Patents

Literature

123results about How to "Highly uniform dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nanotube dispersion liquid and method for producing the same and polymer composite and method for producing the same

InactiveUS20040136894A1Easy to storeGood dispersionMaterial nanotechnologyIndividual molecule manipulationDispersion stabilityActive agent

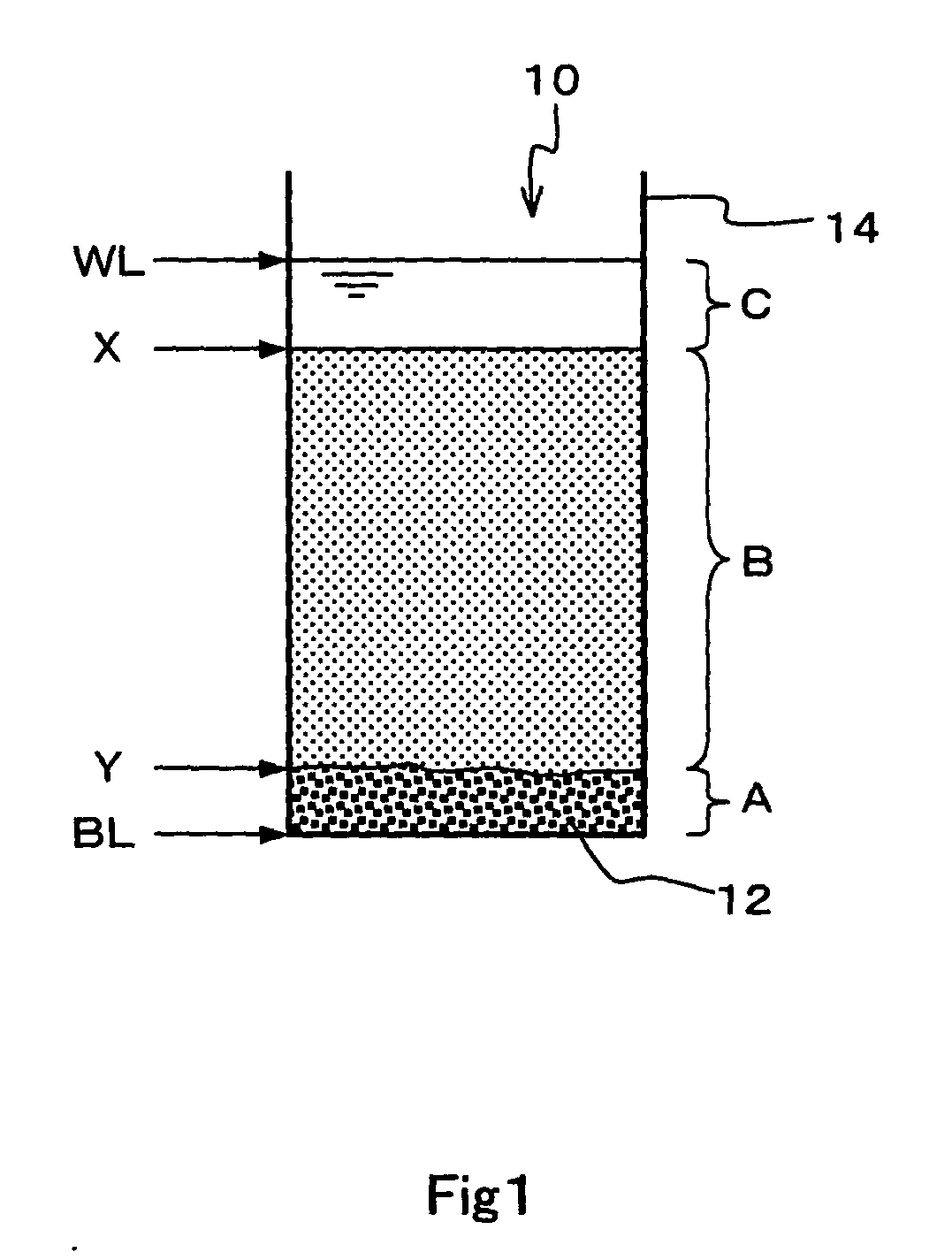

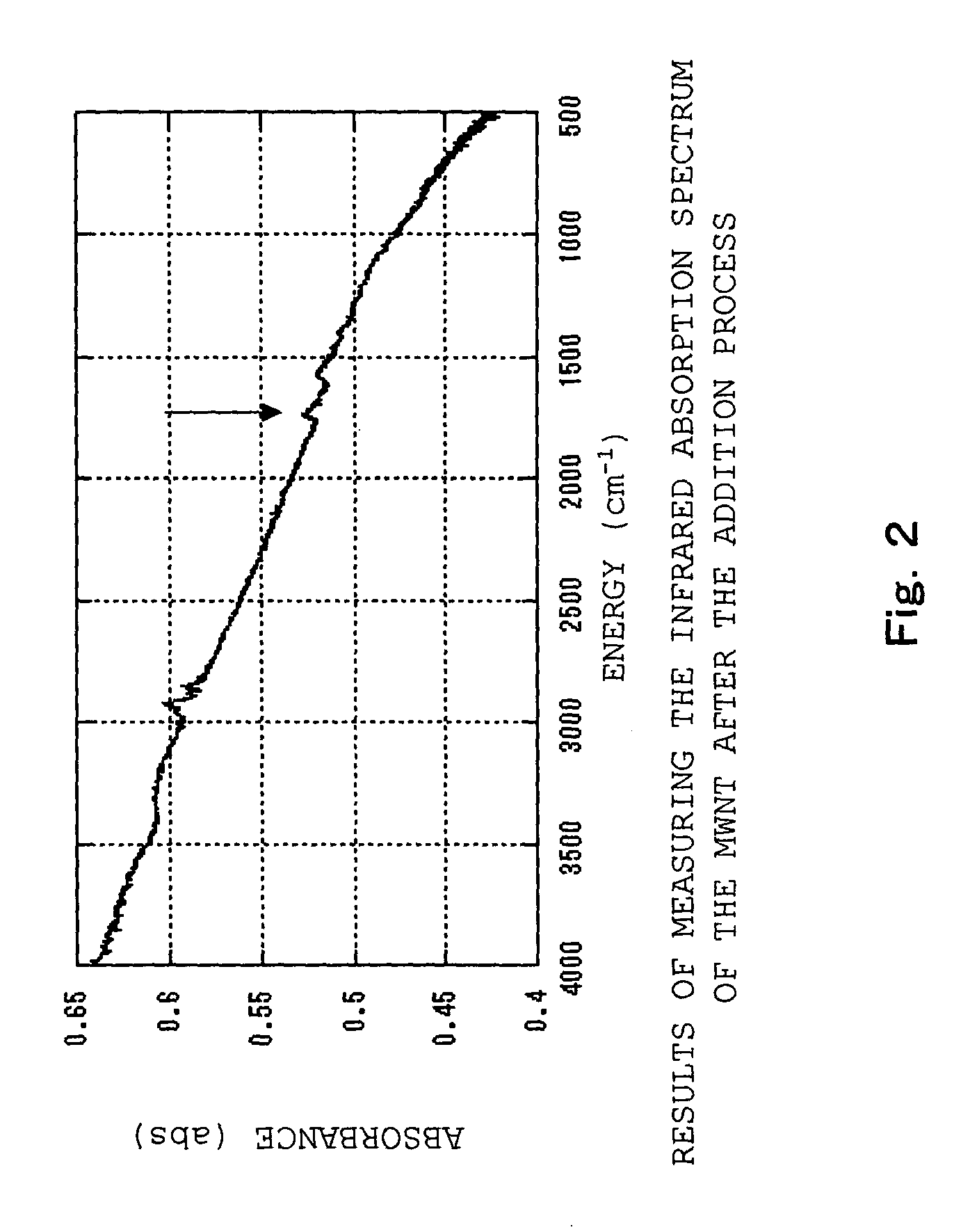

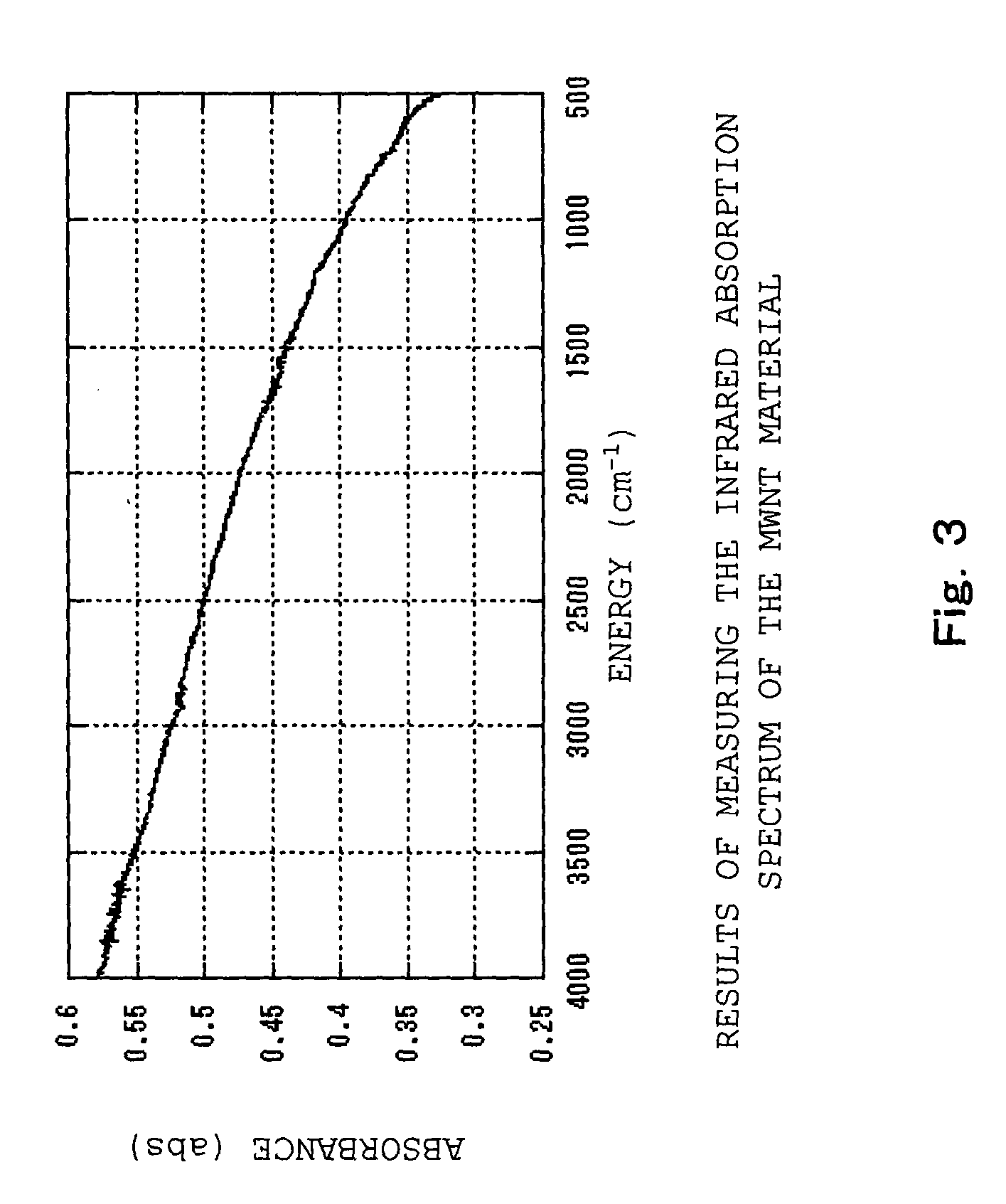

By employing a method of producing a carbon nanotube dispersion liquid, in which a carbon nanotube modified with a basic or acidic functional group is dispersed in a polar solvent having a polarity opposite to a polarity of the functional group, there is provided a carbon nanotube dispersion liquid having a high dispersion stability, in which a carbon nanotube is uniformly dispersed without using any surfactant or the like. By using the carbon nanotube dispersion liquid, a polymer composite in which a carbon nanotube is uniformly dispersed without being mixed with an impurity can be provided. In addition, a method for producing the polymer composite by relatively simple procedures is also provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Preparation method of composite ceramic filter core containing diatomite and charcoal

ActiveCN101920140AImprove filtration efficiencyImprove uniformityCeramic shaping apparatusClay processing apparatusKeatiteComposite ceramic

The invention discloses a preparation method of a composite ceramic filter core containing diatomite and charcoal. In the preparation method, raw materials with high melting points are not used, and a mode of first dispersion and then partial flocculation is used for preparing a slurry for slip casting to enable raw materials and pores in a green body to be highly and uniformly dispersed, thus the sintering temperature is not higher than 950 DEG C, and natural micropores in the diatomite can not collapse because of high-temperature sintering.

Owner:SANDA FILM SCI & TECH XIAMEN

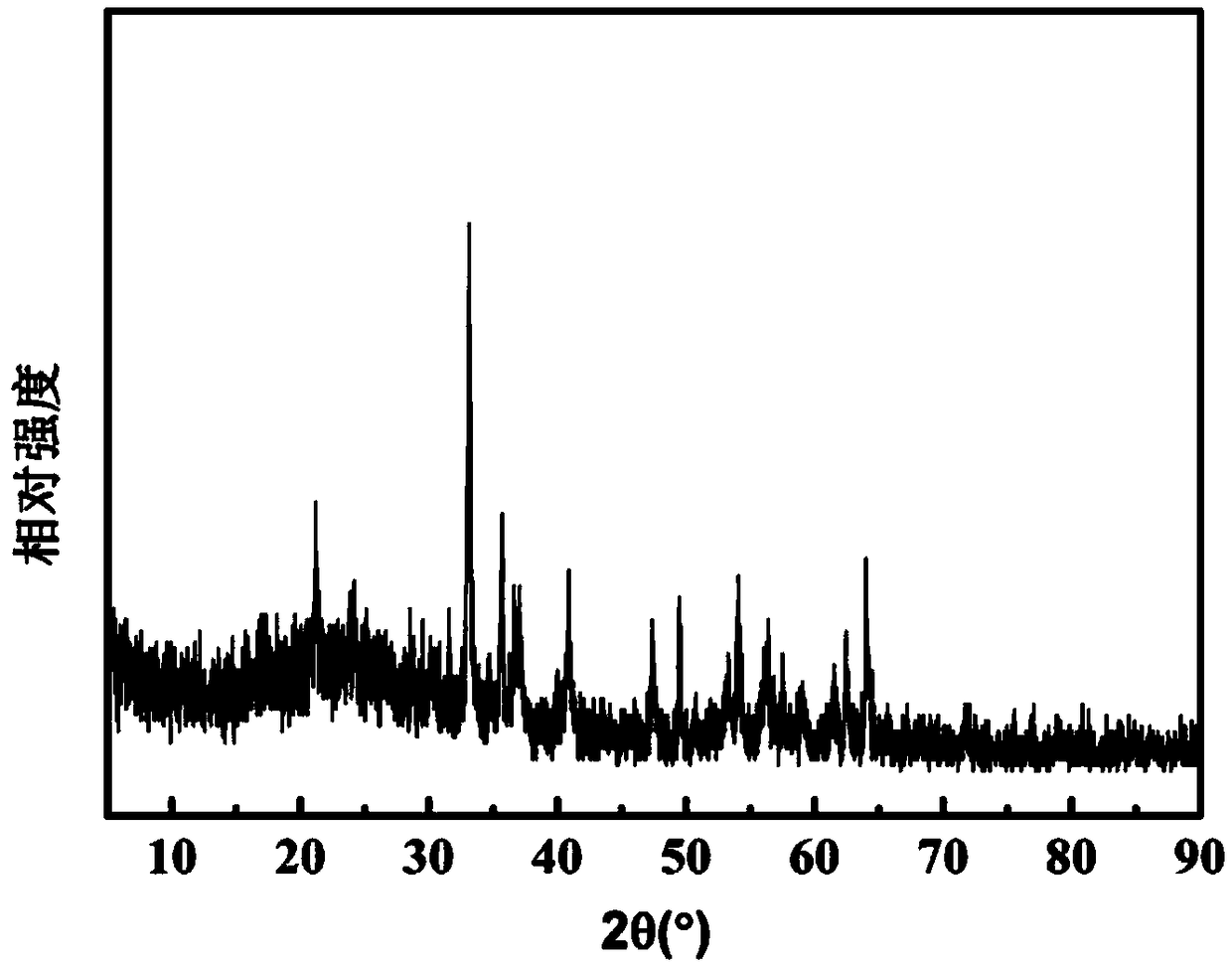

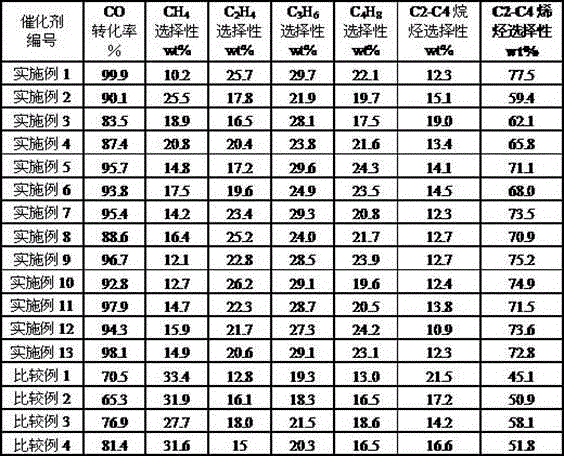

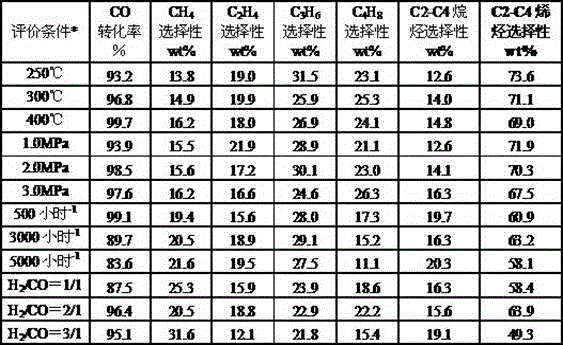

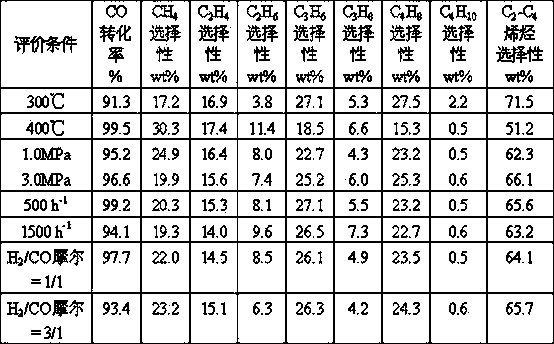

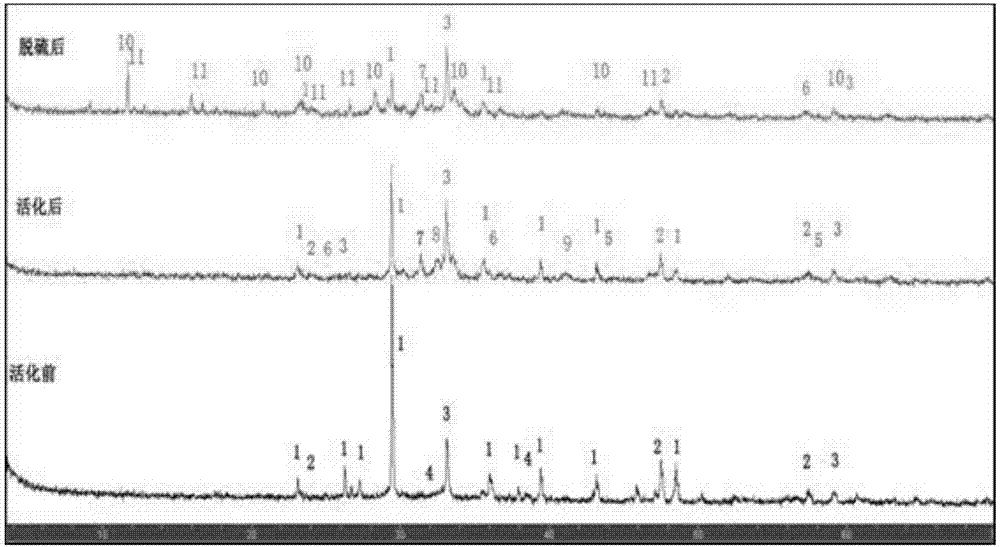

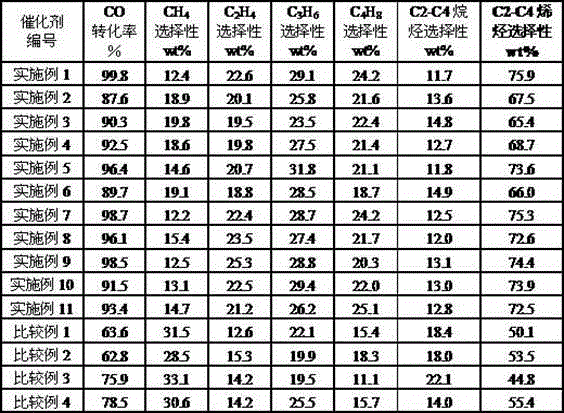

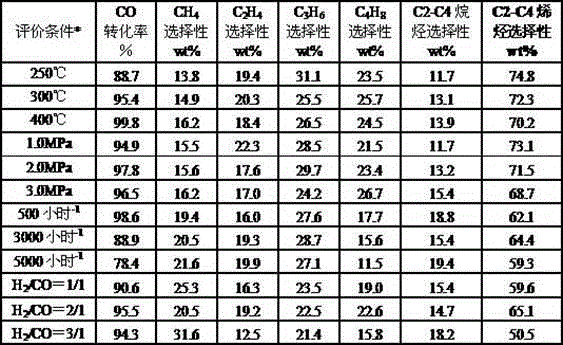

Catalyst for producing low-carbon olefin by using synthesis gas and preparation method of catalyst

ActiveCN104148106AHighly uniform dispersionIncrease the number ofOrganic chemistryMolecular sieve catalystsActive componentLanthanide

The invention relates to a catalyst for producing low-carbon olefin by using synthesis gas and a preparation method of the catalyst, and is mainly used for solving the problem of low CO conversion rate and low low-carbon olefin selectivity in reaction for preparing the low-carbon olefin by using the synthesis gas in the prior art. The catalyst consists of a composite carrier and active components, wherein the composite carrier consists of alpha-aluminium oxide and a ZSM-5 molecular sieve; the silicon-aluminium ratio of the ZSM-5 molecular sieve is 40-200; the active components are loaded on the composite carrier and comprise the following compounds with chemical formulas by atomic ratio: Fe100AaBbCcOx, A is at least one of transition metals of Cu and Mn, B is at least one of lanthanide La and Ce, and C is at least one of alkaline metals of K and Cs; the weight of the composite carrier is 20%-80% of the weight of catalyst; by weight percent of the composite carrier, the weight of alpha-aluminium oxide is 20%-99% of the weight of the composite carrier. With the adoption of the technical scheme, the problem is well solved; the catalyst can be used for industrial production of the low-carbon olefin produced by using the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

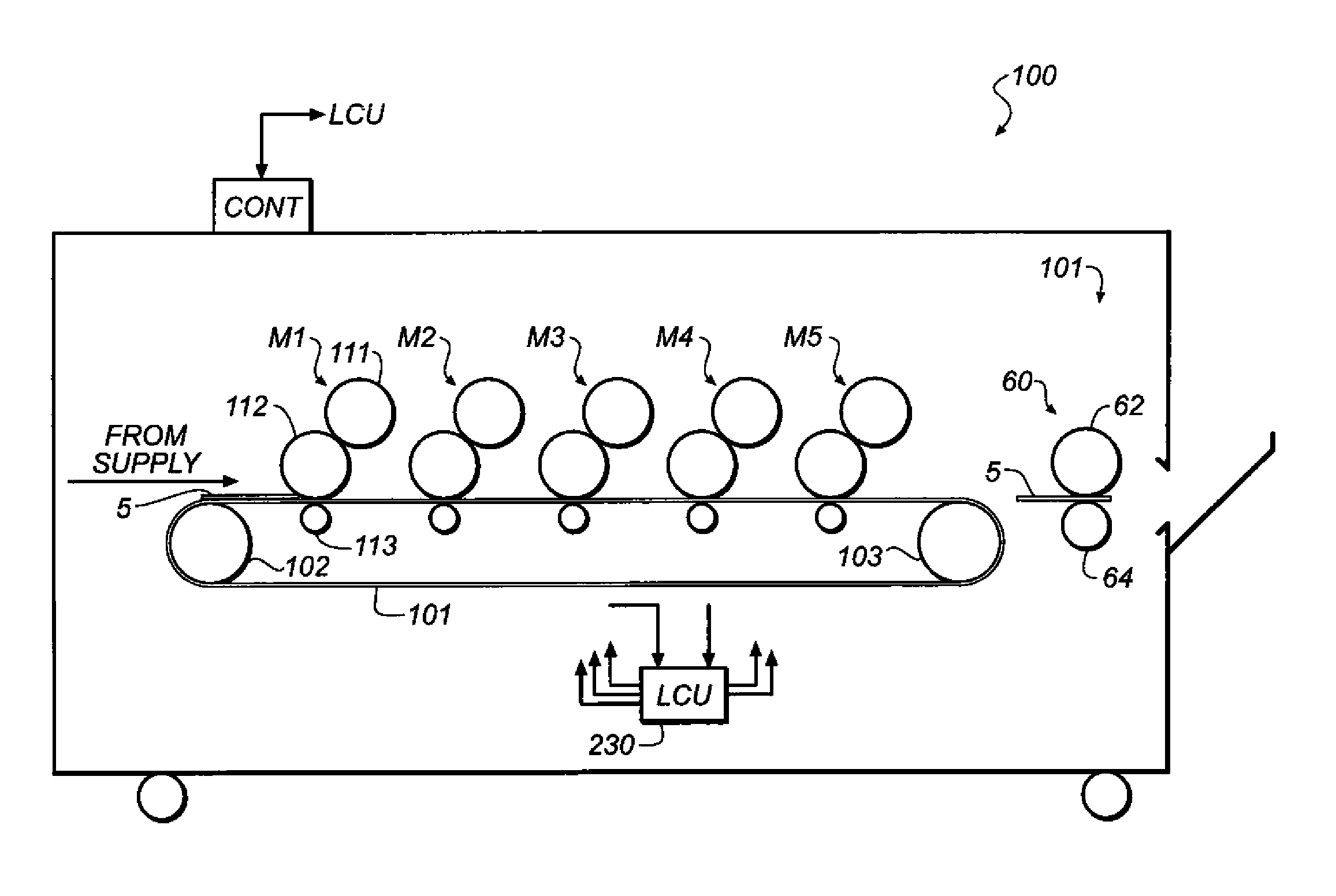

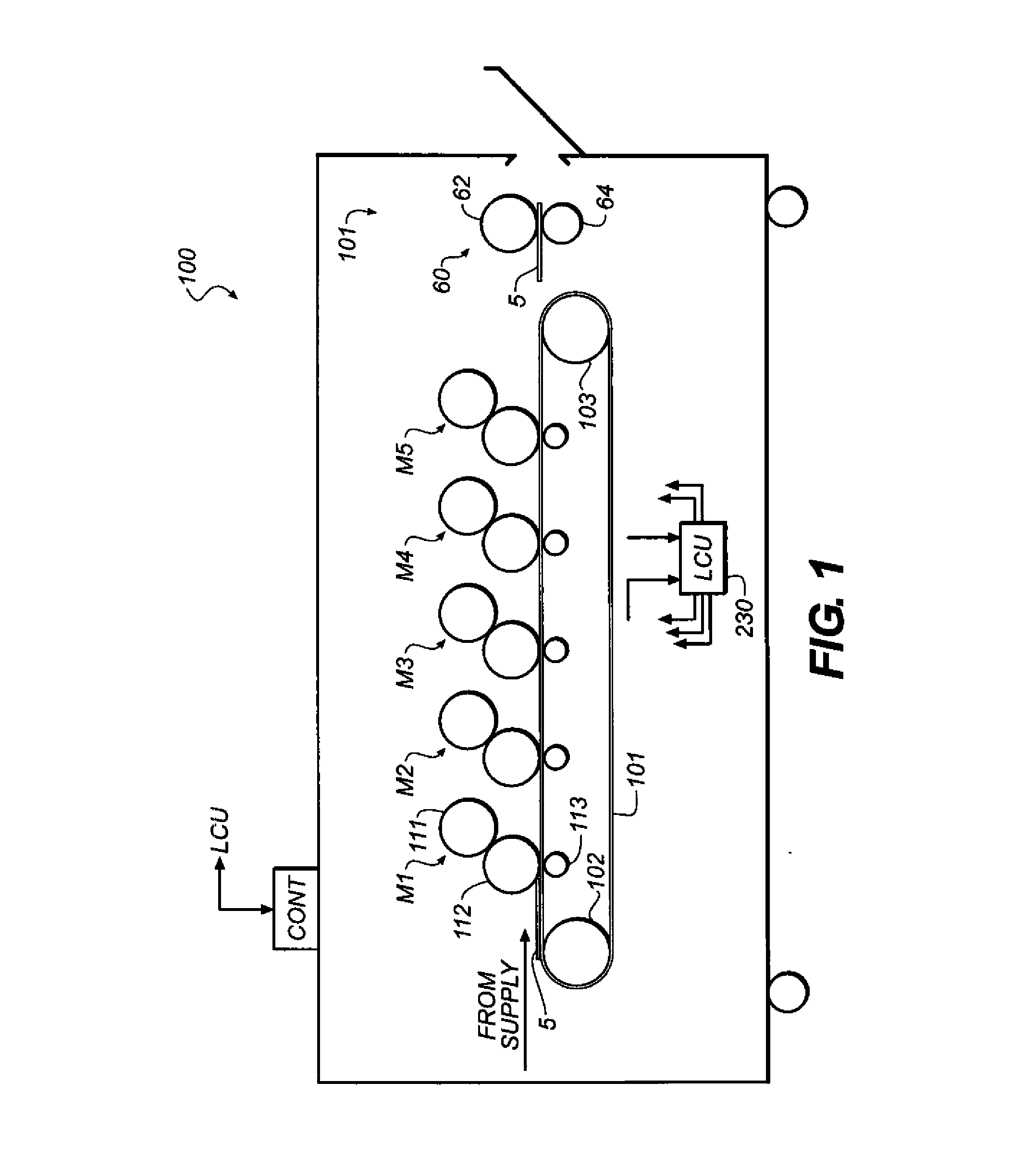

Preparing color toner images with metallic effect

ActiveUS9323169B2Highly uniform dispersionMinimize shearLayered productsDevelopersLatent imageEngineering

A color toner image with a metallic effect can be prepared by forming one or more latent images and developing them with metallic dry toner particles and color toner particles. The developed color toner image can be transferred to a receiver material, and fixed to provide a color toner image with a metallic effect. The metallic dry toner particles have a polymeric binder phase and non-conductive metal oxide particles dispersed therein. Before fixing, the metallic dry toner particle has a mean volume weighted diameter (Dvol) 15-40 μm and the non-conductive metal oxide particles are present in an amount of at least 20-50 weight % based on total metallic dry toner particle weight. The ratio of the metallic dry toner particle Dvol to the average equivalent circular diameter (ECD) of the non-conductive metal oxide particles in the metallic dry toner particles is greater than 0.1 and up to and including 10.

Owner:EASTMAN KODAK CO

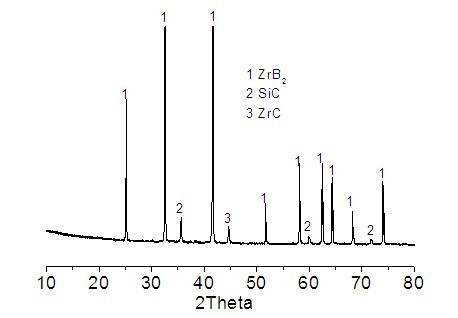

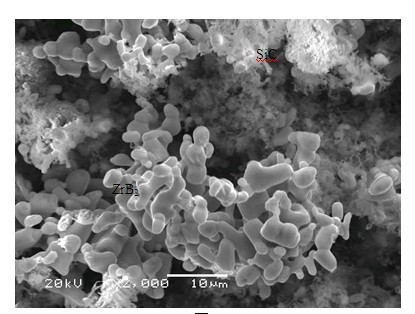

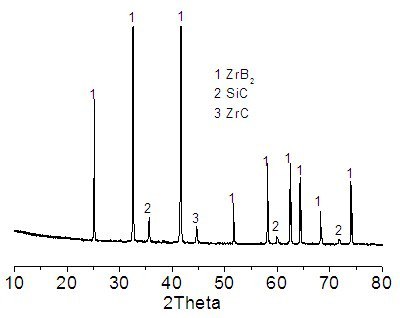

ZrB2-SiC composite powder and preparation method thereof

InactiveCN102320850AFix issues with restricted usageSynthesis temperature is lowUltra-high-temperature ceramicsRefractory

The invention discloses ZrB2-SiC composite powder and a preparation method thereof. According to the invention, zircon sand, a boron raw material and a carbon raw material are adopted as main materials. The main materials are mixed, grinded, and are heated under a temperature of 1350 to 1480 DEG C, such that the powder is obtained. The powder comprises components of, by weight: 37 to 63% of ZrSiO4, 16 to 32% of B2O3, and 20 to 28% of C, wherein the boron raw material is calculated according to the amount of B2O3, and the carbon raw material is calculated according to the amount of C element. According to the invention, natural zircon sand with a relatively low price is used as a raw material for producing high-grade ZrB2-SiC. The advantages of ZrB2 and SiC are combined. Mutual complement of advantages can be realized when ZrB2 and SiC are used in the field of high-temperature materials. ZrB2-SiC provides relatively high thermal conductivity, excellent thermal shock resistance and corrosion resistance. When ZrB2-SiC is introduced into the composite powder, high-temperature mechanical properties, oxidative stabilities and corrosion resistances of ultra-high temperature ceramics and refractory materials can be improved.

Owner:ZHENGZHOU UNIV

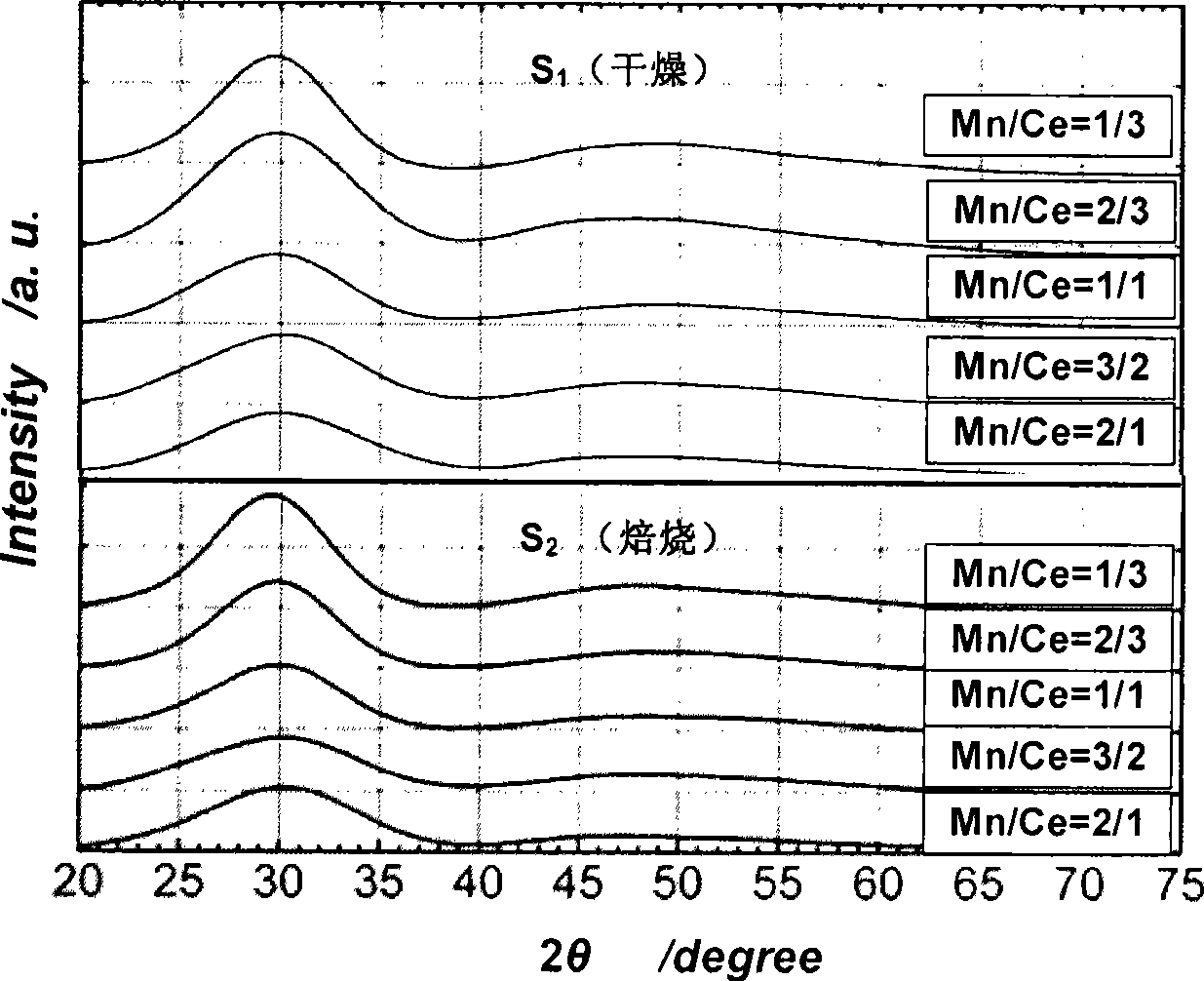

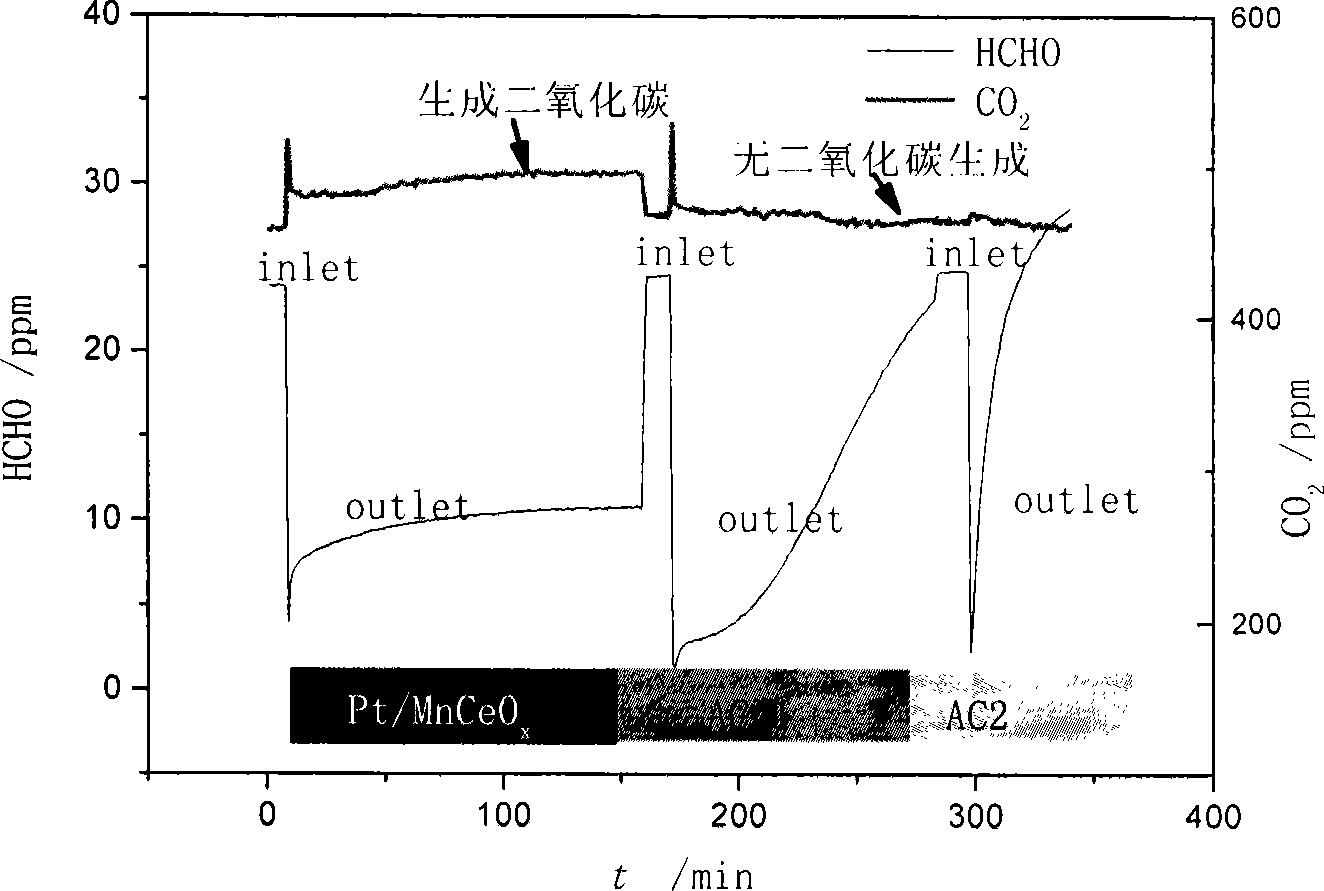

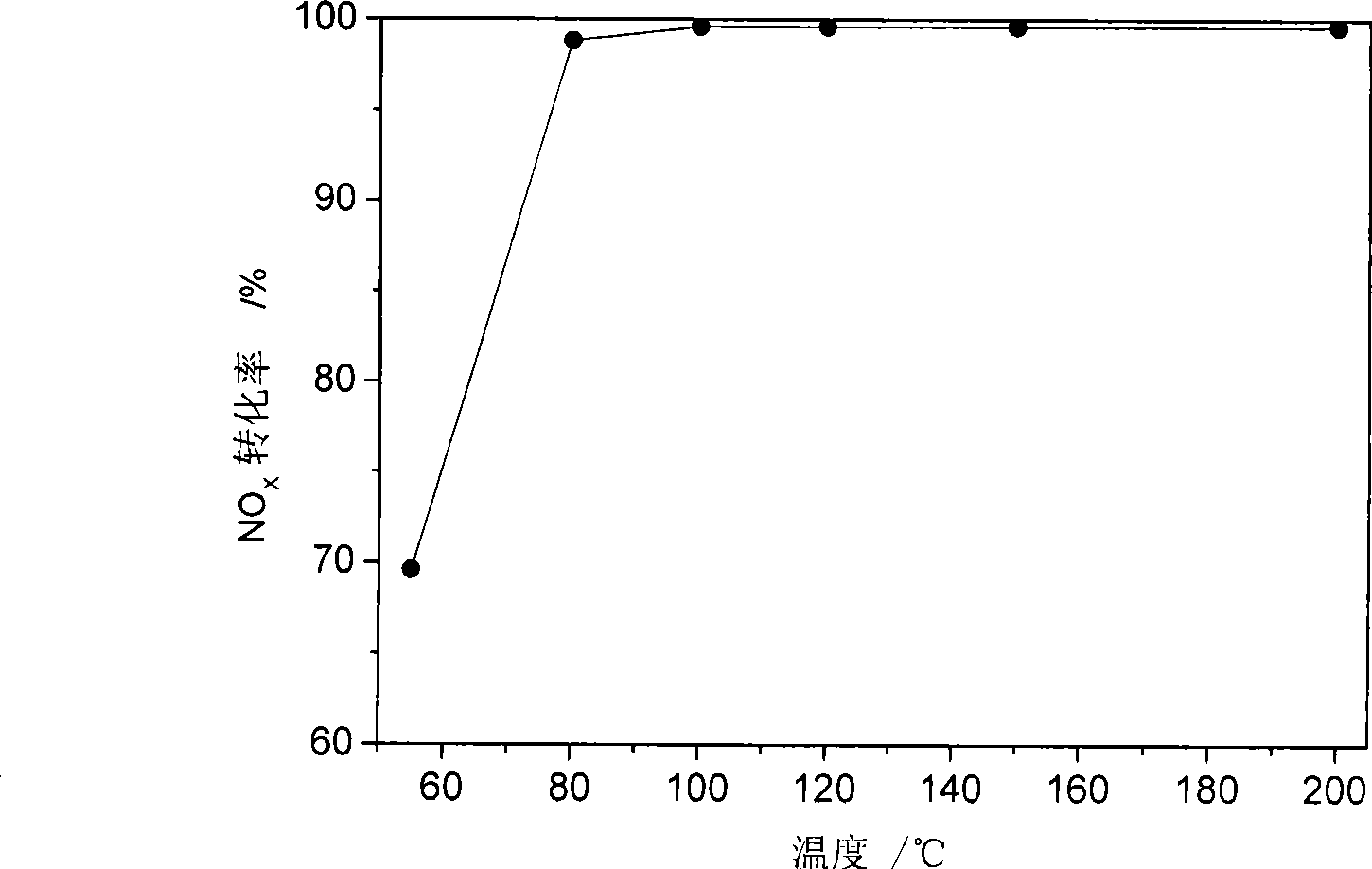

High-dispersion manganese-cerium composite oxides and preparation method thereof

ActiveCN101462049AGentle preparation processGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention discloses manganese-cerium composite oxide, which is prepared in one step through the oxidation reduction-precipitation process among Mn<VII>, Mn<II> and Ce<III> ions, wherein components, namely MnO2 and CeO2 of the manganese-cerium composite oxide have high dispersion on a near molecular scale, the mol ratio of Mn to Ce is randomly adjusted, and the composite oxide has good oxidation reduction and oxygen affinity. As a catalyst carrier of reactions of formaldehyde oxidation at room temperature and low-temperature selective catalytic reduction of nitrogen oxide, the use of the composite oxide can ensure that a catalyst has higher activity, and the stability of the composite oxide is more superior to those of other carriers.

Owner:SUZHOU IND PARK ANZEWEN ENVIRONMENTAL PROTECTION TECH

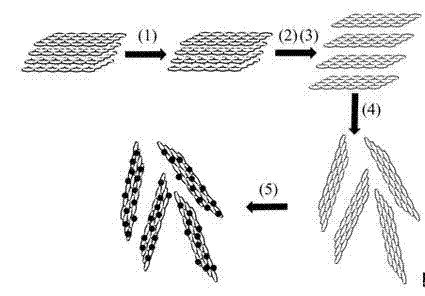

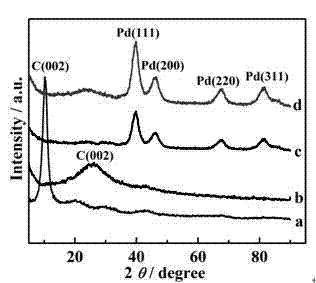

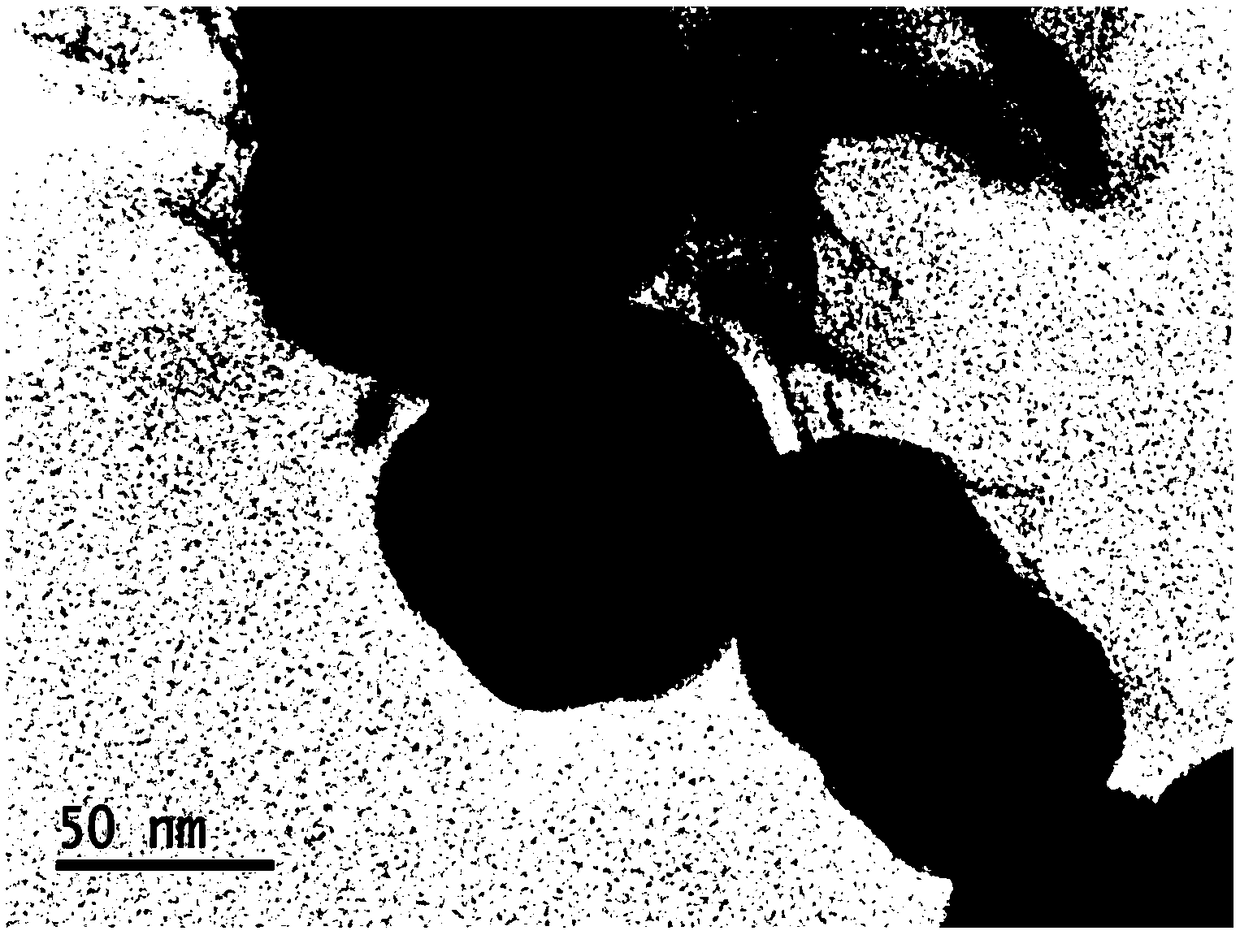

Preparation method for synthesizing graphene loaded noble metal catalyst in organic phase

InactiveCN102198398AEasy to operateAvoid overlappingCatalyst activation/preparationNanotechnologyCvd grapheneStructural stability

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Reversed phase micelle nano catalyst for dreg-oil suspension bed hydrogenation cracking and preparing method

InactiveCN101024186AReduce the amount addedHighly uniform dispersionPhysical/chemical process catalystsHydrocarbon oil crackingOil processingNano catalyst

The invention discloses a catalyst for low quality heavy oil or residue suspended bed hydrocracking and preparation method belongs to oil process technology area. The catalyst is a sulfurization form transition metal nm particle that existing in the reversed phase micelle colloidal solution, the disperse medium of reversed phase micelle colloidal solution is organic phase, the disperse phase is a water phase parceled by surface activity, sulfurization form transition metal nm particle steady consist in the water phase. The transition metal active ingredient in disperse phase elect as Cu,Mn,Fe,Co,Ni,Cr,Mo,W,Zn,Sn,Pb elementary sulfurization form particle and so on, the grain size between 1nm-1000um. This catalyst can uniformly dispersed in the low quality heavy oil,residue, and under the certain reaction temperature and hydrogen aura, the low quality heavy oil or residue containing catalyst through suspended bed hydrocracking translated into light oil. On the premise of reducing catalyst enter quantity, the invention effectively controlled the coking products in heavy oil or residue suspended bed hydrocracking process, improved the yield of light oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

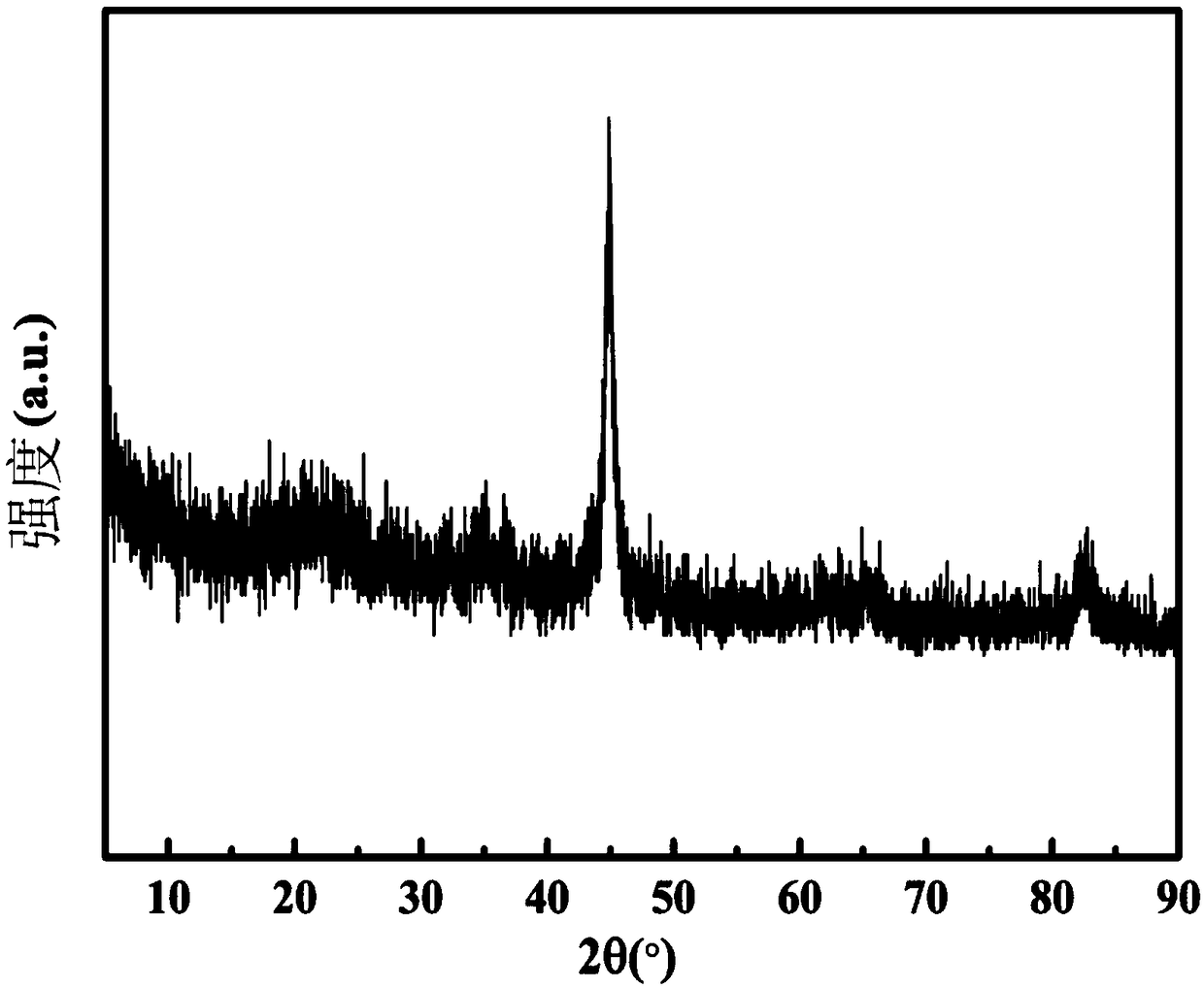

Preparation method of nano zero-valent iron loaded hydrophilic porous biochar composite material

ActiveCN108722356AHighly uniform dispersionImprove utilization efficiencyOther chemical processesWater contaminantsMolten saltMetal particle

The invention discloses a preparation method of a nano zero-valent iron loaded hydrophilic porous biochar composite material, relates to preparation methods of hydrophilic porous biochar composite materials, and aims to solve the problems that an existing matrix loading metal particles is high cost, and nano zero-valent iron is unstable and prone to agglomeration and is low in performance when being applied to heavy metal adsorption. The method includes the steps of firstly, subjecting biomass to pyrolysis and molten salt activation; secondly, preparing a hydrophilic porous biochar material; thirdly, loading the nano zero-valent iron to obtain the nano zero-valent iron loaded hydrophilic porous biochar composite material. The specific surface area of the prepared nano zero-valent iron loaded hydrophilic porous biochar composite material can reach 603.4m<2>*g<-1>. Due to the fact that corn straw is agricultural waste which is low in cost and wide in source, the cost of the preparation method is lowered by using the pyrolysis product of the corn straw as the matrix material. The prepared nano zero-valent iron loaded hydrophilic porous biochar composite material is applicable to the field of environmental pollution remediation.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

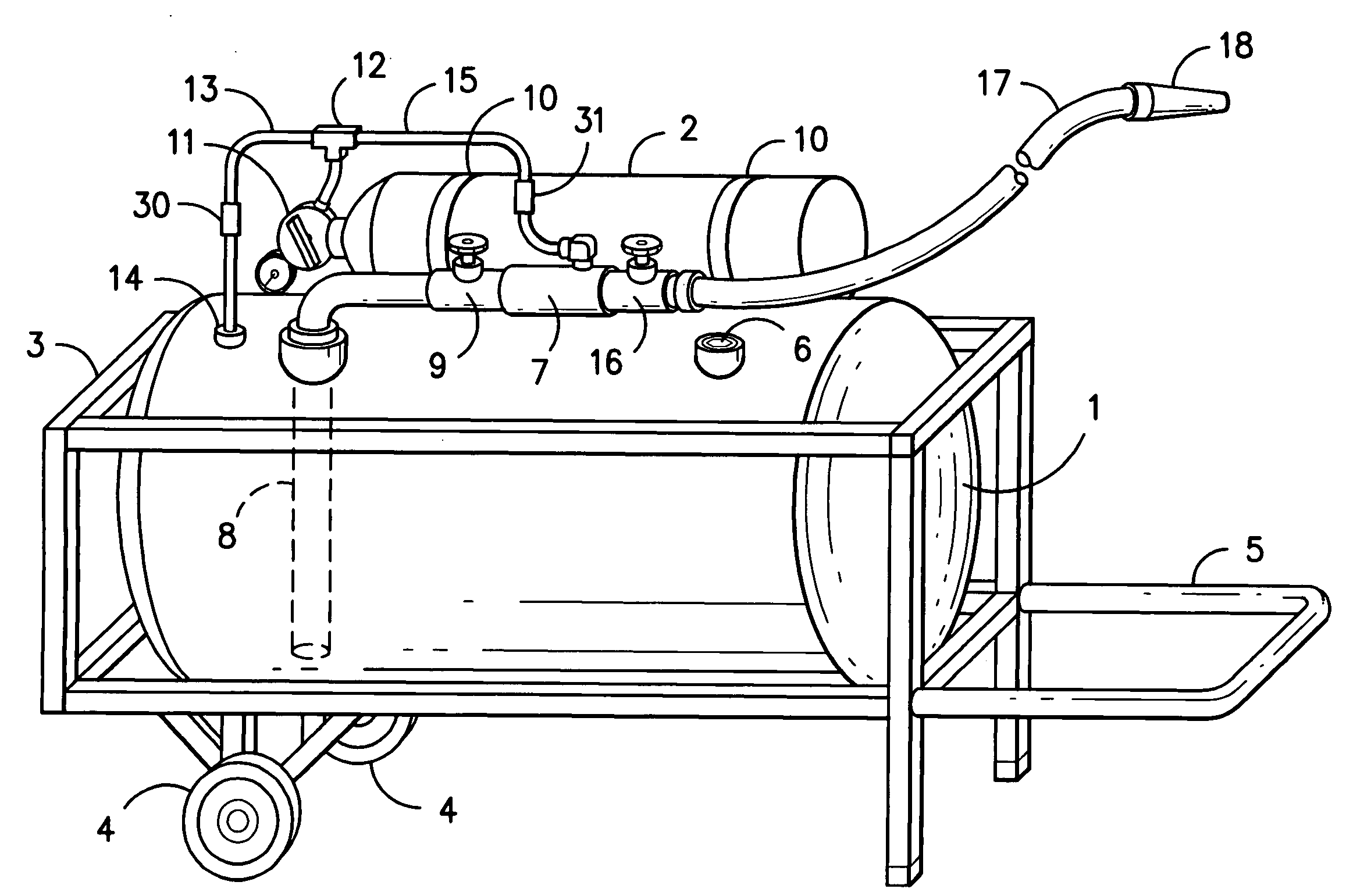

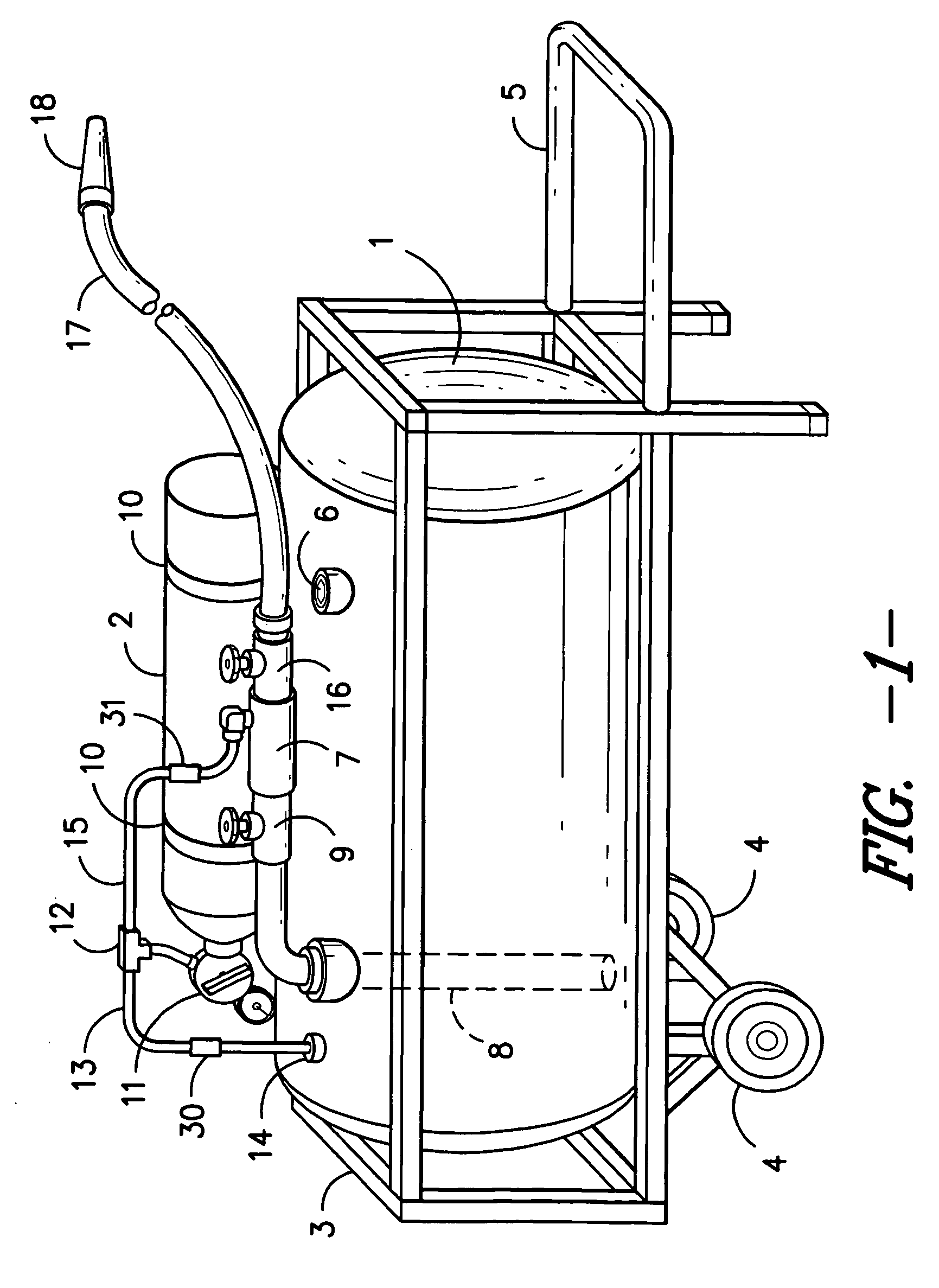

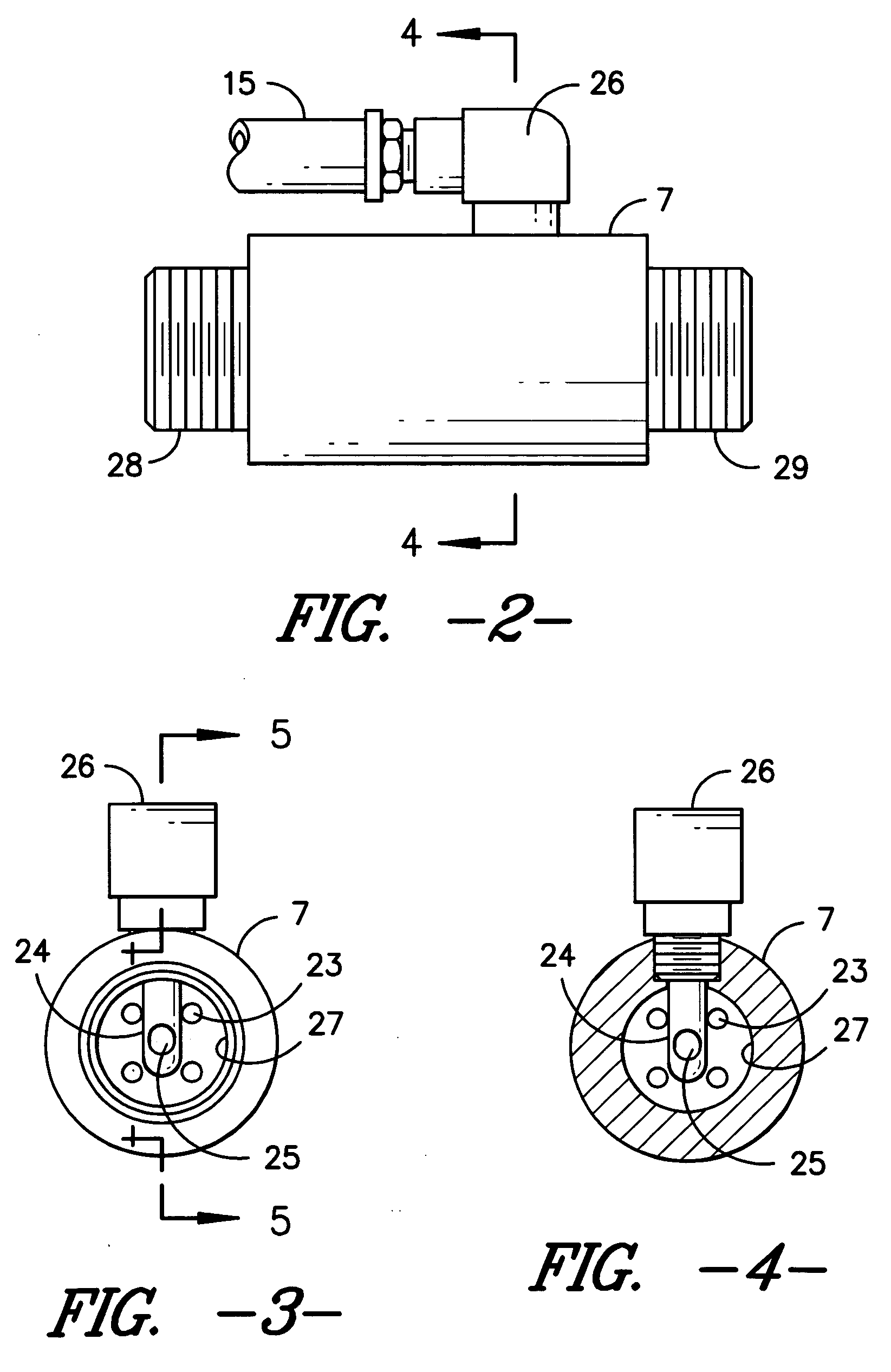

Fire suppression apparatus and method for generating foam

ActiveUS20100116512A1High speedMaximizes entrainmentSpray nozzlesFire rescueCombustible gasEngineering

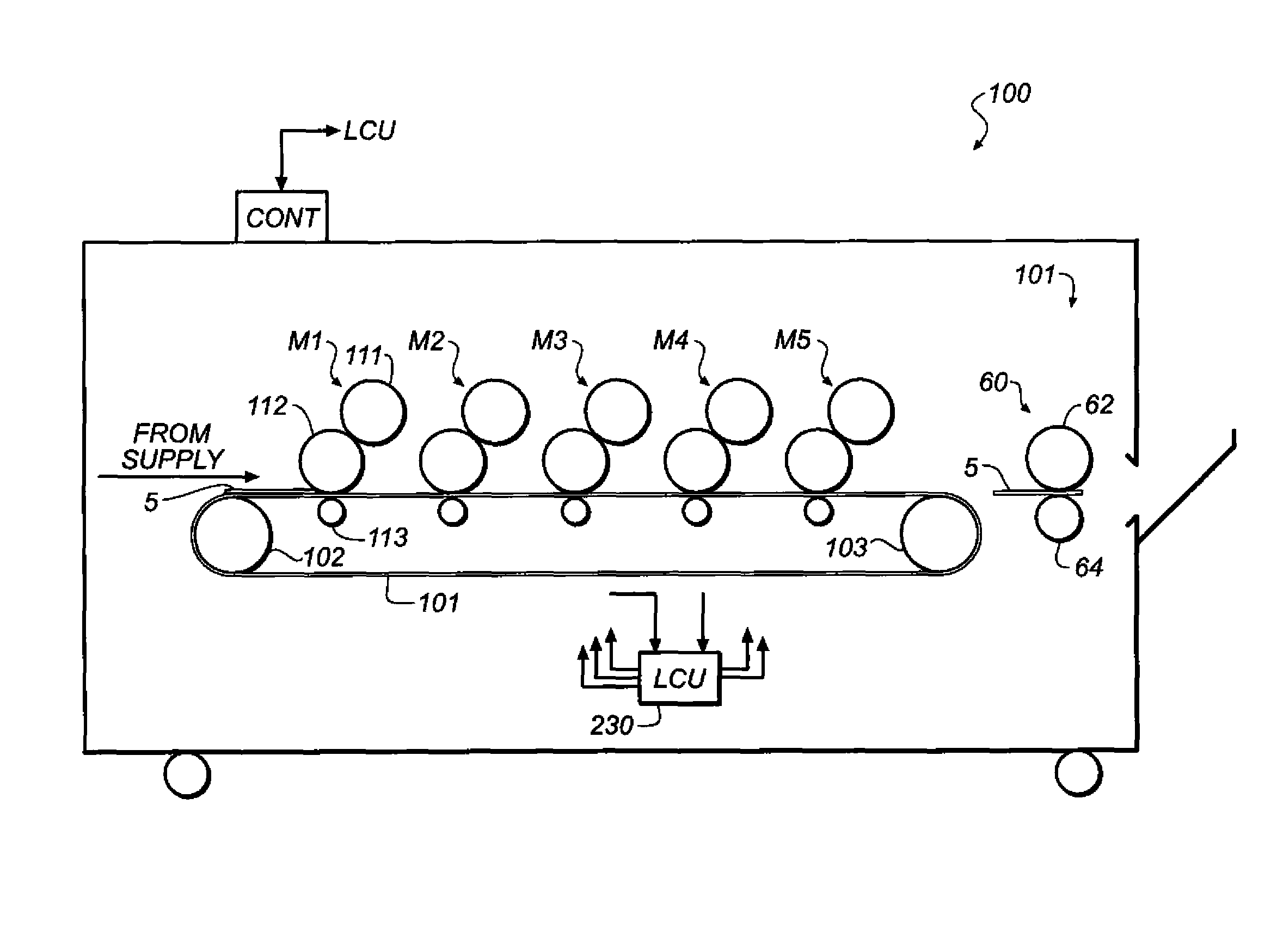

A fire suppression apparatus and method of generating foam are provided in which a foam-forming liquid is introduced under high velocity and pressure into a mixing manifold through a plurality of jets, and a non-combustible gas is introduced under high velocity and pressure into the center of the mixing manifold, downstream of the jets and in the direction of flow of the foam-forming liquid. The foam generated in the mixing manifold is discharged through a hose and nozzle connected to the mixing manifold. The apparatus may be a self-contained unit, supported on a frame, with its own supply of foam-forming liquid and non-combustible gas.

Owner:FORCED GAS TECH

Method of producing fuel hose material and fuel hose material produced by the same

InactiveUS20070202287A1Improve dispersion uniformityResistance to deteriorationSynthetic resin layered productsThin material handlingPlasticizerCarbon nanotube

A method of producing a fuel hose material which is obtained at low costs and has excellent properties such as antistatic property, resistance to thermal aging and resistance to sour gasoline, and a material produced by the method. The method includes the steps of: dispersing a carbon nanotube in a polar plasticizer comprising at least one of a sulfonamide plasticizer and an ester plasticizer; and blending the resulting compound into a polyamide resin having a relative viscosity (ηr) of 2.5 to 3.5, in which the carbon nanotube is present in a proportion of not less than 7 wt %.

Owner:SUMITOMO RIKO CO LTD

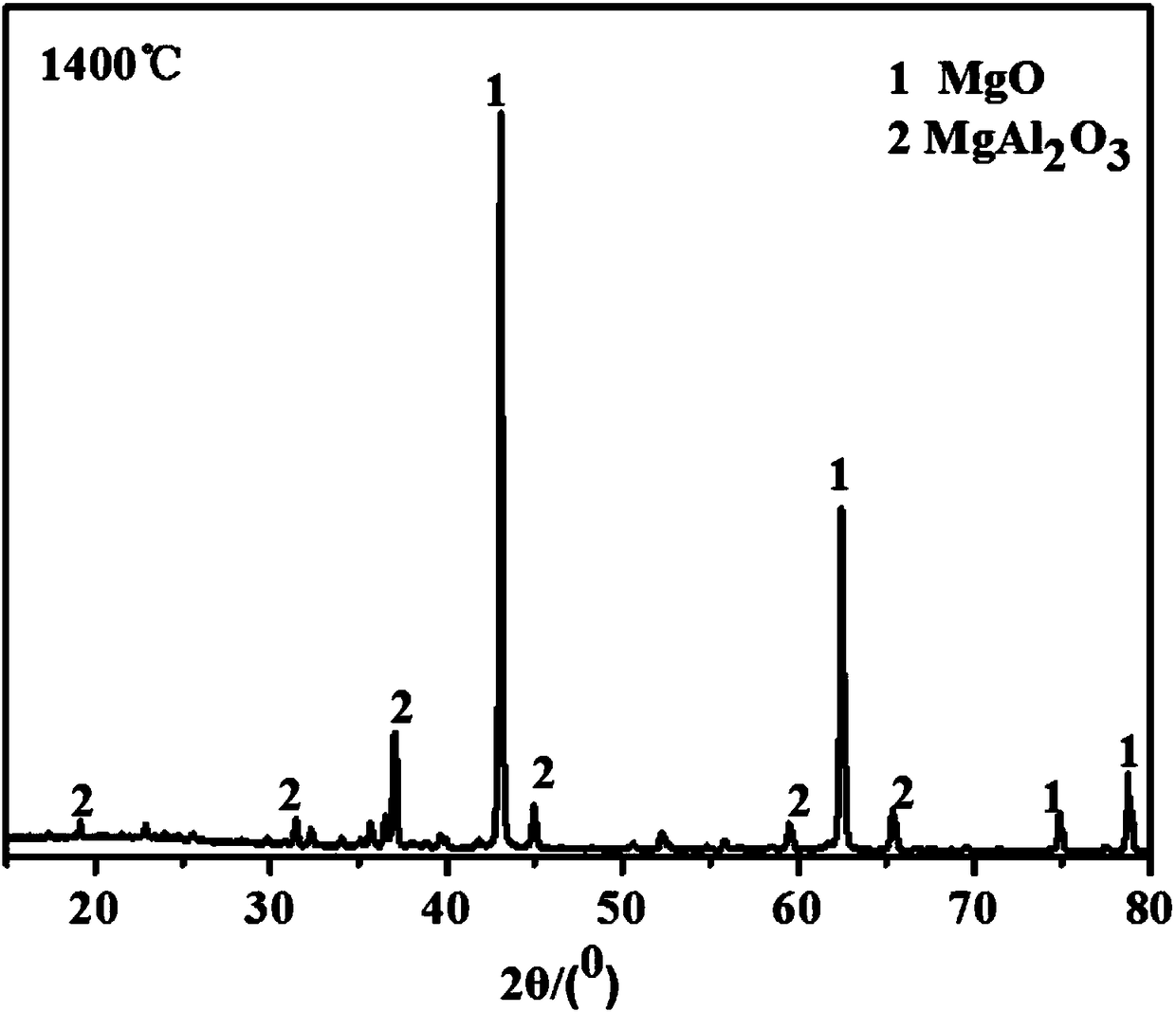

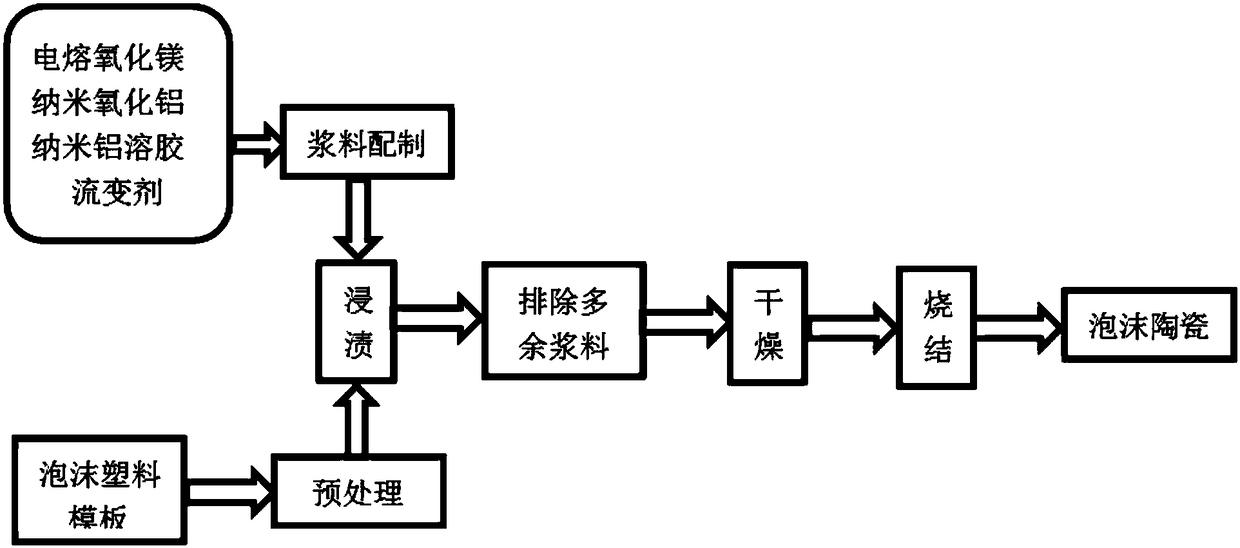

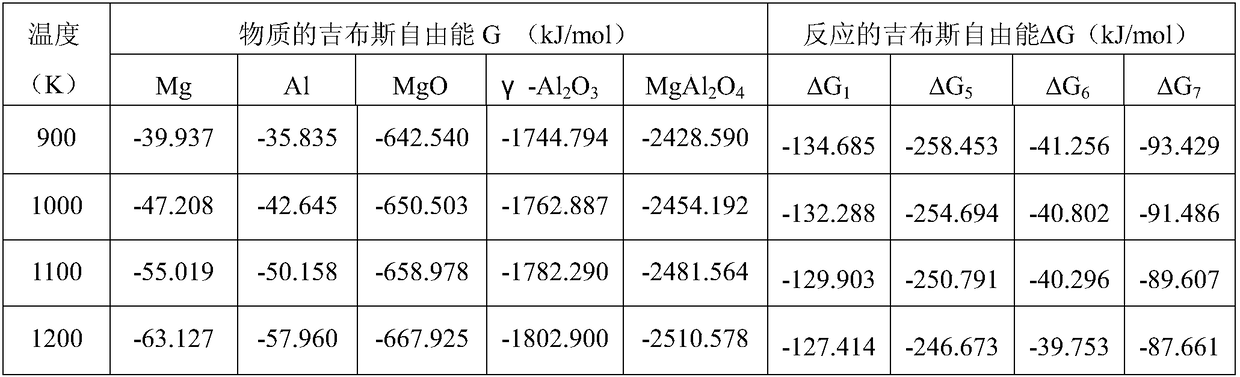

Magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter and preparation method thereof

ActiveCN108516803AAct as a binderAvoid damageFiltration separationCeramicwareOxide ceramicNano al2o3

The invention discloses a magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter with capability of realizing sintering at low temperature, excellent chemical stability and excellentthermal shock resistant performance, and a preparation method thereof. The preparation method comprises the following steps that (1) 10 to 20 percent of nanometer alumina sol, 0.8 to 1.5 percent of rheological agents and the balance of magnesium oxide ceramic powder containing a nanometer aluminum oxide sintering aid are proportioned; deionized water is added; ball milling and uniform mixing areperformed; then, through vacuum exhaust, ceramic slurry with the solid content being 60 to 70 percent is prepared; (2) a polyurethane foamed plastic template is soaked into the ceramic slurry; the polyurethane foamed plastic template is extruded through a roller press for removing the redundant leaching hanging slurry; then, biscuit is prepared; then, the biscuit is heated to 80 to 120 DEG C for drying; (3) the dried biscuit is put into a sintering furnace; the temperature is raised to 1400 to 1600 DEG C; high-temperature sintering is performed; cooling is performed along with the furnace to room temperature; the magnesia-based foamed ceramic filter is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

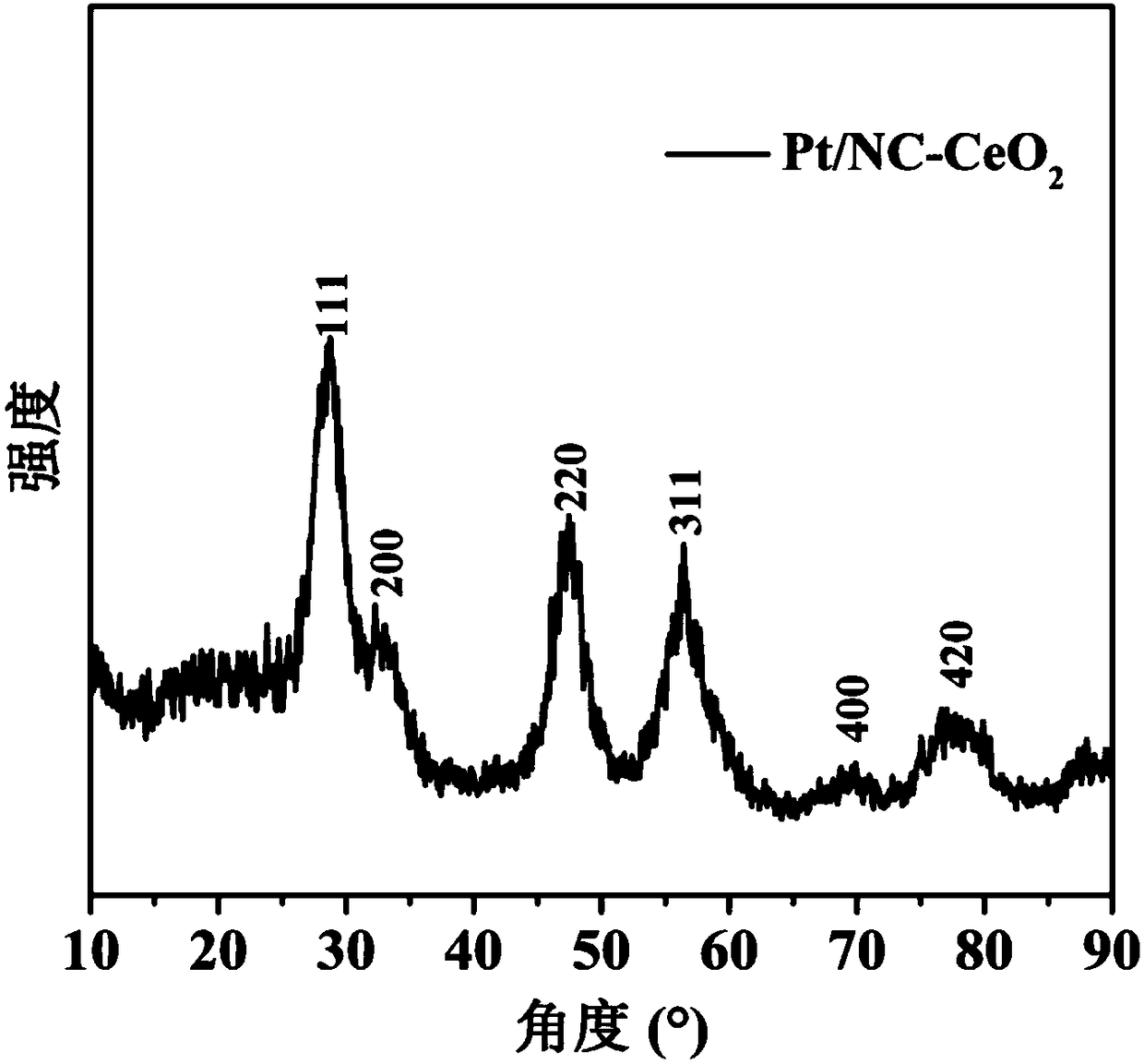

Alkaline high-dispersion loaded Pt-based nano-catalyst and preparation and application thereof

InactiveCN108525697AEvenly distributedHigh activityMaterial nanotechnologyOrganic chemistryFuranNano catalyst

The invention provides an alkaline high-dispersion loaded Pt-based nano-catalyst and preparation and application thereof. The catalyst is represented as Pt / MO-CN, wherein MO is one of CeO2, ZrO2, ZnOand NiO, and the mass percent of Pt is 1% to 5%; the particle size of Pt is 2nm to 4nm; and the mass ratio of CN to MO is 0.2 to 1.2. The method comprises the steps of introducing melamine into metalnitrate, which serves as a raw material, and NaBH4 which serves as a precipitant so as to obtain a metal oxide / melamine precursor, carrying out roasting treatment so as to obtain an alkaline-bit-enriched MO-CN carrier with high specific surface area, highly uniformly dispersing noble metal Pt in the surface of the MO-CN carrier through a liquid-phase reduction method by using NaBH4, , thereby obtaining the Pt / MO-CN. According to the catalyst, under the conditions of no additional alkali liquor introduction, relatively low O2 pressure and relatively low reaction temperature, 2,5-furan diformicacid can be prepared through rapid, efficient and selective catalyzed oxidation of 5-hydroxymethyl furfural, the conversion ratio and selectivity separately reach up to 92% to 98% and 89% to 99%, andthe catalyst has a relatively high application value and prospect.

Owner:BEIJING UNIV OF CHEM TECH

Preparing toner images with metallic effect

InactiveUS20130295502A1Enhance original colorHigh glossDevelopersElectrographic process apparatusLatent imagePolymer

A method is used to provide a toner image with a metallic effect. After forming a latent image, it is developed with metallic dry toner particles to form a developed toner image that is transferred and fixed to a receiver material. Each metallic dry toner particle consists essentially of a polymeric binder phase and non-conductive metal oxide particles. Before fixing, the metallic dry toner particle has a mean volume weighted diameter (Dvol) of at least 15 μm and up to and including 40 μm. The non-conductive metal oxide particles are present in an amount of 20-50 weight %. The ratio of the metallic dry toner particle Dvol to the average equivalent circular diameter (ECD) of the non-conductive metal oxide particles in the metallic dry toner particles, before fixing, is greater than 0.1 and up to and including 10.

Owner:EASTMAN KODAK CO

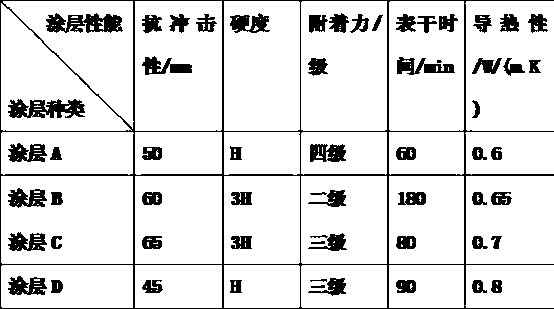

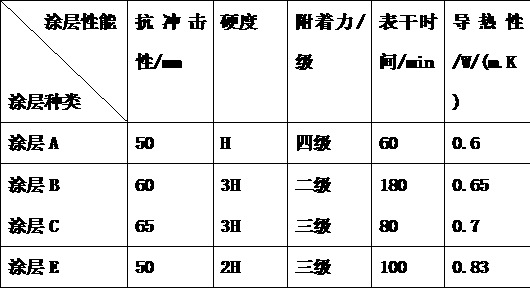

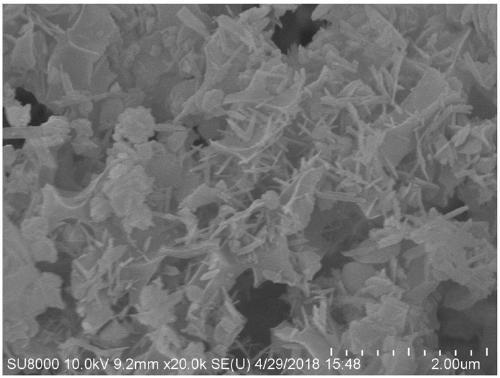

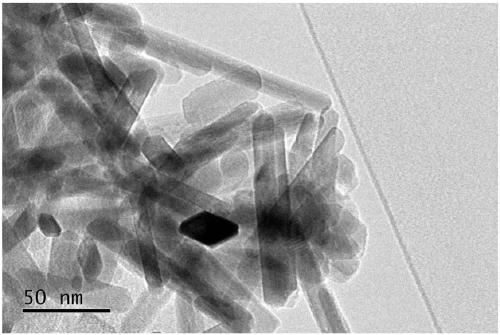

High-dispersion graphene heat-conduction water-based paint and preparation method thereof

The invention relates to high-dispersion graphene heat-conduction water-based paint. The high-dispersion graphene heat-conduction water-based paint is prepared from water-based paint and modifier cellulose nanocrystal / flaky graphene suspension, wherein a mass ratio of the cellulose nanocrystal / flaky grpahene suspension to the water-based paint is (1 to 7): 100, and a mass ratio of the flaky graphene in the cellulose nano crystal / flaky graphene suspension to cellulose nano crystal suspension is (0 to 2.5): 100. The preparation method comprises the following steps: (1) preparing cellulose nano crystal / flaky graphen suspension; (2) mixing the suspension and the water-based paint; (3) smearing the modified water-based paint; and (4) drying, curing, and forming a film. The high-dispersion graphene heat-conduction water-based paint has the advantages that: (1) hydroxyl on the surface of the cellulose nanocrystal sufficiently reacts with the surface active group of a graphene flake layer, sothat the graphene is highly uniformly dispersed; (2) the synergistic effect of the cellulose nanocrystal and the graphene can apparently improve the heat conductivity, impact resistance, hardness andadhesion of a coating; and (3) the high-dispersion graphene heat-conduction water-based paint is low in cost, wide in source, controllable in process and good in applicability.

Owner:NANJING FORESTRY UNIV +1

Method for preparing needle-shaped Fe-Mn-S ternary nano-material supported porous charcoal compound material

ActiveCN109225134AHighly uniform dispersionGood dispersionOther chemical processesWater contaminantsManganateCarbonization

The invention provides a method for preparing a needle-shaped Fe-Mn-S ternary nano-material supported porous charcoal compound material, relates to a method for preparing porous charcoal compound materials to solve the problems that an existing Fe-Mn binary nano-material is easily agglomerated and has low adsorption capacity to heavy metals. The method comprises the following steps: 1, performingpyrolytic carbonization on a biomass material; 2, performing hydrophilic treatment on the pyrolytically carbonized porous charcoal material; 3, stirring the hydrophilic porous charcoal material in a ferric salt aqueous solution, dropwise adding a manganate solution and sulfide solution for stirring, adding a weak alkaline solution for stirring, performing hydrothermal reaction, and drying to obtain the ternary nano-material supported porous charcoal compound material. According to the method, the interaction among molecules of a ternary nano-material is reduced by supporting the Fe-Mn-S ternary nano-material to the surface of the charcoal material, nano-particle agglomeration is reduced, and the dispersibility of ternary nano-particles is improved. The method is applied to the field of charcoal compound materials.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Catalyst for preparing low-carbon olefin from synthesis gas by one-step method, preparation method and application of catalyst

ActiveCN104549325AHighly uniform dispersionIncrease the number ofHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasFixed bed

The invention relates to a catalyst for preparing low-carbon olefin from synthesis gas by a one-step method and a preparation method of the catalyst, which are mainly used for solving the problems of low CO conversion rate and low selectivity of low-carbon olefin in the reaction for preparing low-carbon olefin from synthesis gas in the prior art. The catalyst adopted by the invention comprises the following components in percentage by weight: (a) 5-60% of ferrum element or an oxide of the ferrum element; (b) 1-10% of cobalt element or an oxide thereof; (c) 4-20% of at least one element or an oxide thereof selected from strontium or magnesium; (d) 4-20% of at least one element or an oxide thereof selected from molybdenum and zirconium; (e) 1-10% of erbium element or an oxide thereof; and (f) 30-85% of a cocoanut active charcoal carrier. By adopting the technical scheme, the problem is solved well, and the catalyst and the preparation method thereof can be applied to the industrial production for preparing the low-carbon olefin from synthesis gas by using a fixed bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

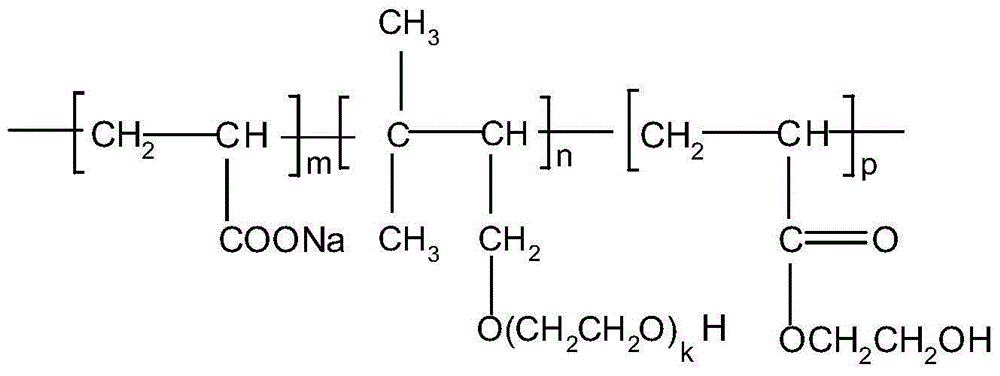

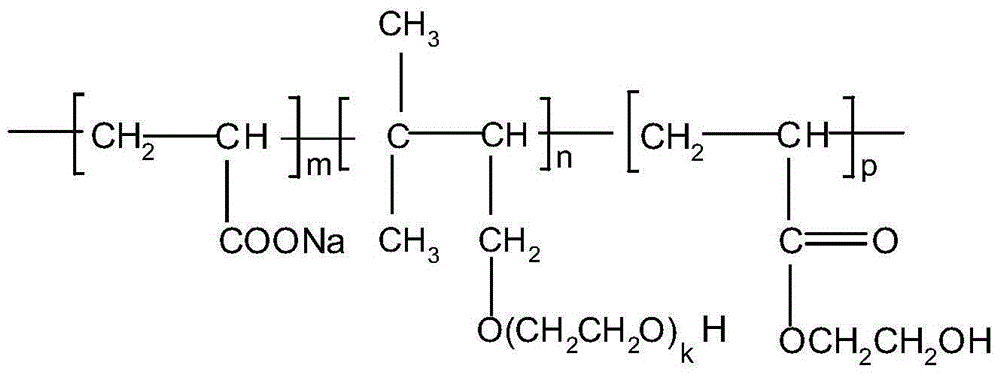

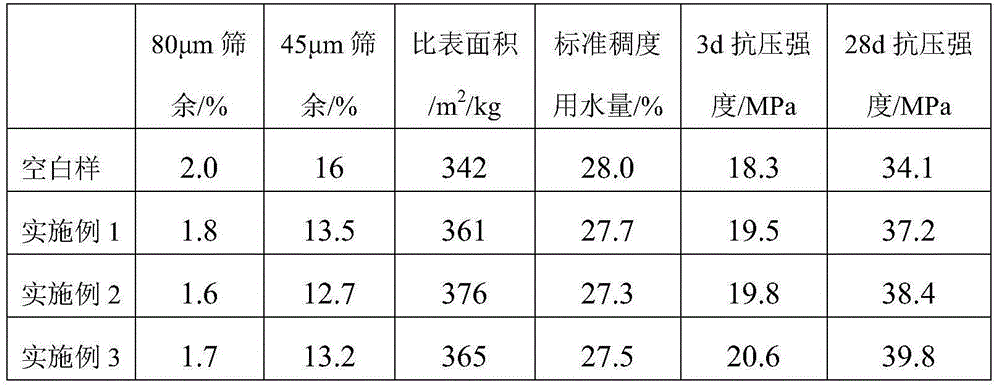

High-limestone-flour-adulterate-amount composite enhanced grinding aid for cement and preparation method of high-limestone flour-adulterate amount composite enhanced grinding aid

The invention relates to a high-limestone-flour-adulterate-amount composite enhanced grinding aid for cement and a preparation method of the high-limestone-flour-adulterate-amount composite enhanced grinding aid. The preparation method comprises the following steps that 1, materials including 18%-25% of triethanolamine, 8%-15% of triisopropanolamine, 20%-28% of ethanediol, 8%-12% of molasses, 4%-8% of polycarboxylate superplasticizer, 6%-10% of sodium sulfate, 5%-8% of glacial acetic acid and 2%-24% of water are taken; 2, the water is poured into an agitator kettle, and sodium sulfate is added to be stirred till sodium sulfate is completely dissolved; 3, glacial acetic acid is added to be completely dissolved, triethanolamine, triisopropanolamine, ethanediol, molasses and polycarboxylate superplasticizer are sequentially added after glacial acetic acid is dissolved, stirring continues to be carried out for 20-30 minutes, and the high-limestone flour-adulterate amount composite enhanced grinding aid is obtained. The high-limestone-flour-adulterate-amount composite enhanced grinding aid has the advantages that cement particles are prevented from clustering, and the cement particles are kept in a high homodisperse state; the strength of an interfacial transition zone is increased, and the strength of the cement is further increased; the grinding aiding efficiency of the grinding aid is improved.

Owner:WUHAN UNIV OF TECH

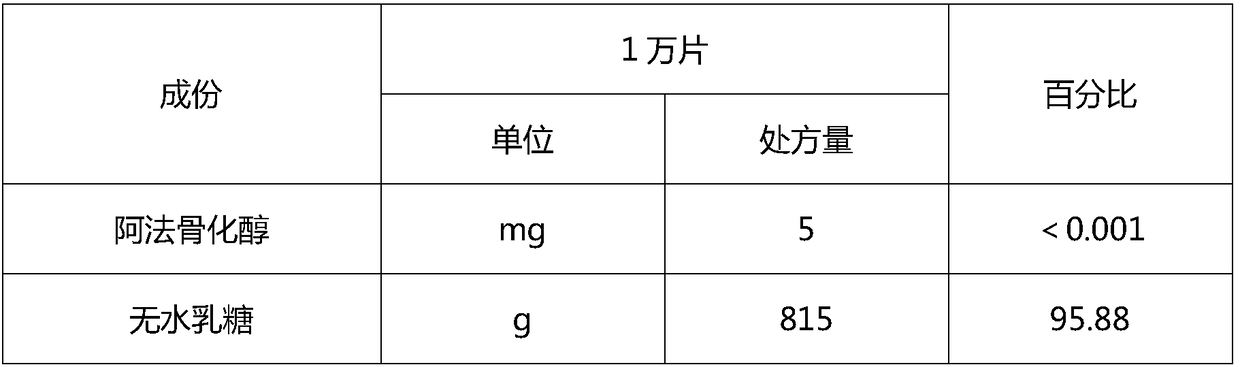

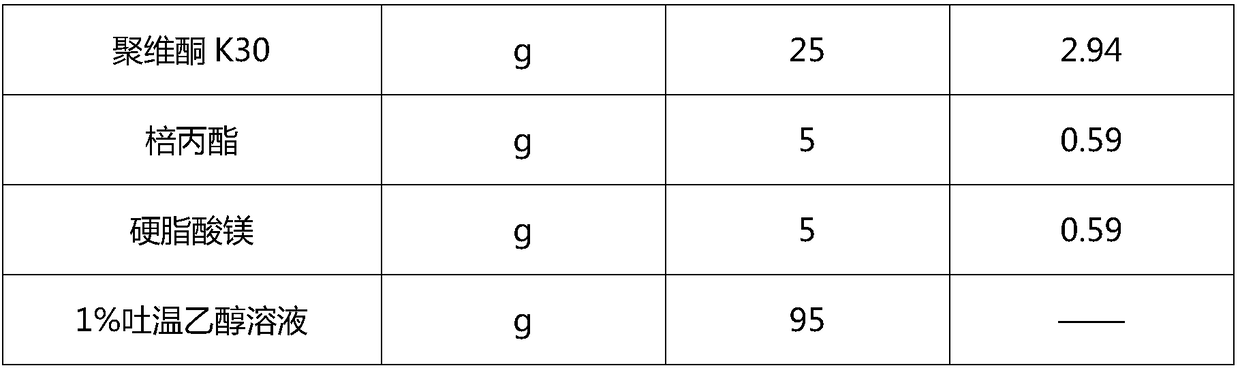

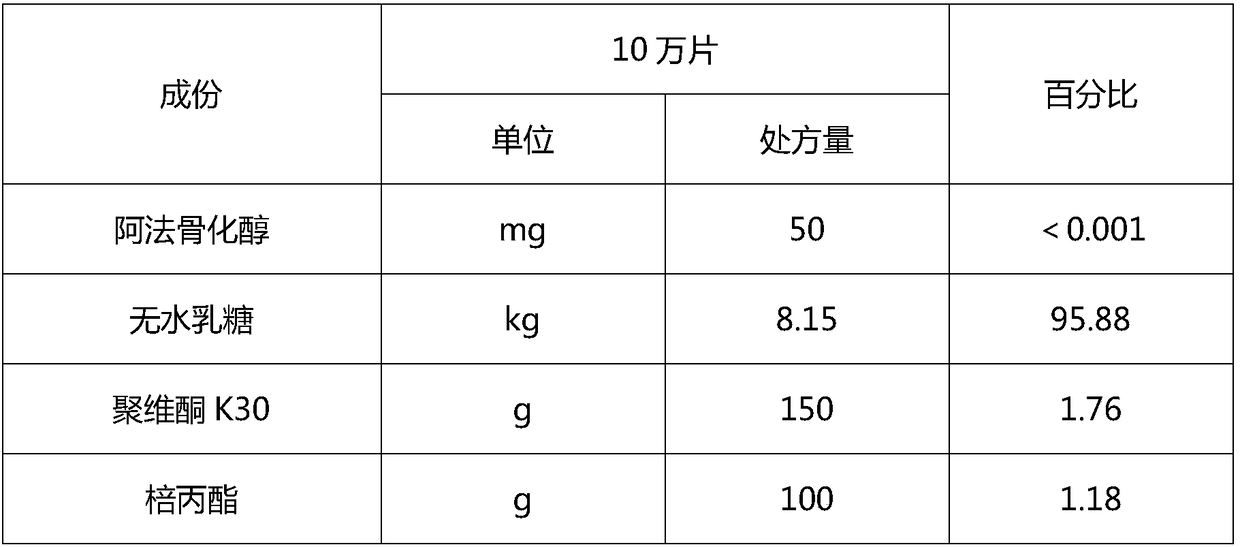

Vitamin D analog preparation and preparation method thereof

ActiveCN108420797AContent uniformity is not highHighly uniform dispersionOrganic active ingredientsSkeletal disorderEldecalcitolDrug product

The invention discloses a vitamin D analog preparation and a preparation method thereof. The invention aims to solve the problems that a conventional preparation method of vitamin D analog has difficulty in meeting the uniformity requirement and during the granulation process, drugs are converted and degraded easily. For the first time, a double screw extrusion technology is used to prepare a solid preparation of vitamin D analog. Various vitamin D analogs are taken as model drugs, on the basis that a preparation technology of solid preparations is deeply researched, alfacalcidol, eldecalcitol, or calcitriol is chosen to prepare the solid preparation by using a double screw extruding machine; the uniformity meets the pharmacopeia requirements; the drug stability is obviously enhanced, andthe drug quality is greatly improved.

Owner:NANJING HERON PHARM CO LTD

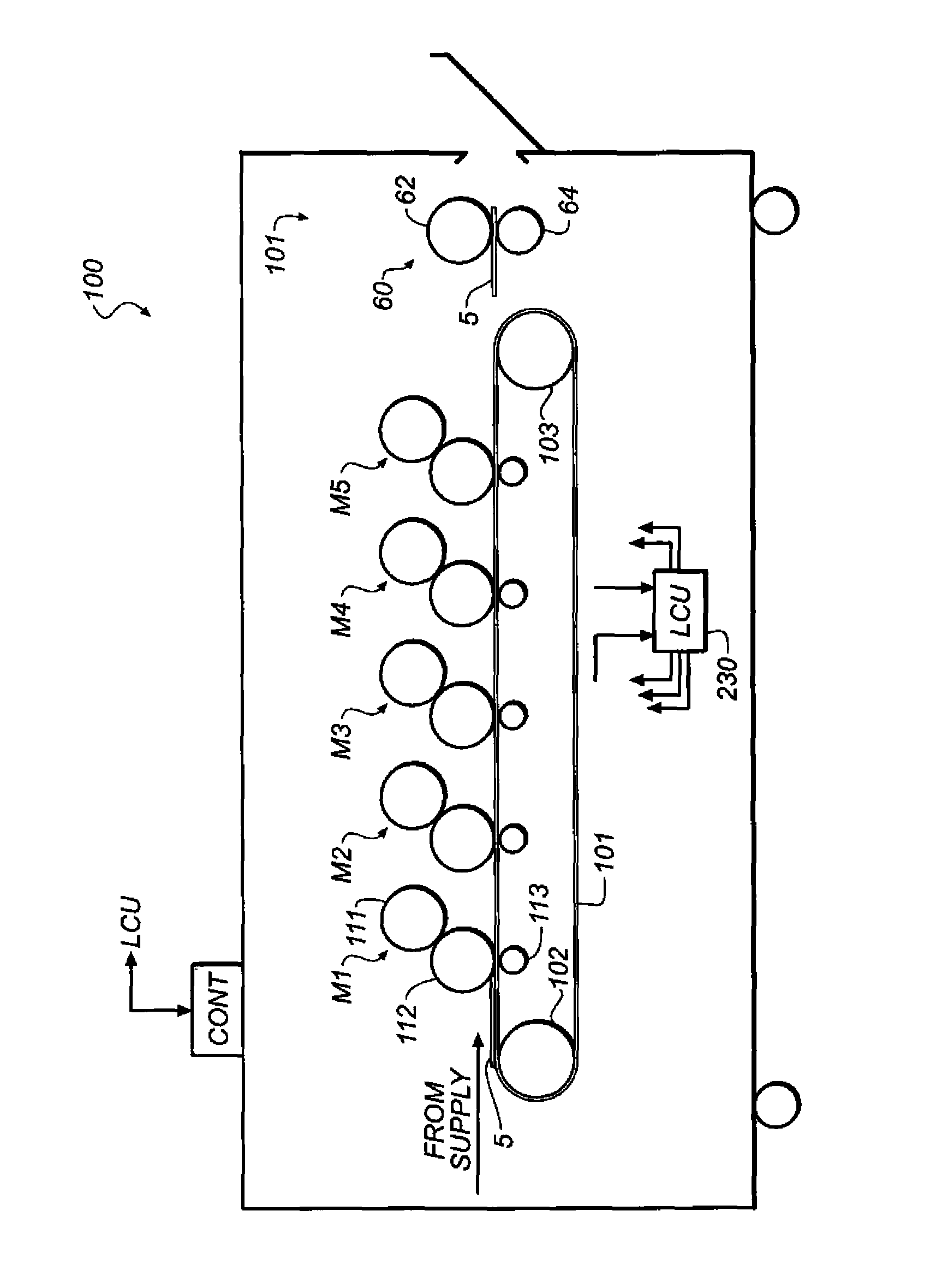

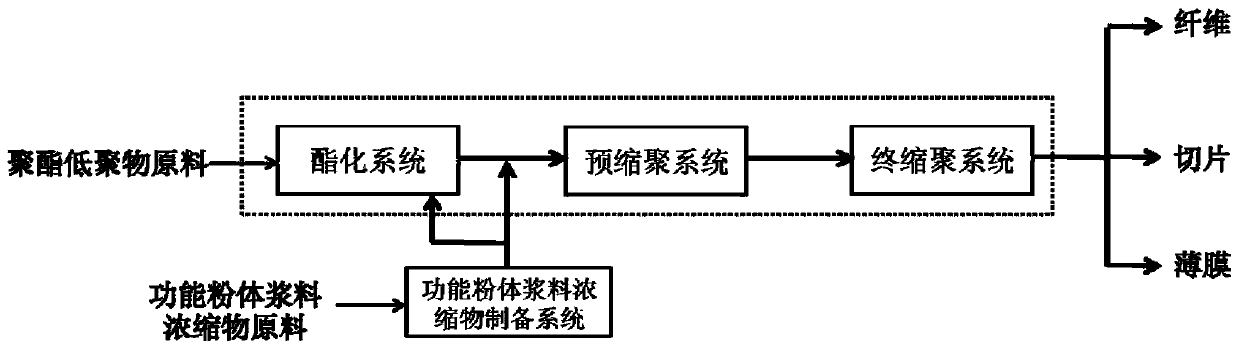

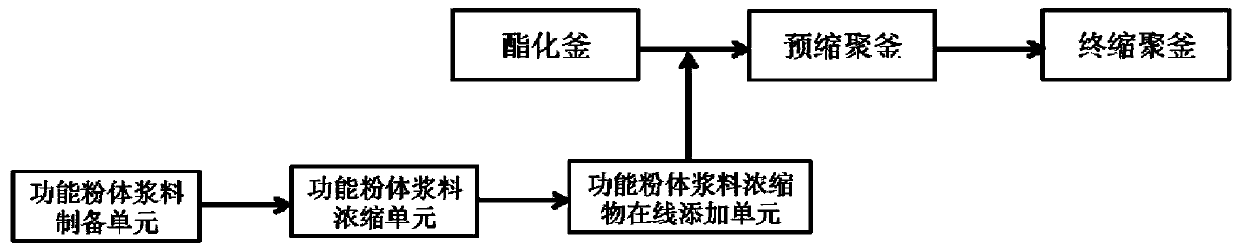

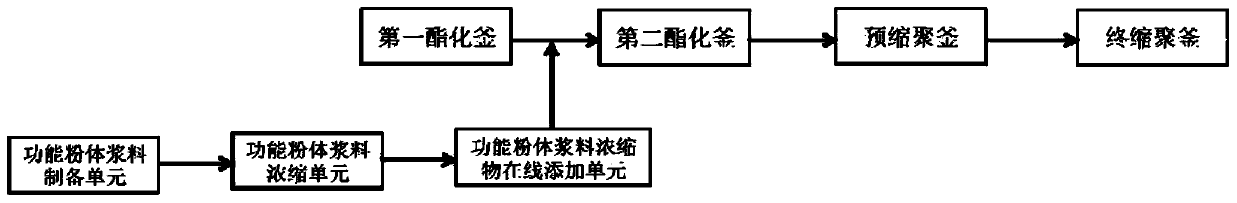

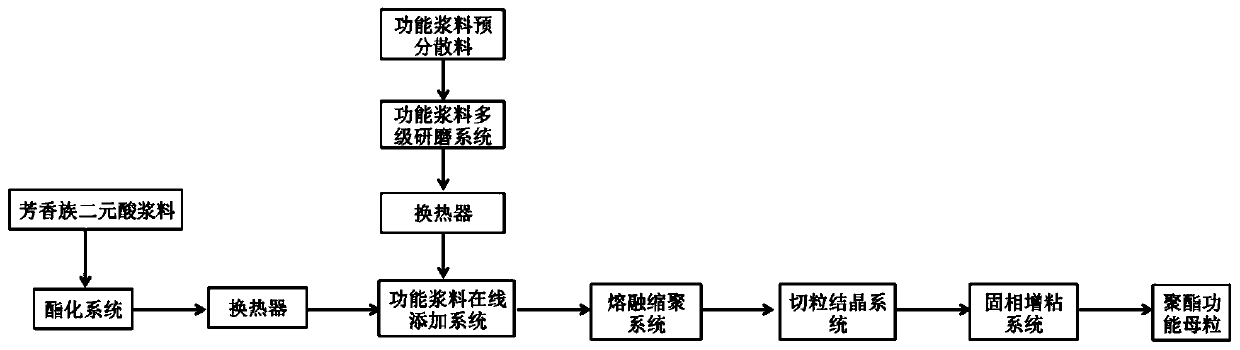

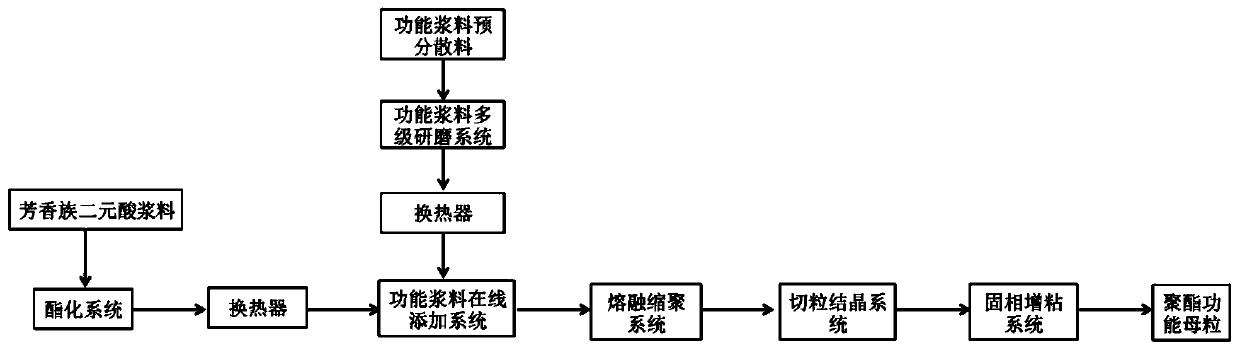

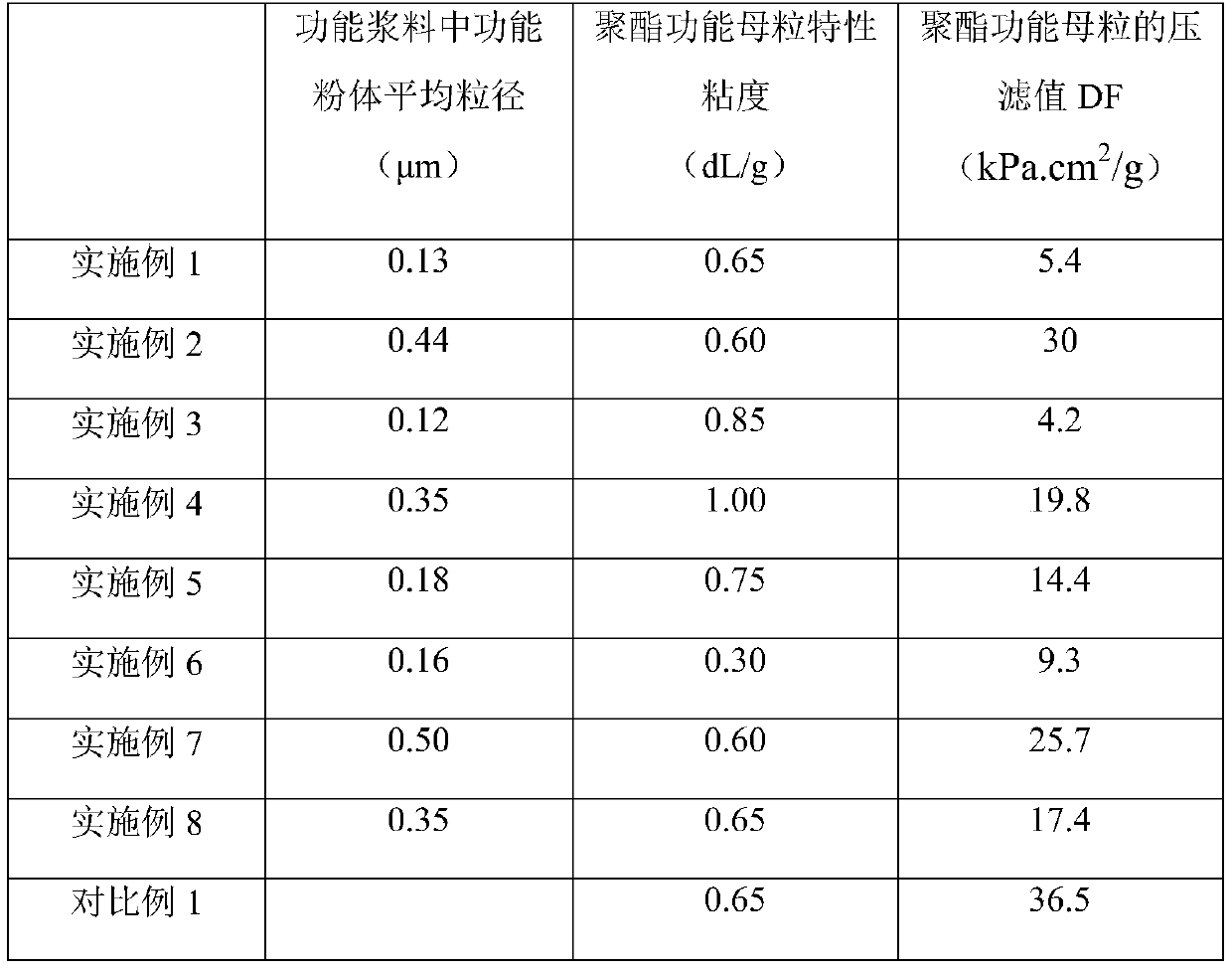

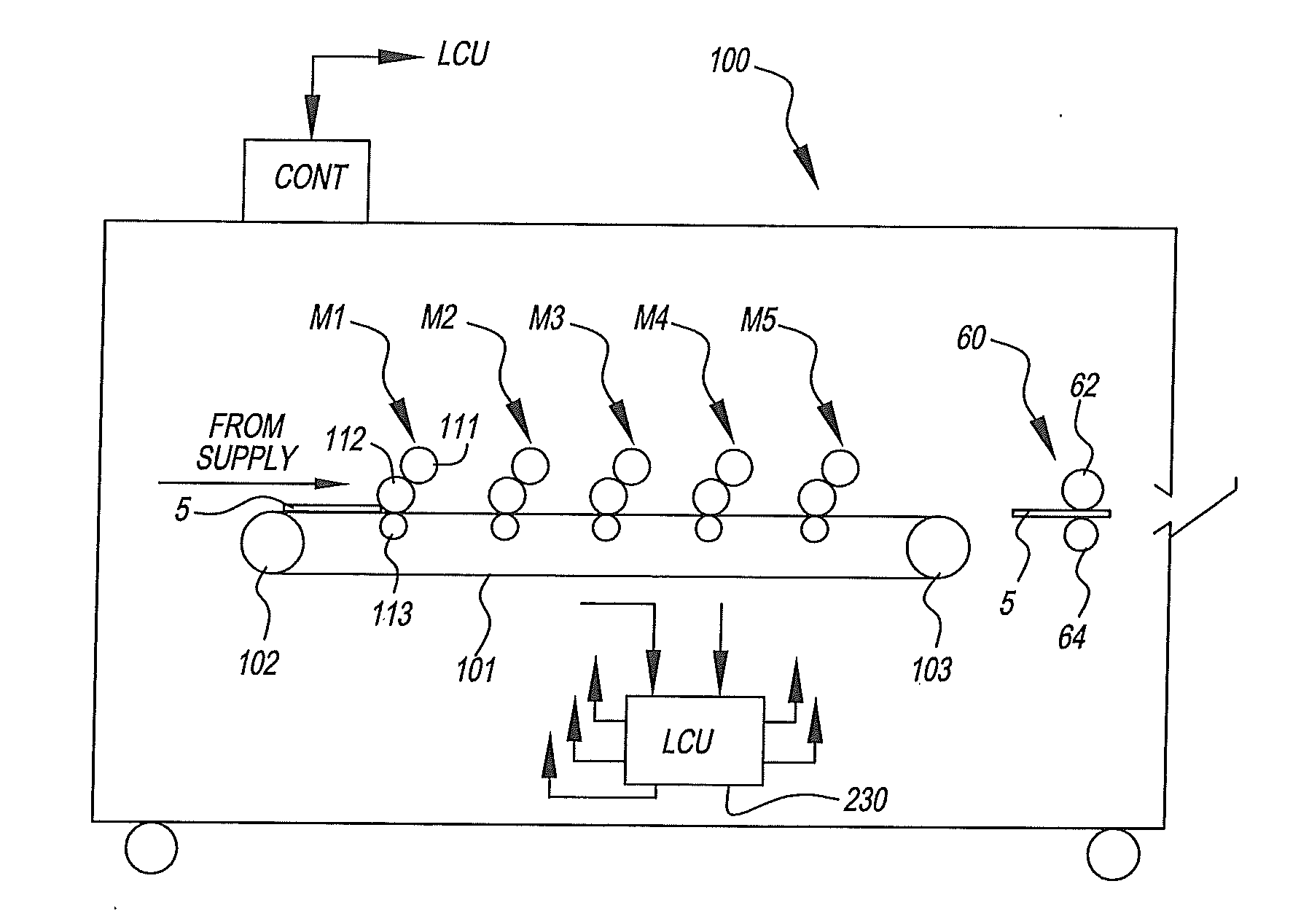

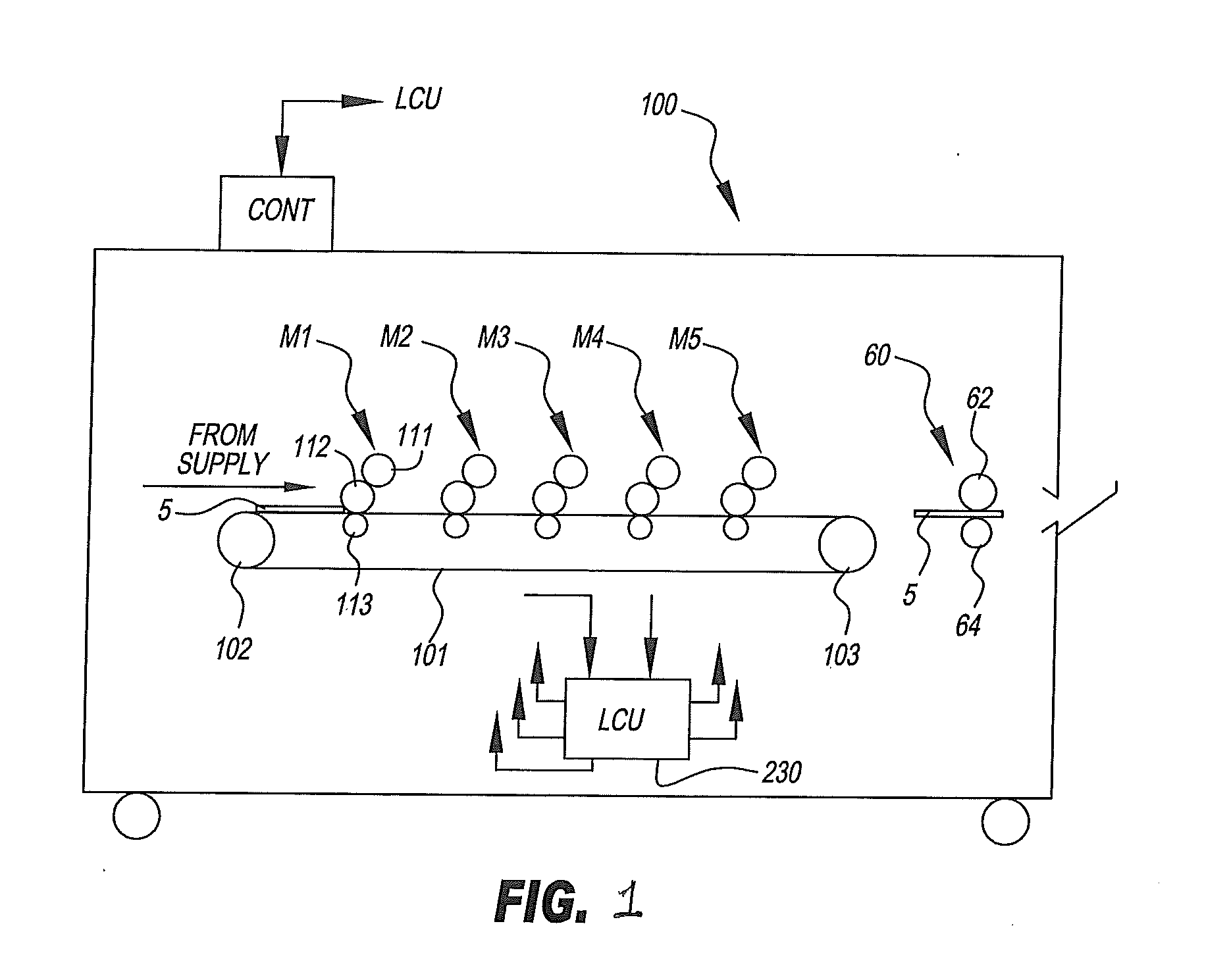

Functional polyester production method and production system and functional polyester fiber

ActiveCN109705319AHighly uniform dispersionLow hydroxyl valuePigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention belongs to the technical field of polymer material synthesis, and particularly relates to a functional polyester production system. The functional polyester production system comprises apolyester main production system, and further comprises a functional powder slurry concentrate preparation system, the polyester main production system comprises an esterification system, a pre-polycondensation system and a final polycondensation system which are connected in sequence, the functional powder slurry concentrate preparation system comprises an online adding device which is connectedwith the esterification system or a part between the esterification system and the pre-polycondensation system. The functional powder slurry concentrate preparation system is introduced in the polyester main production system, and can continuously prepare a functional powder slurry concentrate with low hydroxyl value and low pressure filtration value, and the prepared functional powder slurry concentrate and a polyester oligomer are uniformly mixed for polycondensation reaction to obtain functional polyester with uniformly dispersed functional powder. The invention further relates to a functional polyester production method.

Owner:CHINESE TEXTILE ACAD +1

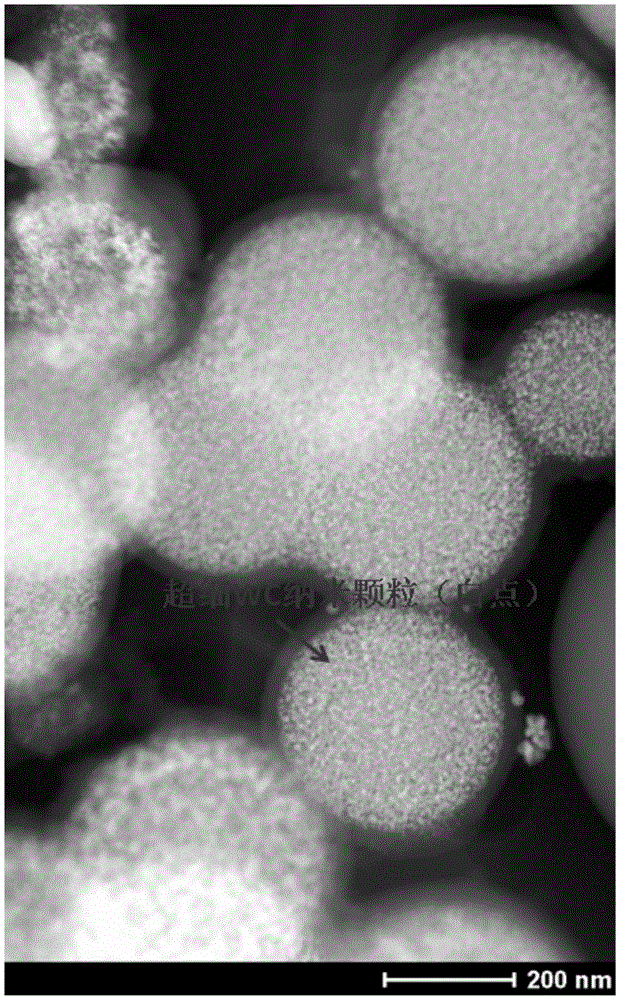

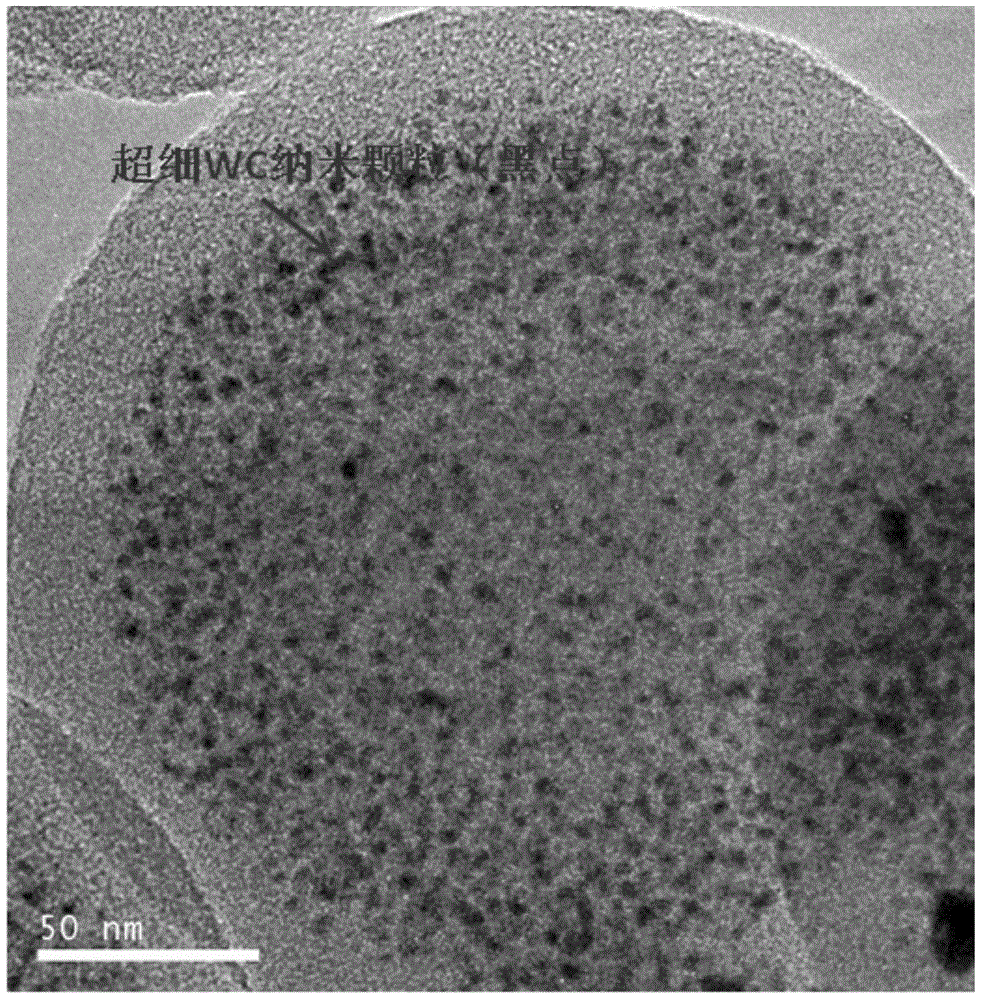

Carbon resistance superfine nano wolfram carbide material as well as preparation method and application thereof

InactiveCN103818906AHighly uniform dispersionAvoid reunionPigmenting treatmentPhysical/chemical process catalystsCarbon resistanceCarbonization

The invention discloses a carbon resistance superfine nano wolfram carbide (WC) material as well as a preparation method and application thereof. The preparation method of the carbon resistance superfine nano WC material comprises the following steps: (1) adding a deionized water solution of a wolfram source in a solution prepared from ethanol, stronger ammonia water and a surfactant, wherein the wolfram source is ammonium metatungstate, sodium tungstate or tungsten chloride, the surfactant is sodium dodecyl benzene sulfonate, hexadecyl trimethyl ammonium bromide or P123, stirring the solution uniformly, adding resorcinol to the solution, stirring uniformly and then adding formaldehyde, and stirring for 8-28 hours at the room temperature to obtain the mixed solution; (2) performing a hydrothermal reaction on the mixed solution, and drying the solution to obtain a mixed polymer; (3) performing high-temperature carbonization on the mixed polymer in a CO atmosphere to obtain the carbon resistance superfine nano WC material. The WC material can enable the WC particles to keep stable in the high temperature process without secondary agglomeration; the WC material can be taken as an electrocatalyst to be applied to an electrocatalysis nitroreduction reaction, or can also be taken as a carrier to prepare a platinum-carried catalyst, and the prepared platinum-carried catalyst can be applied to anode catalysis of a methanol fuel cell.

Owner:ZHEJIANG UNIV OF TECH +1

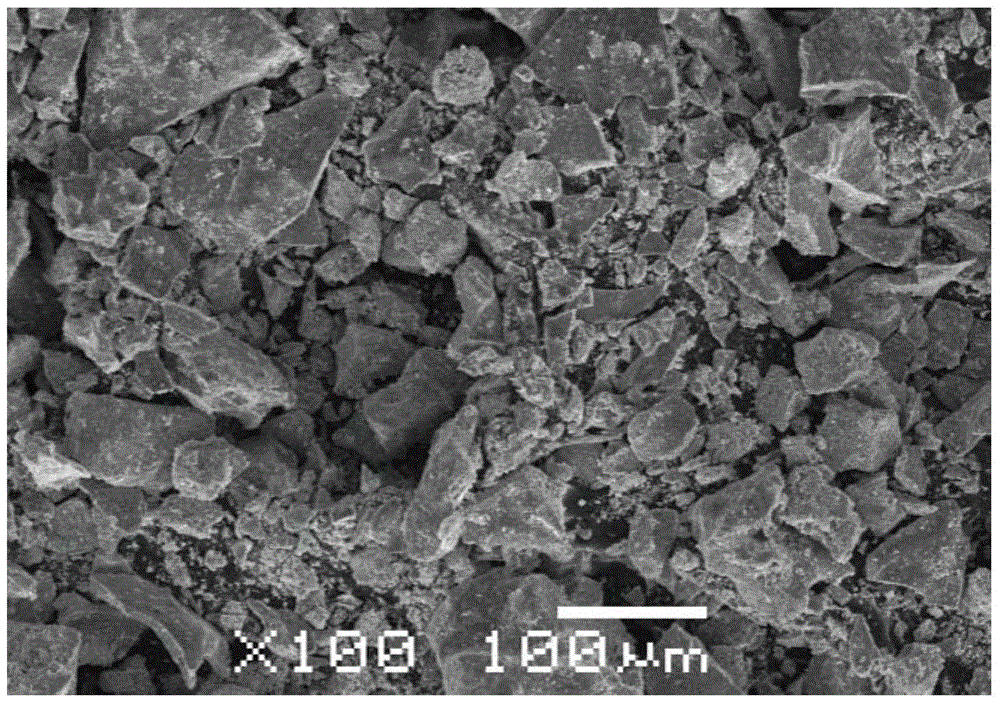

Method for continuously producing polyester functional master batch and polyester functional master batch

ActiveCN109705320ARealize continuous productionSimple structureFlame-proof filament manufactureMonocomponent polyesters artificial filamentOligomerMaterial synthesis

The invention belongs to the technical field of polymer material synthesis, and relates to a method for continuously producing a polyester functional master batch and the polyester functional master batch, the method comprises the following steps: using aromatic binary acid, aliphatic dihydric alcohol and a catalyst to prepare an aromatic binary acid aliphatic dihydric alcohol ester oligomer; mixing functional powder and aliphatic dihydric alcohol to obtain functional slurry; and adding the functional slurry into the aromatic binary acid aliphatic dihydric alcohol ester oligomer on line, uniformly mixing, carrying out melt polycondensation reaction, and carrying out pelletizing forming, crystallizing and solid-phase polycondensation reaction to obtain polyester functional master batch slices. According to the invention, the functional slurry online addition procedure, the melt polycondensation reaction procedure, the pelletizing forming and crystallizing procedures and the solid-phasepolycondensation reaction procedure are introduced, the continuous production of the polyester functional master batch and the accurate addition and height dispersion of the functional powder are realized, and the structure uniformity of the polyester functional master batch is improved.

Owner:CHINESE TEXTILE ACAD +1

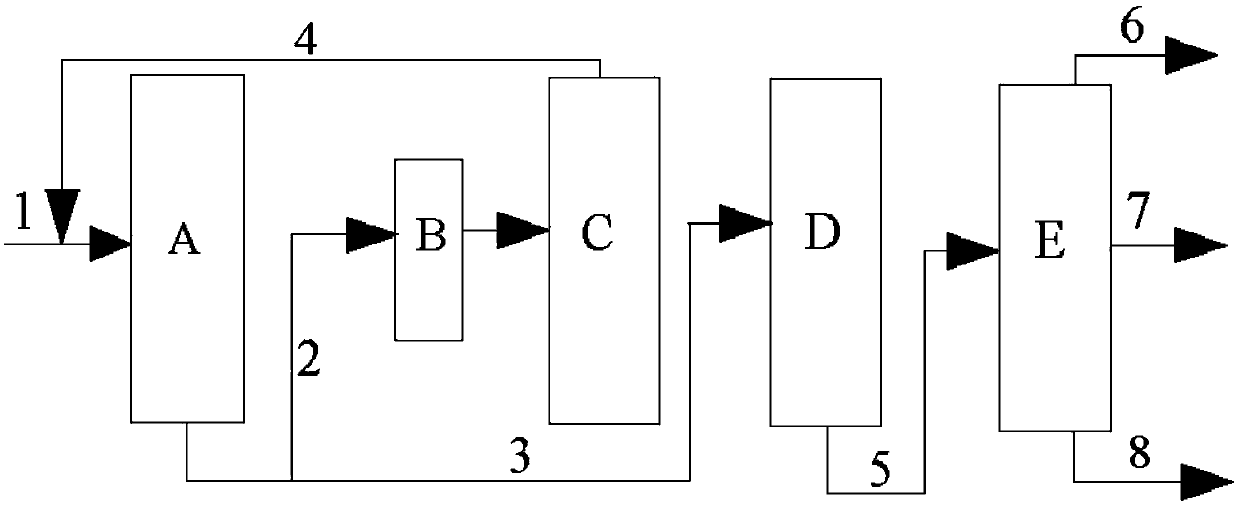

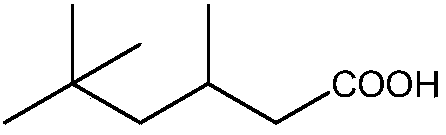

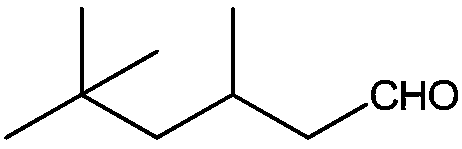

System and method for preparing isononanoic acid and method for preparing metal organic skeletal catalyst

ActiveCN108047027AHigh selectivityPromote decompositionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDecompositionMetal-organic framework

The invention provides a system and method for preparing isononanoic acid and a method for preparing a metal organic skeletal catalyst. The system includes an oxidation reactor used for oxidizing isononylaldehyde to isononanoic acid; a cooler used for cooling a part of material flow that flows out of the oxidation reactor; a metal ion separator used for separating excessive metal ions from the material flow that flows out of the cooler; a peroxide decomposition reactor used for decomposing a peroxide in the other part of the material flow that flows out of the oxidation reactor; and a rectification apparatus used for separating the material flow that flows out of the peroxide decomposition reactor to obtain the isononanoic acid product, wherein the material outlet of the metal ion separator is connected to the material inlet of the oxidation reactor. The invention further provides an isononanoic acid preparation method that is good in selectivity and safety and high in yield.

Owner:WANHUA CHEM GRP CO LTD

Method for directly transforming synthesis gas into low-carbon olefin

ActiveCN103664436AHighly uniform dispersionImprove conversion rateHydrocarbon from carbon oxidesMolecular sieve catalystsSyngasActivated carbon

The invention relates to a method for directly transforming a synthesis gas into low-carbon olefin. The problems of low CO conversion ratio and low selectivity of low-carbon olefin in reaction of producing the low-carbon olefin by fischer-tropsch synthesis of a fixed bed in the prior art are mainly solved. The method adopts the technical scheme as follows: a mixture of a fischer-tropsch synthesis catalyst and a ZSM-5 molecular sieve catalyst is adopted as the catalyst to prepare the low-carbon olefin, wherein the fischer-tropsch synthesis catalyst selects coconut shell activated carbon as a carrier, and the loaded active component contains a composition with the following chemical formula based on atomic ratio: Fe100AbBbOx, wherein A is selected from transition metal Mn, and B is selected from alkali metal K, so that the problem can be well solved, and the method can be applied to industrial production for producing the low-carbon olefin from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-bacterial composite particles and anti-bacterial resin composition

InactiveUS7250453B2High antibacterial activityEvenly dispersedAntibacterial agentsHeavy metal active ingredientsShell moldingInjection moulding

Anti-bacterial composite particles which comprise a polymer base material comprising a thermal melting polymer, such as a polyolefine, exhibiting good dispersibility in a basic material resin and having a lower molecular weight or a lower softening point than that of the basic material resin, and inorganic fine particles comprising a metal having anti-bacterial activity carried thereon. An antibacterial resin composition can be prepared by melting and kneading a synthetic resin composition as the basic material resin together with the anti-bacterial composite particles and forming by known molding methods such as extrusion molding and injection molding, and can be used for producing various synthetic resin moldings which have an inorganic anti-bacterial agent uniformly dispersed in a synthetic resin composition and thus exhibits good anti-bacterial effect.

Owner:FUJIFILM BUSINESS INNOVATION CORP

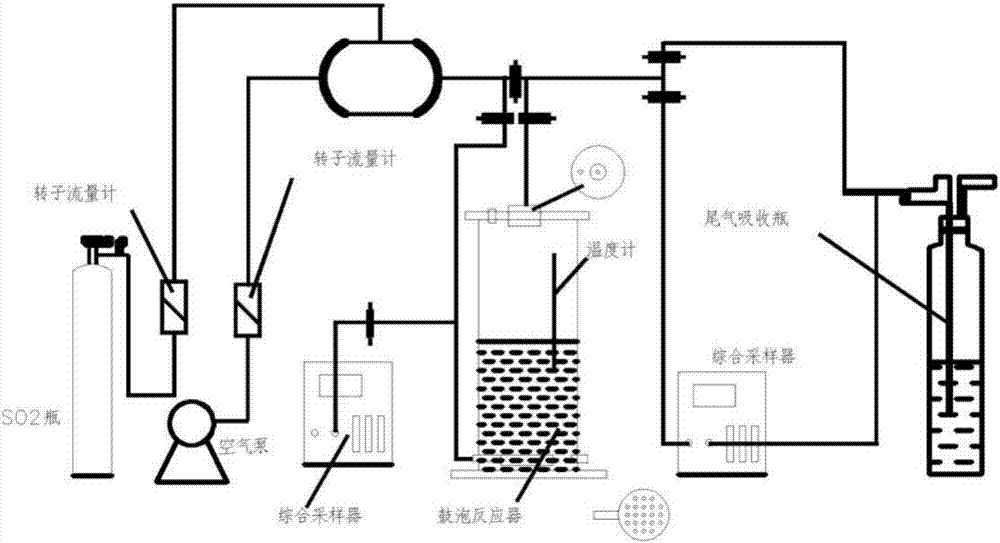

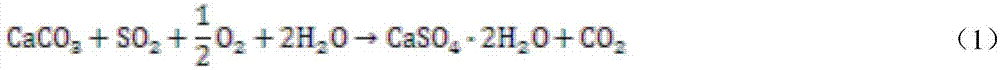

Method for preparing desulfurizing agent by carrying out thermal activation on red mud and active carbon

InactiveCN106881019AEasy to get from a wide range of sourcesThe source is easy to getGas treatmentDispersed particle separationMass ratioRed mud

The invention discloses a method for preparing a desulfurizing agent by carrying out thermal activation on red mud and active carbon and belongs to the field of coal desulfurization. The method comprises the specific steps: step a: sieving the red mud and the active carbon with a 300-mesh sieve respectively; drying at 105 DEG C until the weight is constant; step b: mixing the red mud and the active carbon according to the mass ratio ranging from (1 to 10) to (1 to 30); step c: activating a mixture in the step b in a muffle furnace at 700 DEG C to 1100 DEG C for 10min to 30min; after finishing the thermal activation, naturally cooling to room temperature under a sealed condition. The method disclosed by the invention has the advantages that the waste dreg red mud produced in a production process of aluminum oxide is prepared into the desulfurizing agent; a preparation process is simple and the activation time is short; the wet-method desulfurizing efficiency can reach 90 percent; the desulfurizing rate can be maintained to be 87 percent when the desulfurizing agent is continuously used under a low pH (Potential of Hydrogen) condition; the dosage of the desulfurizing agent is reduced so that the desulfurizing agent is economical and feasible.

Owner:CHINA UNIV OF MINING & TECH

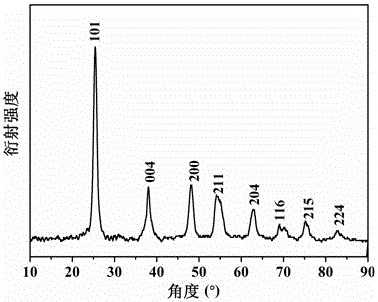

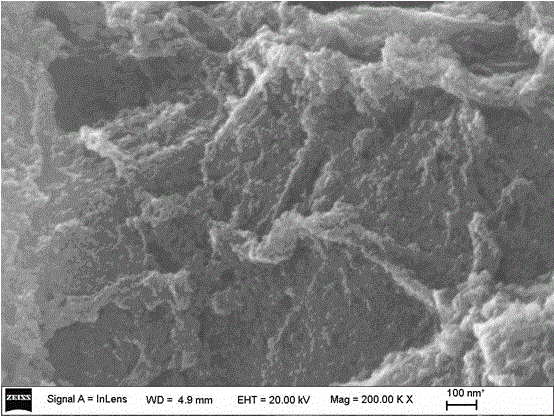

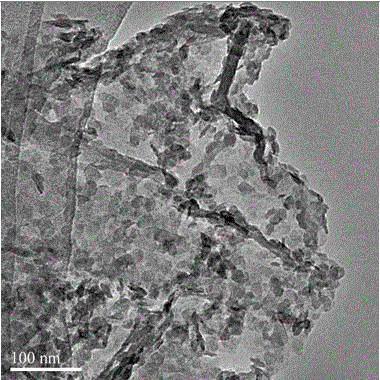

Titanium dioxide/graphene composite nanometer photocatalyst, method for preparing same and application of titanium dioxide/graphene composite nanometer photocatalyst

InactiveCN106311206AHigh specific surface areaHighly uniform dispersionWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationSolvent

The invention discloses a titanium dioxide / graphene composite nanometer photocatalyst, a method for preparing the same and application of the titanium dioxide / graphene composite nanometer photocatalyst. The titanium dioxide / graphene composite nanometer photocatalyst, the method and the application have the advantages that solvothermal processes are adopted, alcohol is used as a solvent, hexamethylene tetramine is decomposed under solvothermal conditions to generate alkaline and reduction species, accordingly, the titanium dioxide / graphene composite nanometer photocatalyst can be prepared at one step, and the problems of secondary stacking of graphene lamellar structures and aggregation of TiO2 nanometer particles in procedures for preparing titanium dioxide and graphene composite materials by the aid of fractional-step methods can be solved; the titanium dioxide / graphene composite nanometer photocatalyst is high in dispersion, has a large specific surface area and is extremely high in photocatalytic degradation capacity for nitrogen-containing organic dyestuff in printing and dyeing wastewater, and accordingly the titanium dioxide / graphene composite nanometer photocatalyst and the method have broad application prospects.

Owner:北京清淞泉生物科技有限公司

Preparing dry toner particles for metallic effect

Metallic dry toner particles are prepared by dry blending resin particles with non-conductive metal oxide particles to form a dry blend. This dry blend is melt extruded under low shear conditions to form an extruded composition that is broken up into metallic dry toner particles. Each metallic dry toner particle consists essentially of a polymeric binder phase formed from the resin particles, and the non-conductive metal oxide particles dispersed within the polymeric binder phase. The metallic dry toner particles have a mean volume weighted diameter (Dvol) before fixing of 15 μm to 40 μm, and the non-conductive metal oxide particles are present in an amount of 20 to 50 weight %. The ratio of the metallic dry toner particle Dvolto the average equivalent circular diameter (ECD) of the non-conductive metal oxide particles in the metallic dry toner particles is greater than 0.1 and to 10.

Owner:EASTMAN KODAK CO

Catalyst for producing low carbon olefin from synthesis gas and use method of catalyst

ActiveCN104549352AHighly uniform dispersionIncrease the number ofHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasPotassium oxide

The invention relates to a catalyst for producing low carbon olefin from synthesis gas and a use method of the catalyst for producing the low carbon olefin from the synthesis gas. According to the catalyst and the use method, the problems of low CO conversion rate and low carbon olefin selectivity in reaction for preparing low carbon olefin from the synthesis gas in the prior art are mainly solved. The catalyst for producing low carbon olefin from the synthesis gas comprises the following components in percentage by weight: (a) 5%-50% of an iron element or oxides of the iron element, (b) 4%-20% of at least one element selected from manganese and zirconium or oxides of the element, (c) 1%-10% of a bismuth element or oxides of the bismuth element and (d) 25%-90% of a carrier, wherein the carrier comprises the following components in parts by weight: (1) 15-40 parts of alpha-aluminum oxide, (2) 1-45 parts of calcium oxide, (3) 1-5 parts of titanium dioxide and (4) 1-20 parts of potassium oxide. According to the technical scheme, the problems are well solved; the catalyst can be applied to the industrial production for producing low carbon olefin from the synthesis gas by virtue of a fixed bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

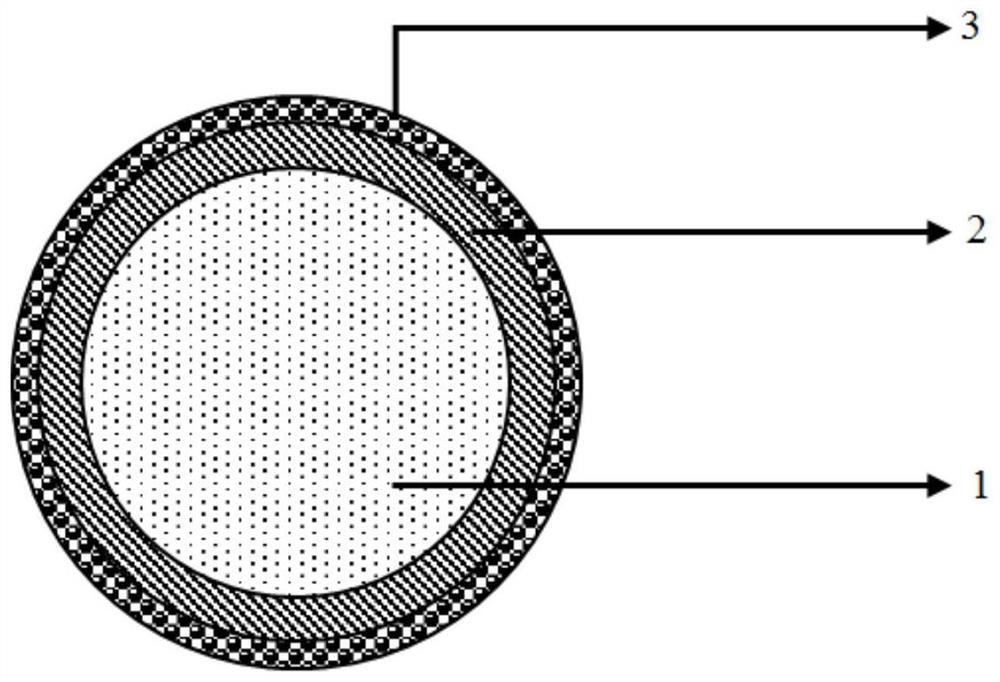

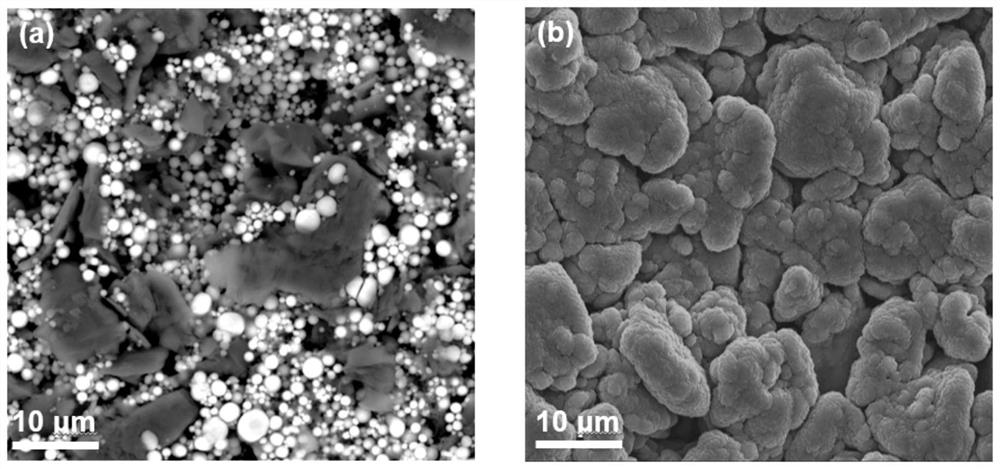

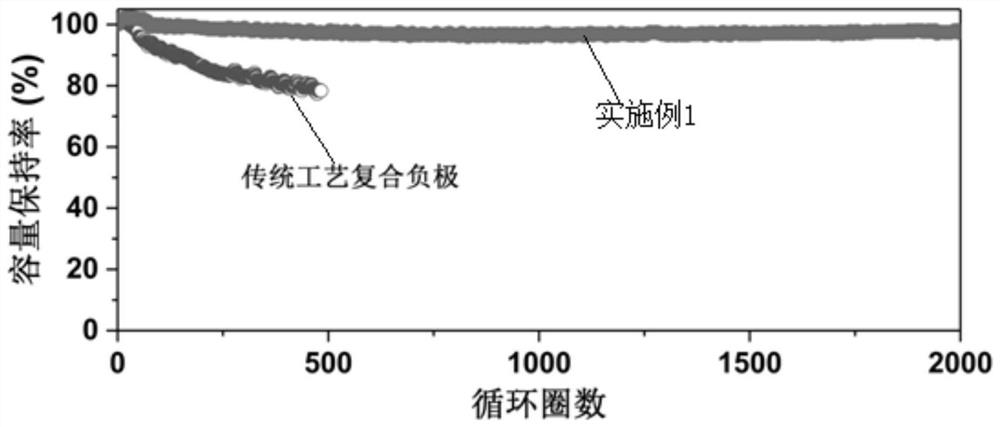

Composite material and preparation method thereof

ActiveCN111816856AHighly uniform dispersionImprove cycle stabilitySecondary cellsNegative electrodesElectrolytic agentLithium-ion battery

The invention belongs to the technical field of battery materials, and particularly relates to a composite material, a preparation method thereof and a negative electrode. The composite material comprises a carbon active substance core, and an alloyed active substance layer and a shell layer which are coated on the surface of the carbon active substance core, wherein the alloyed active substance layer is positioned between the carbon active substance core and the shell layer. The composite material can realize high-degree uniform dispersion of different active substance phases, so that stressconcentration is effectively relieved, electrolyte can be isolated, side reactions are reduced, and the composite material with a special structure can be used as a negative electrode active materialof a lithium ion battery, so that the cycling stability of the negative electrode active material can be remarkably improved.

Owner:SHENZHEN INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com