Liquid injection automatic control valve

A technology for automatic control of valves and liquids, applied in the direction of fluid distribution valves, valve details, valve devices, etc., can solve the problems of complex maintenance, easy to be exposed to winter, manual care, etc., and achieve the effect of overcoming complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

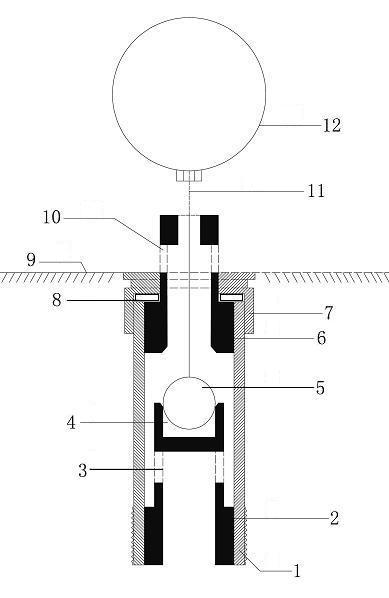

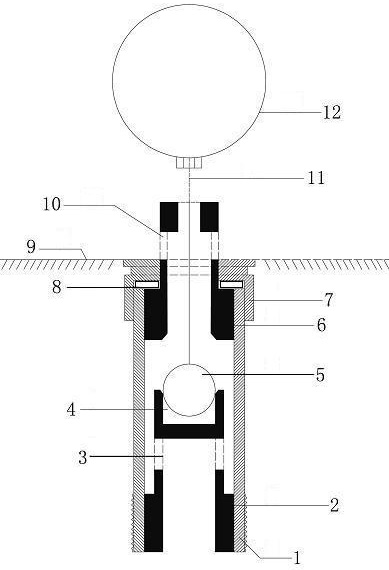

[0019] The specific implementation of the liquid filling automatic control valve of the present invention will be described below with reference to the accompanying drawings.

[0020] Such as figure 1 As shown, the liquid filling automatic control valve of the present invention includes a valve body 1, a valve front seat 2, a valve front seat cross flow hole 3, a valve chamber 4, a valve ball 5, a valve back seat 6, a valve connecting cap 7, a leak-proof pad 8, For those skilled in the art, it is obvious to those skilled in the art that the cross flow hole 10 in the back seat of the valve, the valve stem 11 and the float 12 have a design value of the maximum buoyancy of the float 12 greater than the total weight of the float 12, the valve ball 5 and the valve stem 11.

[0021] When the liquid filling automatic control valve of the present invention is connected with the casing, the control valve is fixed on the bottom of the casing container 9 through the valve connection cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com