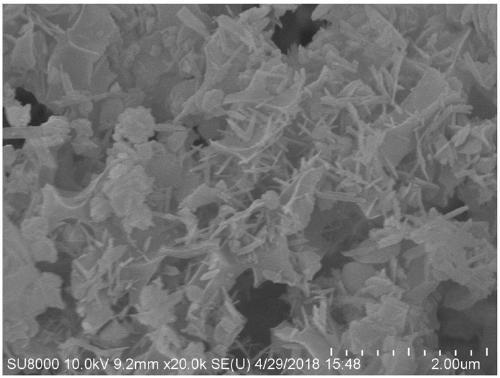

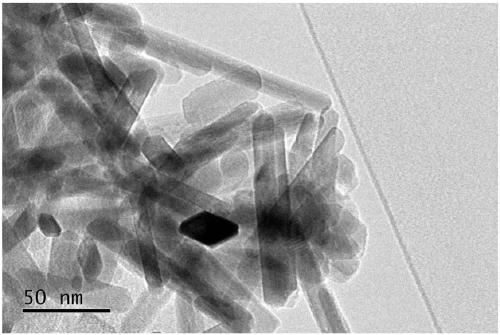

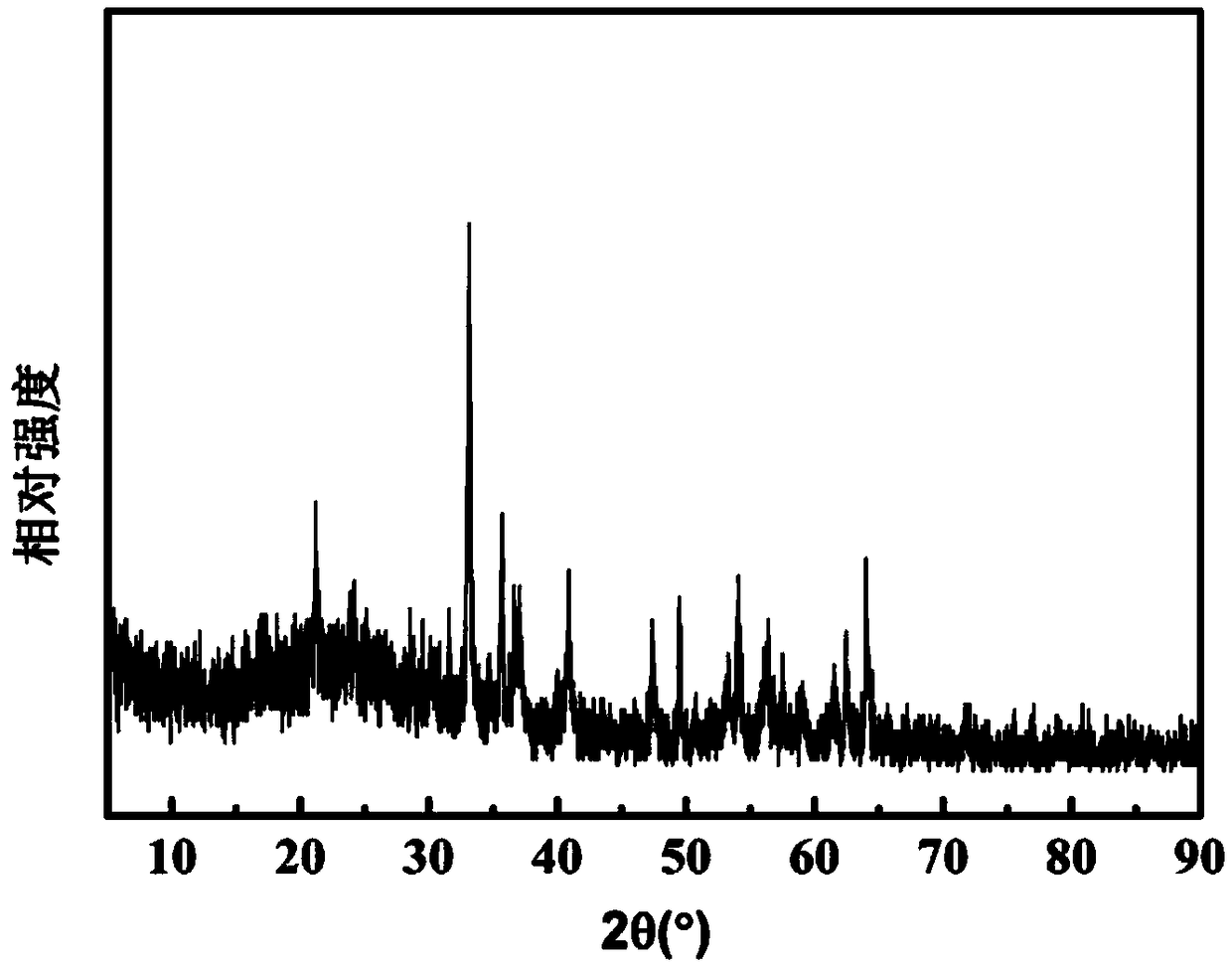

Method for preparing needle-shaped Fe-Mn-S ternary nano-material supported porous charcoal compound material

A technology of nanomaterials and composite materials, applied in the field of preparation of porous biochar composite materials, can solve the problems of easy agglomeration and low heavy metal adsorption, and achieve the effect of improving interaction, changing the chemical state of Fe, and reducing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment one: the preparation method of needle-shaped Fe-Mn-S ternary nanomaterial loaded porous biochar composite material in this embodiment comprises the following steps:

[0037] 1. Pyrolytic carbonization of biomass materials;

[0038] cutting the biomass material, washing it with distilled water for 3 to 10 times, drying it, pulverizing it, passing through a 20-mesh sieve to 100-mesh sieve to obtain a finely divided powder of the biomass material;

[0039] Mix and grind the finely divided biomass material powder and metal salt to obtain a mixture, place the obtained mixture in a tube furnace for carbonization, pass a protective gas into the tube furnace, heat up to 700-900°C for pyrolysis, and pyrolysis The time is 1 to 3 hours, and the porous biochar material after pyrolysis and carbonization is obtained;

[0040] Wherein the mass ratio of the biomass material finely divided powder to the metal salt is (1~5):(1~5);

[0041] 2. Hydrophilicize the poro...

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment differs from Embodiment 1 in that the biomass material described in step 1 is one or a mixture of eucalyptus leaves, corn stalks, sawdust, and bamboo stalks. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the metal salt described in step one is KHCO 3 , NaHCO 3 、K 2 CO 3 、Na 2 CO 3 one or a mixture of several. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com