Molten salt electroplating preparation method of iridium coating with non-columnar grain structure

A non-columnar, molten salt technology, applied in the field of molten salt electrochemistry and surface treatment, can solve the problem of inability to change the columnar crystal structure, and achieve the effect of low raw material cost, low cost and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

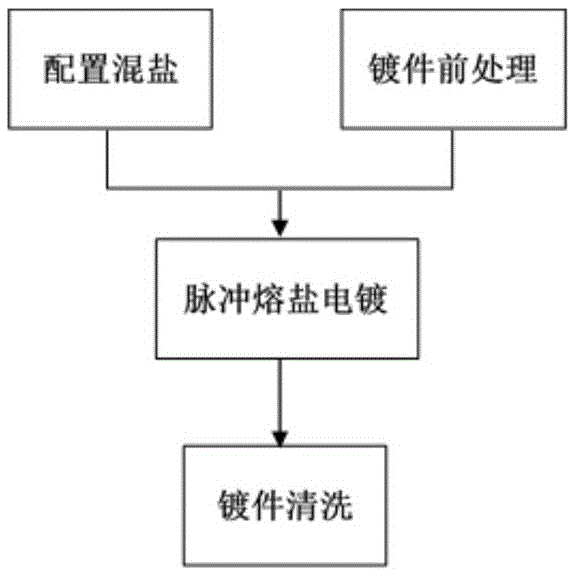

[0034] A kind of molten salt electroplating preparation method of non-columnar structure iridium coating of the present invention, its technical process is as follows figure 1 shown, including the following steps:

[0035] (1) Prepare mixed salt:

[0036] According to the mass percentage, NaCl: 22%, KCl: 28%, CsCl: 40%, IrCl 3 : 10% prepared mixed salt, ground and mixed to get NaCl-KCl-CsCl-IrCl 3 Mix salt.

[0037] (2) Pre-treatment of plating parts:

[0038] The plated parts are made of powder metallurgy rhenium sheet. Before electroplating, the usual methods are used for degreasing, pickling, rust removal, water washing, acetone ultrasonic cleaning (15min), and drying to obtain the powder metallurgy rhenium sheet plating substrate.

[0039] (3) Pulse molten salt electroplating:

[0040] NaCl-KCl-CsCl-IrCl obtained in step (1) 3 Put the mixed salt into the electroplating tank, and heat it from room temperature to the electroplating temperature of 640 °C at a heating ra...

Embodiment 2

[0047] A kind of molten salt electroplating preparation method of non-columnar structure iridium coating of the present invention, its flow process is as follows figure 1 shown, including the following steps:

[0048] (1) Prepare mixed salt:

[0049] According to the mass percentage, NaCl: 15.4%, KCl: 19.6%, CsCl: 60%, IrCl 3 : 5% prepared mixed salt, ground and mixed to get NaCl-KCl-CsCl-IrCl 3 Mix salt.

[0050] (2) Pre-treatment of plating parts:

[0051] The plated piece is a graphite sheet with a rhenium coating. Before electroplating, it is degreased, derusted, washed with water, ultrasonically cleaned with acetone (15min), and dried to obtain a graphite plated piece substrate with a rhenium coating.

[0052] (3) Pulse molten salt electroplating:

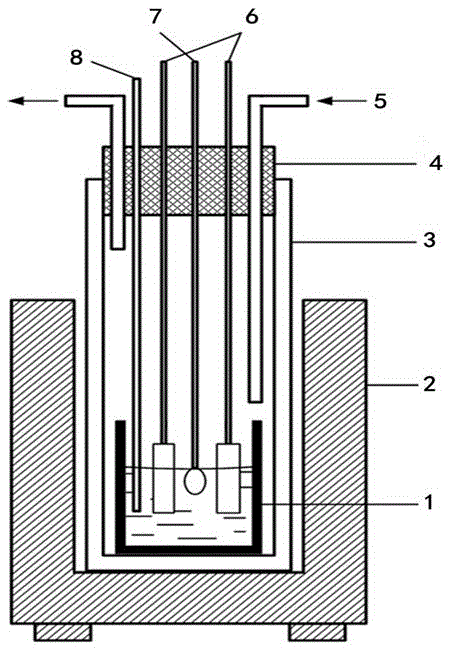

[0053] use as figure 2 In the pulse plating device shown, the NaCl-KCl-CsCl-IrCl obtained in step (1) 3 Put the mixed salt into the electroplating tank, and heat it from room temperature to the electroplating temperatu...

Embodiment 3

[0059] A kind of molten salt electroplating preparation method of non-columnar structure iridium coating of the present invention, its technical process is as follows figure 1 shown, including the following steps:

[0060] (1) Prepare mixed salt:

[0061] According to mass percentage, NaCl: 11%, KCl: 14%, CsCl: 65%, IrCl 3 : 10% prepared mixed salt, ground and mixed to get NaCl-KCl-CsCl-IrCl 3 Mix salt.

[0062] (2) Pre-treatment of plating parts:

[0063] The plated parts are made of powder metallurgy molybdenum sheet. Before electroplating, the usual methods are used for degreasing, rust removal, water washing, acetone ultrasonic cleaning (15min), and drying to obtain the powder metallurgy molybdenum sheet plating substrate.

[0064] (3) Pulse molten salt electroplating:

[0065] use as figure 2 In the pulse plating device shown, the NaCl-KCl-CsCl-IrCl obtained in step (1) 3 Put the mixed salt into the electroplating tank, and heat it from room temperature to the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com