Titanium dioxide/graphene composite nanometer photocatalyst, method for preparing same and application of titanium dioxide/graphene composite nanometer photocatalyst

A nano-photocatalyst and graphene composite technology, which can be used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. To achieve the effect of high mechanical strength and toughness, beneficial to recycling and reuse, and strong high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of titanium dioxide / graphene composite nano photocatalyst, comprising the following steps:

[0027] A, using graphite as a raw material, adopting the Hummer method to prepare graphene oxide, ultrasonically dispersing the prepared graphene oxide into an alcohol solution to obtain a graphene oxide suspension with a concentration of 0.5 g / L to 2 g / L;

[0028] B, the titanium source is dispersed in the graphene oxide suspension that 60 mL step A gains, the molar concentration that obtains titanium salt is the suspension of 0.01 M ~ 0.5 M;

[0029] C, configuration molar concentration is the precipitating agent solution of 0.04 M ~ 3 M, under the stirring condition of 1000 rpm ~ 2000 rpm, the precipitating agent solution is added dropwise to the suspension obtained in step B;

[0030] D, transfer the suspension obtained in step C into a polytetrafluoroethylene liner, react under hydrothermal conditions at 100°C to 220°C for 3 h to 48 h, naturally cool to...

Embodiment 1

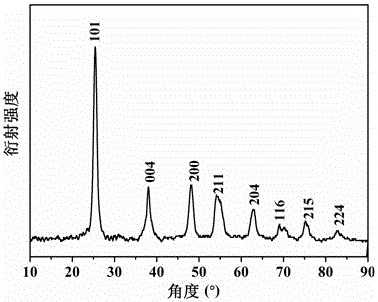

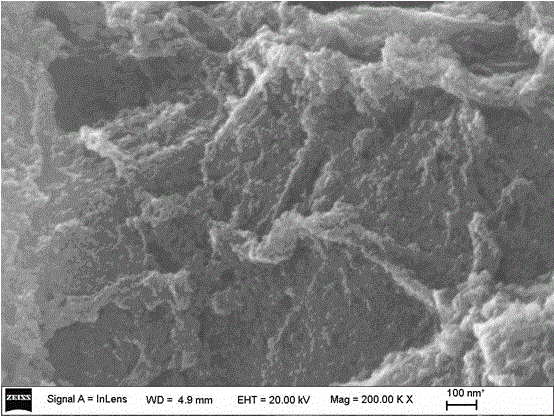

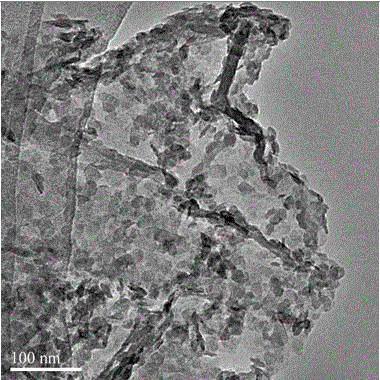

[0036] Accurately weigh 0.1 g of graphene oxide prepared by the Hummer method, and ultrasonically disperse it in 60 mL of ethanol solution to form suspension A; then accurately measure 0.14 mL of titanium tetrachloride solution to disperse in suspension A, Suspension B was formed after dispersing for 5 minutes. The concentration of titanium tetrachloride in suspension B was 0.0212 M; another 20 mL of hexamethylenetetramine solution with a concentration of 0.254 M was prepared, and the concentration of titanium tetrachloride in suspension B was 0.254 M. Add dropwise to the suspension B under stirring conditions, transfer to the polytetrafluoroethylene liner after the dropwise addition, react under 180 ° C hydrothermal conditions for 24 hours, naturally cool to room temperature after the reaction, and suction filter and washing to obtain a titanium dioxide / graphene composite nano photocatalyst. Among them, TiO 2 The mass percentage content is 48%, TiO 2 The morphology of the n...

Embodiment 2

[0039] Accurately weigh 0.1 g of graphene oxide prepared by the Hummer method, ultrasonically disperse it in 60 mL of methanol solution to form suspension A; then accurately measure 0.45 mL of tetrabutyl titanate solution and disperse in suspension A, Suspension B was formed after ultrasonic dispersion for 5 minutes. The concentration of tetrabutyl titanate in suspension B was 0.0219 M; another 20 mL of hexamethylenetetramine solution with a concentration of 0.263 M was prepared, and the Add dropwise in the suspension B under the stirring condition of minute, transfer to the polytetrafluoroethylene liner after dropwise addition, react 12 hours under 180 DEG C of hydrothermal conditions, naturally cool to room temperature after reaction finishes, Suction filtration and washing to obtain titanium dioxide / graphene composite nano photocatalyst. Among them, TiO 2 The mass percentage content is 51 %, TiO 2 The morphology of the nanoparticles is granular, the particle size distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com