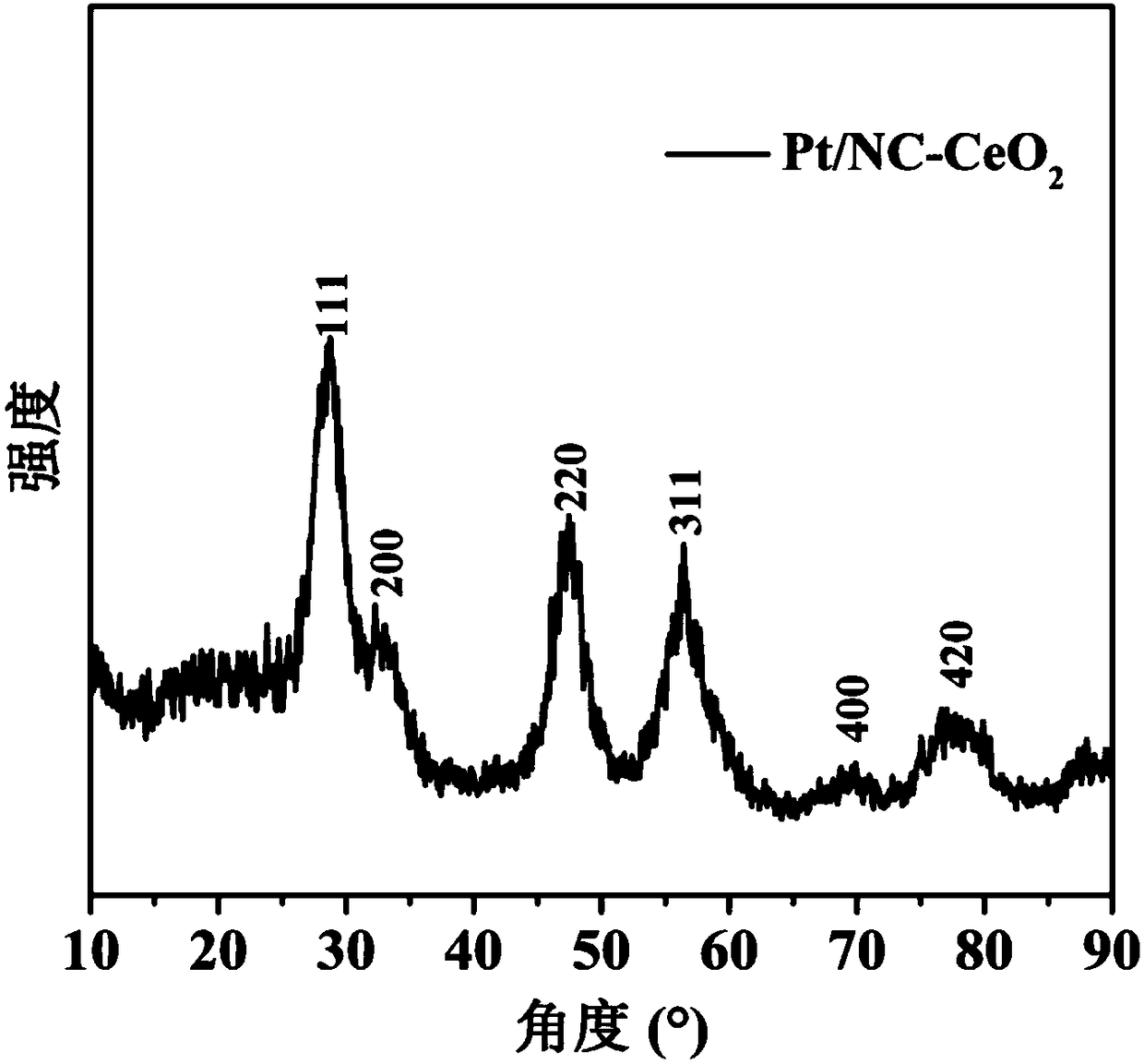

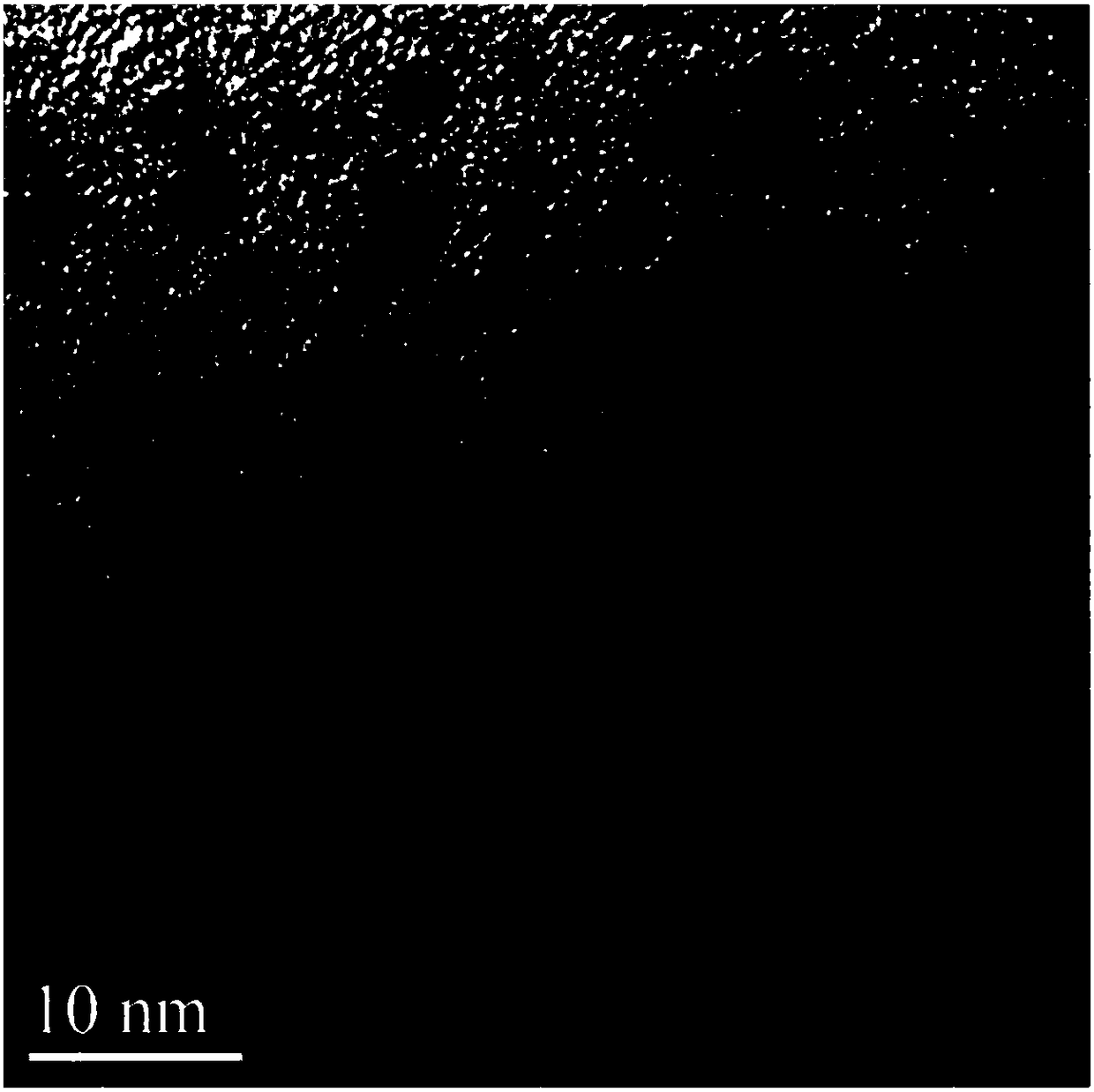

Alkaline high-dispersion loaded Pt-based nano-catalyst and preparation and application thereof

A nano-catalyst, high-dispersion technology, applied in catalyst activation/preparation, physical/chemical process catalyst, nanotechnology, etc., to achieve the effects of high dispersion, high activity, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A: Prepare 80mL of cerium nitrate solution with a concentration of 0.05mol / L, then add 0.004mol of melamine, ultrasonicate for 3-5min, and then prepare 80mL of sodium borohydride solution with a concentration of 0.5mol / L; add the two solutions at the same time at a speed of Thoroughly stir in a colloid mill at 4000r / min for 5min.

[0028]B: Transfer the obtained white suspension to a 250mL three-neck flask, conduct hydrothermal crystallization at 90°C for 12h, centrifuge, wash until neutral, and dry at 70°C to obtain CeO 2 / melamine composite precursor material.

[0029] C: will get CeO 2 / melamine composite precursor is placed in a muffle furnace, roasted under air atmosphere conditions, heated to 500 °C at a heating rate of 5 °C / min and kept for 2 h, and after natural cooling to room temperature, CeO 2 - CN carrier material.

[0030] D: Accurately weigh 0.5g CeO 2 -CN carrier material was dispersed in 50mL deionized water, and 3.98mL19.3mmol / L of H 2 PtCl 6 solu...

Embodiment 2

[0033] A: Prepare 80mL of zirconium nitrate solution with a concentration of 0.06mol / L, then add 0.0048mol of melamine, ultrasonicate for 3-5min, and then prepare 80mL of sodium borohydride solution with a concentration of 0.6mol / L; At the same time, it was added to a colloid mill with a rotation speed of 4000r / min and fully stirred for 5 minutes.

[0034] B: Transfer the obtained white suspension to a 250mL three-necked flask, conduct hydrothermal crystallization at 80°C for 12h, centrifuge, wash until neutral, and dry at 70°C to obtain ZrO 2 / melamine composite precursor material.

[0035] C: ZrO will be obtained 2 / melamine composite precursor is placed in a muffle furnace, roasted under air atmosphere conditions, heated to 500°C at a heating rate of 5°C / min and kept for 2h, and after being naturally cooled to room temperature, ZrO 2 - CN carrier material.

[0036] D: Accurately weigh 0.5g ZrO 2 -CN carrier material was dispersed in 50mL deionized water, and 2.66mL19.3m...

Embodiment 3

[0039] A: Prepare 80 mL of nickel nitrate solution with a concentration of 0.1 mol / L, then add 0.008 mol of melamine, ultrasonicate for 3 to 5 minutes, and prepare 80 mL of sodium borohydride solution with a concentration of 1 mol / L; Add it into a colloid mill with a rotating speed of 4000r / min and stir well for 5min.

[0040] B: Transfer the obtained light green suspension to a 250mL three-neck flask for hydrothermal crystallization at 70°C for 12h, centrifuge, wash until neutral, and dry at 70°C to obtain a NiO / melamine composite precursor Material.

[0041] C: The obtained NiO / melamine composite precursor is placed in a muffle furnace, roasted in an air atmosphere, heated to 600°C at a heating rate of 5°C / min and kept for 2h, and after being naturally cooled to room temperature, NiO is obtained - CN carrier material.

[0042] D: Accurately weigh 0.5g of NiO-CN carrier material and disperse it in 50mL of deionized water, add 6.64mL of 19.3mmol / L H 2 PtCl 6 solution, tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com