Pulse detonation rocket engine oil supply scheme beneficial to cooling and detonation initiation of wall surface

A rocket engine and pulse detonation technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of weakening the self-boosting effect of detonation, affecting the working performance of the engine, and poor detonability of the gas mixture in the tube. Achieve the effect of simplifying system complexity, improving uniformity, and suppressing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with specific embodiment, accompanying drawing, the present invention will be further described:

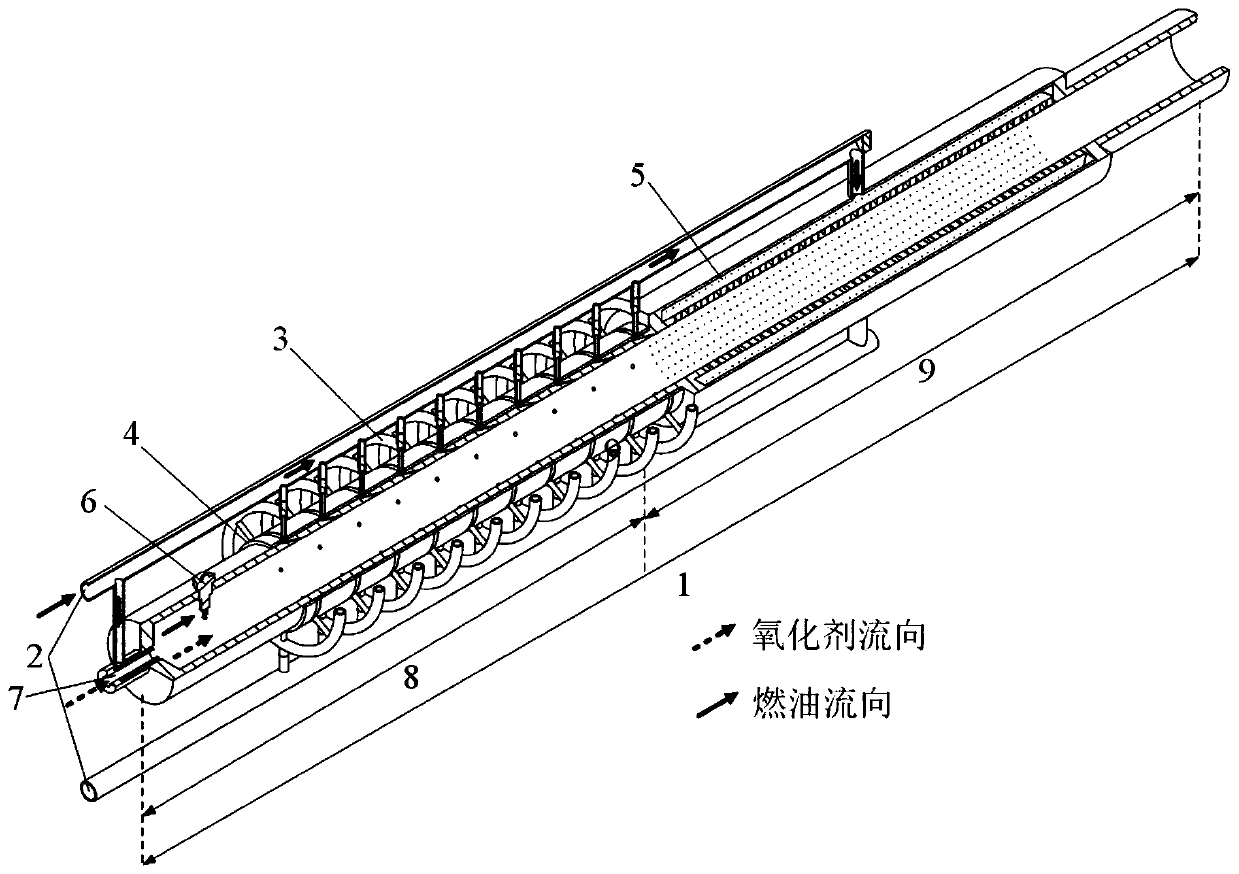

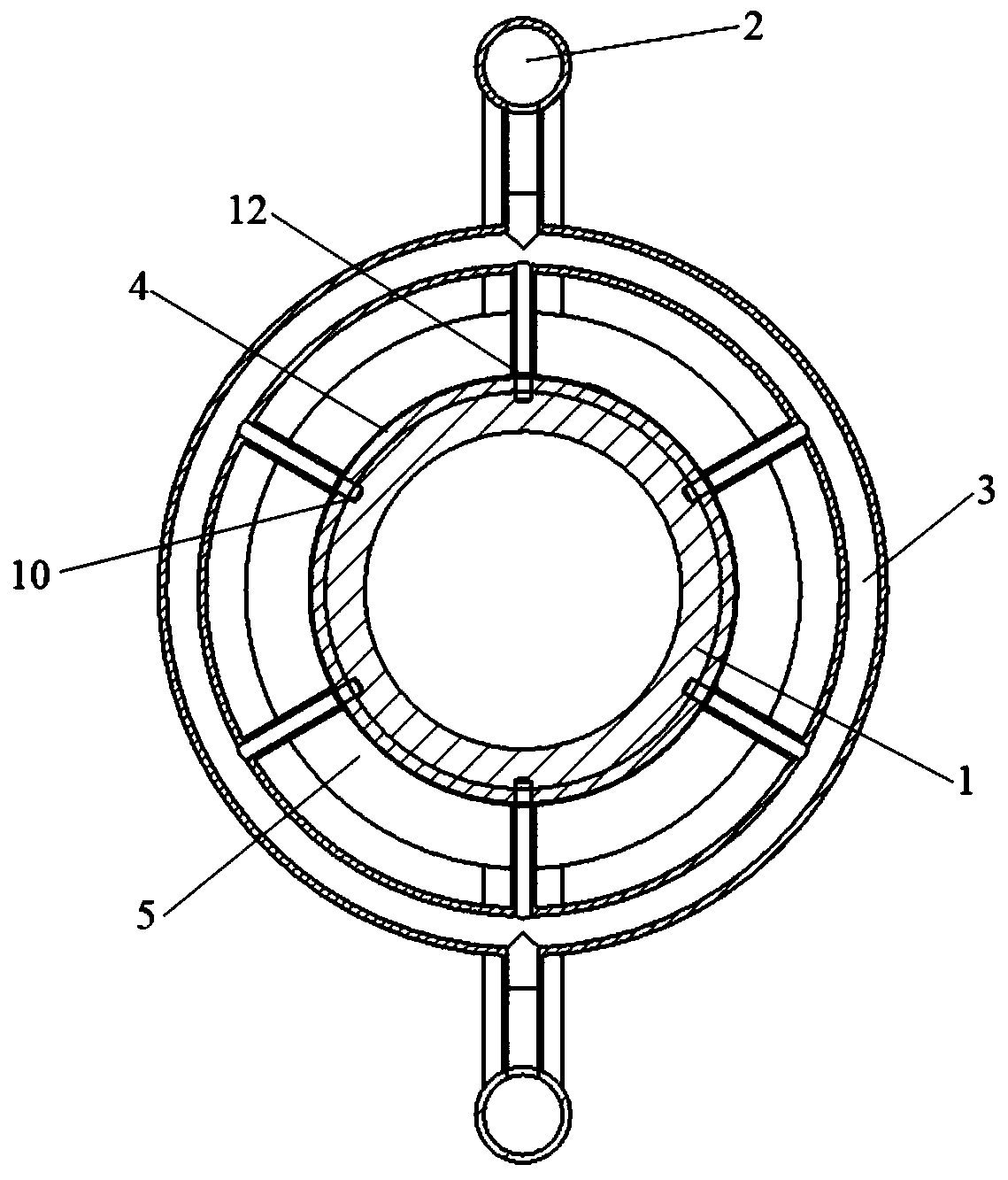

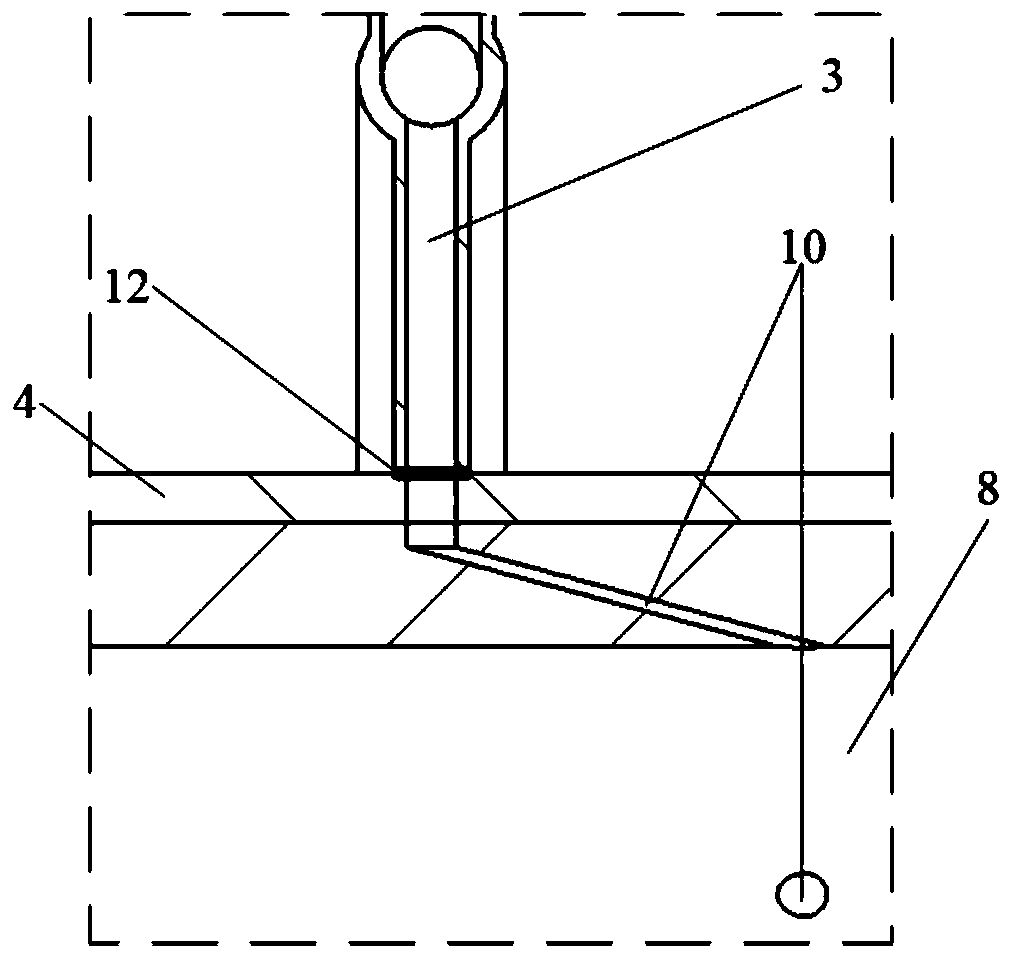

[0026] Example Figure 1~4 As shown, the present invention proposes a fuel supply scheme for pulse detonation rocket engines that is beneficial to wall cooling and detonation, figure 1 It is a structural schematic diagram of the present invention, including a detonation combustion chamber (1), a common rail oil supply pipeline (2), an oil supply ring pipe (3), a rotary valve (4), a fuel preheating chamber (5), a spark plug (6 ), coaxial nozzles (7), etc., wherein the detonation combustion chamber (1) is divided into two parts, the DDT section (8) and the detonation propagation section (9), along the incoming flow direction. figure 2 is the section along the axis of the ring pipe of the ring oil supply pipeline, image 3 and Figure 4 The schematic diagrams of the cross-sectional details of the injection hole (10) and the sweating cooling hole (11); the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com