Tubular and tube-in-tube structure organic oxide and preparation method thereof

An inorganic oxide, tube-in-tube technology, which is applied in the fields of inorganic raw material rayon, textiles and papermaking, fiber processing, etc., can solve the problems of difficult control, complicated device, unable to build fibers, etc., achieves simple operation and overcomes complex structure. , Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

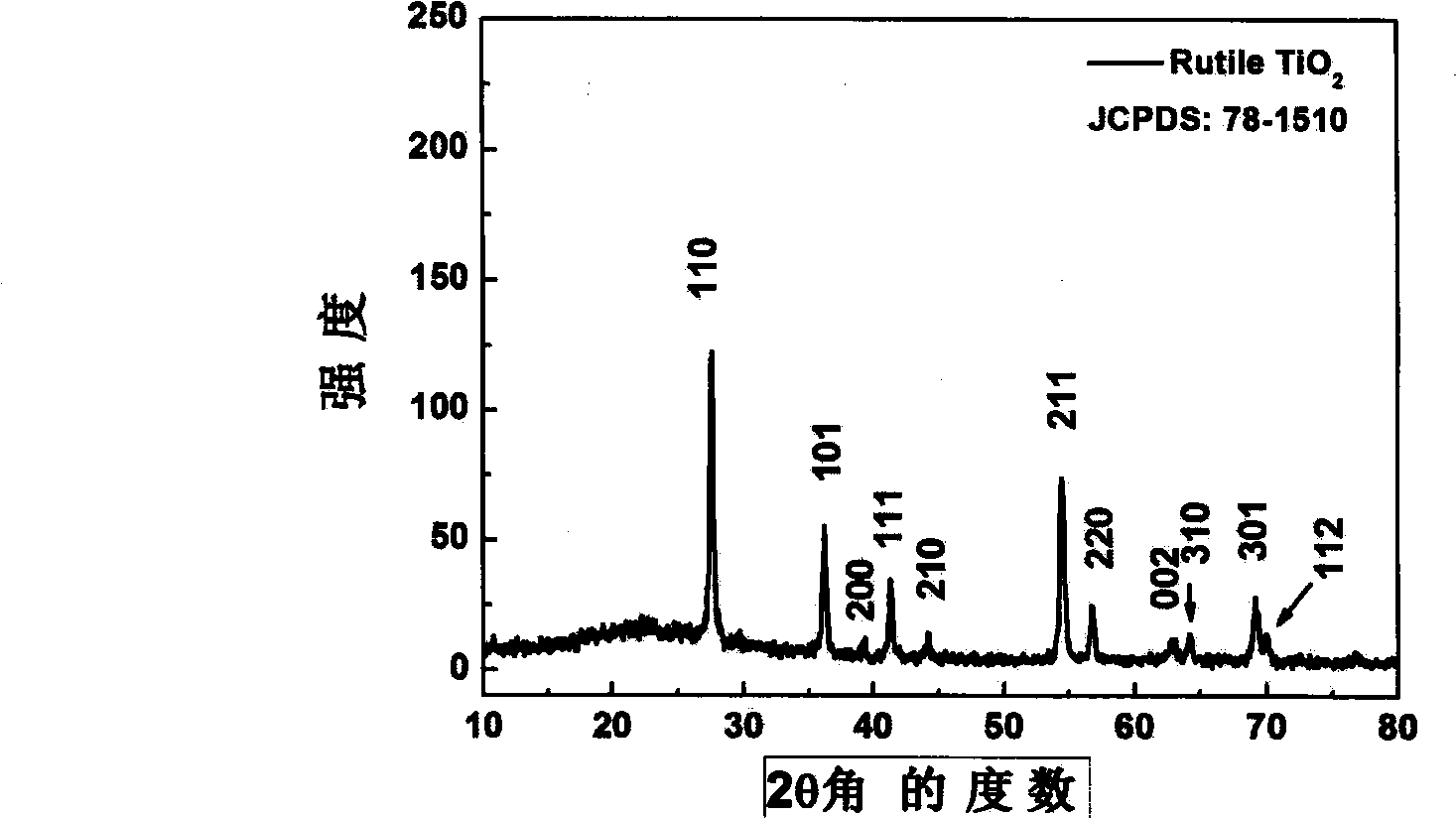

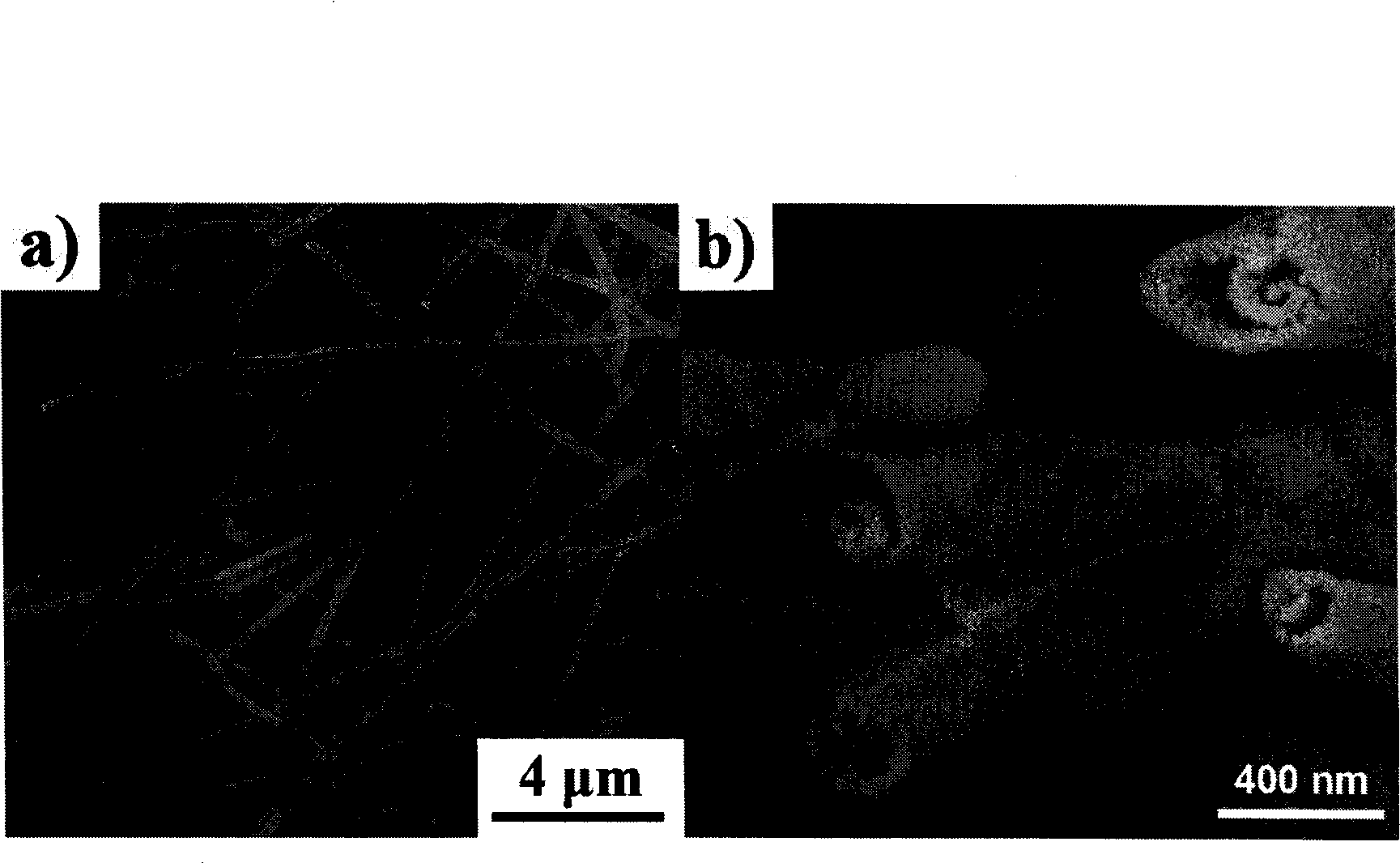

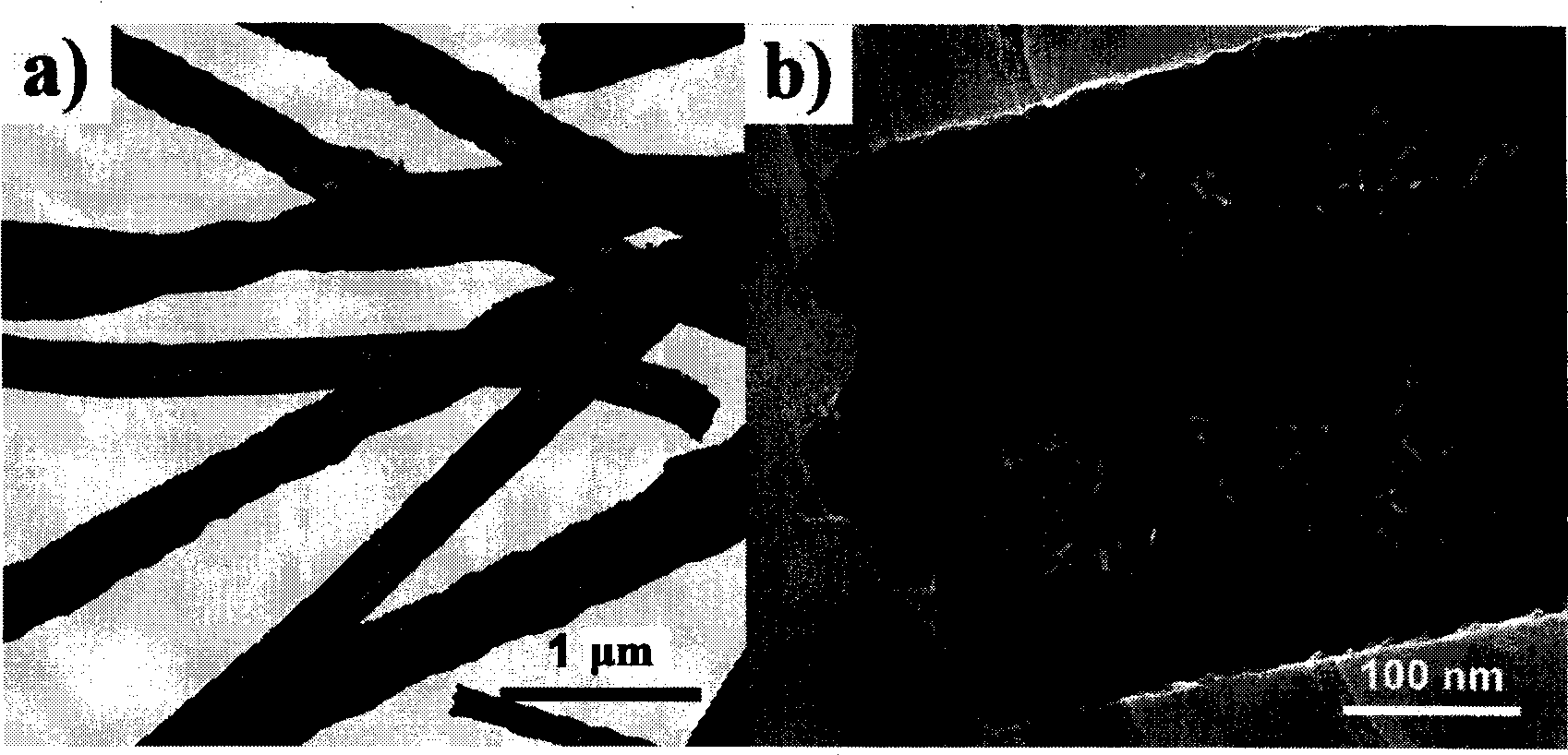

[0038] Weigh 2.5g of PVP-K30 (molecular weight 25000-40000) and dissolve it in 5ml of ethanol to form a transparent and uniform solution, then add 0.5ml of acetic acid to it, stir uniformly and add 1.5ml of butyl titanate (the amount of butyl titanate is A relatively good TiO can be formed between 0.5-4ml 2 Tube-in-tube), mix evenly to form a transparent electrospinning solution with a certain viscosity, and then put it into a 10ml glass syringe, the needle used is a No. 15cm, the advancing speed of the syringe pump is 0.3ml / min, the ambient temperature is 10°C, and the relative humidity is lower than 50%. Calcined at 700°C for 5 hours to obtain TiO 2 Tube in tube. figure 1 is TiO 2 XRD pattern of tube-in-tube, figure 2 a is a large-area scan image, figure 2 b is a high-magnification scan image, image 3 a is a transmission electron microscope image at low magnification, image 3 b is the tube-in-tube transmission picture alone, from figure 2 and image 3 It can be...

Embodiment 2

[0040] Weigh 2.5g of PVP-K30 (molecular weight 25,000-40,000) and dissolve it in 3ml of ethanol to form a transparent and uniform solution, then add 1ml of acetic acid to it, stir uniformly and add 6ml of butyl titanate (the amount of butyl titanate should be more than 4ml The formation is basically TiO 2 Porous fiber), mixed evenly to form a transparent electrospinning solution with a certain viscosity, and then put it into a 10ml glass syringe, the needle used is No. 15cm, the propulsion speed of the syringe pump is 0.1ml / min, the ambient temperature is 0°C, and the relative humidity is 35%. After the electrospinning, the fiber is removed and placed in a tube furnace to raise the temperature to 500°C at a rate of 2°C / min. Calcined for 10 hours to get TiO 2 Solid porous fiber. from Figure 4 It can be seen that the prepared TiO 2 Most of them are porous fibers with a relatively uniform diameter between 350 and 450 nm.

Embodiment 3

[0042] Weigh 2.5g of PVP-K30 (molecular weight 25,000-40,000) and dissolve it in 5ml of ethanol to form a transparent and uniform solution, then add 0.5ml of acetic acid to it, stir uniformly and add 0.3ml of butyl titanate (the amount of butyl titanate is TiO is basically formed below 0.5ml 2 single tube), mix evenly to form a transparent electrospinning solution with a certain viscosity, and then put it into a 10ml glass syringe, the needle used is a No. 15cm, the advancing speed of the syringe pump is 0.3ml / min, the ambient temperature is 20°C, and the relative humidity is lower than 35%. Calcined at 500°C for 2 hours to obtain TiO 2 hollow fiber. from Figure 5 It can be seen that the prepared TiO 2 Most of them are single tubes, and there are a small number of tubes with very thin nanowires. The diameter of the tubes is relatively uniform, between 300 and 400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com