Preparation method and preparation device of nano fibers

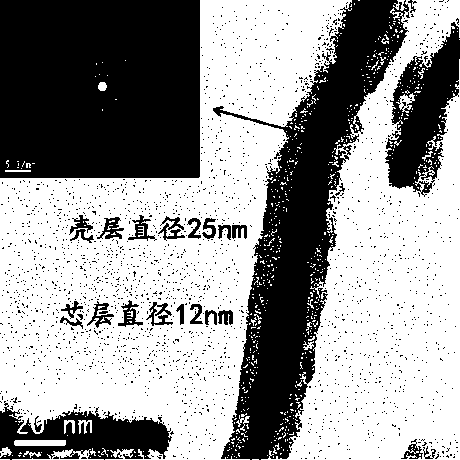

A nanofiber and preparation device technology, applied in fiber processing, fiber chemical characteristics, conjugated artificial filaments, etc., can solve the problems of unclear interlayer interface, uneven coating, low yield, etc., and achieve interlayer interface Clear, good coating, small diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention is a kind of nanofiber preparation method and its preparation device, and the steps of its method are:

[0019] (1) Prepare the precursor solution:

[0020] The composition of the precursor liquid of the core is: Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 6H2O and Fe(NO 3 ) 3 9H 2 The molar ratio of O is 0.5:0.5:2, accounting for 15.6wt%, PVP / C 2 h 5 OH accounted for 65.9wt%, CHCl 3 18.5wt%;

[0021] The composition of the precursor of the shell is: Zn(NO 3 ) 2 ·6H 2 O accounted for 14.9wt%, PVP / C 2 h 5 OH accounted for 66.4wt%, C 3 h 8 o 3 18.7wt%;

[0022] (2) Coaxial electrospinning:

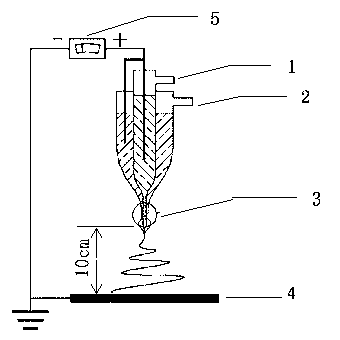

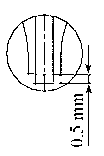

[0023] Such as figure 1 , figure 2 As shown, the core precursor solution and the shell precursor solution were put into the core layer liquid storage container 1 and the shell layer liquid storage container 2 respectively, and a thin copper wire with a diameter of 20 μm was added to the inner wall of the core layer liquid storage container 1, The ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com