System and method for preparing isononanoic acid and method for preparing metal organic skeletal catalyst

A metal-organic framework, isononanoic acid technology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the unsolved safety problem of local accumulation of peroxides in the rectification process , There are no reports of the decomposition of peroxide heterogeneous catalysts, and the metal ions are not easy to separate, so as to avoid excessive heat release rate, improve product selectivity, and fast decomposition rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

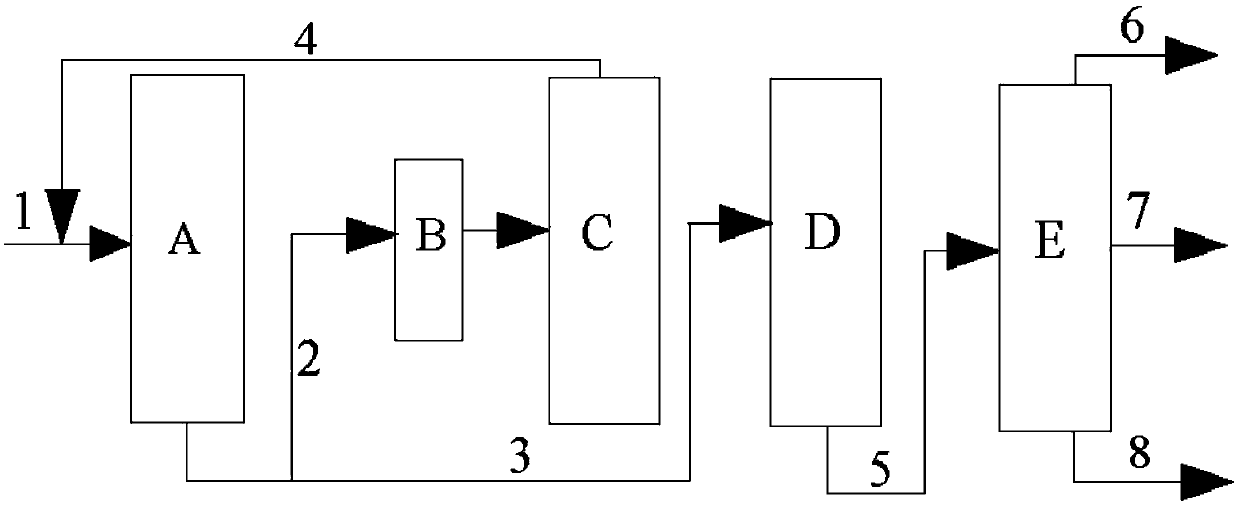

[0092] The isononanal 1 is passed into the bubble column reactor to carry out the oxidation reaction, and the oxidant is air; the isononanal 1 is obtained after the oxidation reaction in the oxidation reactor A and the total flow is divided into a decomposition flow 3 and a recycle flow 2;

[0093] The decomposition stream 3 is decomposed through catalytic decomposition in the peroxide decomposition reactor D, and the catalyst in the peroxide decomposition reactor D is the catalyst prepared above. Obtain isononanoic acid 7, light components 6 and high boilers 8 after the peroxide decomposition reactor D outlet flow 5 is processed through the conventional rectification unit E rectification tower;

[0094] The recycle stream 2 is cooled in the heat exchanger of the cooling device B, and then the excessive metal ions such as iron in the recycle stream 2 are separated in the metal ion separation device C, so as to avoid the accumulation of metal ions in the stream after the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com