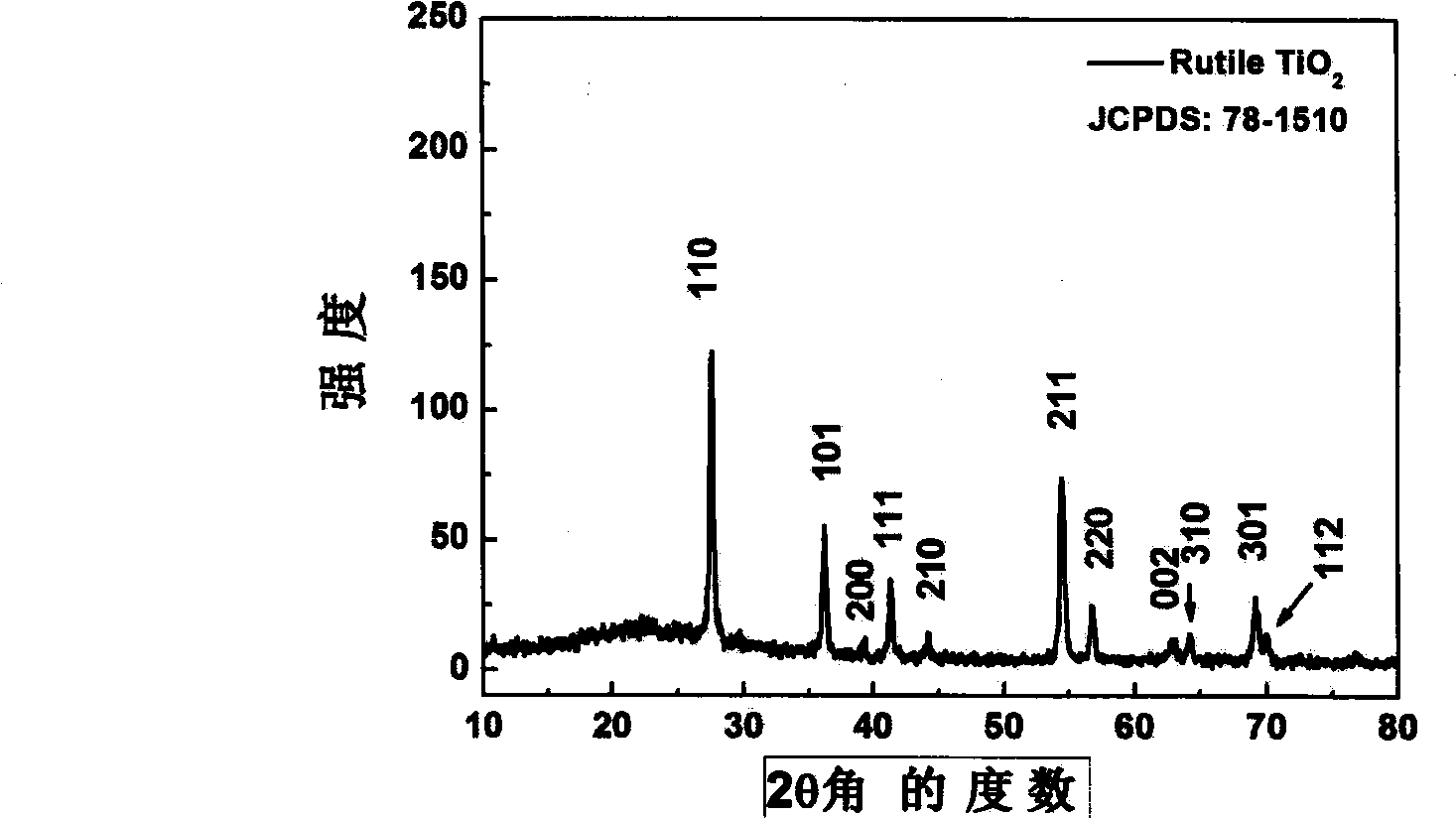

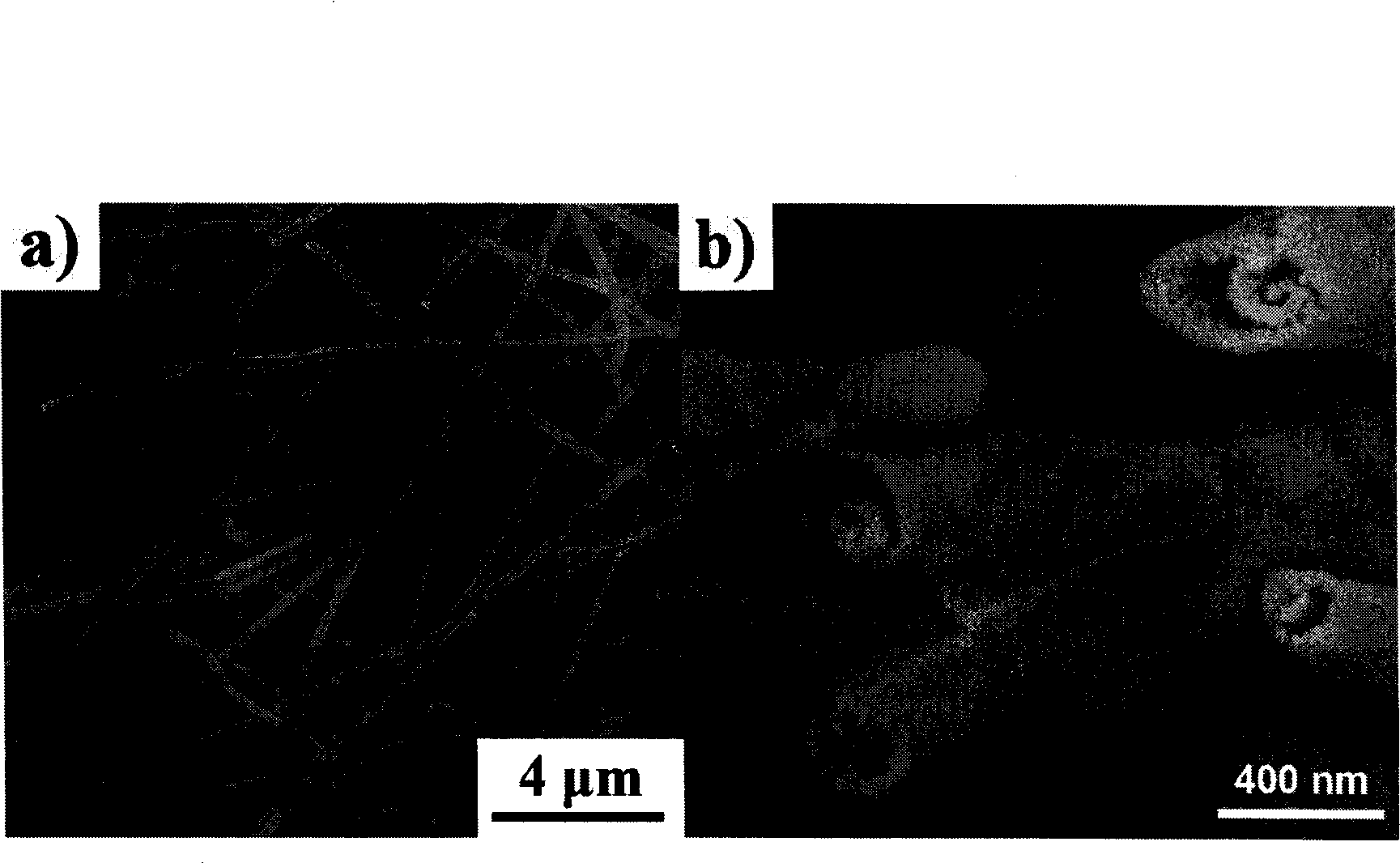

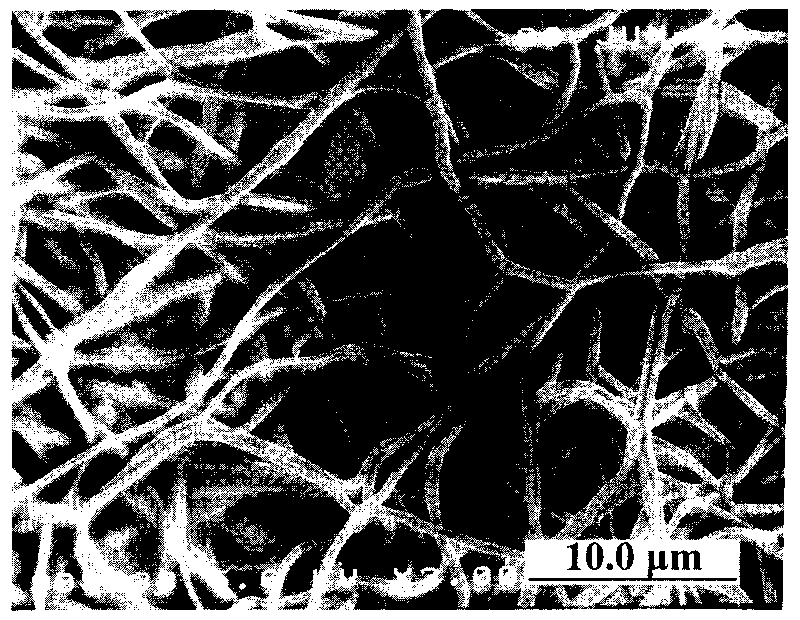

Tubular and tube-in-tube structure organic oxide and preparation method thereof

InactiveCN101545158AOvercoming structural complexityOvercome operabilityInorganic material artificial filamentsFilament/thread formingFiberHigh pressure

The invention discloses a tubular and tube-in-tube structure organic oxide and a preparation method thereof. The organic oxide has a caliber from 100 nanometers to 1 micron and a tube wall of a porous structure. The preparation method utilizes various organic salts and comprises the following steps: using metal alkoxide and nitrate as raw materials; fully mixing salt solutions with an alcoholic solution of PVP to be electrically spun into fibers under a high-pressure electrostatic field; and treating the fibers at a high temperature to form the tubular and tube-in-tube structure organic oxide. The method is used to prepare the tubular and tube-in-tube structure organic oxide comprising Ti, Si, Zr, V, In, Sn, B, Fe and Co. The invention adopts a traditional single-tube nozzle electrostatic spinning technology to prepare a tubular and tube-in-tube nanometer material, is different from a traditional hydrothermal method, an electrochemic method and a coaxial nozzle electric spinning method for preparing organic tubes, only needs the simplest electric spinning process and the roasting process, has convenient and rapid operation, simple method, novel product structure and strong universality and is suitable for mass production.

Owner:NANJING UNIV

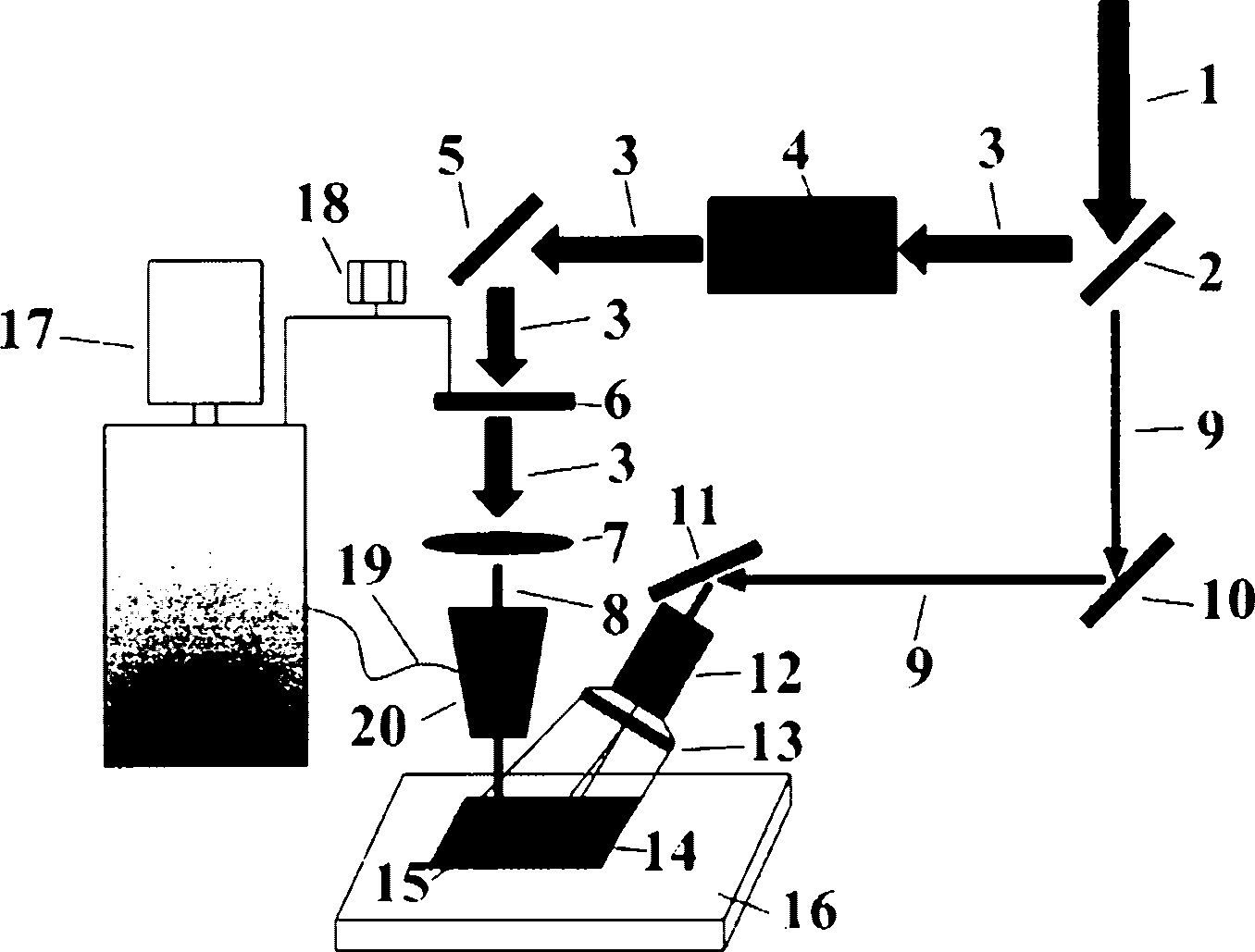

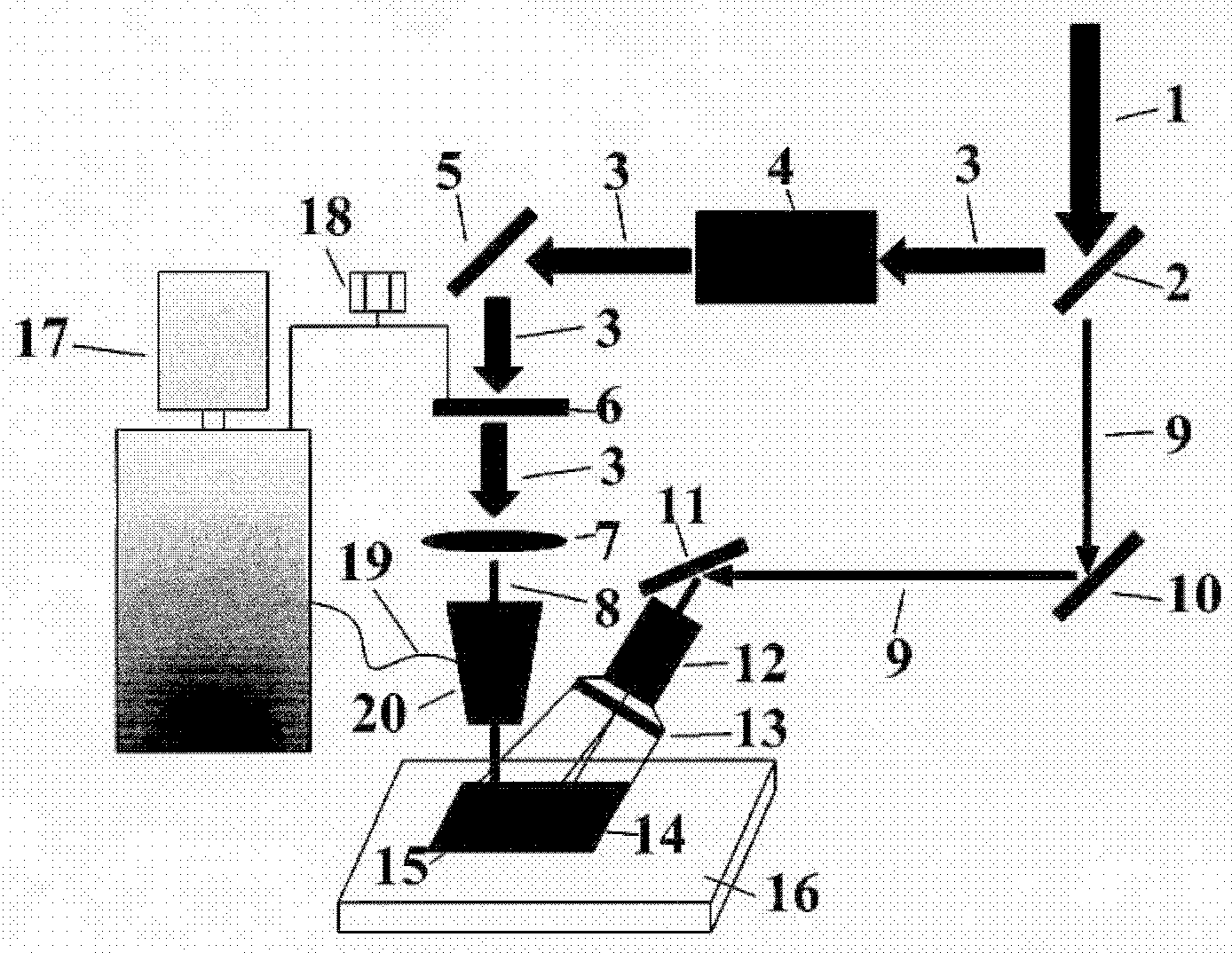

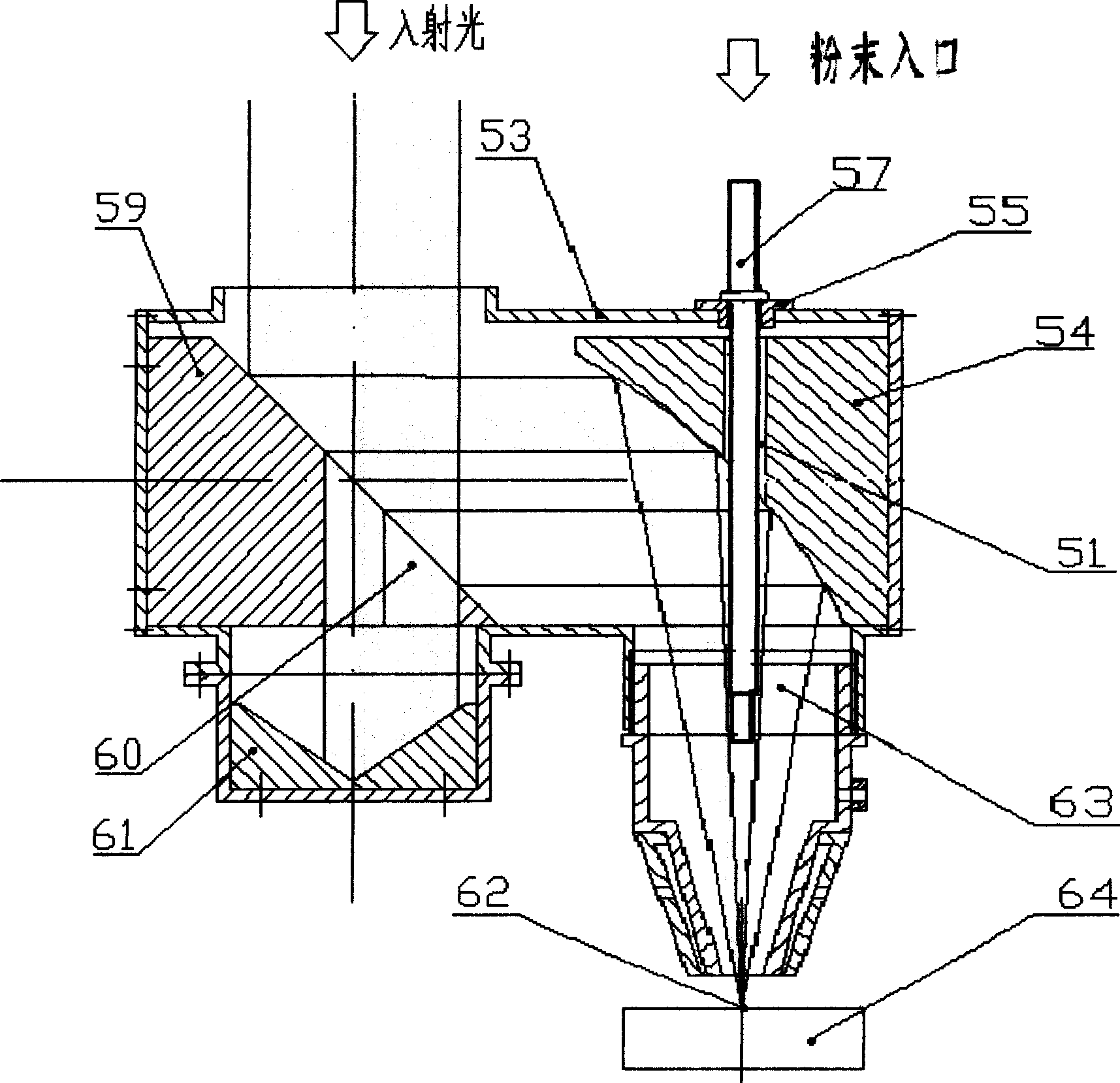

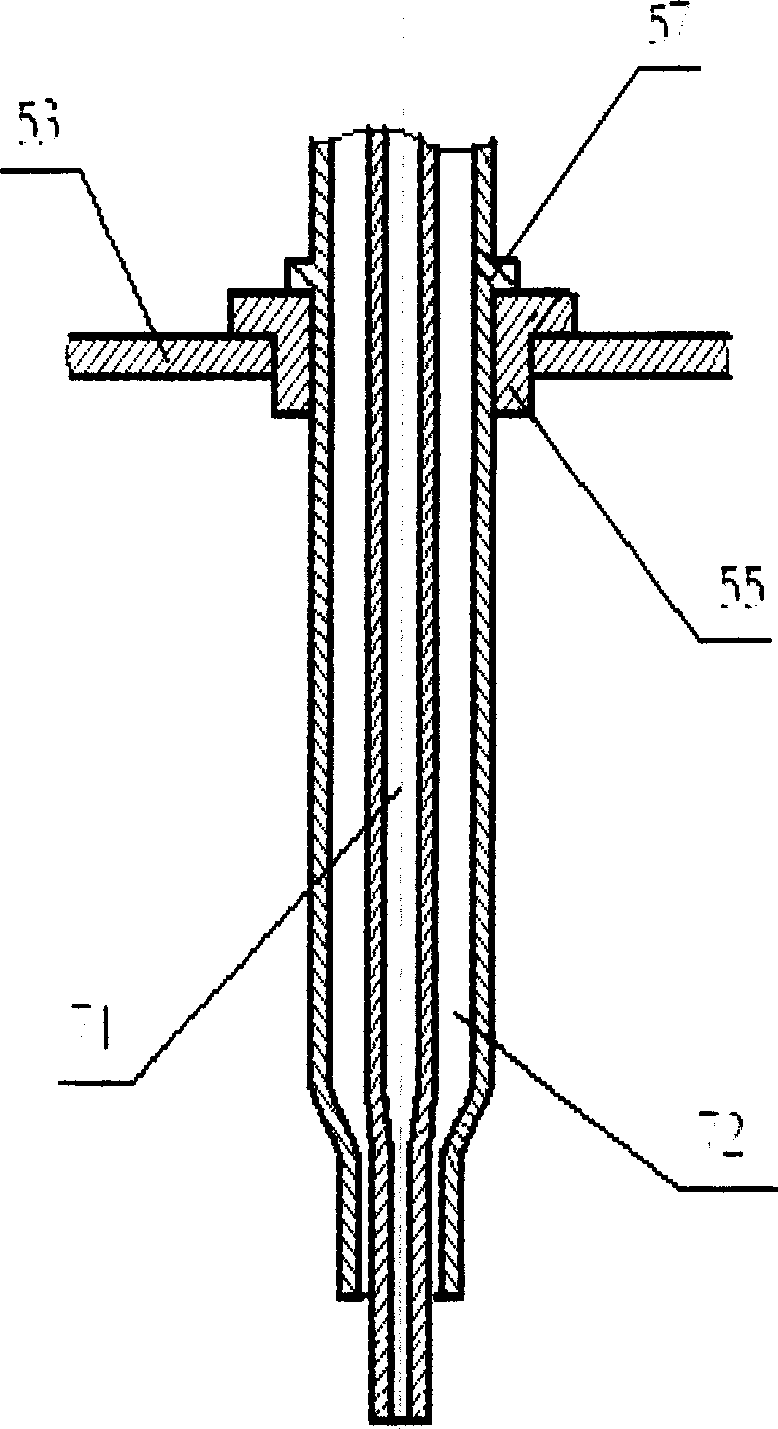

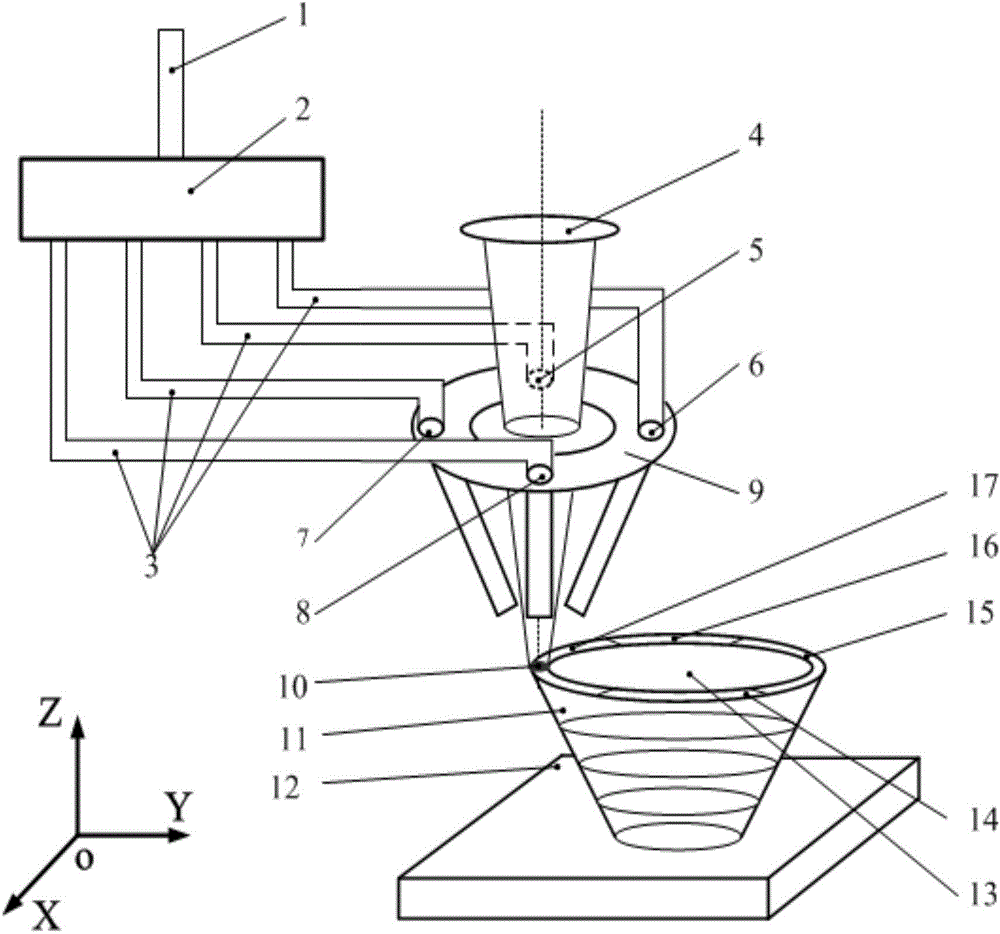

Method for realizing near-net-shape forming of ceramic structure by laser beam

ActiveCN102432302AAchieve laser near net shape manufacturingEasy to operateLaser beam welding apparatusIntegratorBeam splitter

The invention discloses a method for realizing near-net-shape forming of a ceramic structure by a laser beam. The method is characterized in that a laser beam Nd: YAG is divided into a main laser beam and an auxiliary laser beam by a beam splitter; the main laser beam orderly passes through a beam expanding and beam correction system, a holophote A, an optical switch, a focusing lens and a coaxial nozzle; the focused main laser beam heats ceramic powder until the ceramic powder is melted so that a ceramic structure is formed on a substrate through layer-by-layer accumulation; the auxiliary laser beam orderly passes through a holophote B, a holophote C, an optical integrator and a columnar prism and is utilized for providing preheating and slow-cooling temperature conditions to the formed ceramic structure in a main beam active zone, and the ceramic powder is heated and melted by the focused main laser beam so that the layer-by-layer accumulation of the ceramic structure is realized under the control of a preset digital control program. Through the method, a compact ceramic microstructure can be obtained; a temperature gradient of a forming process is reduced; crack defect appearance probability is reduced effectively; a complex ceramic structure can be directly formed; and unnecessary subsequent processing processes are reduced.

Owner:DALIAN UNIV OF TECH

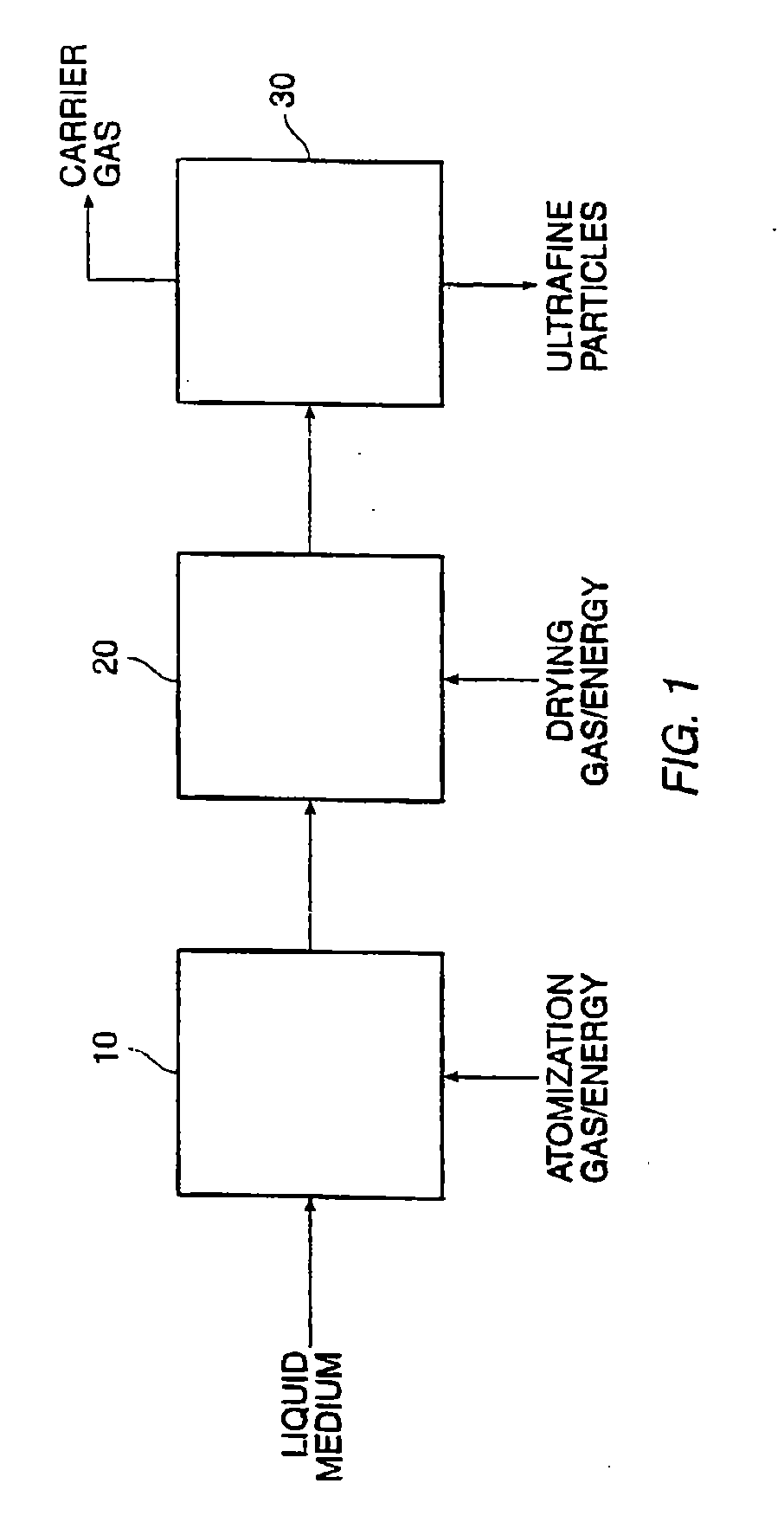

Systems and processes for spray drying hydrophobic drugs with hydrophilic excipients

Methods for preparing dry powders having hydrophobic and hydrophilic components comprise combining solutions of the components and spray drying them simultaneously in a spray dryer. The hydrophilic and hydrophobic component are separately dissolved in separate solvents and directed simultaneously through a nozzle, usually a coaxial nozzle, into the spray dryer. The method provides dry powders having relatively uniform characteristics.

Owner:NOVARTIS FARMA

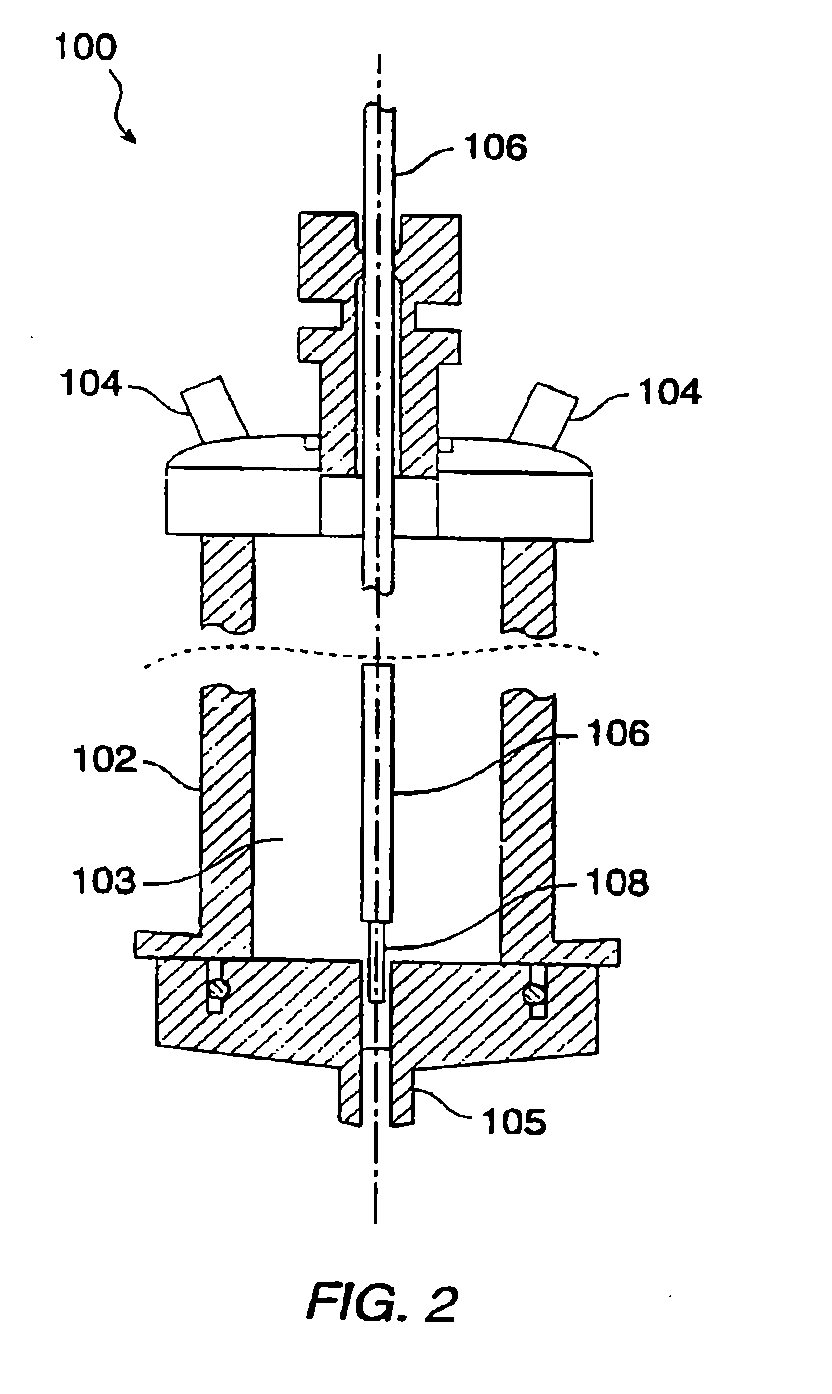

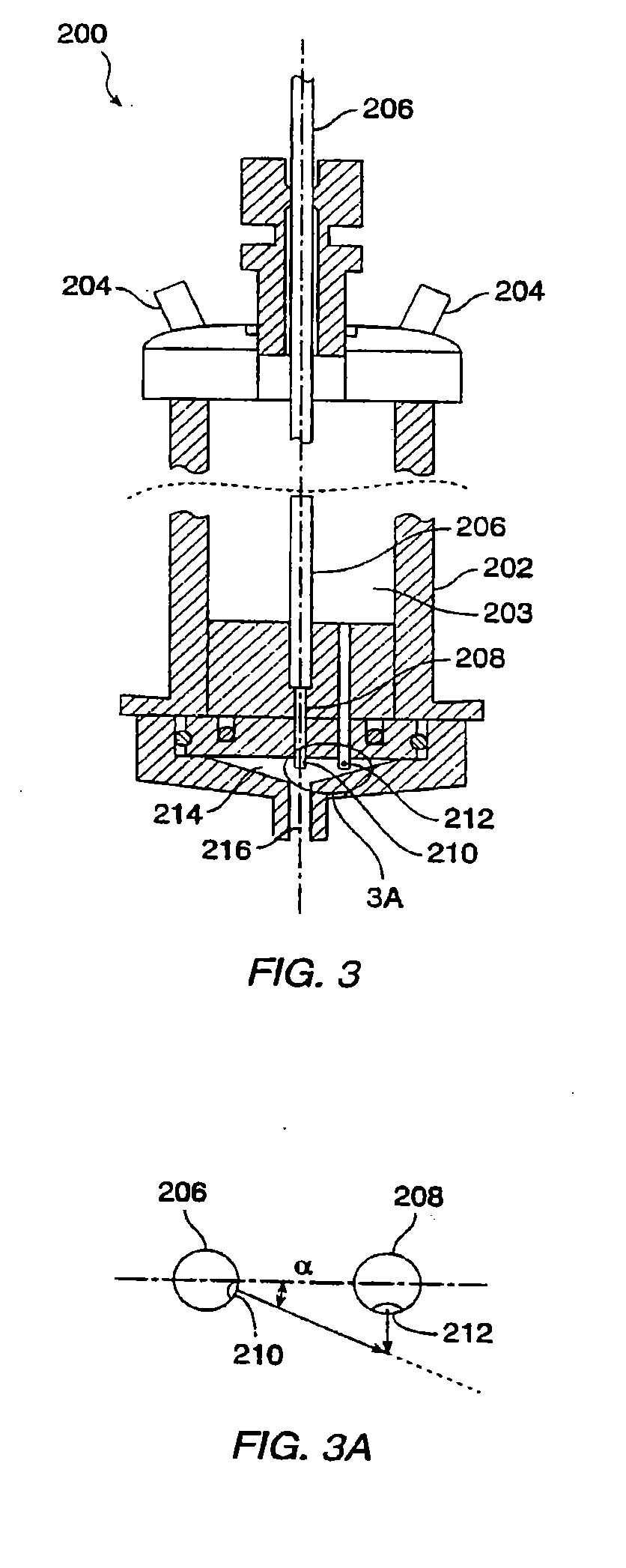

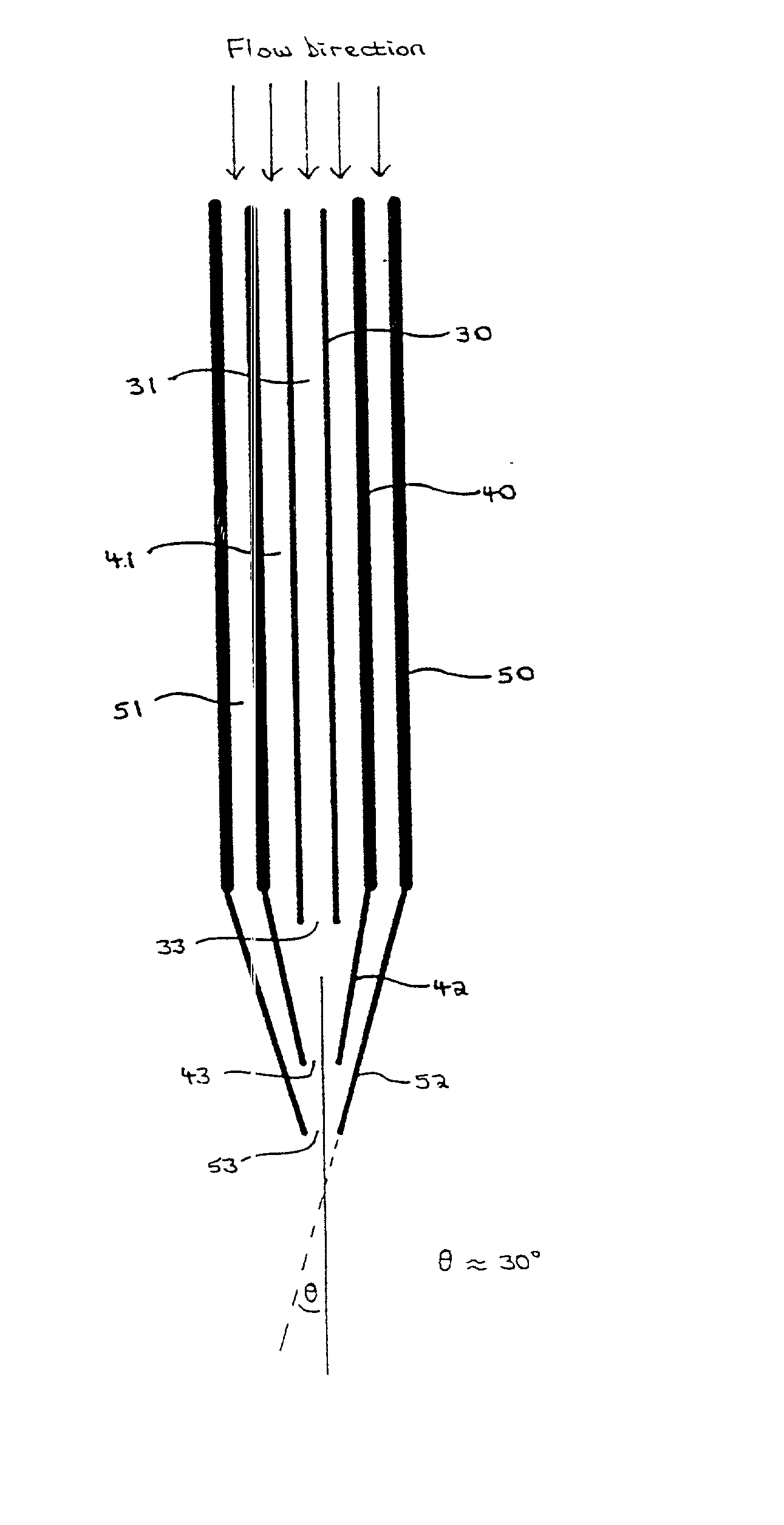

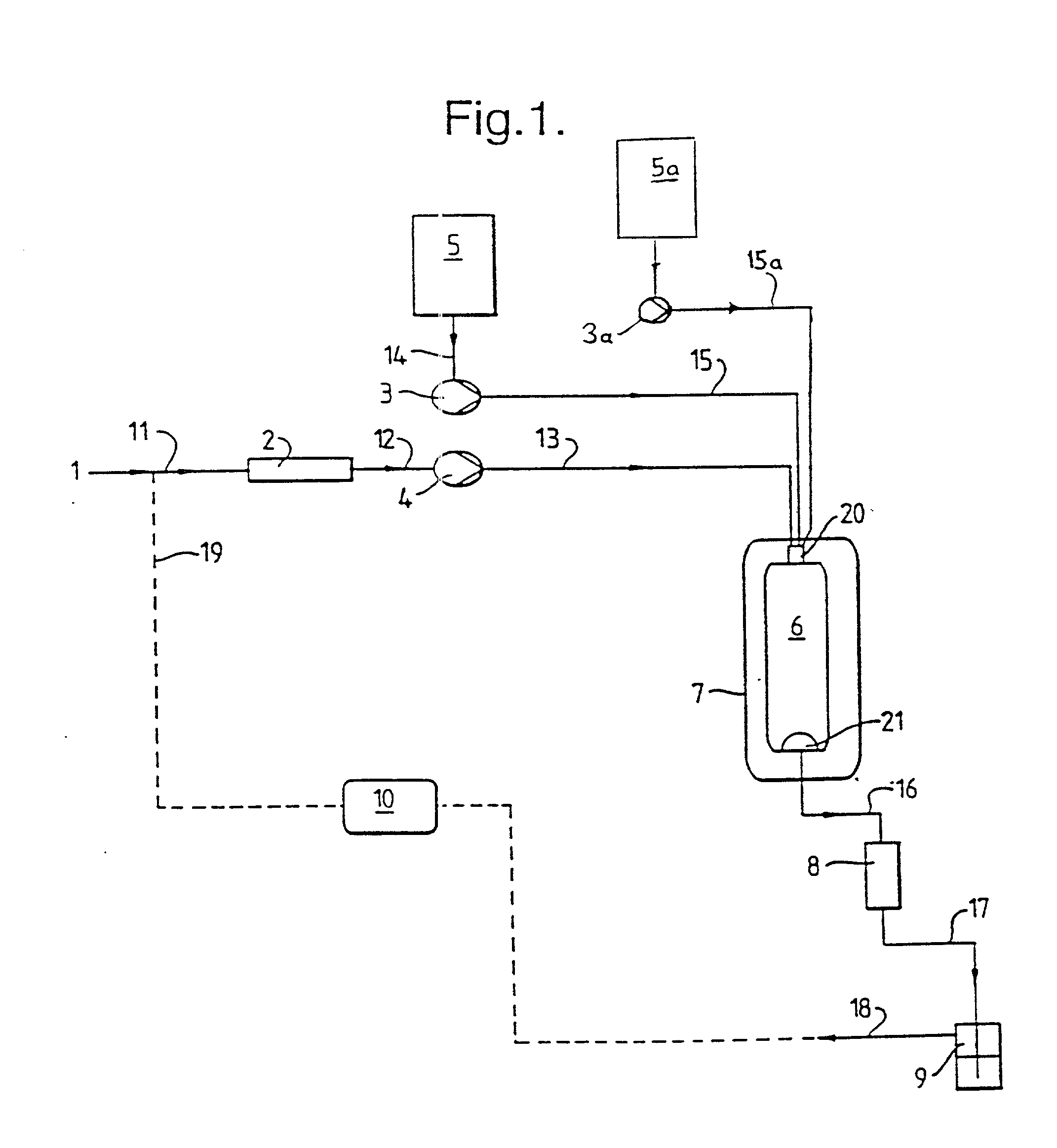

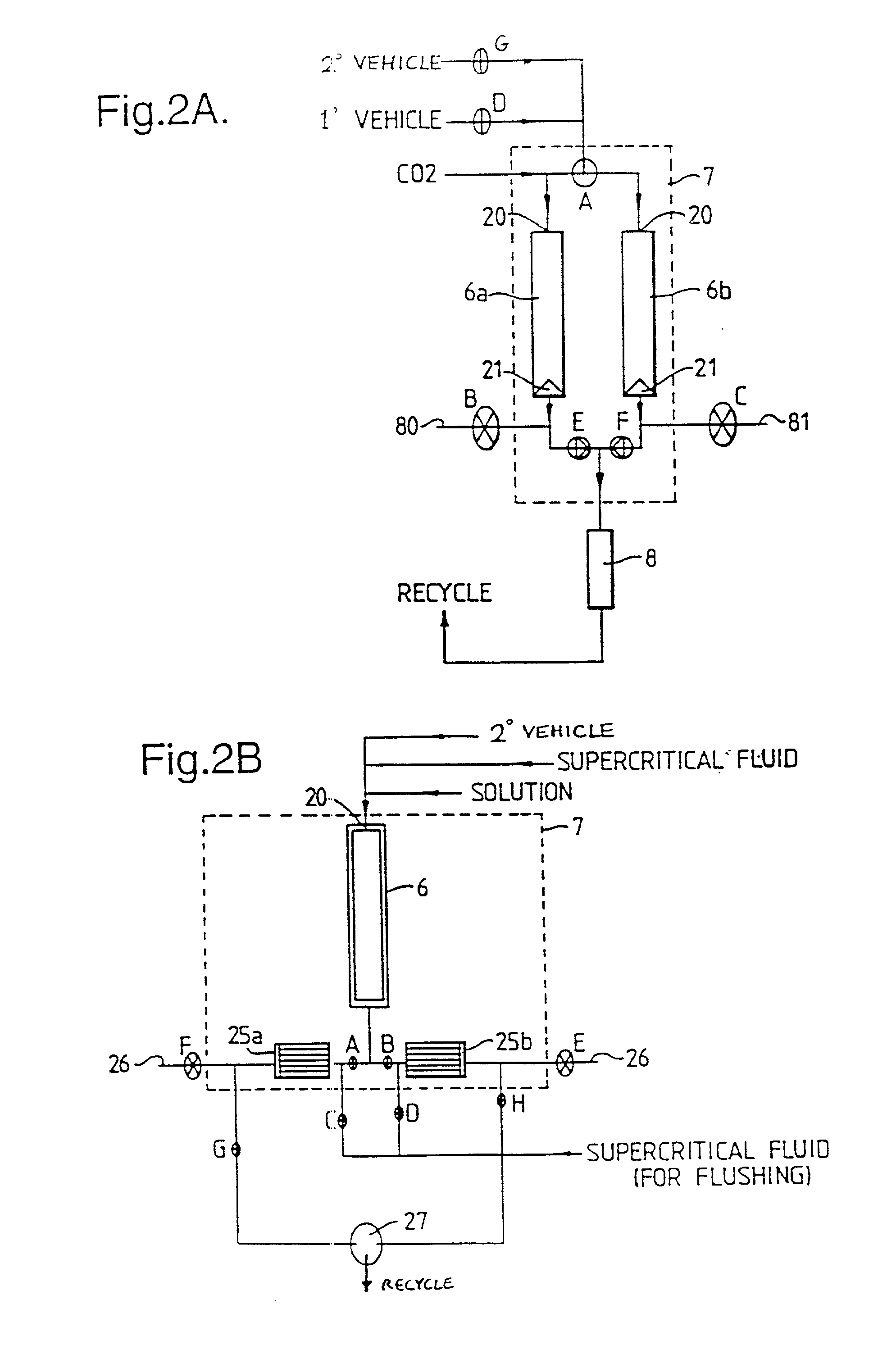

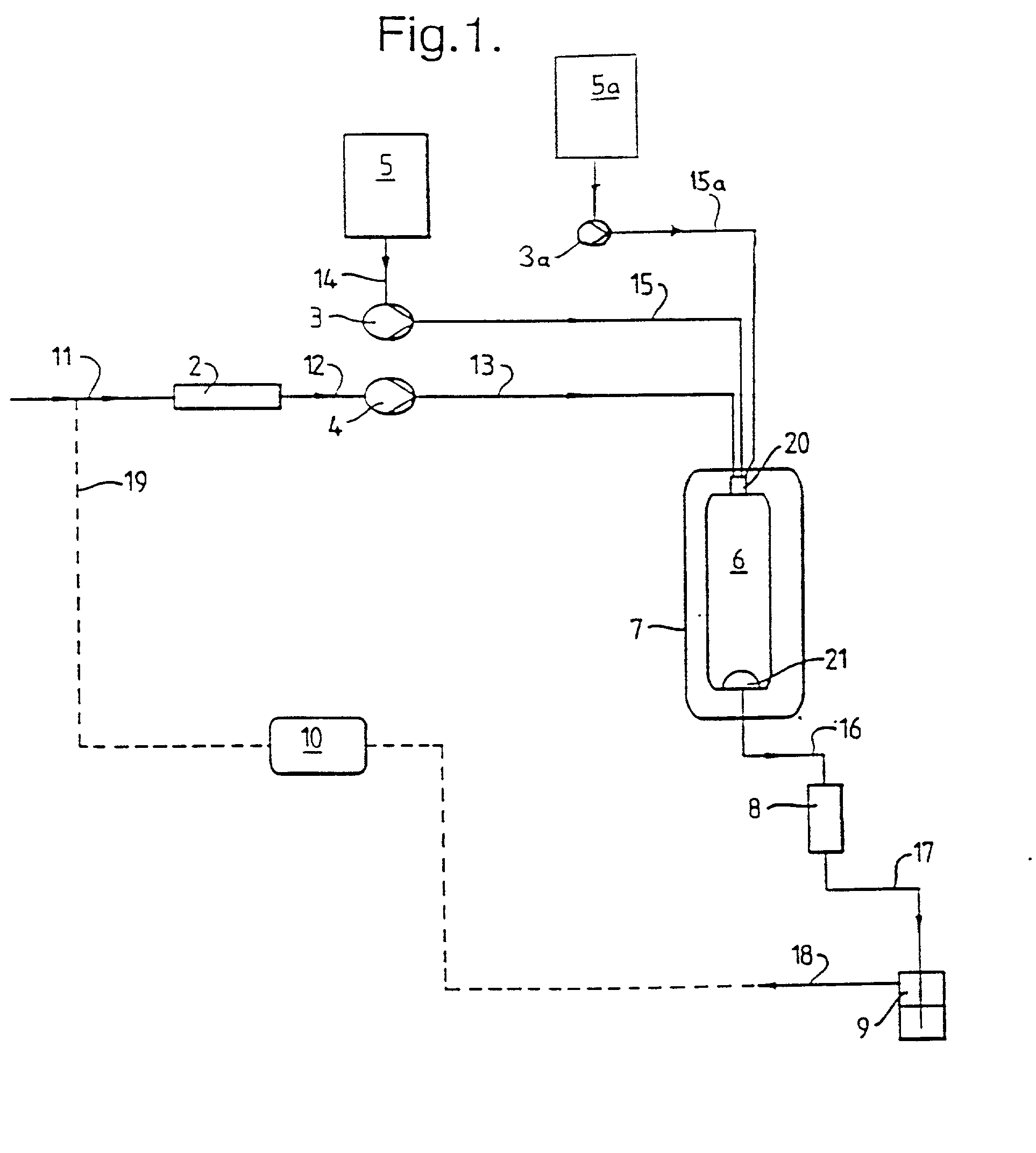

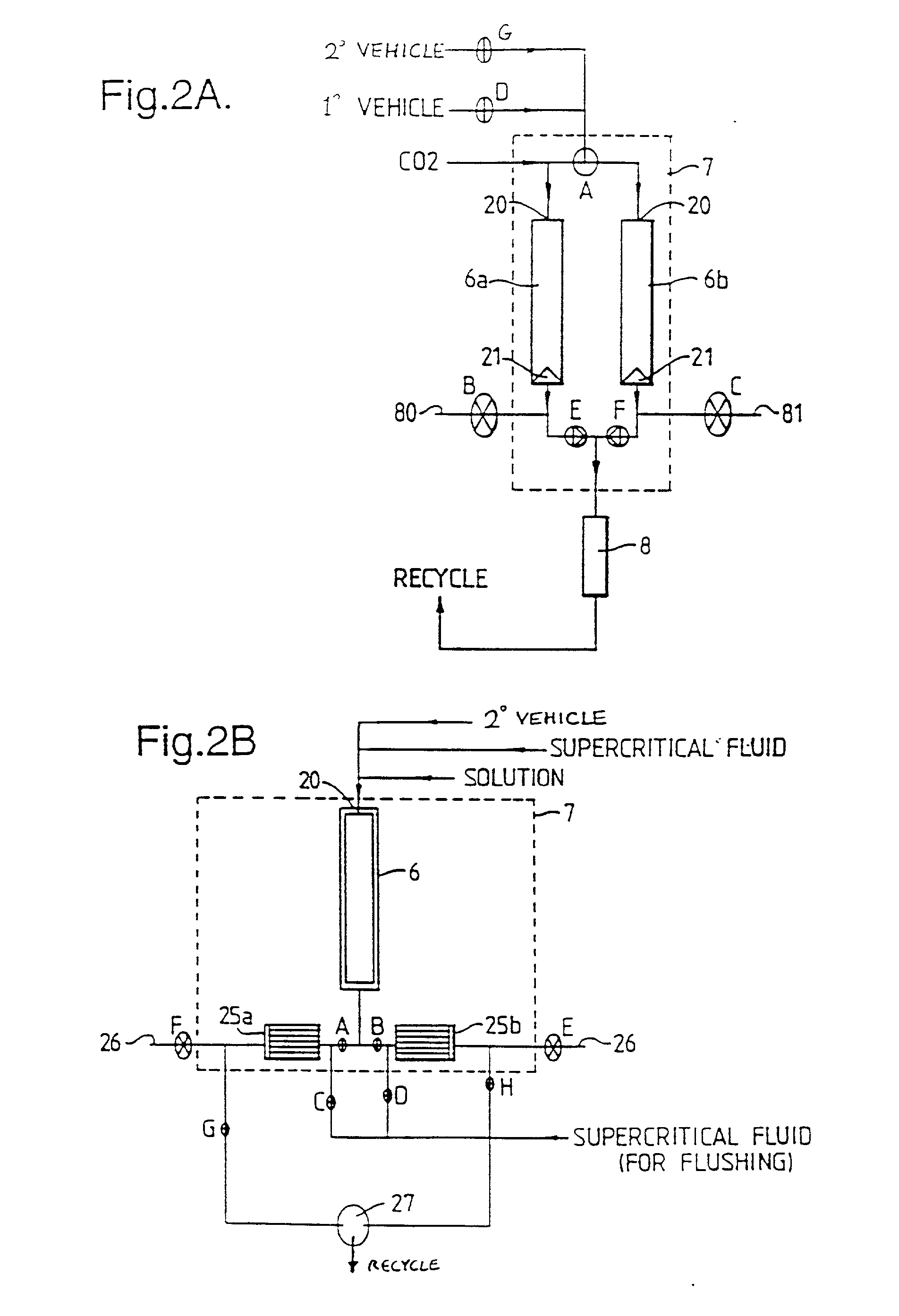

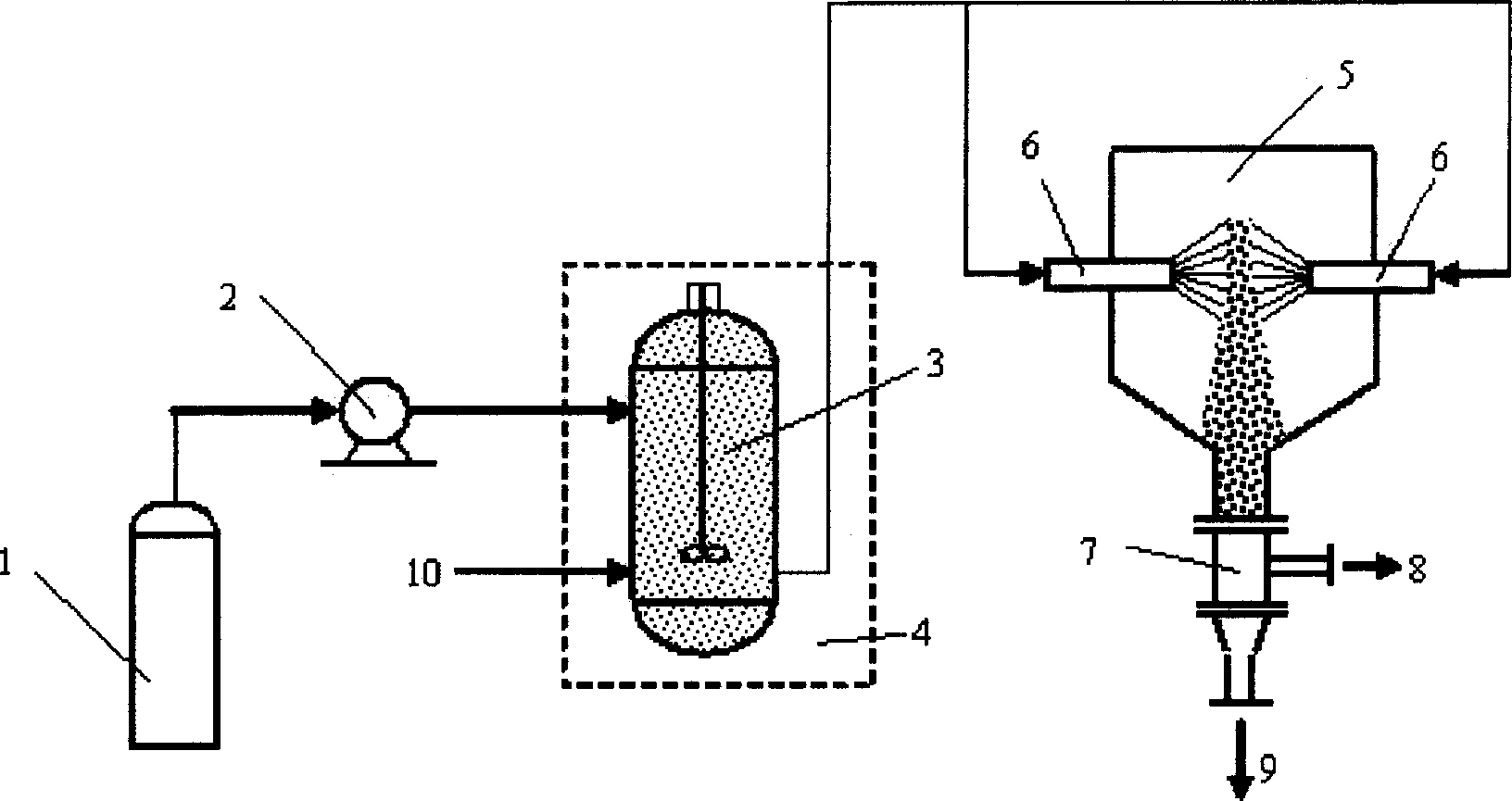

Method and apparatus for the formation of particles

InactiveUS20020010982A1Reduce solubilitySolvent extractionCrystallization separationParticulatesCompound (substance)

The invention provides a method for forming particles of a substance, by co-introducing into a particle formation vessel, in which the temperature and pressure are controlled, of a supercritical fluid; a solution or suspension of the substance in a first vehicle; and a second vehicle which is both substantially miscible with the first vehicle and substantially soluble in the supercritical fluid, in such a way that dispersion of the solution or suspension and the second vehicle, and extraction of the vehicles, occur substantially simultaneously and substantially immediately on introduction of the fluids into the vessel, by the action of the supercritical fluid. Preferably the solution / suspension of the substance is introduced separately from the second vehicle, in such a way that contact between the solution / suspension and the second vehicle occurs either substantially simultaneously with, or immediately before, their dispersion by the supercritical fluid and extraction of the vehicles by the supercritical fluid. The method allows a high degree of control over the size, shape, crystalline form and other physico-chemical properties of the particulate product. The invention also provides apparatus for carrying out such a method, using a coaxial nozzle to introduce the fluids into the particle formation vessel, and a particulate product made using the method or the apparatus.

Owner:BRADFORD PARTICLE DESIGN

Laser spot coating-shaping process and coaxial spray head

A technology that using laser to melt speckle and mould: using profilometry to layout the scan path of the parts in every layer. Using pipe that has small facula and caliber to deliver powder and melt the outline of the layer, using pipe that has big facula and caliber to deliver powder and melt the inner field of the layer. The beam of single powder and the beam of light have the same axis and perpendicular to the surface of the mould. The diameter of the small facula is 0.5mm to 2mm and the big is 2mm to 10mm, and the diameter of powder spot is slightly big than the facula. The coaxial nozzle that this technology used includes a cylinder, a plane reflector that has placket in the radial, a focusing reflector that has a hole in center, a pipe that use to deliver the powder. The invention can melt in various size of facula. Needn't to adjust multi-channel pipes of powder to pool, The beam of powder and the beam of light can couple the focus of facula and any other space off the focus. The round powder spot of single-channel can scan along any direction and isn't sensitive to direction.

Owner:SUZHOU UNIV

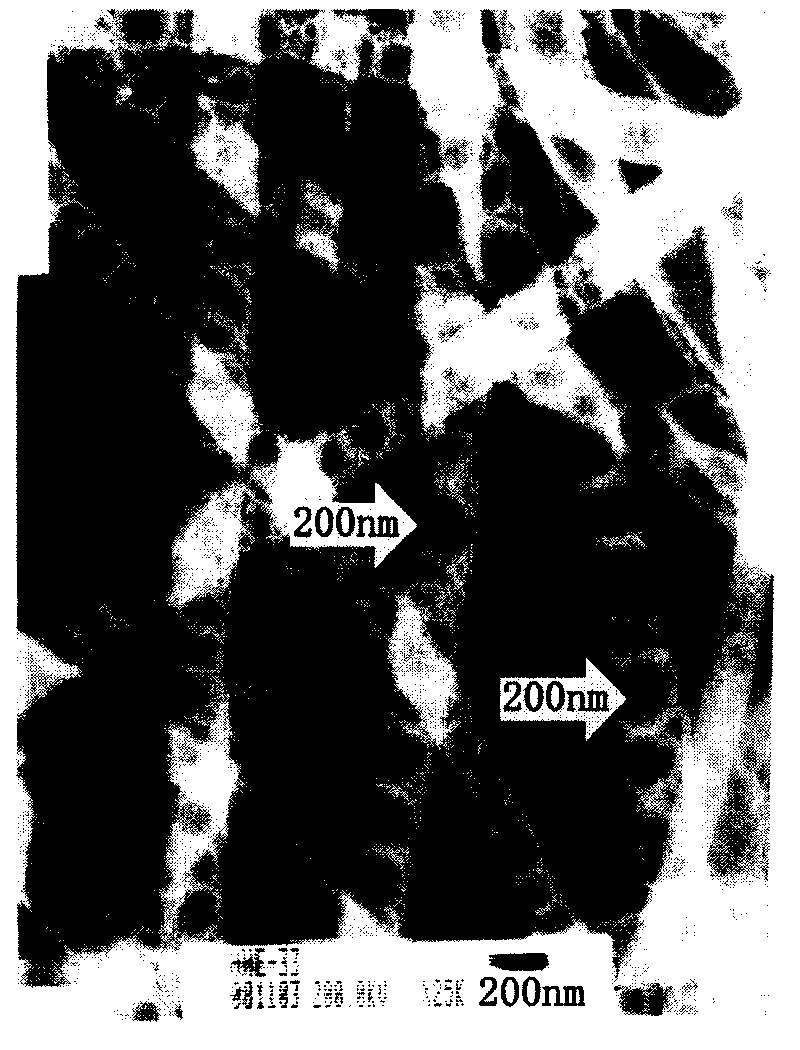

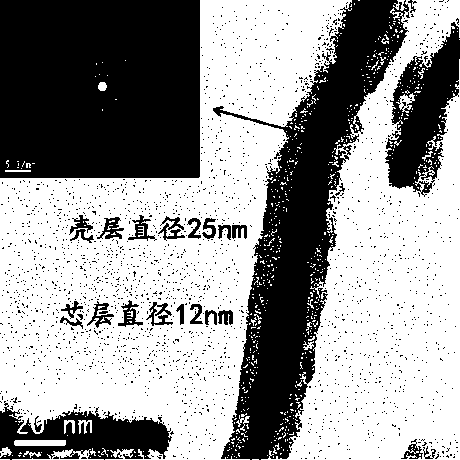

Process for preparing uropium-doped yttrium oxide @ silicon dioxide bean-shaped nano-cables

InactiveCN101694018ANanostructure manufactureInorganic material artificial filamentsN dimethylformamideGlycerol

The invention relates to a process for preparing uropium-doped yttrium oxide @ silicon dioxide bean-shaped nano-cables, which belongs to the technical field of nano-material preparation. The process includes three steps: (1) preparing spinning liquor; (2) preparing (PVP + rare-earth nitrate) @ (PVP + tetraethoxysilane) recombination nano-cables; (3) preparing Y2O3 @ SiO2 or Y2O3: Eu3 + @SiO2 bean-shaped nano-cables. The first step includes: adding a certain amount of mixed liquor(volume ratio is 5:1) including polyvinyl-pyrrolidone (PVP), N,N-dimethylformamide (DMF) and glycerol into the rare-earth nitrate; stirring the mixed liquor for 4-6 hours with a magnetic force under room temperature; standing the mixed liquor for 2-3 hours to obtain core layer spinning liquor, wherein mass percentage includes that the PVP is 9%, the rare-earth nitrate is 8%, the DMF is 65% and the glycerol is 18%; mixing a certain amount of mixed liquor ( volume ratio is 4:1) including the PVP, absolute ethyl alcohol and the tetraethoxysilane, stirring the mixed liquor with the magnetic force for 3-6 hours, and standing the mixed liquor to obtain shell layer spinning liquor, wherein the mass percentage includes that the PVP is 12%, the tetraethoxysilane is 20% and the ethyl alcohol is 68%. The second step includes that coaxial electrostatic spinning technology is adopted, and parameters include: coaxial nozzles are formed by adopting a 10# stainless steel injection needle after being cut flat (outer diameter=1.0 millimeter, inner diameter=0.7 millimeter) as an inner nozzle needle and adopting a 12# stainless steel needle head (outer diameter=1.4 millimeters, inner diameter=1.2 millimeters) as an outer nozzle needle. Further, the two nozzle needles are sleeved and fixed, the prepared shell layer spinning liquor is placed in an outer pipe of a coaxial spinning device, the core layer spinning liquor is added in an inner pipe.

Owner:CHANGCHUN UNIV OF SCI & TECH

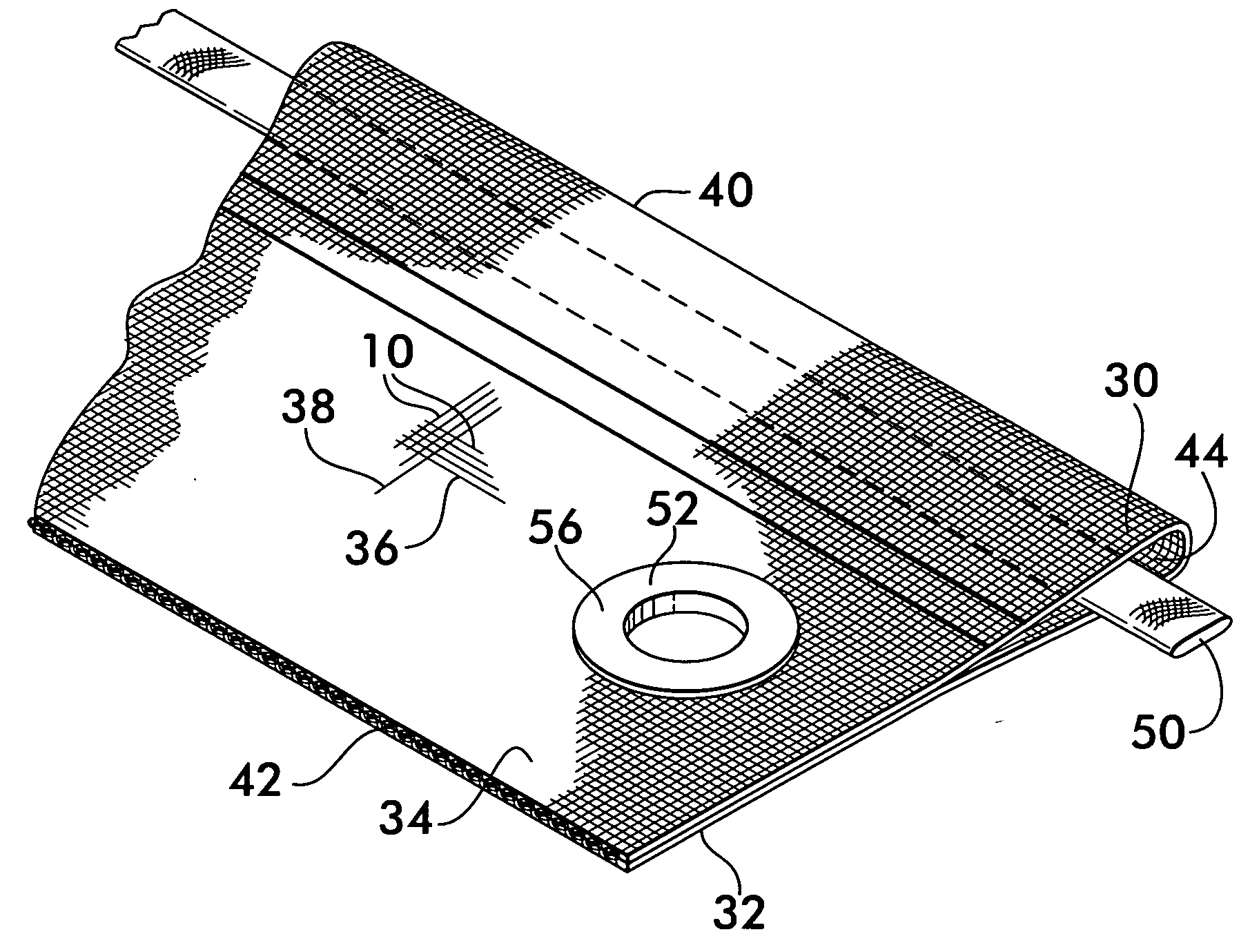

High-strength abrasion-resistant monofilament yarn and sleeves formed therefrom

InactiveUS20050136255A1High tensile strengthImprove wear resistanceLayered productsPedestrian/occupant safety arrangementYarnMolten state

A filamentary member and a sleeve made therewith are disclosed. The filamentary member has an inner core formed of a material with a high tensile strength. The core is surrounded by an outer sheath formed of an abrasion resistant material. The filamentary member is formed by co-extruding the core and the sheath together through a spinnerette having coaxial nozzles. When spun from a molten state, the core and sheath fuse at the interface between them to provide transverse shear continuity. The sleeve may be woven, knitted or braided using the filamentary members and has the characteristics of abrasion resistance and high tensile strength without the need for separate yarns having these characteristics.

Owner:FEDERAL MOGUL WORLD WIDE

Coaxial ejecting apparatus and multilayer microcapsule preparing method utilizing same

InactiveCN103203992AHigh positioning accuracyLow costDuplicating/marking methodsSpray nozzleEngineering

The invention relates to a coaxial ejecting apparatus and a multilayer microcapsule preparing method utilizing the same. The coaxial ejecting apparatus includes a coaxial nozzle, a liquid storage body structure, disturbance devices and a pressure and flow control device, wherein the coaxial nozzle includes at least two layers of nozzles bodies, a gap is arranged between two adjacent layers of nozzles bodies, and the coaxial nozzle is connected with the liquid storage body structure; and the liquid storage body structure comprises at least two liquid rooms and at least one partition board, the number of the liquid rooms corresponds with the layer number of the coaxial nozzle and the number of the disturbance device, the inlet of every liquid room is respectively connected with different liquid storage devices through the pressure and flow control device, the partition board is arranged between two adjacent liquid rooms, and the disturbance devices are respectively connected with corresponding liquid rooms. Compared with the prior art, the coaxial ejecting apparatus has the advantages of being low in price, high in positioning accuracy, raw-material-saving and the like.

Owner:TONGJI UNIV

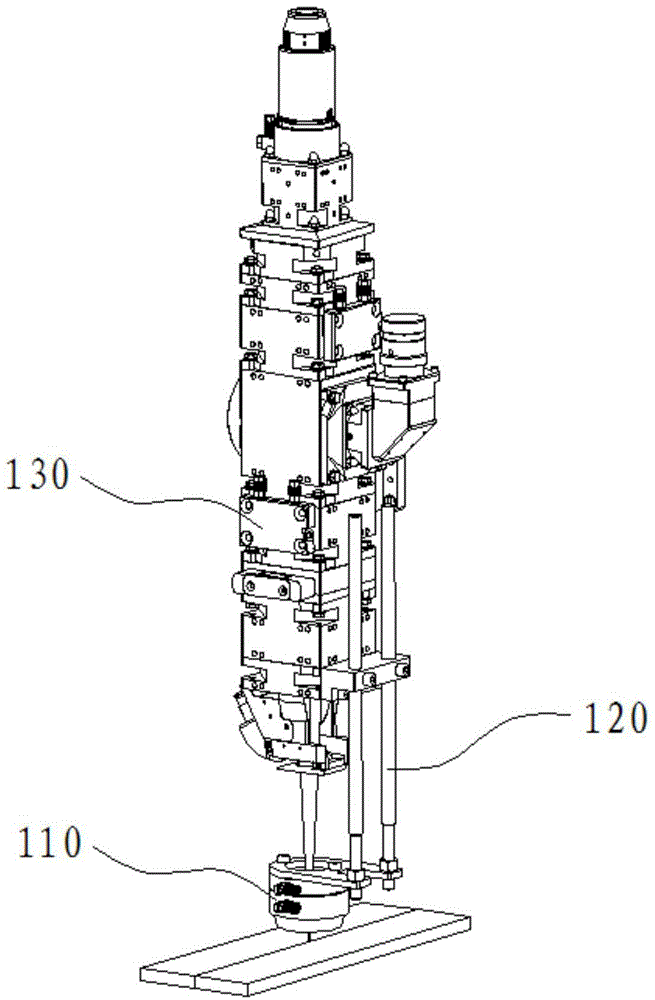

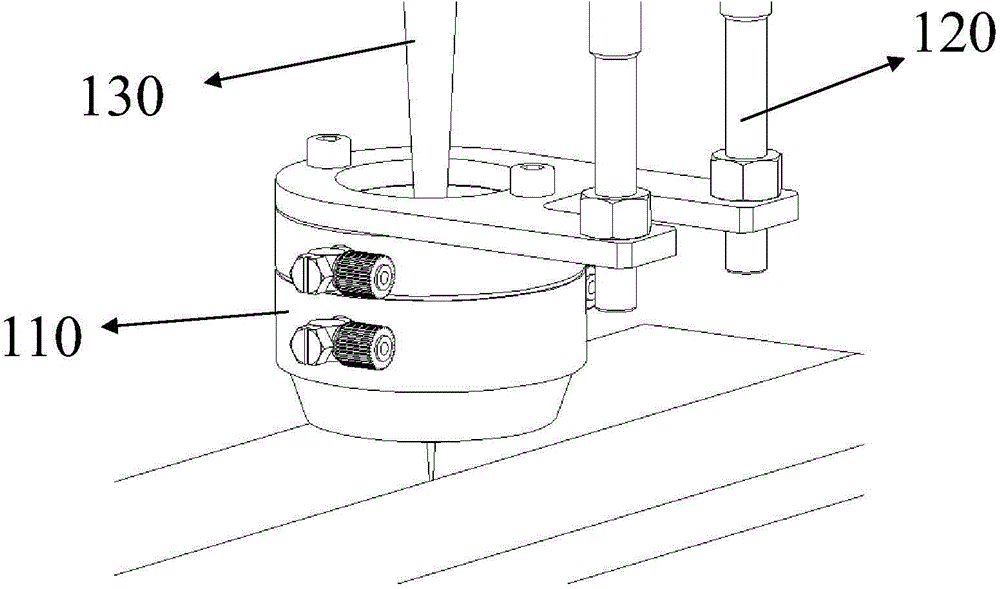

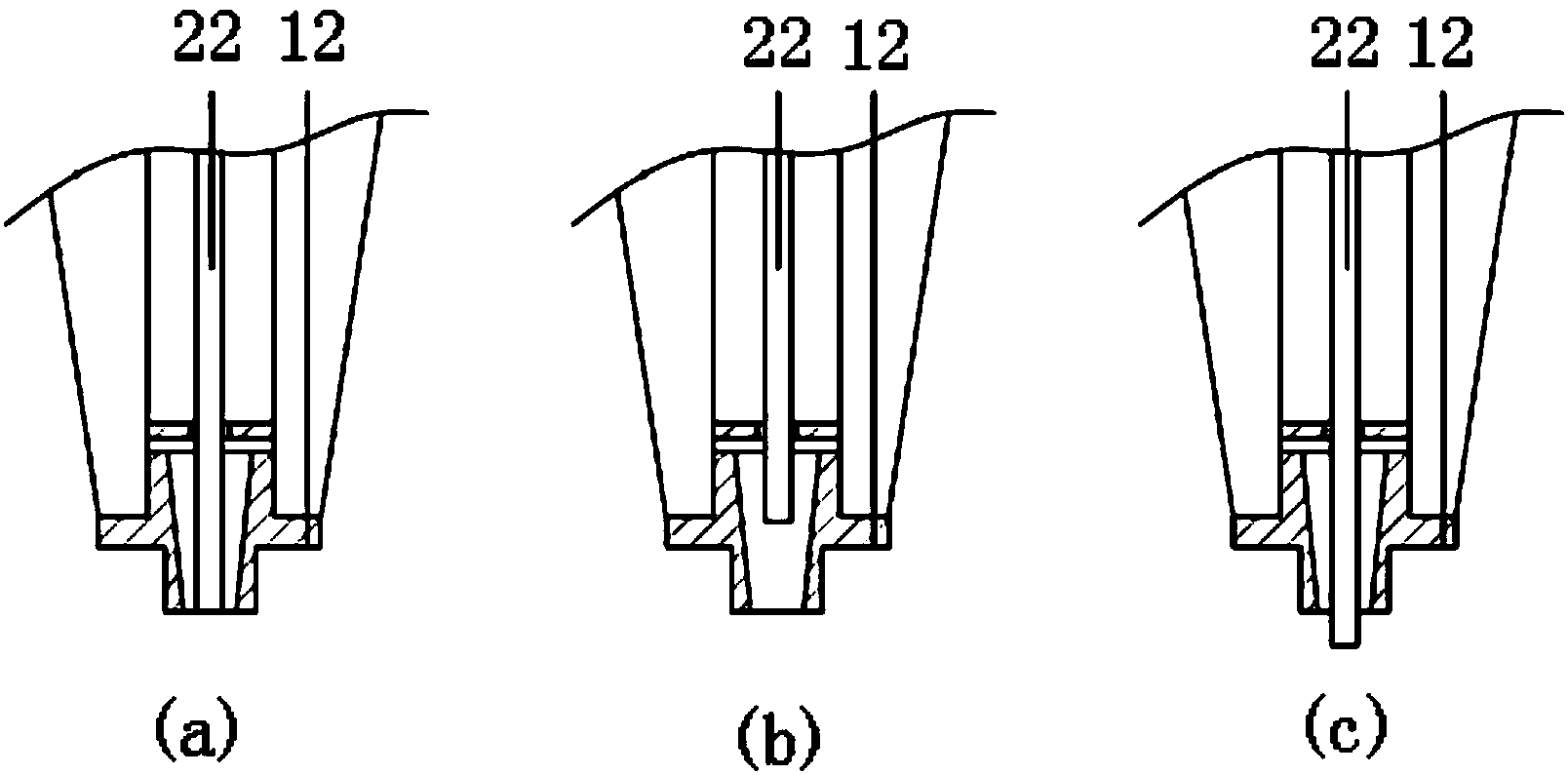

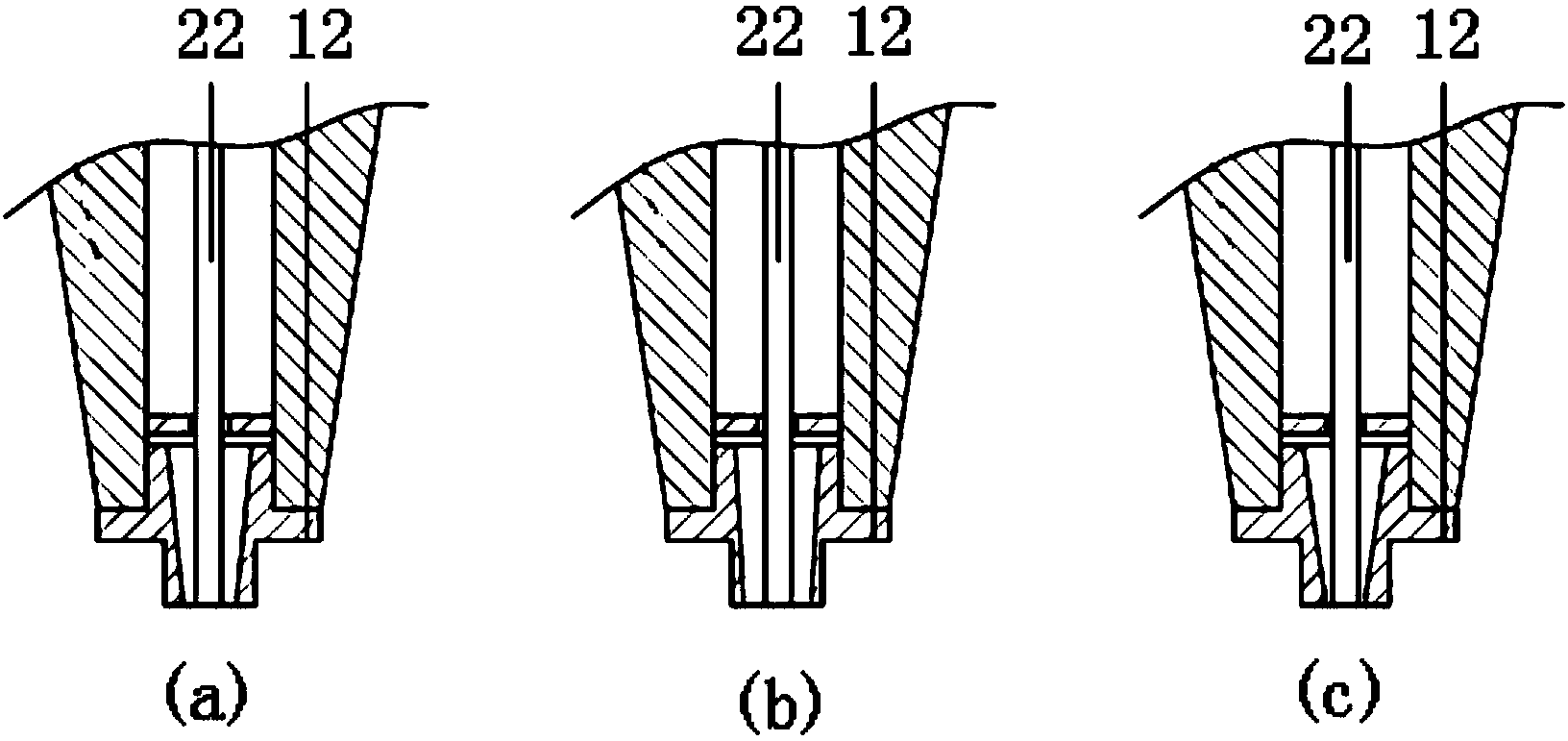

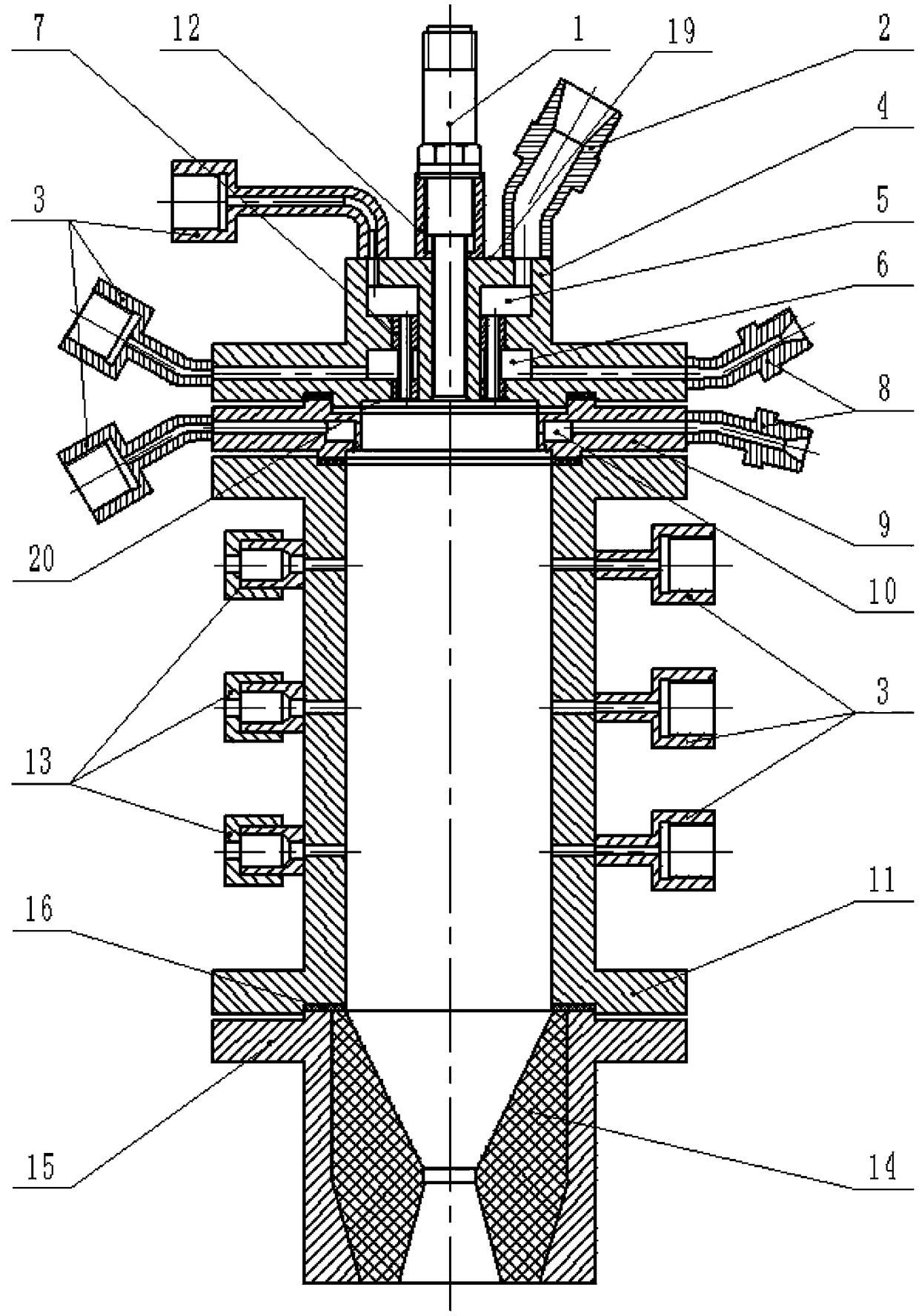

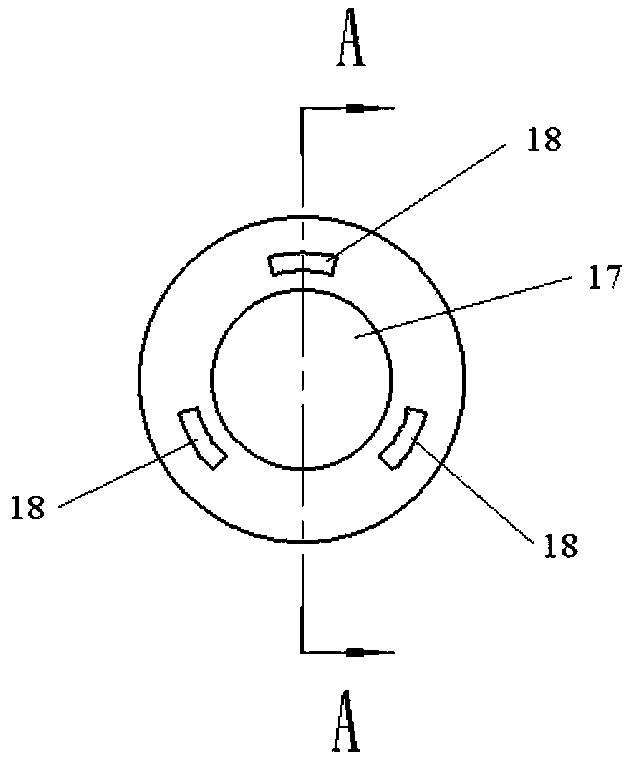

3D printing method and device of large-inclination part and electronic control multifunctional powder distribution device

The invention provides a 3D printing method and device of a large-inclination part and an electronic control multifunctional powder distribution device. The printing method includes the steps of part region division, corresponding spray tube determining when different border regions are formed and part forming. When the interior region of the part is formed, the electronic control multifunctional powder distribution device equally divides the powder in a power feeding tube and powder spraying is conducted by multiple spray tubes; when any border of the border region of the part is formed, the electronic control multifunctional powder distribution device conveys all the powder in the powder feeding tube to the corresponding spray tubes of the border, and the corresponding spray tubes convey the powder to a molten bath. By means of the 3D printing method and device of the large-inclination part, the spray tubes at the different positions of multi-tube coaxial nozzles are used for spraying the powder separately when the borders of the inclined part are formed, the force direction of the molten bath is changed, flow phenomenon of the powder in the molten bath caused by the gravity and the powder impact force when the borders of the inclined part are formed is reduced even is eliminated, and the limit of the inclined angle of the formed part can be finally increased without adding support conditions.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

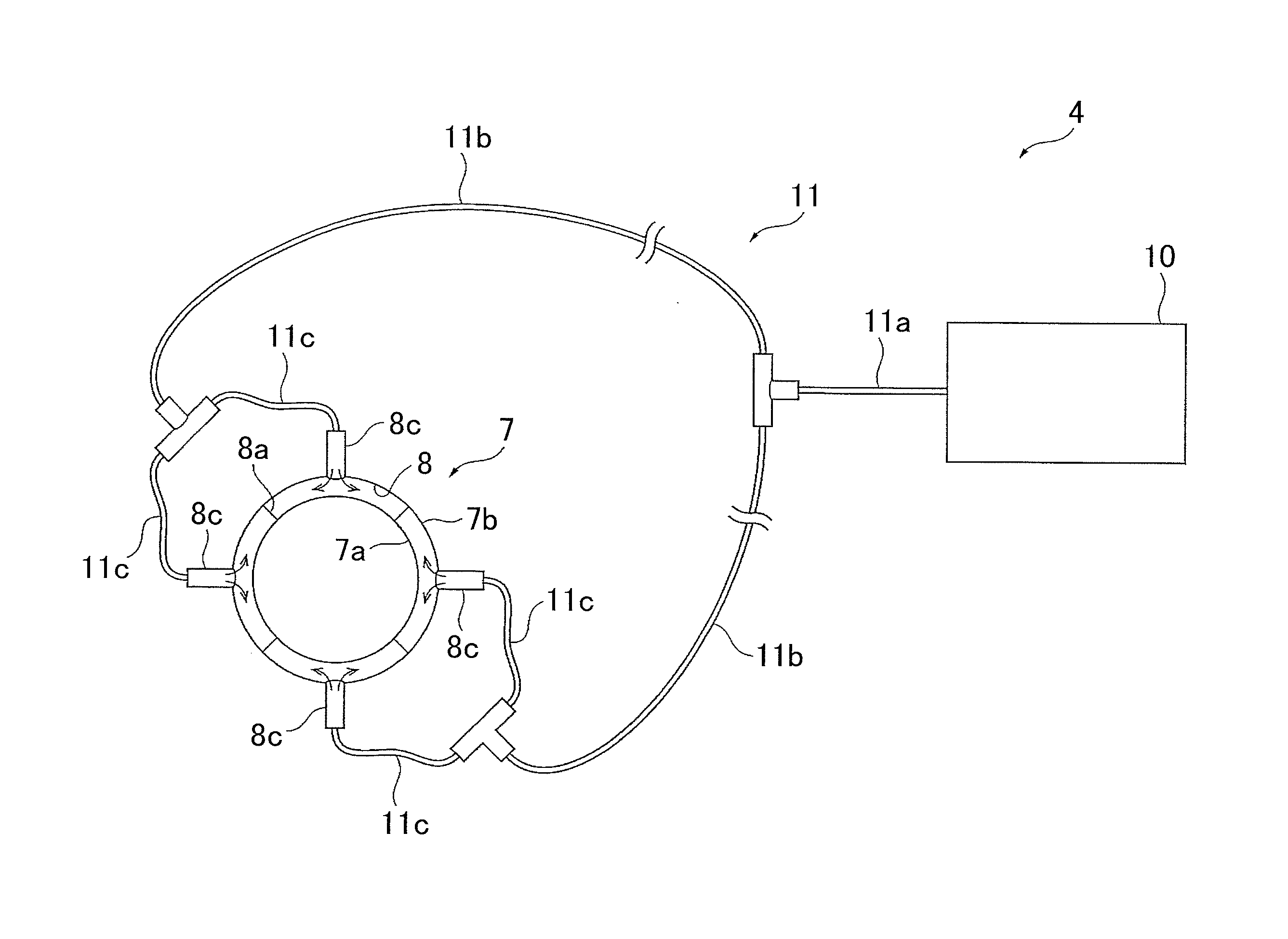

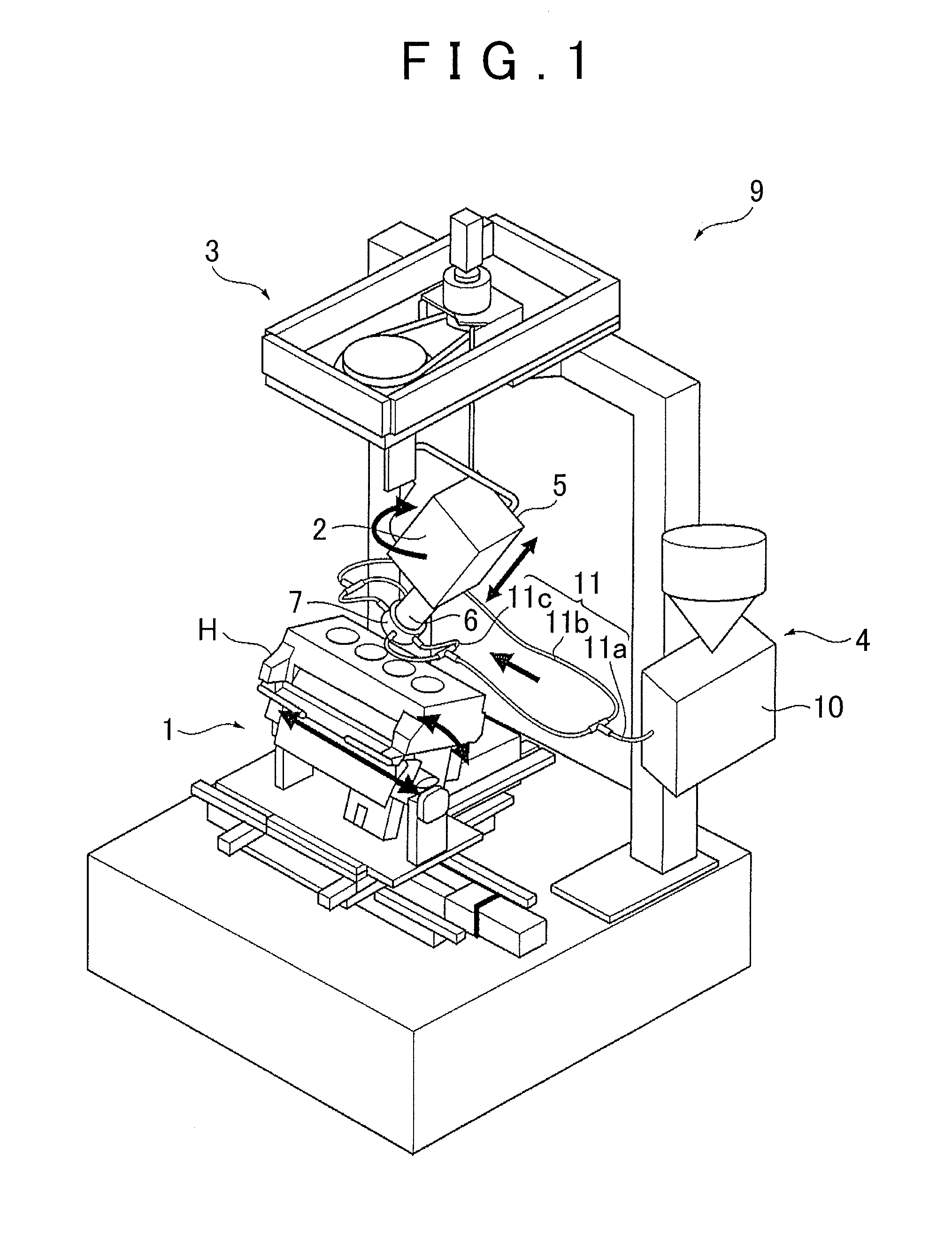

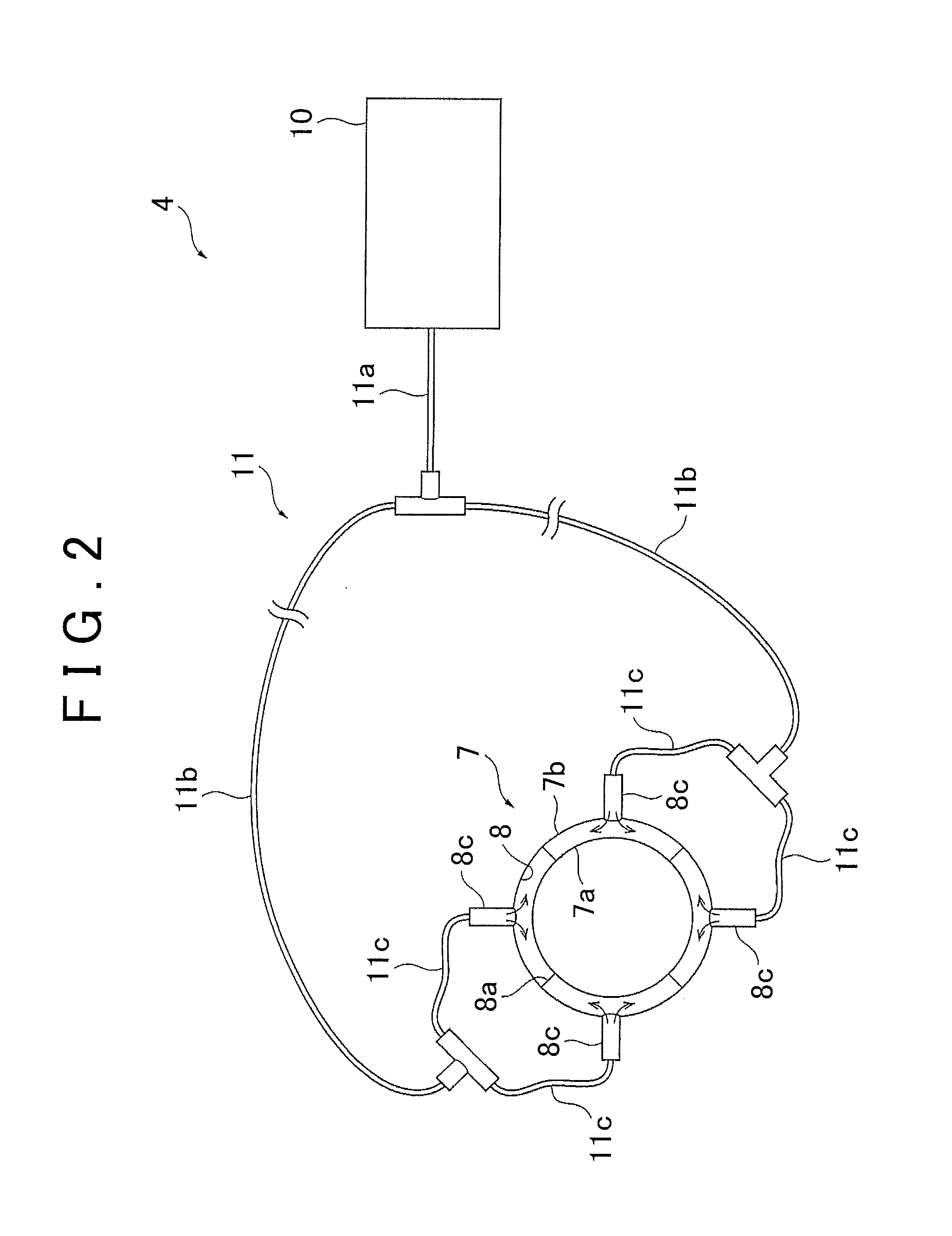

Powder supply method in cladding

ActiveUS20150328718A1Inhomogeneous suppressionQuality improvementMachines/enginesMetallic material coating processesCoaxial nozzleWaste management

In a powder supply method in cladding, an outlet pressure of a coaxial-nozzle side of a supply pipe connecting a feeder to a coaxial nozzle is set within a predetermined range, and powder is supplied from the feeder to the coaxial nozzle.

Owner:TOYOTA JIDOSHA KK

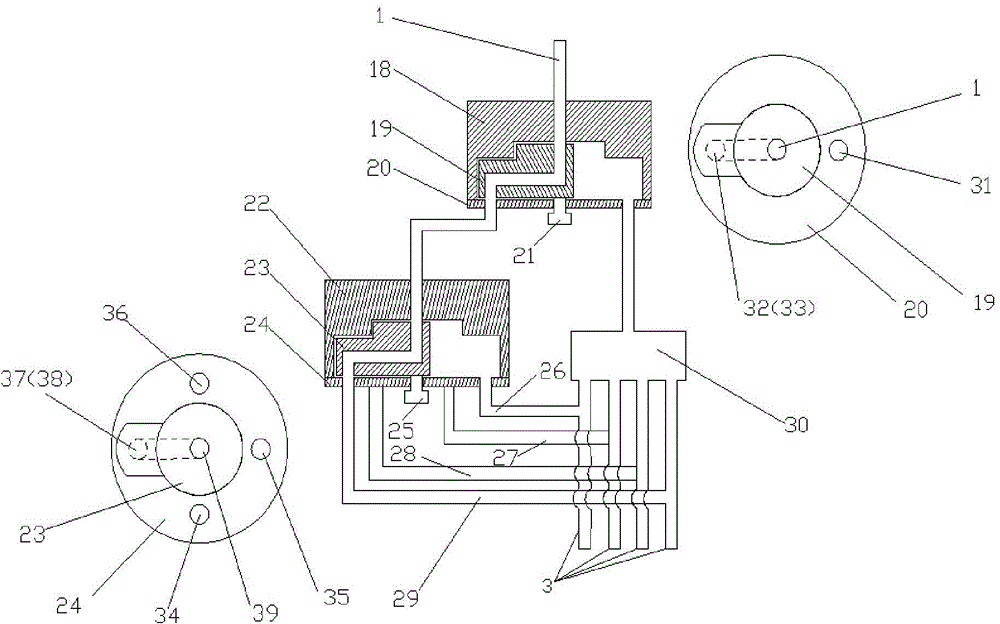

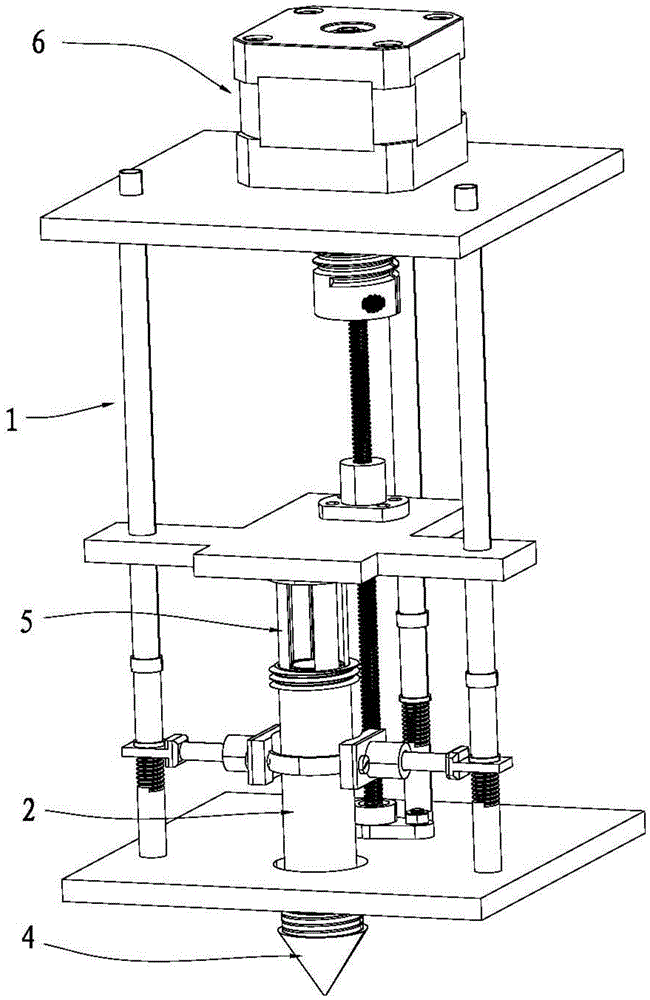

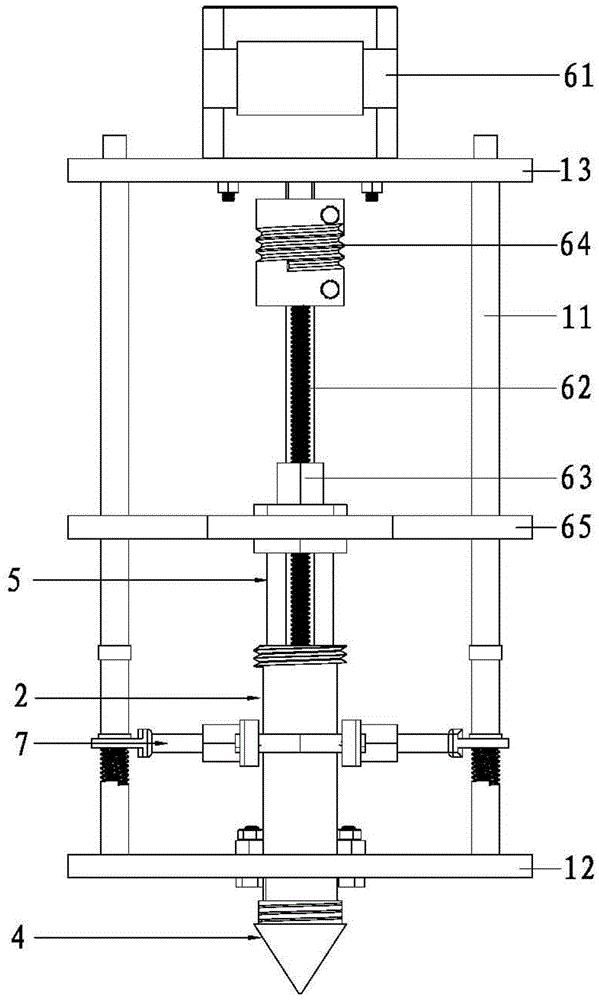

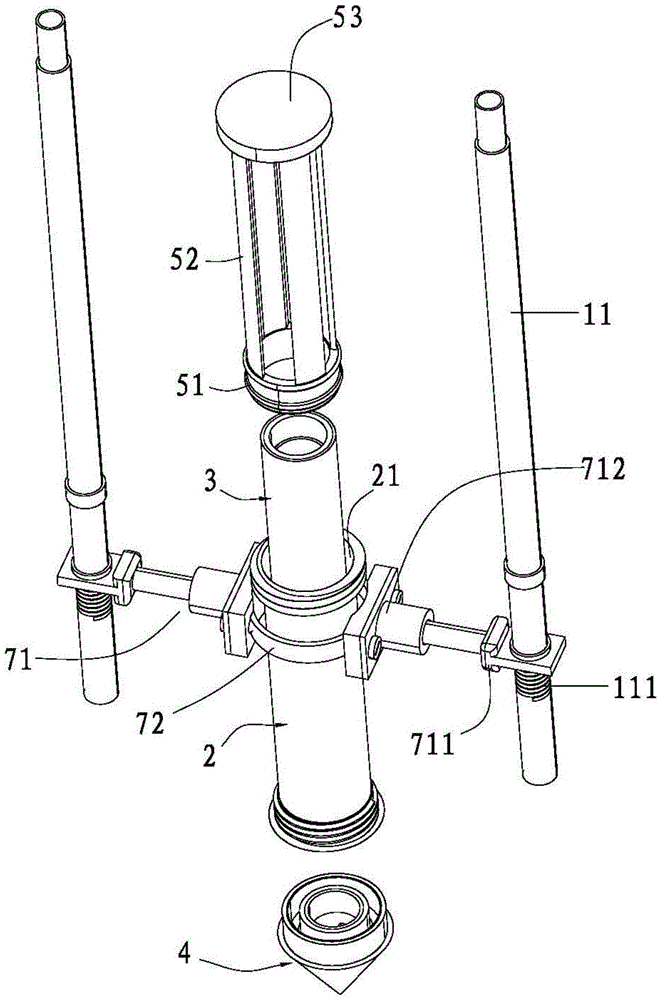

Coaxial 3D printer nozzle and working method thereof

InactiveCN105538732AReasonable structural designShorten the timeAdditive manufacturing apparatusCeramic shaping apparatusReciprocating motionEngineering

The invention discloses a coaxial 3D printer nozzle and a working method thereof. The coaxial 3D printer nozzle comprises a support, an outer barrel, an inner barrel, a coaxial nozzle body, an extrusion piston and a linear driving device. The outer barrel is arranged at the bottom of the support; the inner barrel is arranged in the outer barrel and a cylinder cavity is formed; the coaxial nozzle body is arranged at the lower end of the outer barrel; the extrusion piston is movably arranged in the cylinder cavity; the linear driving device is arranged on the support and can drive the extrusion piston to reciprocate in the cylinder cavity. The coaxial 3D printer nozzle is reasonable in structural design, the outer barrel and the inner barrel are coaxially arranged ingeniously, different materials can be placed into the outer barrel and the inner barrel, then the two different materials are extruded at the same time through the coaxial nozzle body, printing time is saved to a large extent, printing quality is improved, 3D printer consumables do not need to be replaced when different colors or different material portions are printed, it is only needed that the linear driving device and a compressor are correspondingly controlled to be in a work state or in a stop state, and the coaxial 3D printer nozzle is easy and convenient to use and favorable for wide application and popularization.

Owner:XINJIANG UNIVERSITY

Method and apparatus for the formation of particles

InactiveUS20020073511A1Reduce solubilitySolvent extractionGranulation by liquid drop formationParticulatesCompound (substance)

The invention provides a method for forming particles of a substance, by co-introducing into a particle formation vessel, in which the temperature and pressure are controlled, of a supercritical fluid; a solution or suspension of the substance in a first vehicle; and a second vehicle which is both substantially miscible with the first vehicle and substantially soluble in the supercritical fluid in such a way that dispersion of the solution or suspension and the second vehicle, and extraction of the vehicles, occur substantially simultaneously and substantially immediately on introduction of the fluids into the vessel, by the action of the supercritical fluid. Preferably the solution suspension of the substance is introduced separately from the second vehicle, in such a way that contact between the solution / suspension and the second vehicle occurs either substantially simultaneously with, or immediately before, their dispersion by the supercritical fluid and extraction of the vehicles by the supercritical fluid. The method allows a high degree of control over the size, shape, crystalline form and other physico-chemical properties of the particulate product. The invention also provides apparatus for carrying out such a method, using a coaxial nozzle to introduce the fluids into the particle formation vessel, and a particulate product made using the method or the apparatus.

Owner:NEKTAR THERAPEUTICS UK LTD

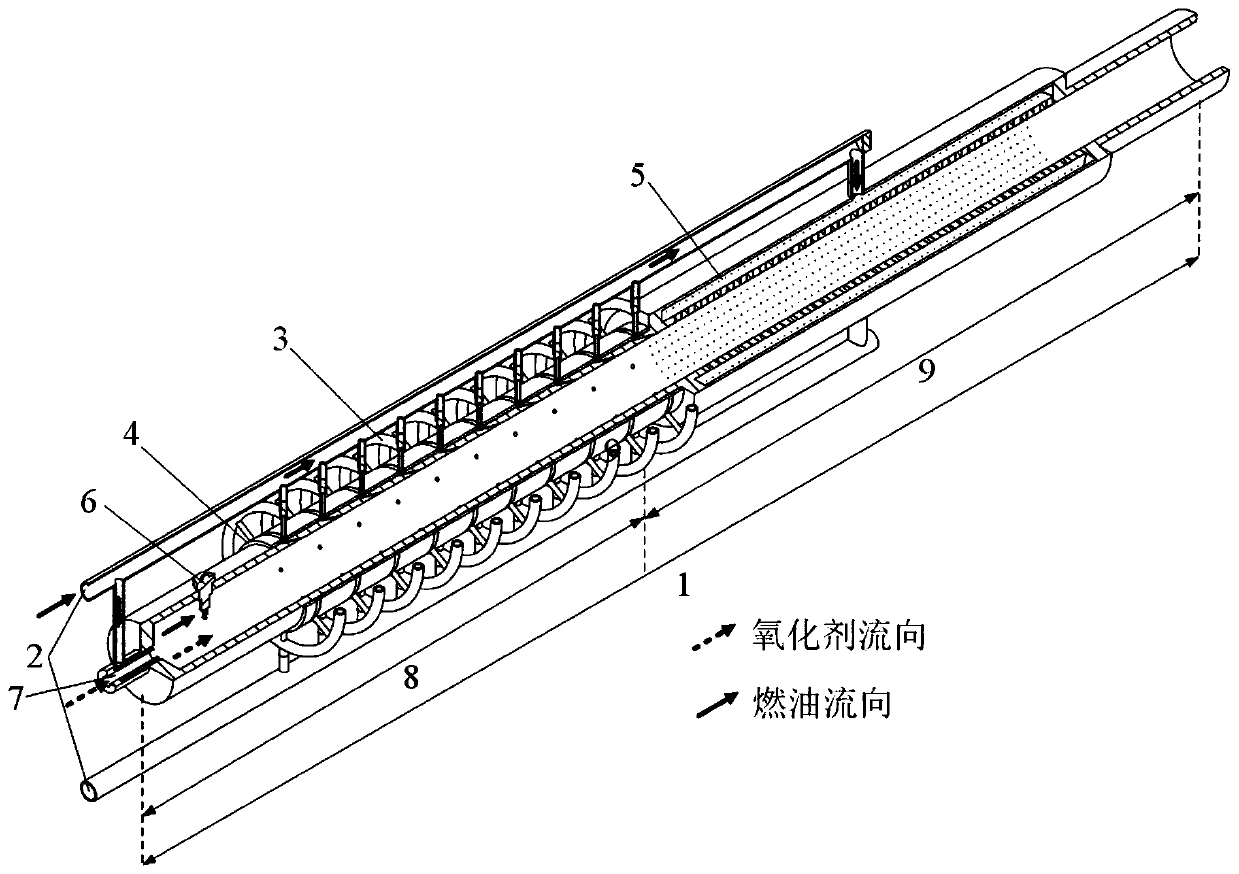

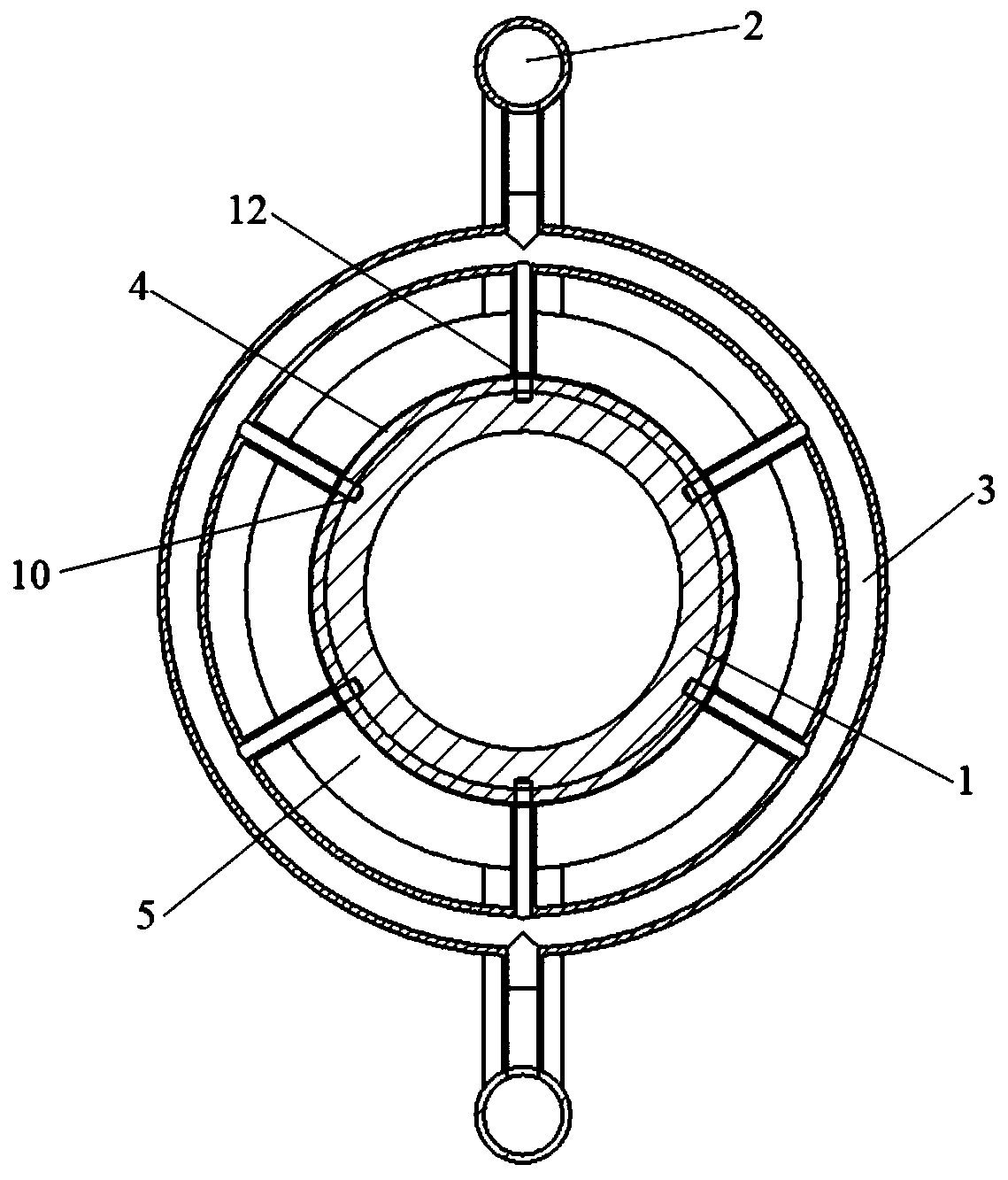

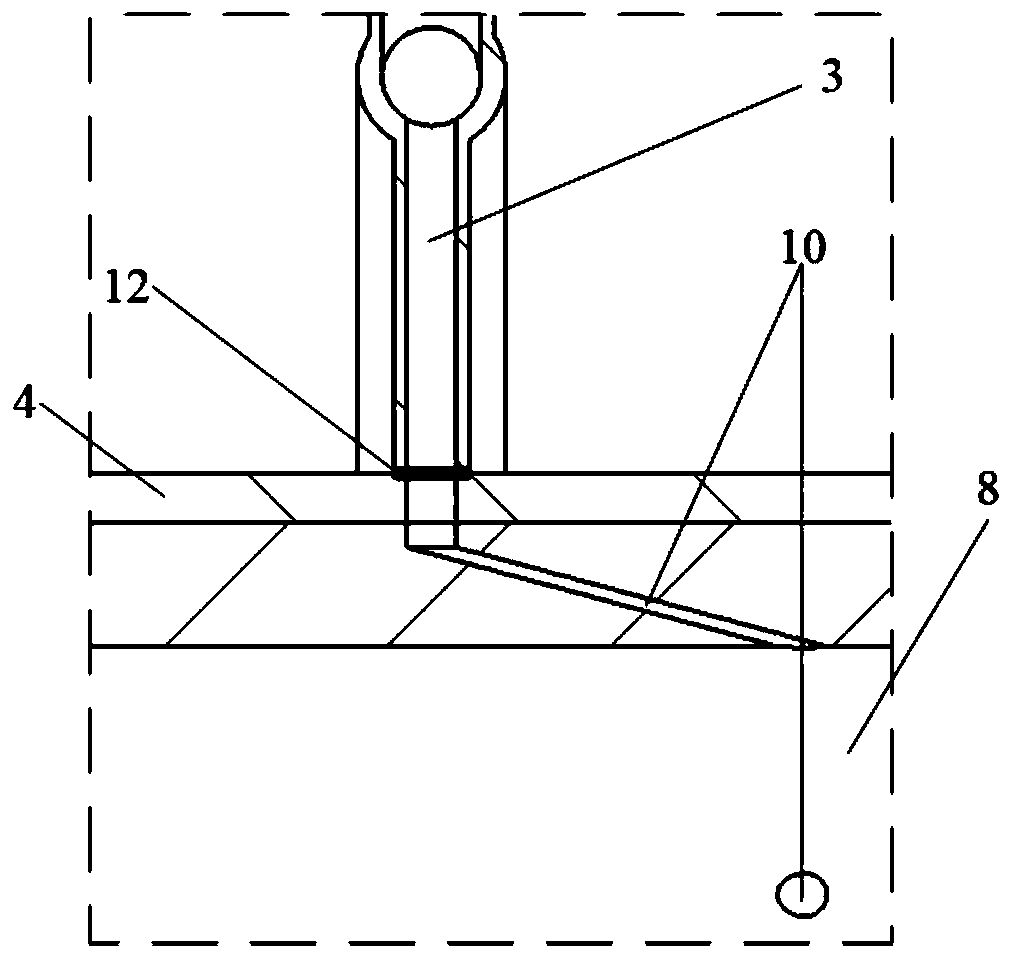

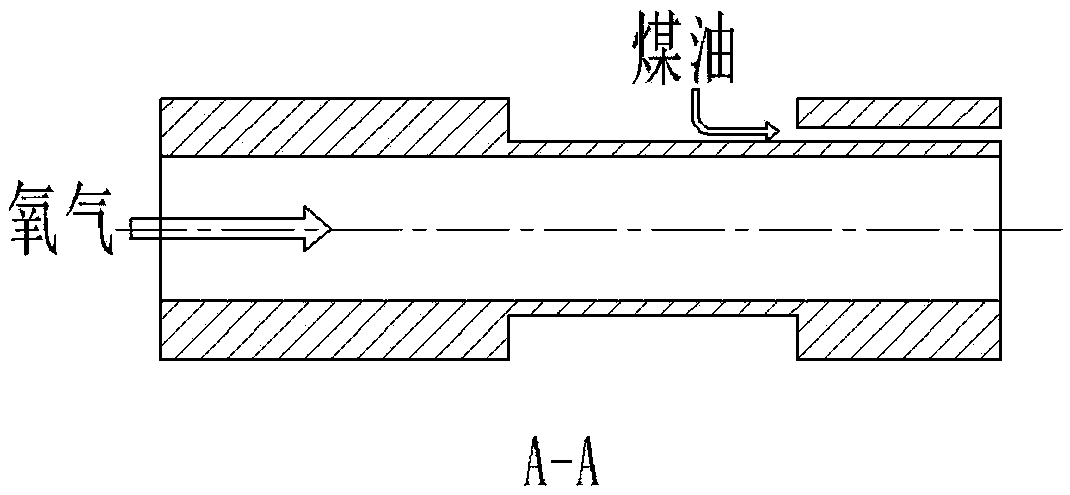

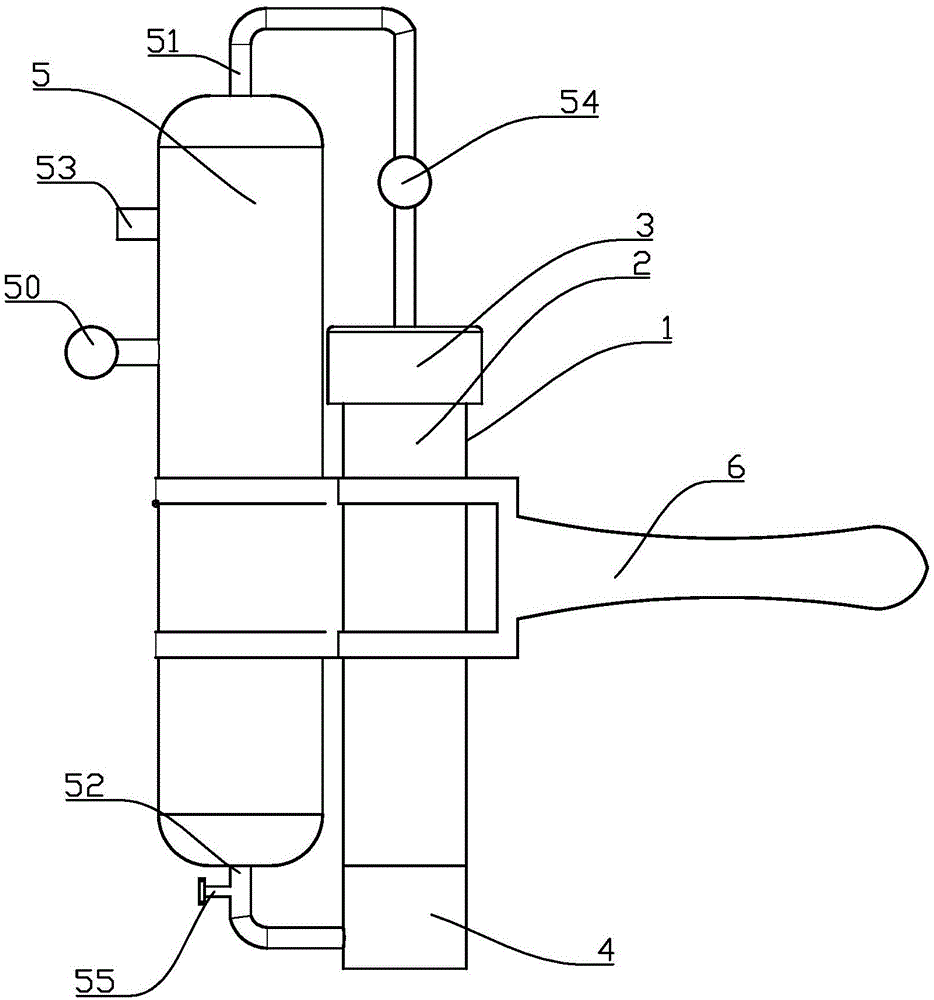

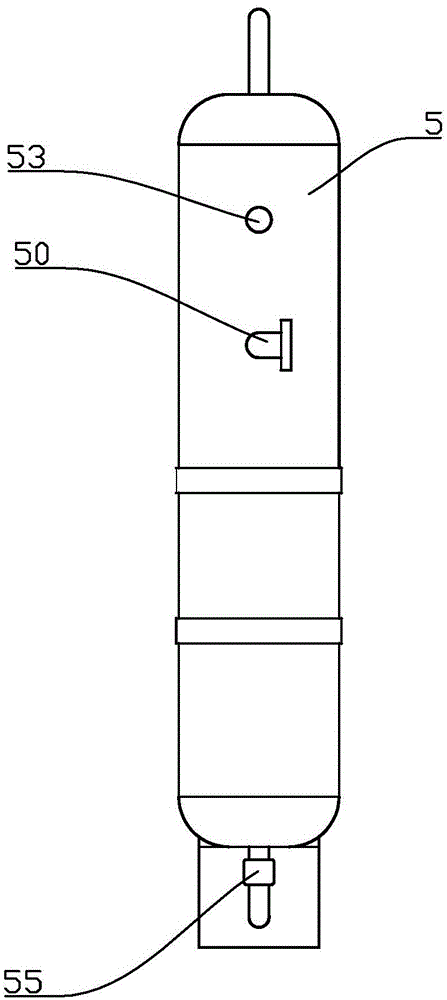

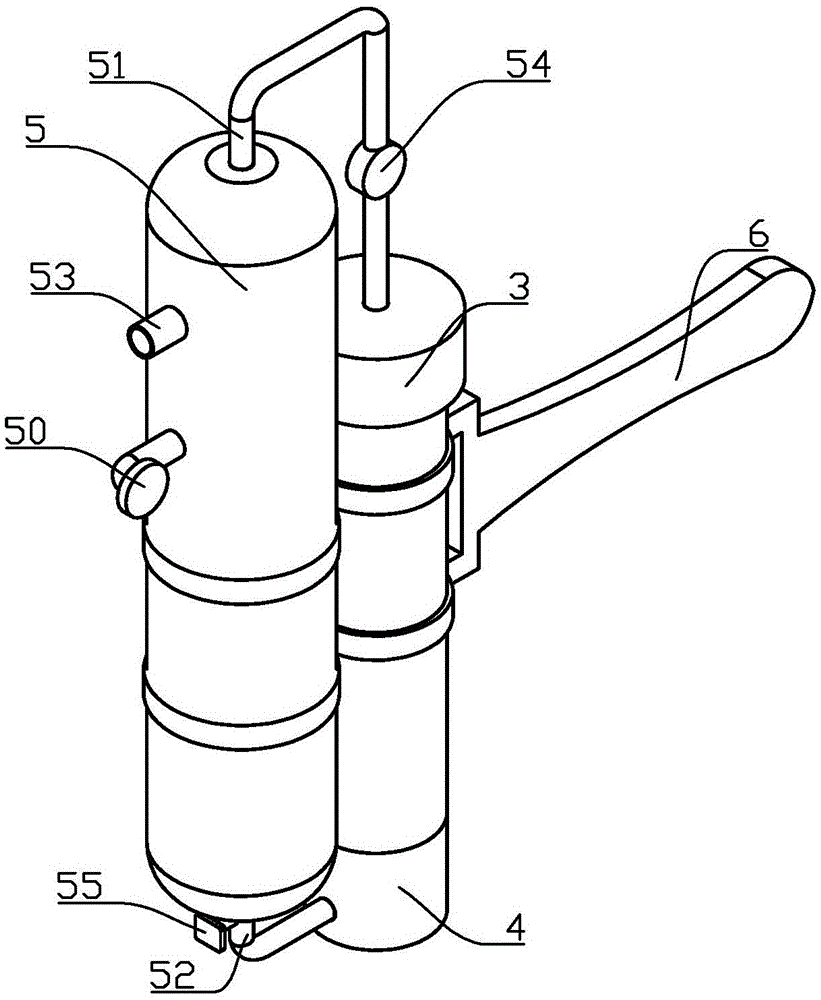

Pulse detonation rocket engine oil supply scheme beneficial to cooling and detonation initiation of wall surface

ActiveCN109915281AImprove uniformityIncrease exhaust temperatureRocket engine plantsCombustion chamberDetonation

The invention provides a pulse detonation rocket engine oil supply scheme beneficial to cooling and detonation initiation of a wall surface. The pulse detonation rocket engine oil supply scheme structurally comprises a detonation combustion chamber, common rail oil supply pipes, an oil supply ring pipe, a rotating valve, a fuel oil preheating cavity, a sparking plug and a coaxial nozzle, wherein the detonation combustion chamber is sequentially divided into two parts of a DDT section and a detonation transmission section in the direction of an incoming flow. Fuel oil serves as fuel in the detonation combustion chamber, and is mixed with an oxidizing agent to form a detonable mixture, the fuel oil also serves as a cooling medium, carries out oil film cooling on the wall surface of the DDT section of the detonation combustion chamber and carries out sweat cooling on the wall surface of the detonation transmission section, and a part of fuel oil is preheated, so that the fuel injection uniformity in the detonation combustion chamber is improved, the discharge temperature after detonation is raised; and the oil supply scheme serves as a fluid DDT scheme, and an original solid DDT device is replaced, so that change from slow combustion to the detonation is accelerated, and the total pressure loss during the detonation initiation is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

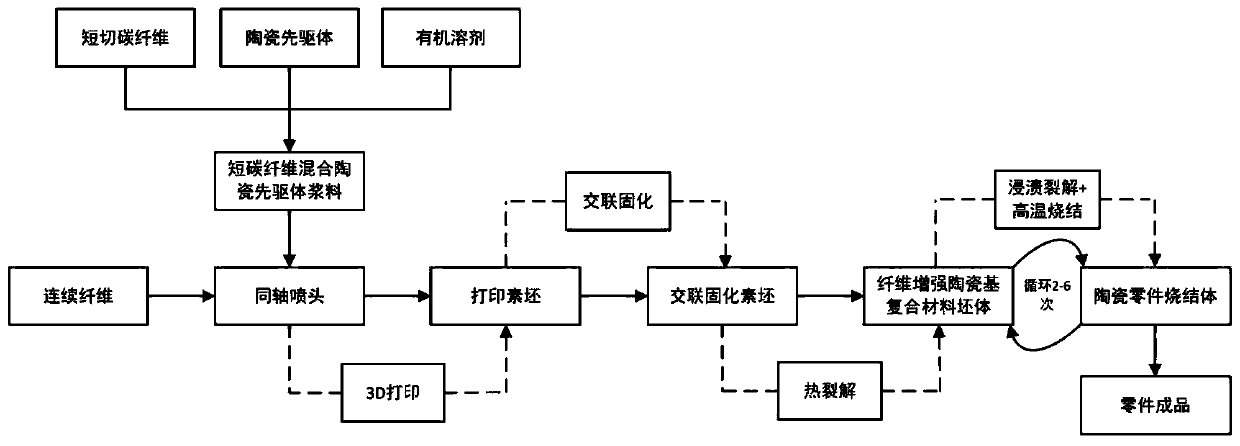

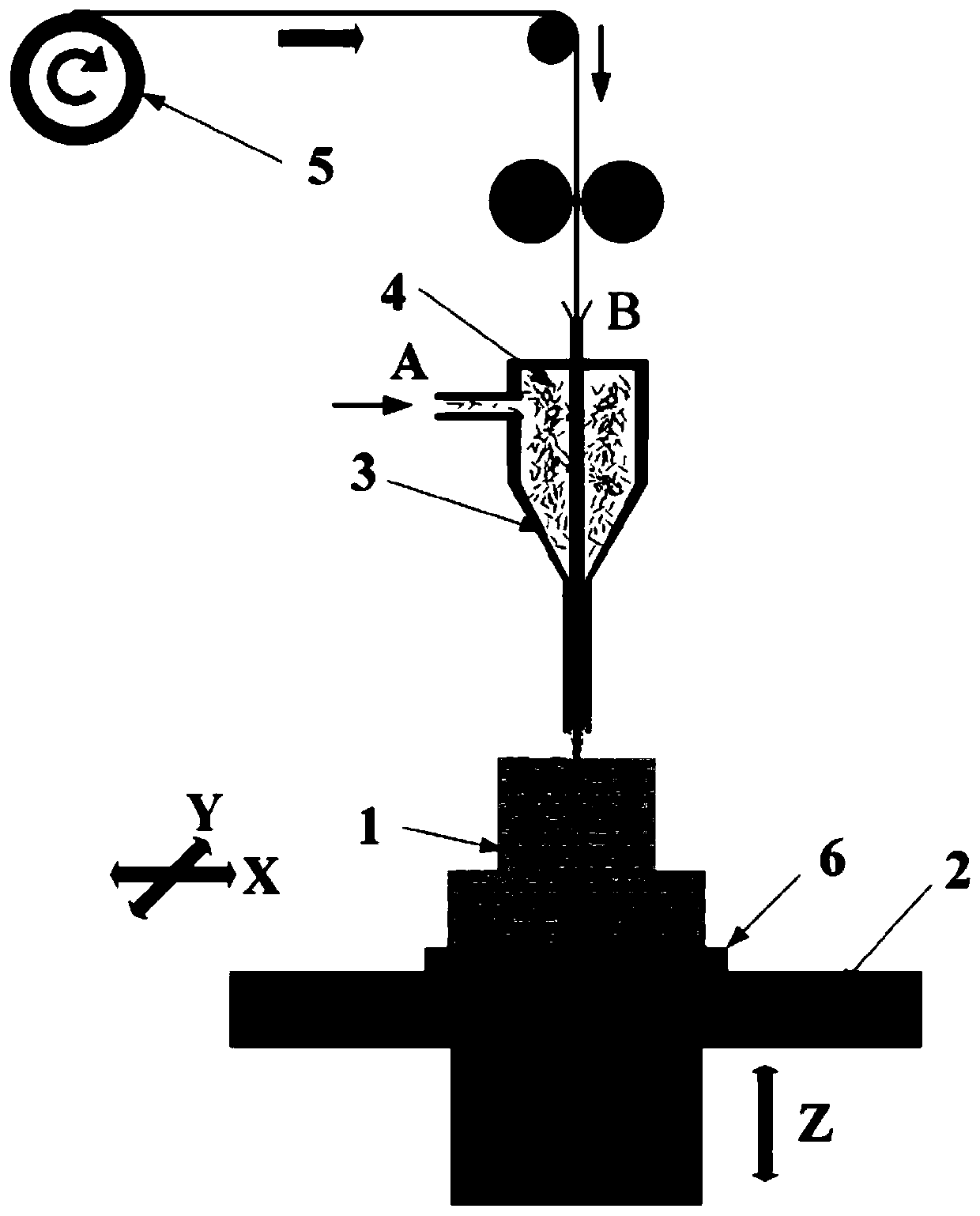

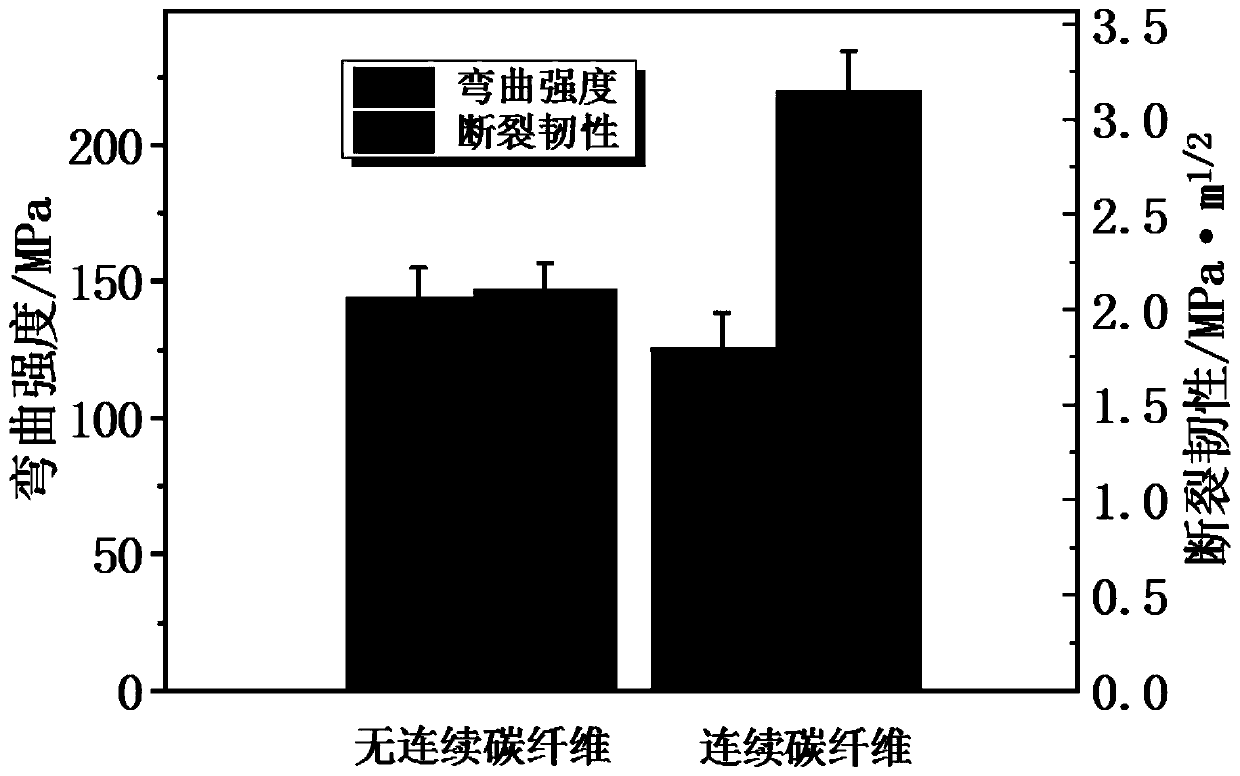

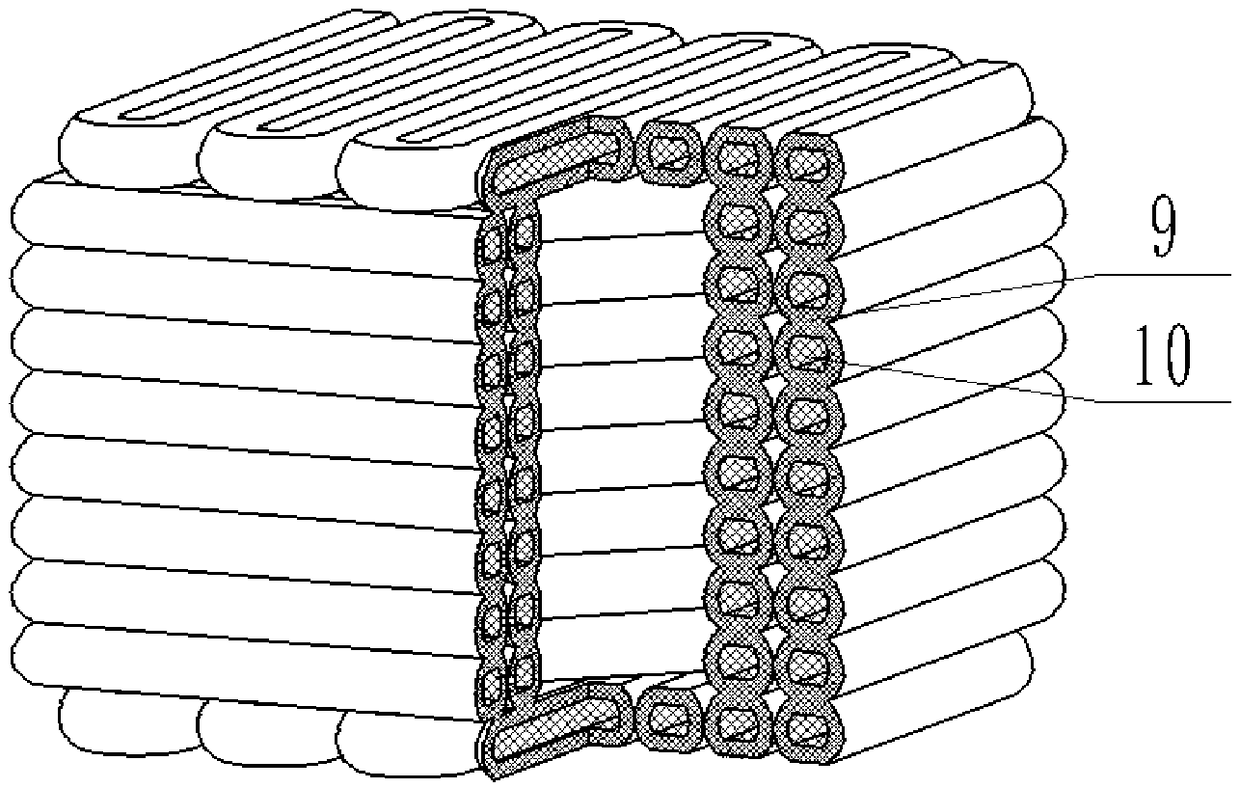

Method for forming continuous fiber-bonded short carbon fiber toughened ceramic matrix composite material

InactiveCN110229012AForming accuratelyImprove toughnessAdditive manufacturing apparatusOrganic solventCarbon fibers

The invention discloses a method for forming a continuous fiber-bonded short carbon fiber toughened ceramic matrix composite material. A ceramic precursor, an organic solvent and chopped carbon fibersare mixed to form a direct writing slurry, the direct writing slurry is added into the outer cylinder of a coaxial nozzle, a continuous fiber is added into the inner cylinder of the coaxial nozzle tomake a finally printed blank have a core-shell structure with the continuous fiber as the core and a short carbon fiber toughened ceramic matrix as the shell, the ceramic matrix is formed by crackingand converting the ceramic precursor, the chopped carbon fibers are directionally distributed in the matrix, and the chopped carbon fibers in the outer layer are directionally arranged, so the toughness of the ceramic material can be greatly improved. A 3D printing technology makes the ceramic precursor quickly and accurately molded, and the ceramic material matrix with different components can be prepared in different sintering environments in the high temperature sintering process by means of a precursor conversion process, so the original materials can be widely selected.

Owner:XI AN JIAOTONG UNIV

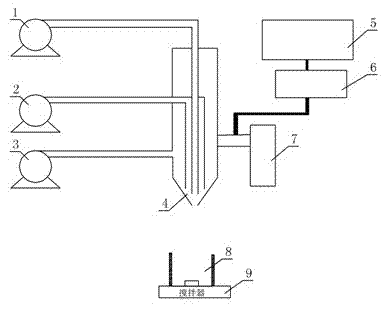

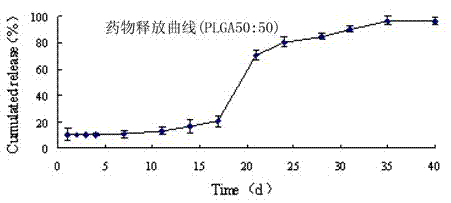

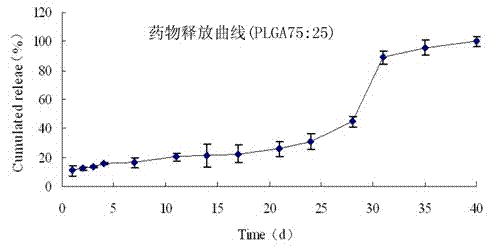

Device and method for preparing pulsatile release microspheres

InactiveCN102847494AIdeal delivery methodAvoid damageMicroballoon preparationMicrocapsule preparationDrugs solutionUltrasonic sensor

The invention discloses a device and a method for preparing pulsatile release microspheres. The device comprises three constant-flow pumps, coaxial nozzles, a frequency generator, a signal amplifier, an ultrasonic transducer, a collection container and a stirrer. The coaxial nozzles are three homocentric nozzles comprising an inner nozzle, a middle nozzle and an outer nozzle. The inner nozzle, the middle nozzle and the outer nozzle are connected respectively to the three constant-flow pumps by independent liquid delivery pipes and respectively convey a drug solution, a polymer solution and a stabilizing solution. The method comprises that through adjustment of flowing rates of the constant-flow pumps, jet flows produced by the coaxial nozzles; the ultrasonic transducer vibrates and resonates with the coaxial nozzles so that the jet flows are broken into uniform micro-droplets; the micro-droplets drop in the collection container with the stirrer; and particles prepared by the previous step are polymer solution-coated drugs and contact with the stabilizing solution so that a polymer is precipitated and is solidified into core-shell microspheres. Microsphere drug release is controlled by properties of a polymer and after a polymer shell is degraded, a drug is released intensively in a pulse way.

Owner:ZHEJIANG PHARMA COLLEGE

Supercritical impact flow method for wrapping micro granule

InactiveCN1879957AIncrease resistanceReduce resistanceMicroballoon preparationMicrocapsule preparationParticle packingPaper production

The invention relates to a ultra-critical impact flow particle packing method, which is characterized in that: adding the wall material into the mixer to be dissolved into solution; mixing and dispersing the particle uniformly, to form suspension; using a couple of coaxial nozzles to output the wall material to be deposited on the surface of packed particle to form the coat, and separated by the separator to obtain the micro capsule product. The invention can combine the advantages of present packing fluid bed packing method and impact flow method, to be used in food industry, paper production, etc.

Owner:DALIAN UNIV OF TECH

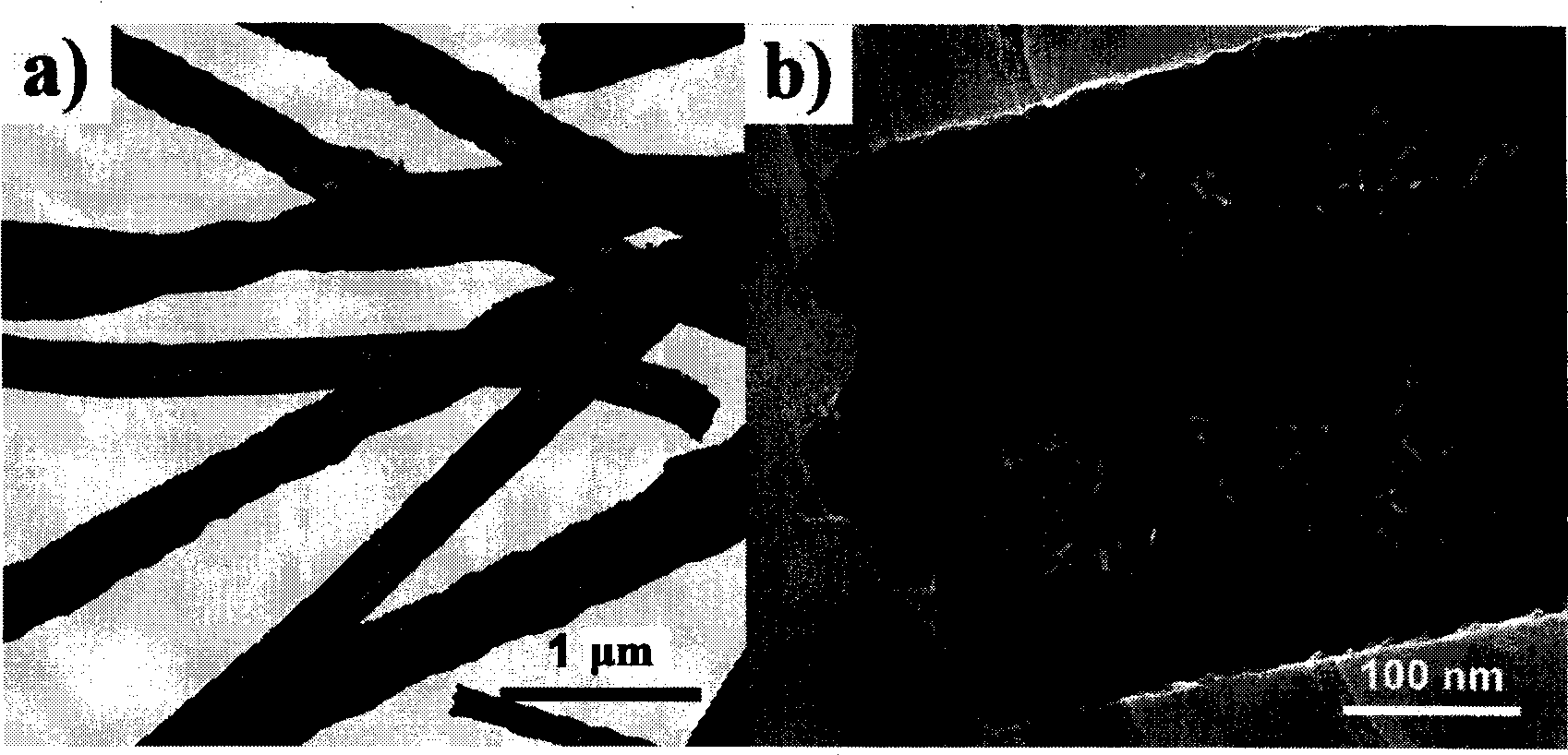

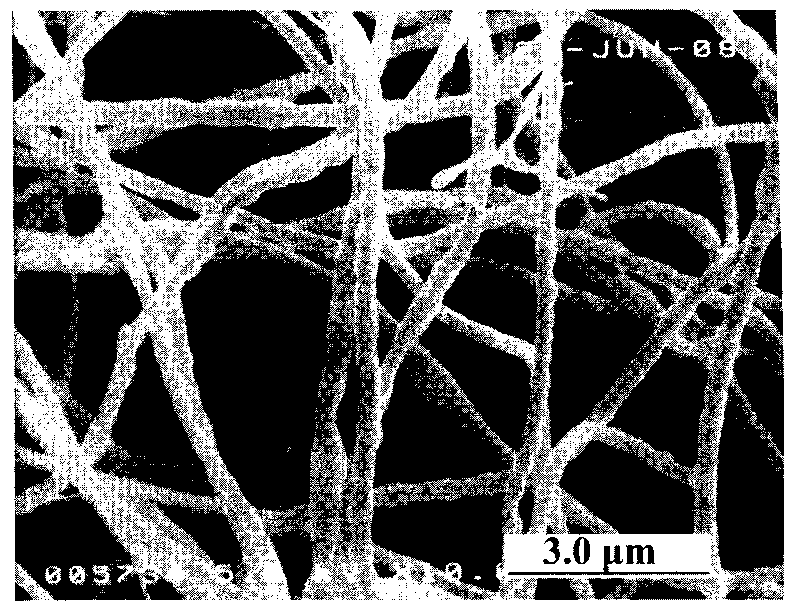

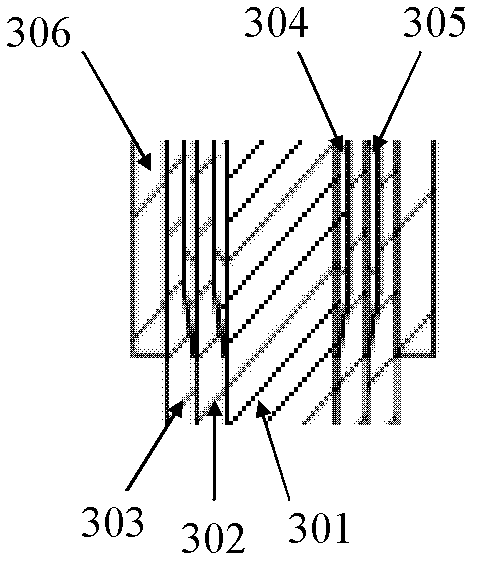

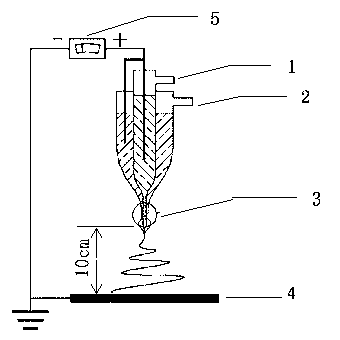

Preparation method and preparation device of nano fibers

InactiveCN103215690AClear interface between layersImprove spin performanceFilament/thread formingConjugated artificial filamentsFiberSpinning

The invention provides a preparation method and a preparation device of of nano fibers. The method comprises the following steps of: preparing precursor solutions; carrying out coaxial electrostatic spinning; respectively filling a core precursor solution and a shell precursor solution into a core layer solution storage container (1) and a shell layer solution storage container (2); adding a thin copper wire with the diameter of 20 microns into an inner wall of the core layer solution storage container (1), wherein the applying voltage of a high-voltage direct-current power supply (5) is 16-18 KV, the environment temperature is 20 DEG C and the environment humidity is 50%; powering on the power supply and spinning; then carrying out drying treatment on spun wires, wherein the drying temperature is 70 DEG C and the drying time is 6 hours; then carrying out annealing treatment: and raising the temperature to 800 DEG C, keeping the heat at 800 DEG C for 300 min, and then naturally cooling, wherein the core layer solution storage container (1) is mounted in the shell layer solution storage container (2), an axial shower nozzle (3) is formed by the lower end of the core layer solution storage container (1) and the lower end of the shell layer solution storage container (2), and a thin copper wire is arranged on the inner wall of the core layer solution storage container (1).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Coaxial 3D printing process and equipment

ActiveCN109177150AReduce weightReduce usage3D object support structuresApplying layer meansRelative VolumeVolumetric Mass Density

The invention provides a coaxial 3D printing process and equipment, which are used for printing different coaxial fuse wires of inner and outer materials through coaxial nozzles. According to the process, the outer layer is a main use layer and determines the mechanical performance of a product; the inner layer for extruding wire materials is an assistant forming layer, the section of the extrudedouter layer annular material is prevented from collapsing; the assistant forming layer can be made of a material with relatively small relative volume density or a material which can be removed later; the outer layer is a performance guarantee layer, the section of a coaxial wire material can be similar to an annulus during performance analysis, and the strength of a product with an annular section is better than that of a product with a round section when the section areas are the same according to theoretically mechanic analysis, so that the strength of the product manufactured by the process and equipment under the situation that weight is not changed, and further light weight of 3D printing technology can be realized. The process and equipment can be used for optimizing product performance, such as fire-proof products, anticorrosive products and performance enhanced products to meet the requirement of different use conditions, so that the application range of 3D printed products can be expanded.

Owner:BEIJING UNIV OF CHEM TECH

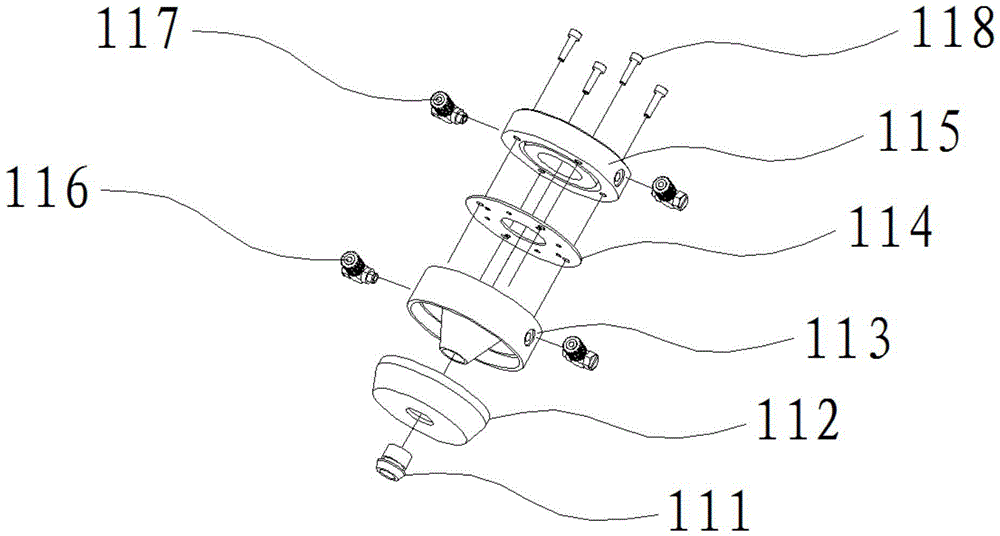

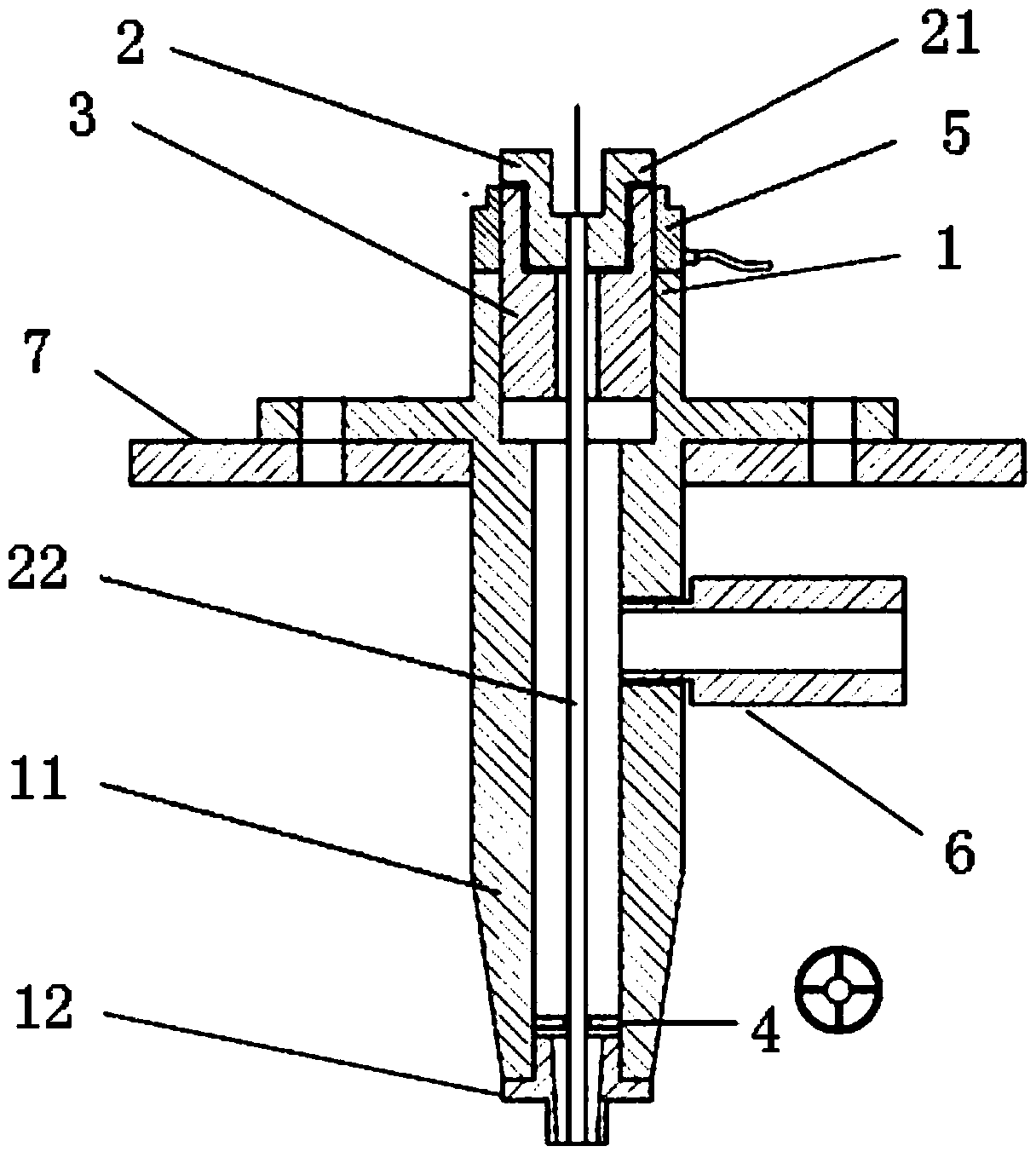

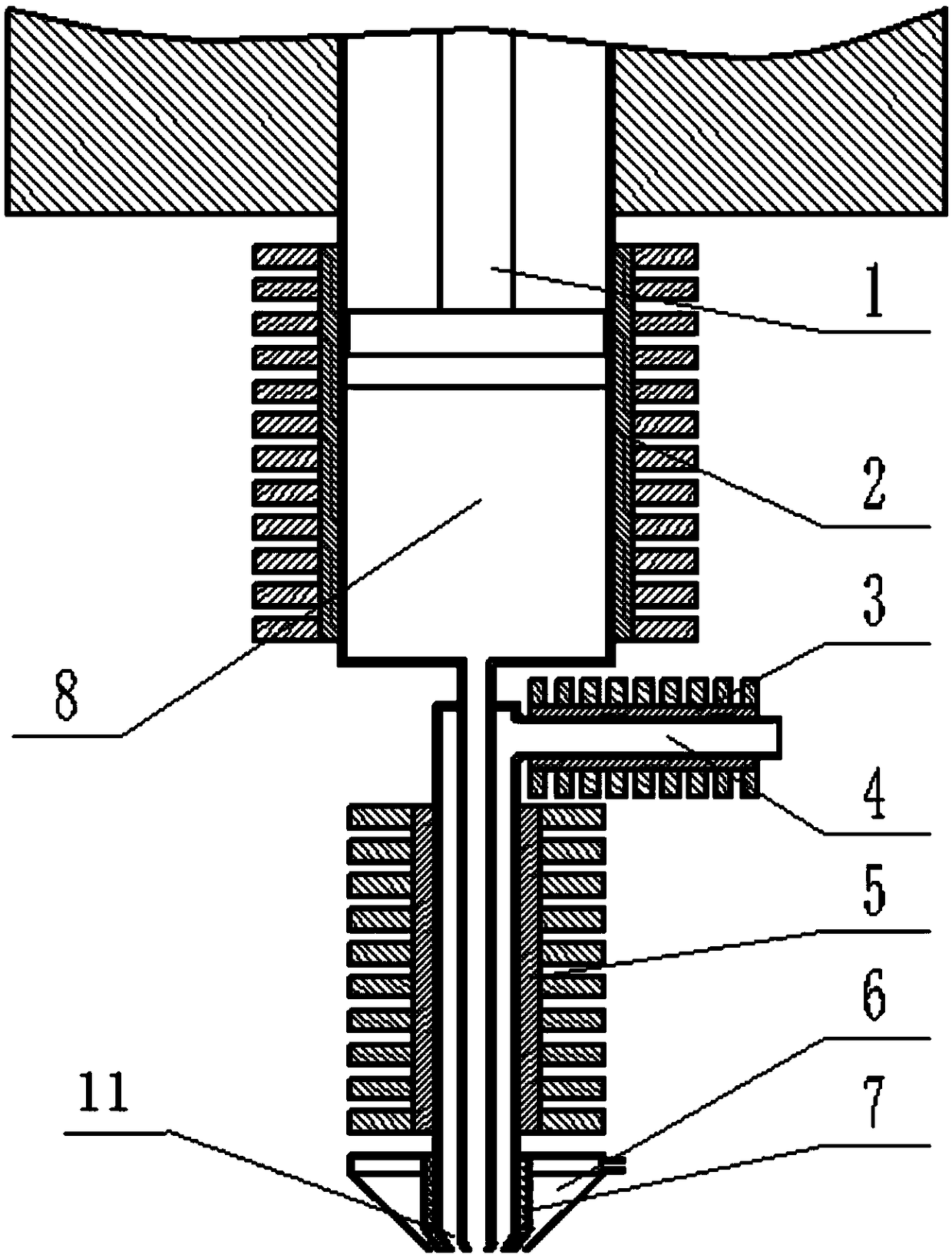

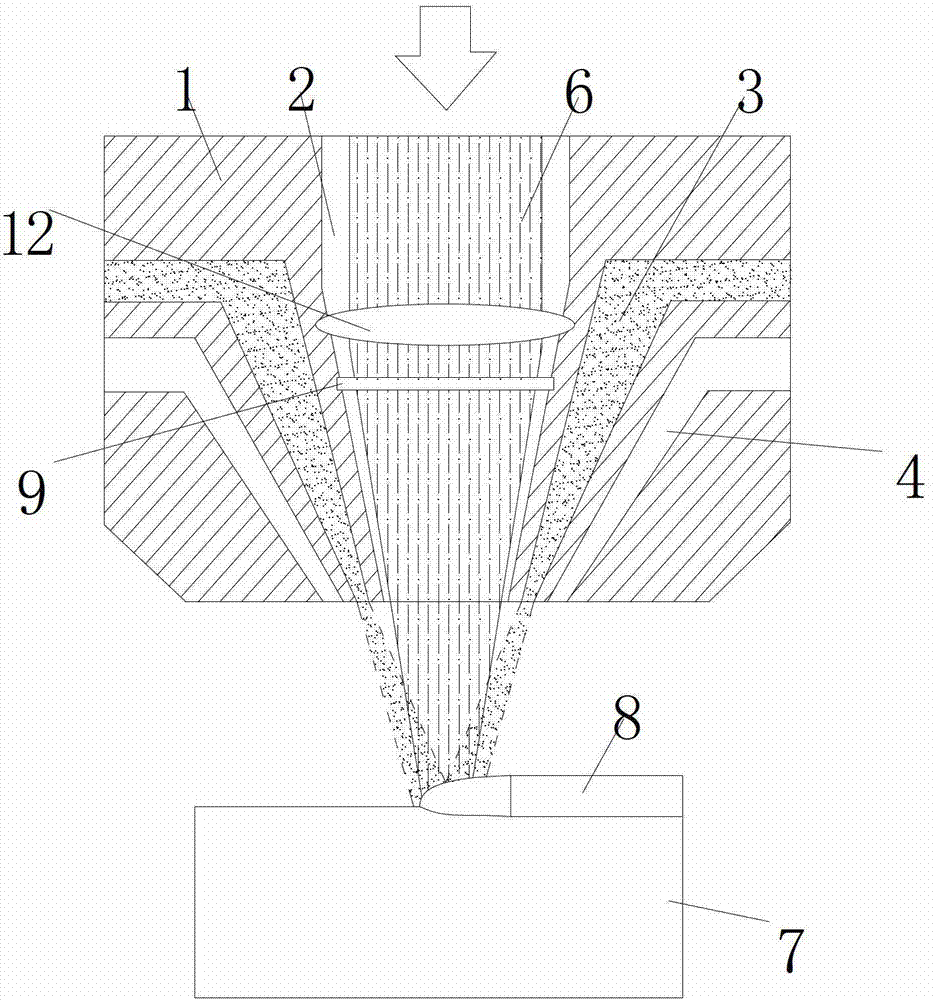

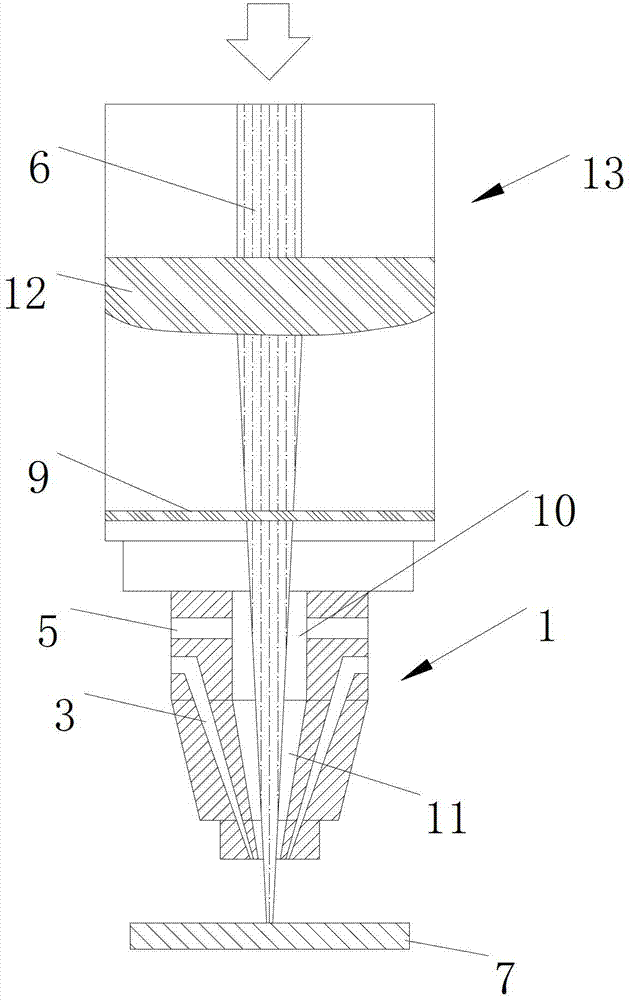

Coaxial nozzle for laser cladding

ActiveCN102828178AAvoid dangerUniform and symmetrical powder flow fieldMetallic material coating processesLaser beam welding apparatusCoaxial nozzleMaterials science

The invention discloses a coaxial nozzle for laser cladding, which is provided with a central channel disposed at the center of the nozzle and running through the nozzle from up to down, and a plurality of powder channels disposed at the periphery of the central channel; the central channel comprises a first chamber and a second chamber disposed below the first chamber and communicated with the first chamber; the second chamber is funnel-shaped; a protective gas inlet is disposed on the nozzle, wherein one ee protective gas inlet is connected with a protective gas adding device, and the other end is communicated with the central channel. Laser enters the central channel of the nozzle through a protective lens; high-pressure protective lens enters the central channel through the protective gas inlet, forms flowing wind from up to down in the central channel, is ejected out from the central channel, and mixed with powder ejected from the powder channel to reach a workpiece base material surface to be cladded. With the above technical scheme, the powder is effectively prevented from crushing into the central channel to cause danger, and simultaneously a uniform and symmetric powder flow field is formed.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

Liquid film cooling injection rocket engine thrust chamber for rocket ramjet combined engine

The invention discloses a liquid film cooling injection rocket engine thrust chamber of a rocket ramjet combined engine, which comprises a head part, wherein the head part comprises a head shell, andone end of the head shell is provided with an ignition device; the head shell is also provided with an oxygen through joint and a kerosene through joint, and the oxygen through joint and the kerosenethrough joint are both communicated with a gas-liquid coaxial nozzle; the gas-liquid coaxial nozzle comprises an oxygen direct flowing spraying hole arranged in the head shell and coaxially arranged with the gas-liquid coaxial nozzle, and also comprises a segmented direct flowing slit nozzle for kerosene circulation, wherein the segmented direct flowing slit nozzle which is arranged outside the oxygen direct flowing spraying hole, is a three-section slit; the other end of the head shell is coaxially communicated with a liquid film flange plate, a thrust chamber shell and a graphite spraying pipe through a graphite gasket. The problems that the engine cannot work for a long time by using a passive cooling mode in the prior art, and the structure of a jacket cooling thrust chamber body is complex are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Portable handheld spinning device

InactiveCN105113028AAvoid the dangers of spinningAvoid High Voltage HazardsDry spinning methodsStretch-spinning methodsNanofiberEngineering

The invention discloses a portable handheld spinning device which comprises a solution container. The solution container comprises a cylinder body and a piston, and the piston divides the cylinder body into an air pressure cavity and a solution cavity; a needle head communicated with the interior of the solution cavity is arranged under the solution cavity, the outer surface of the needle head is sleeved with an air chamber, the tail end of the needle head penetrates through a third air outlet of the air chamber to stretch out of the air chamber and then is coaxially installed with the third air outlet to form a coaxial nozzle system, and the air chamber is provided with a second air inlet. According to the portable handheld spinning device, the spinning solution feeding speed is changed by changing pushing force of the piston, according to the Bernoulli principle, the gas speed can be rapidly increased on the condition that the pressure of the gas is quickly decreased from the high pressure to the low pressure, and therefore under the action of the high and low pressure of the interior and exterior of a coaxial nozzle formed by the needle head and the third air outlet, cone-shaped liquid drops can be formed at the needle tip; high-speed airflow viscosity force overcomes surface tension of the liquid drops, then polymeric nanofibers are stretched out from the needle tip to form jet flow, and finally the polymeric nanofibers are deposited on a collecting device.

Owner:GUANGDONG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com