Rigid rotor system for helicopter

A helicopter and rigid technology, applied in the aviation field, can solve the problems of poor maintainability, complex mechanical structure, short life, etc., and achieve the effect of simple structure, good maintainability and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

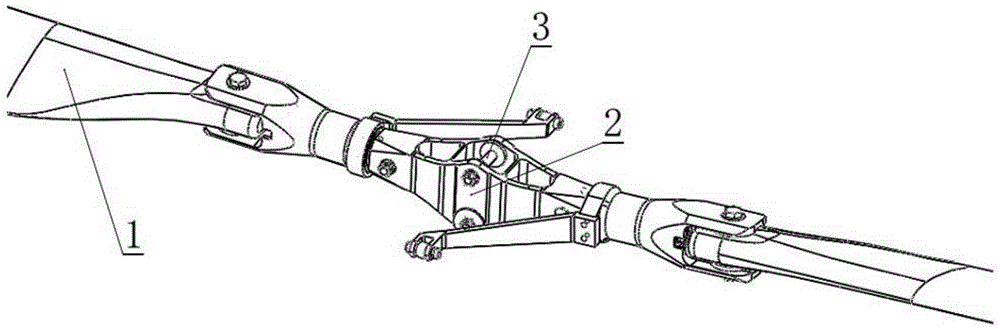

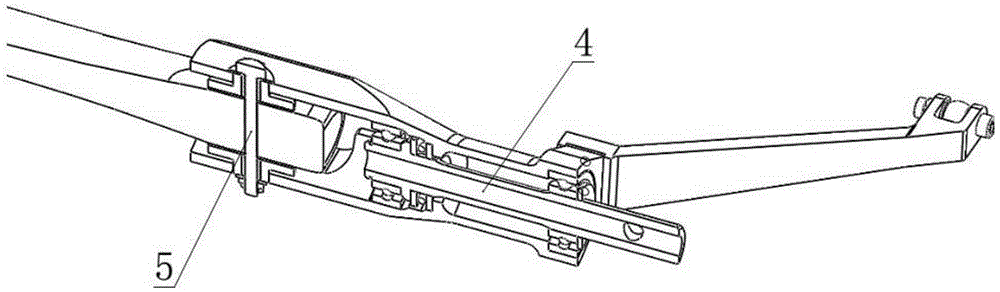

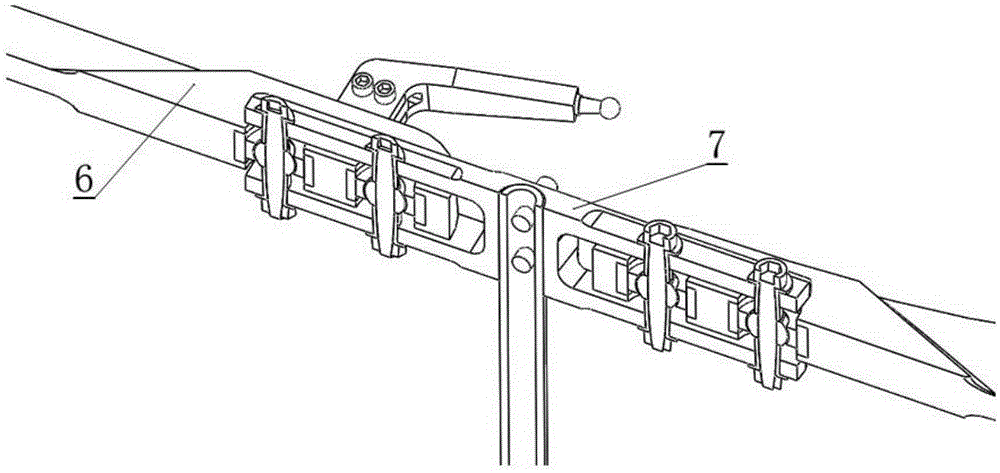

[0021] See figure 1 — Figure 5 , the present invention will be further described below in conjunction with accompanying drawing.

[0022] In order to overcome the deficiencies of the prior art, according to the embodiment of the present invention, see Figure 3-Figure 5 , provides a rigid rotor system for helicopters, which overcomes the problems of complex structure, heavy weight and short life of conventional seesaw propeller hubs of helicopters, and at the same time avoids that the backward propellers are more likely to enter the aerodynamic stall state due to waving when flying forward at high speed Therefore, problems such as aerodynamic efficiency are reduced, and the utility model has the advantages of simple structure, light weight, long life and good maintainability.

[0023] See Figure 3-Figure 5 , the rigid rotor system of a kind of helicopter of present embodiment, it mainly comprises rigid rotor hub 7, rigid rotor pitch change mechanism and rigid rotor blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com