Power spinning spinnability analysis value simulating method

A powerful spinning and numerical simulation technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of easy wrinkling and cracking of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

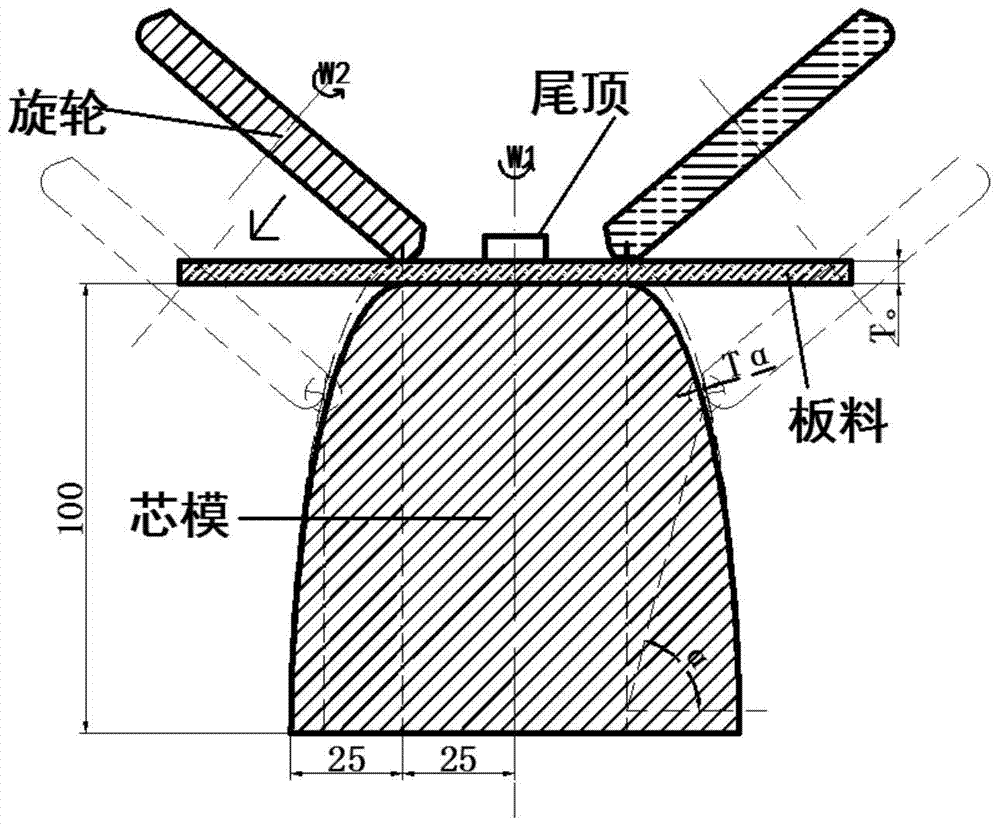

[0096] The powerful spinning adopts 5A06 aluminum alloy, the blank diameter is 150mm, the plate thickness is 5mm, the inner diameter is 25mm, the long axis of the ellipsoidal busbar is 200mm, the short axis is 50mm, the angle of attack of the rotary wheel is 30 degrees, and the rotary wheel feed rate is 0.666 mm / r, the fillet radius of the rotary wheel is 4mm, the maximum diameter is 50mm, the mold speed is 300r / min, the entry rotation angle is 35 degrees, the deviation rate is 0, the friction between the sheet and the tail top is 0.4, and the blank holder force of the tail top It is 10KN, and other coefficients of friction are all 0.1.

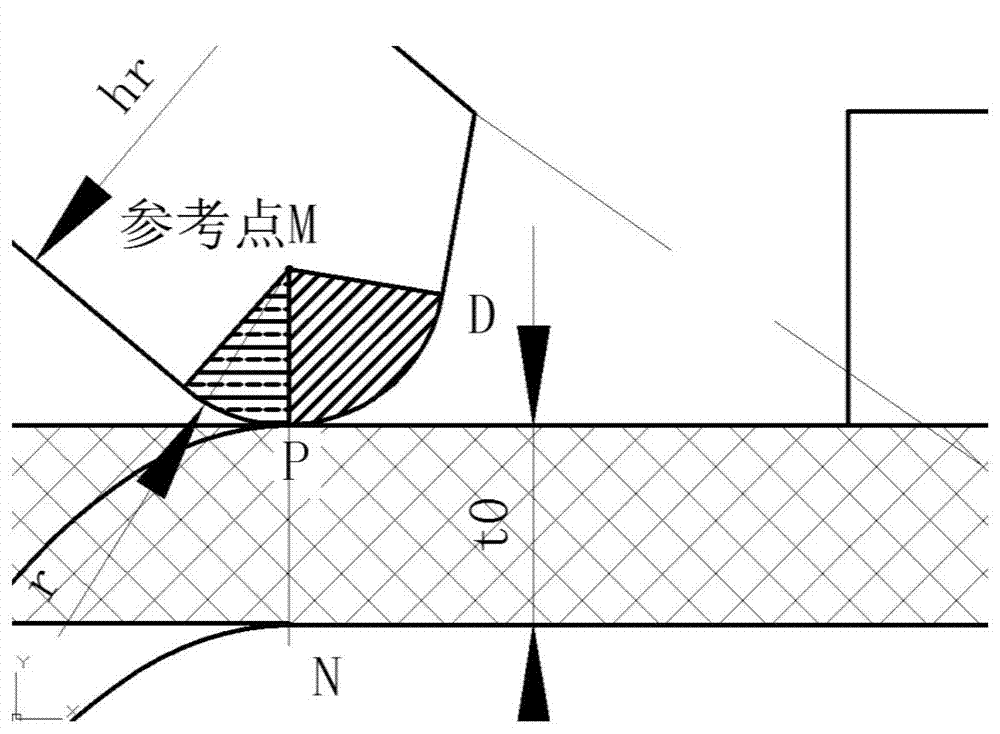

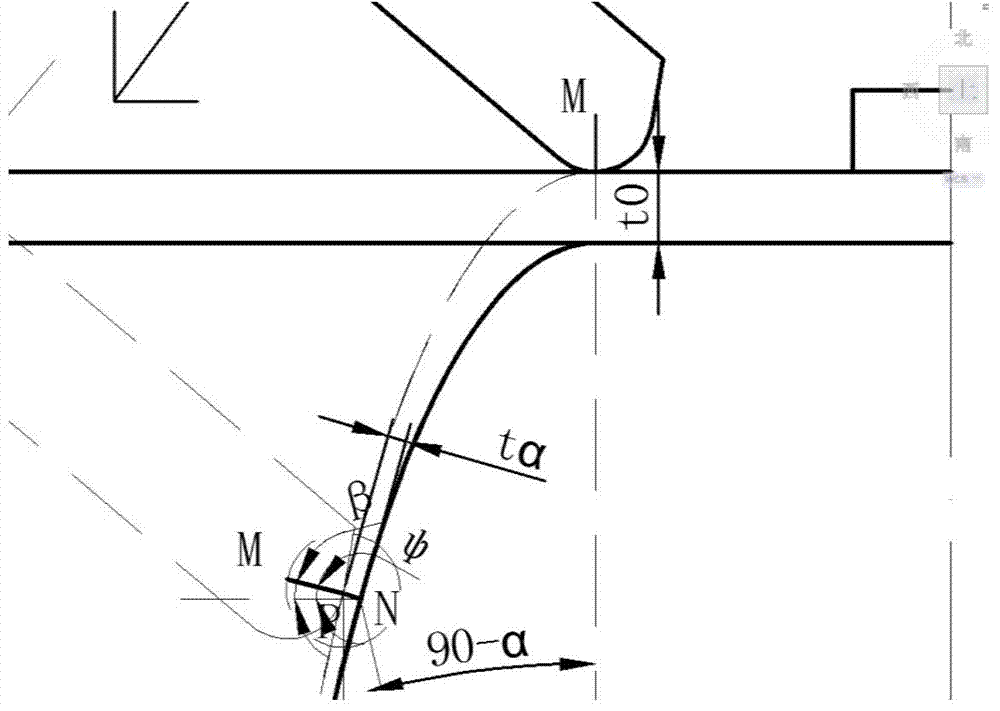

[0097] First, obtain the process parameters of the rotary wheel, mold and sheet, and the thickness of the sheet t 0 =5mm, diameter D=150mm and inner diameter d=25mm, the thickness of the rotary wheel h r =8mm, fillet r=4mm, angle of attack ψ=35° (that is, the angle between the axis of the rotary wheel and the horizontal direction), the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com