Method for directly transforming synthesis gas into low-carbon olefin

A technology for low-carbon olefins and synthesis gas, applied in chemical instruments and methods, hydrocarbon production from carbon oxides, organic chemistry, etc., can solve the problems of low low-carbon olefins selectivity, low CO conversion rate, etc. The effect of olefin selectivity, improving selectivity, and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The required amount of shaped coconut shell activated carbon carrier washed by pickling water is subjected to ultrasonic and drying treatment; the required amount of ferric nitrate, manganese nitrate and potassium nitrate are dissolved in water to make mixed solution I; under vacuum conditions, the above The mixed solution I was impregnated on the required amount of processed shaped activated carbon carrier to obtain the Fischer-Tropsch synthesis catalyst precursor J; the impregnated catalyst precursor J was dried at 110°C to obtain the Fischer-Tropsch synthesis catalyst K; the required amount The Fischer-Tropsch synthesis catalyst K and the ZSM-5 molecular sieve catalyst are uniformly mixed to obtain a catalyst for direct conversion of synthesis gas into low-carbon olefins, which is made by weight and consists of:

[0029] 60%(30%Fe 100 mn 60 K 5 o x +70%C)+40%ZSM-5

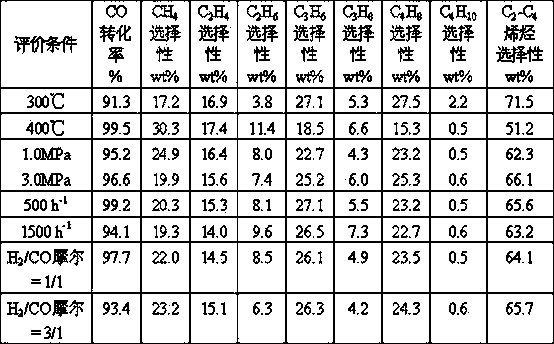

[0030] The experimental results of the direct conversion of synthesis gas into light olefins with ...

Embodiment 2

[0033] The required amount of shaped coconut shell activated carbon carrier washed by pickling water is subjected to ultrasonic and drying treatment; the required amount of ferric nitrate, manganese nitrate and potassium nitrate are dissolved in water to make mixed solution I; under vacuum conditions, the above The mixed solution I was impregnated on the required amount of processed shaped activated carbon carrier to obtain the Fischer-Tropsch synthesis catalyst precursor J; the impregnated catalyst precursor J was dried at 110°C to obtain the Fischer-Tropsch synthesis catalyst K; the required amount The Fischer-Tropsch synthesis catalyst K and the ZSM-5 molecular sieve catalyst are uniformly mixed to obtain a catalyst for direct conversion of synthesis gas into low-carbon olefins, which is made by weight and consists of:

[0034] 60%(70%Fe 100 mn 40 K 20 o x +30%C)+40%ZSM-5

[0035] The experimental results of the direct conversion of synthesis gas into light olefins with...

Embodiment 3

[0038] The required amount of shaped coconut shell activated carbon carrier washed by pickling water is subjected to ultrasonic and drying treatment; the required amount of ferric nitrate, manganese nitrate and potassium nitrate are dissolved in water to make mixed solution I; under vacuum conditions, the above The mixed solution I was impregnated on the required amount of processed shaped activated carbon carrier to obtain the Fischer-Tropsch synthesis catalyst precursor J; the impregnated catalyst precursor J was dried at 110°C to obtain the Fischer-Tropsch synthesis catalyst K; the required amount The Fischer-Tropsch synthesis catalyst K and the ZSM-5 molecular sieve catalyst are uniformly mixed to obtain a catalyst for direct conversion of synthesis gas into low-carbon olefins, which is made by weight and consists of:

[0039] 30%(20%Fe 100 mn 20 K 30 o x +80%C)+70%ZSM-5

[0040] The experimental results of the direct conversion of synthesis gas into light olefins with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com