Composite structure alumina/alumina-zirconia layered composite material and preparation method

A layered composite material, alumina layer technology, applied in layered products and other directions, can solve problems such as difficulty in preparation, and achieve the effects of simple preparation process, high surface hardness and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

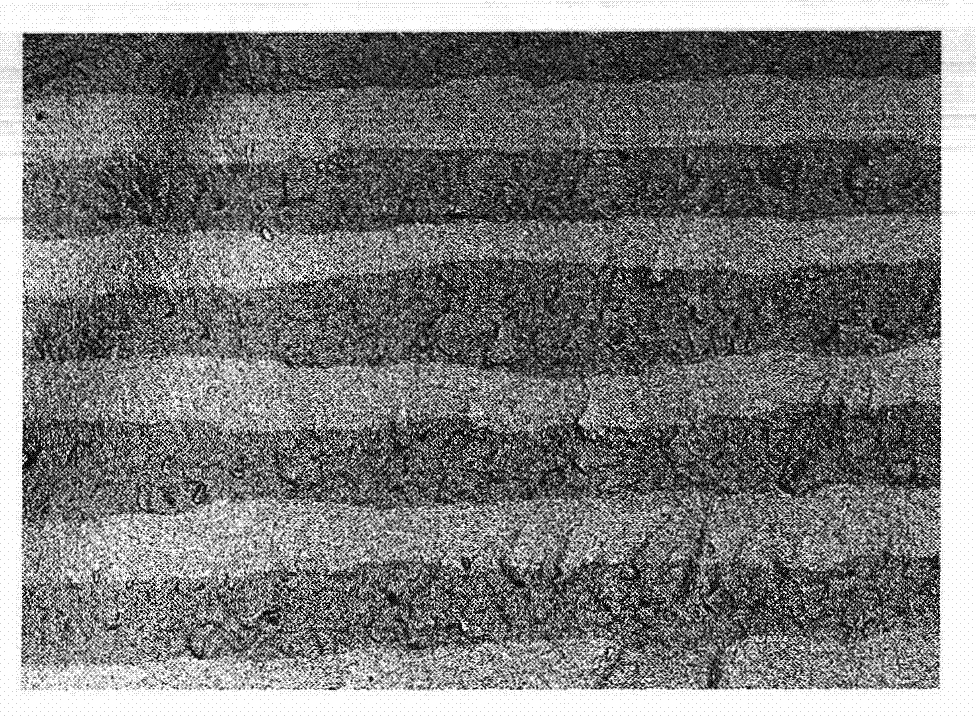

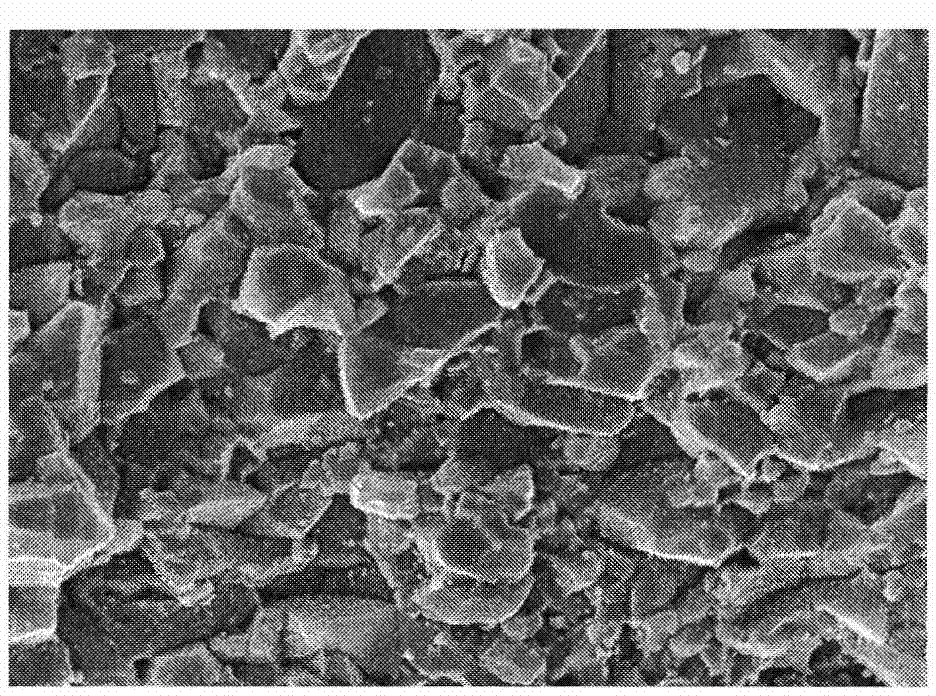

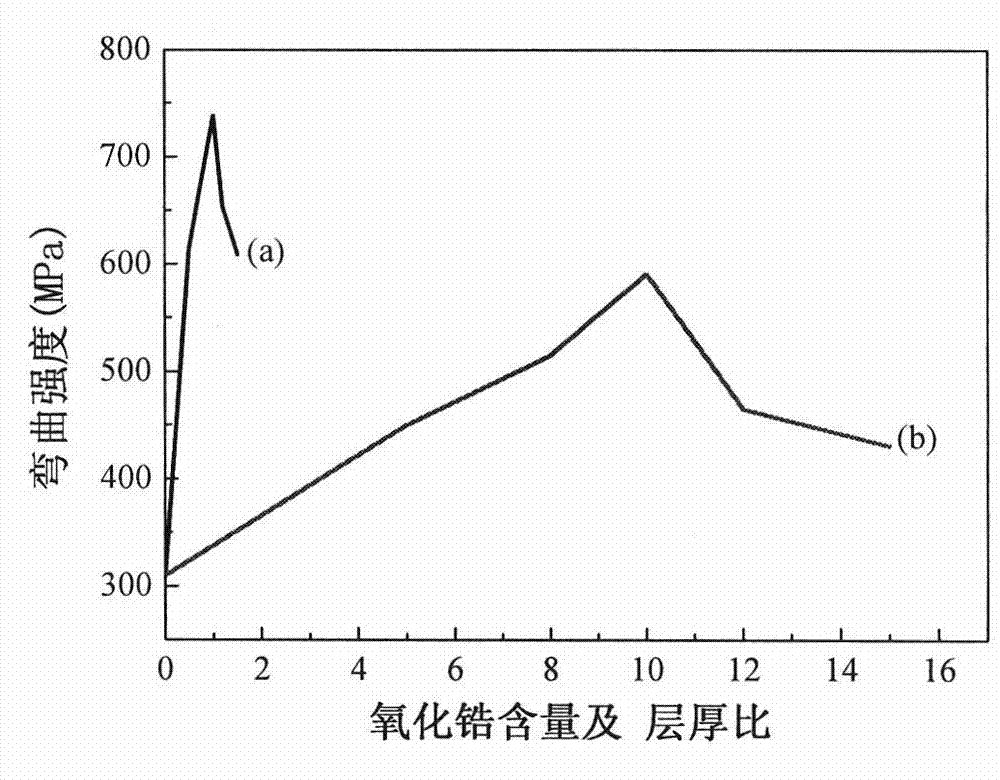

[0018] Ball mill 50 grams of alumina, 10 grams of zirconia, 2.5 grams of titanium oxide and 0.5 grams of copper oxide with a particle size range of 100-200 mesh in an alcohol medium for 24 hours to obtain alumina-zirconia mixed powder; 50 grams of alumina, 2 grams of titanium oxide and 0.5 grams of copper oxide were ball-milled in an alcohol medium for 24 hours to obtain alumina mixed powder. Alternate layers of ball-milled alumina and alumina-zirconia powders are laid in graphite molds with a layer thickness of 0.5mm, put into a hot-press furnace for sintering, the heating rate is 15°C / min, and the sintering temperature is 1350°C , the sintering pressure is 25MPa, the sintering time is 100 minutes, and the whole sintering process is carried out under the protection of argon. According to X-ray diffraction and SEM analysis of the finally obtained sintered sample, the phase composition is mainly α-alumina and tetragonal zirconia, and there is a small amount of monoclinic zircon...

Embodiment 2

[0020] Mill 50 grams of alumina, 5 grams of zirconia, 2 grams of titanium oxide and 0.5 grams of copper oxide with a particle size ranging from 100 to 200 meshes in an alcohol medium for 24 hours to obtain alumina-zirconia mixed powder. 50 grams of alumina, 2 grams of titanium oxide and 0.5 grams of copper oxide were ball-milled in an alcoholic medium for 24 hours to obtain a mixed alumina powder, and the ball-milled alumina and alumina-zirconia powder were laid alternately in a graphite mold. The layer thickness is 1.5mm, put it into a hot-press furnace for sintering, the heating rate is 15°C / min, the sintering temperature is 1350°C, the sintering pressure is 25MPa, and the sintering time is 100 minutes. The whole sintering process is under the protection of argon. conduct. According to X-ray diffraction and SEM analysis of the finally obtained sintered sample, the phase composition is mainly α-alumina and tetragonal zirconia, and there is a small amount of monoclinic zirconi...

Embodiment 3

[0022] Mill 50 grams of alumina, 5 grams of zirconia, 2 grams of titanium oxide and 0.5 grams of copper oxide with particle sizes ranging from 100 to 200 meshes in an alcohol medium for 24 hours to obtain alumina-zirconia mixed powder; mix 100 to 200 meshes 50 grams of alumina, 2 grams of titanium oxide and 0.5 grams of copper oxide were ball-milled in an alcohol medium for 24 hours to obtain alumina mixed powder. Alternate layers of ball-milled alumina and alumina-zirconia powders are laid in a graphite mold, the layer thickness of the alumina layer is 0.5mm, and the layer thickness of the alumina-zirconia layer is 0.8mm, and placed in a hot-press furnace For medium sintering, the heating rate is 15°C / min, the sintering temperature is 1350°C, the sintering pressure is 25MPa, and the sintering time is 100 minutes. The whole sintering process is carried out under the protection of argon. The final obtained sintered sample is analyzed by X-ray diffraction and SEM. The phase comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com