Brushless harmonic excitation synchronous motor

A synchronous motor and harmonic excitation technology, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of permanent magnet motor dependence and expensive permanent magnet materials, and achieve the effects of good performance, convenient manufacturing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

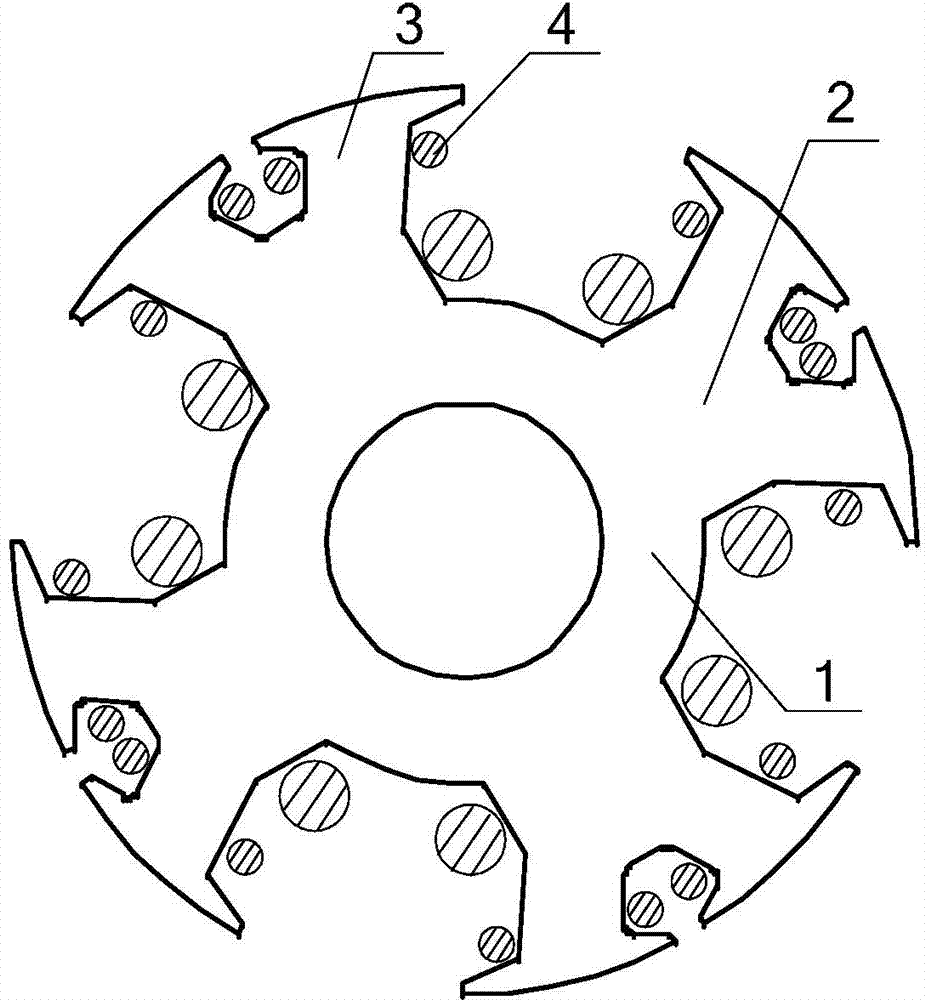

[0020] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, a brushless harmonic excitation synchronous motor described in this embodiment, the rotor core 1 of the motor has a 4-pole structure, and a winding slot is opened in the middle of the pole shoe 2 of each pole. The winding slots divide the four pole pieces into eight rotor teeth 3, and each rotor tooth 3 is nested with a harmonic winding 4.

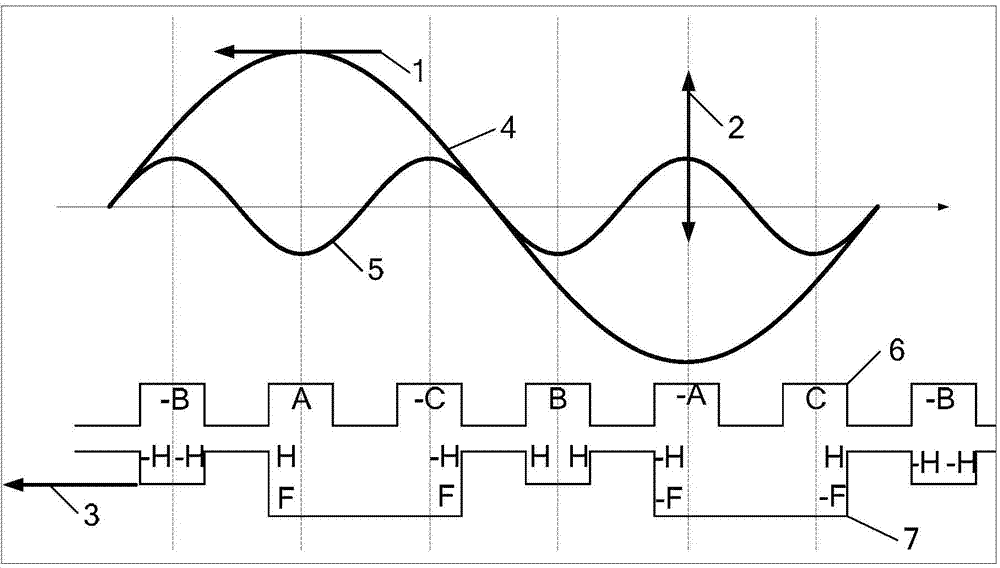

[0021] In this embodiment, compared with the common electric excitation synchronous motor, the brushless harmonic excitation synchronous motor has a set of harmonic windings added on the rotor, and the harmonic windings can utilize the Harmonic magnetic field induces harmonic potential, and the harmonic potential provides excitation current to the excitation winding through the rotating rectifier, so as to realize brushless excitation. The motor described in this embodiment is completely based on electric excitation, does not rely on permanent...

specific Embodiment approach 2

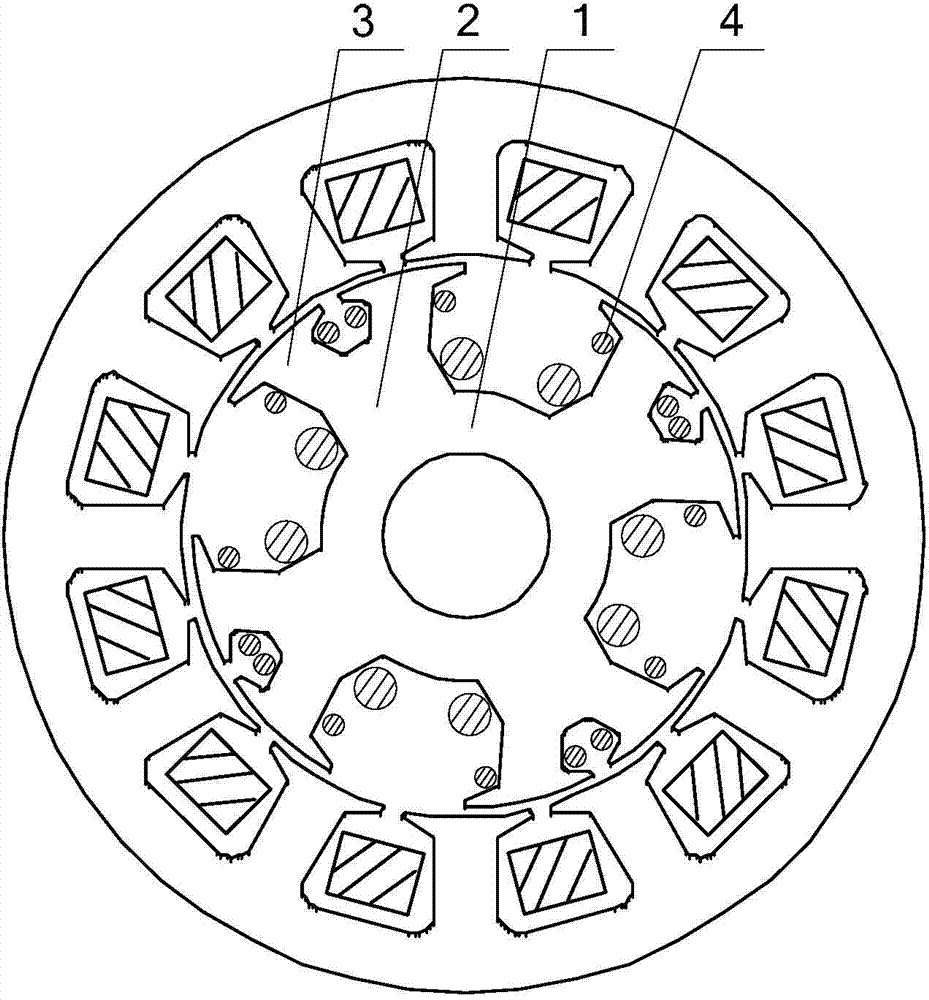

[0022] Specific implementation mode two: refer to figure 2 Describe this embodiment in detail. This embodiment is a further description of a brushless harmonic excitation synchronous motor described in Embodiment 1. In this embodiment, the stator core of the motor has a 12-slot structure, and the stator winding It is a single-layer structure with a pitch of 3 and an open winding.

specific Embodiment approach 3

[0023] Specific embodiment three: This embodiment is a further description of a brushless harmonic excitation synchronous motor described in specific embodiment one. In this embodiment, the stator core of the motor is a 12-slot structure, and the stator winding is Double-layer structure with a pitch of 3.

[0024] In this embodiment, when the stator core of the motor has a 12-slot structure, the stator winding has a double-layer structure, and the pitch is 3, the harmonic potential generated by the motor is the largest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com