Patents

Literature

48results about How to "Act as a pore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of precipitated silicon dioxide

InactiveCN1669922AChange surface electrical propertiesPrevent rapid aggregationSilicaSaline solutionsUltra fine

The invention relates to a preparing method for depositing silica dioxide, which comprises the following steps: dissolving the silicate of alkali metal to saline solution a with water, dissolving the soluble salt of metallic ion with 2 valency or above 2 valency to saline solution b with water as a polymerization inhibitor, reacting with between saline solution a and saline solution b at a temperature of 10 -80 Deg. C to get the compound c, heating the compound c to 60-95 Deg. C, acidifying by adding acidating agent and adjust the PH in 1-5 to get the compound d1, then maturing 3-100 min with respect to heat to get the compound d2, filtering, washing and drying compound d2, to get the ultra-fine disposition silica dioxide.

Owner:SHANDONG HAIHUA GRP CO LTD

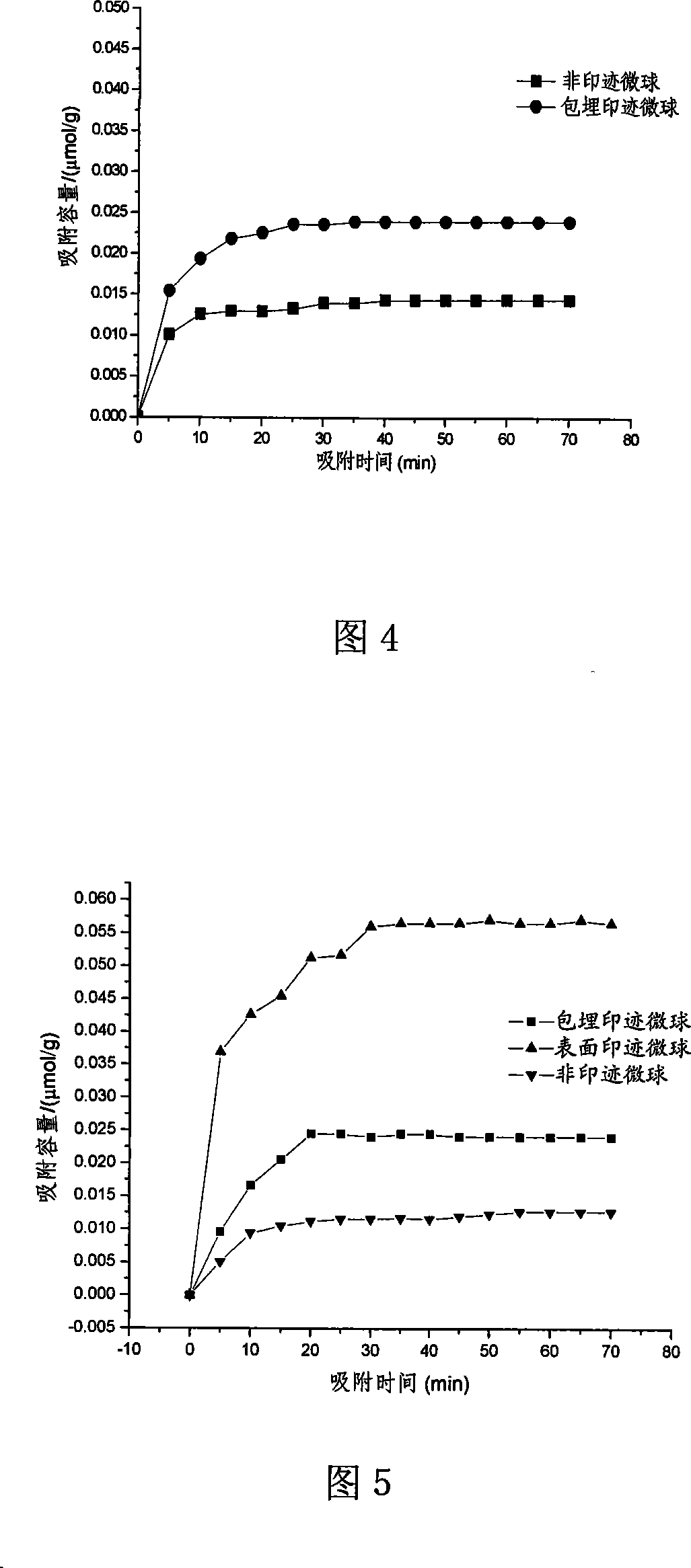

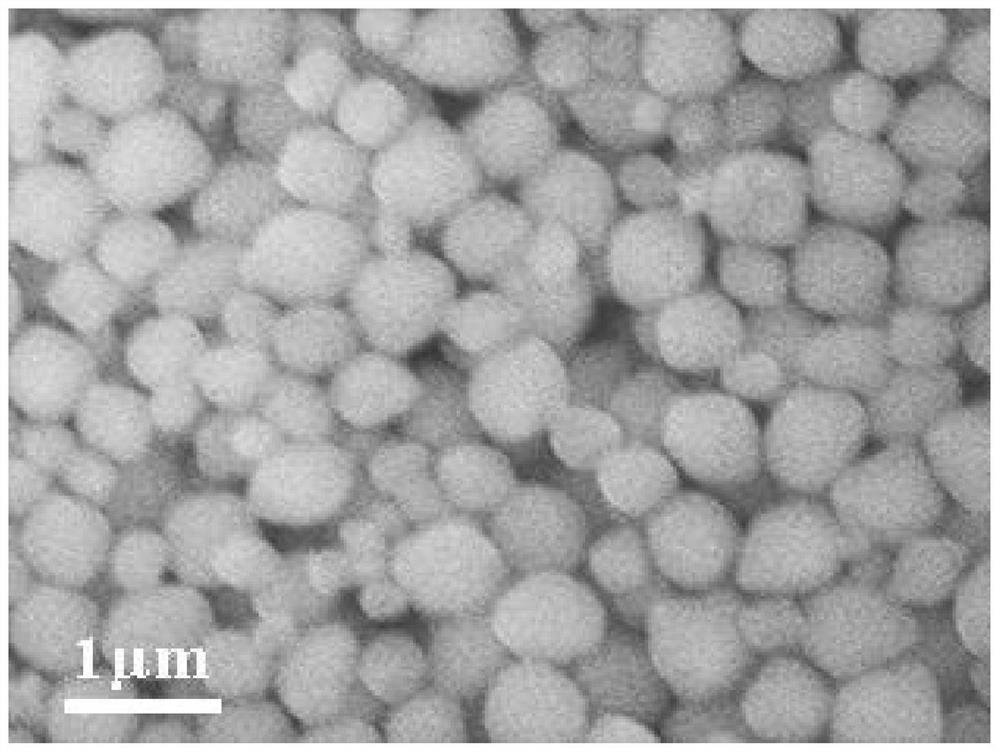

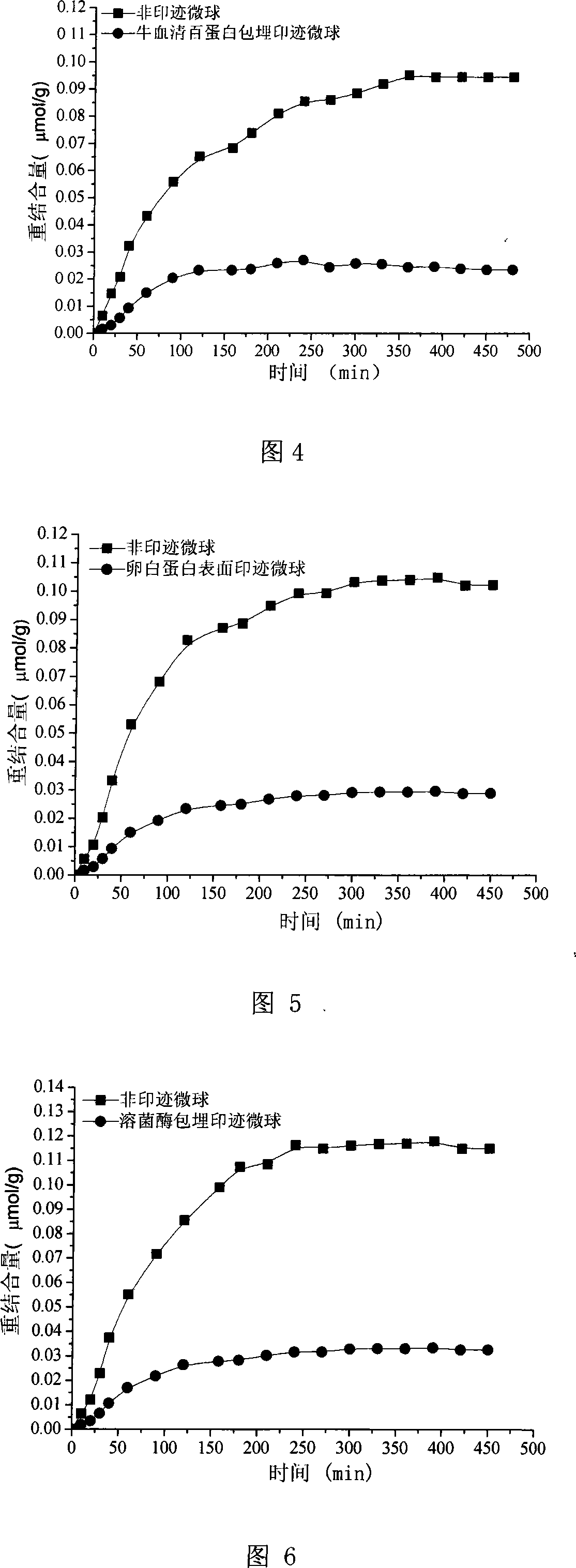

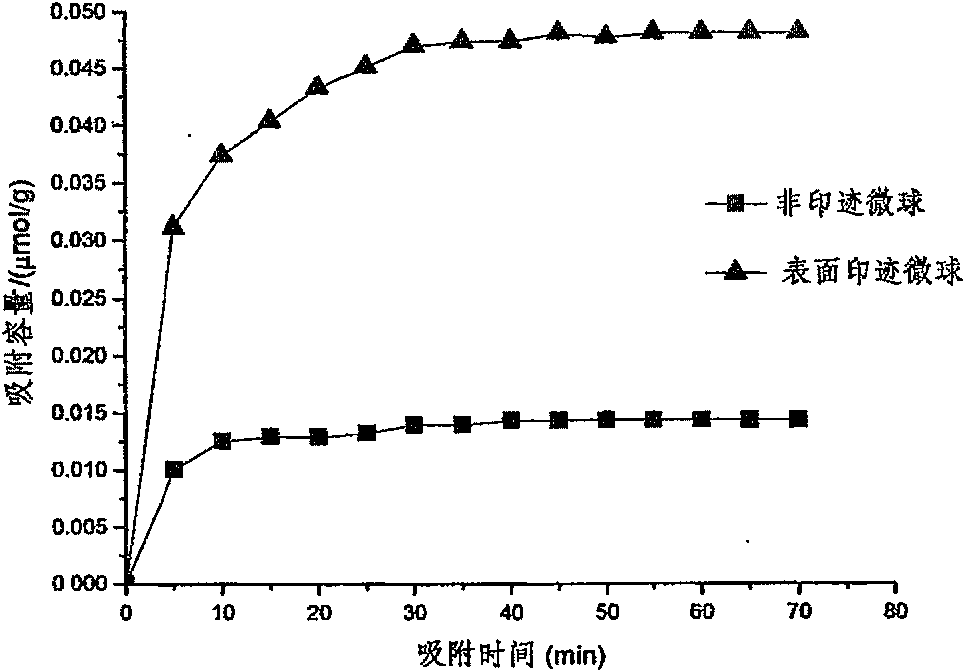

Big molecular engram calcium orthophosphate/calcium alginate hybridized micro-balloon and method for preparing the same

InactiveCN101081911AEasy to prepareThe reaction process is easy to controlPhosphoric acidDiammonium phosphate

The present invention relates to one kind of macromolecular protein engram calcium phosphate / calcium alginate hybridized microsphere and its preparation process. The protein engram calcium phosphate / calcium alginate hybridized microsphere is prepared with sodium alginate 20-40 wt%, diammonium hydrogen phosphate 1-10 wt%, calcium chloride 50-65 wt% and protein 0.5-10 wt%. Test shows that the protein engram calcium phosphate / calcium alginate hybridized microsphere has protein adsorbing amount 1.8-5 times that of non-engram microsphere without protein, and that sodium alginate, diammonium hydrogen phosphate and calcium chloride may form new hybridized component. The present invention has simple preparation process, easy control and broad application foreground.

Owner:TIANJIN UNIV

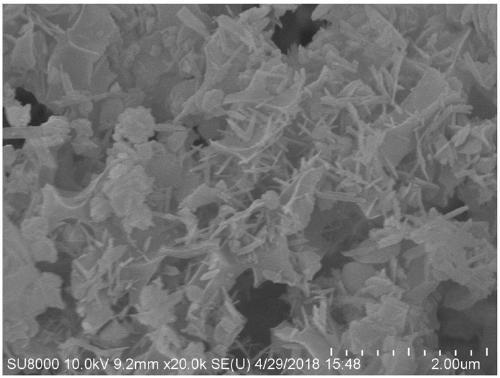

Method for preparing needle-shaped Fe-Mn-S ternary nano-material supported porous charcoal compound material

ActiveCN109225134AHighly uniform dispersionGood dispersionOther chemical processesWater contaminantsManganateCarbonization

The invention provides a method for preparing a needle-shaped Fe-Mn-S ternary nano-material supported porous charcoal compound material, relates to a method for preparing porous charcoal compound materials to solve the problems that an existing Fe-Mn binary nano-material is easily agglomerated and has low adsorption capacity to heavy metals. The method comprises the following steps: 1, performingpyrolytic carbonization on a biomass material; 2, performing hydrophilic treatment on the pyrolytically carbonized porous charcoal material; 3, stirring the hydrophilic porous charcoal material in a ferric salt aqueous solution, dropwise adding a manganate solution and sulfide solution for stirring, adding a weak alkaline solution for stirring, performing hydrothermal reaction, and drying to obtain the ternary nano-material supported porous charcoal compound material. According to the method, the interaction among molecules of a ternary nano-material is reduced by supporting the Fe-Mn-S ternary nano-material to the surface of the charcoal material, nano-particle agglomeration is reduced, and the dispersibility of ternary nano-particles is improved. The method is applied to the field of charcoal compound materials.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

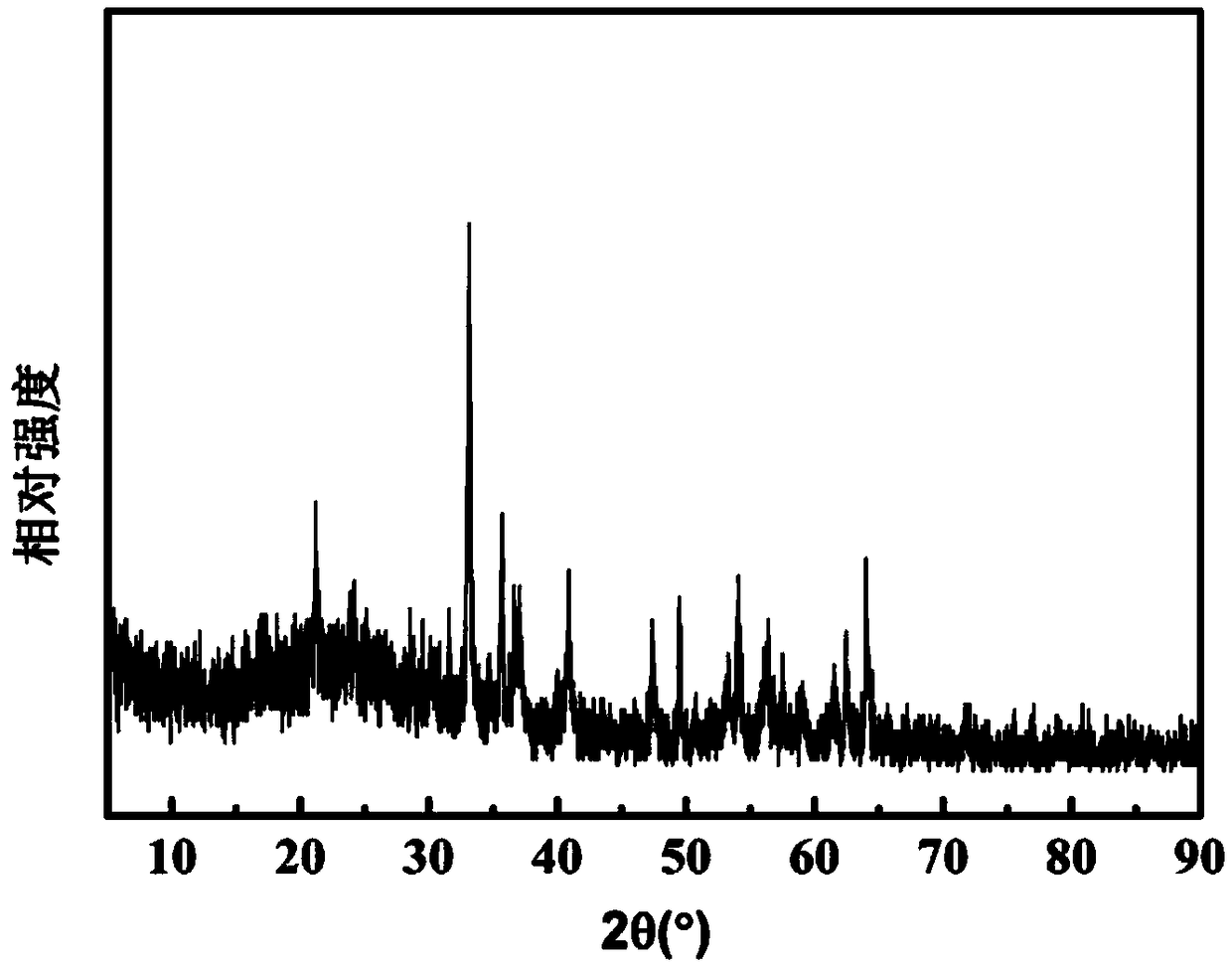

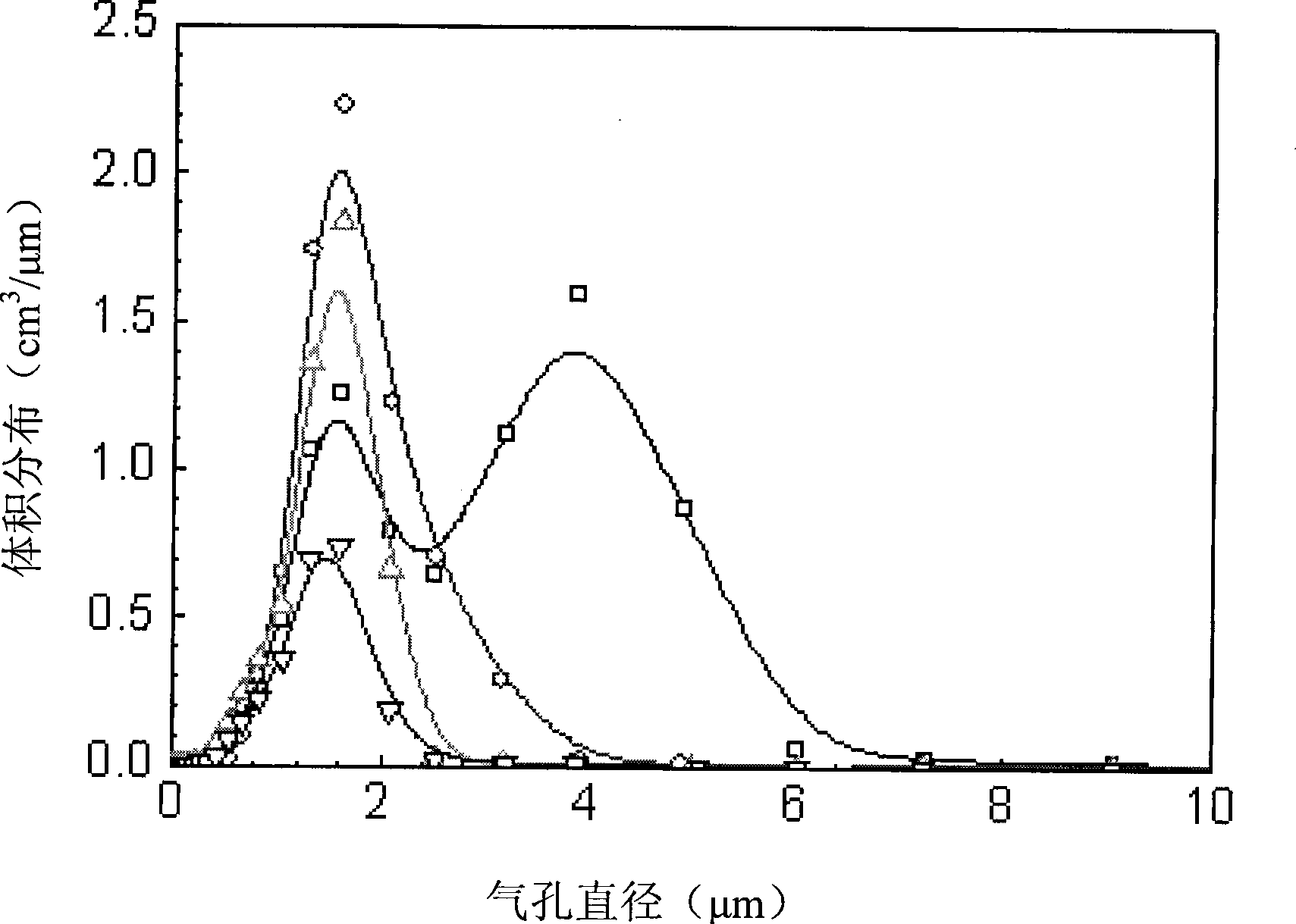

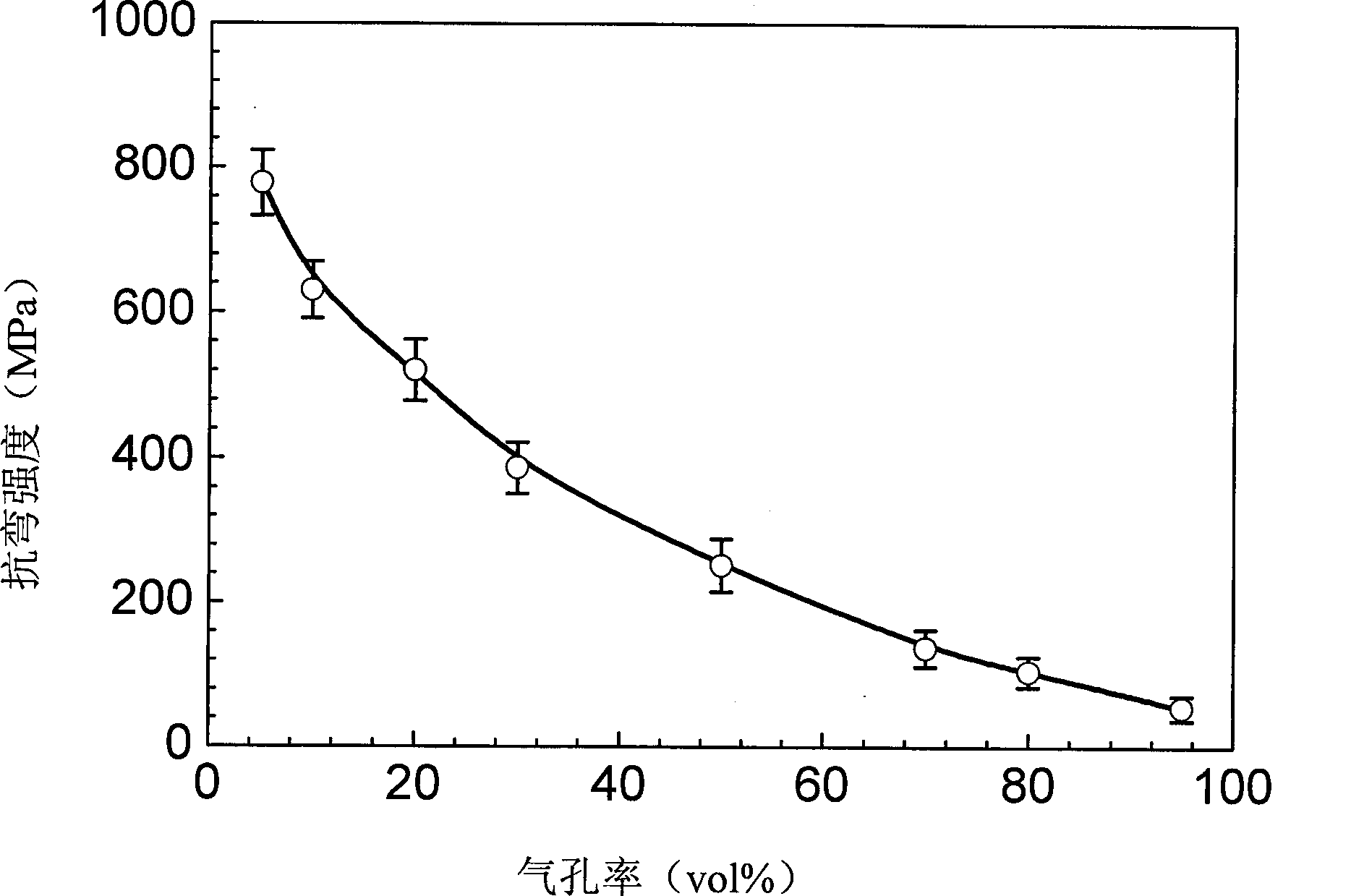

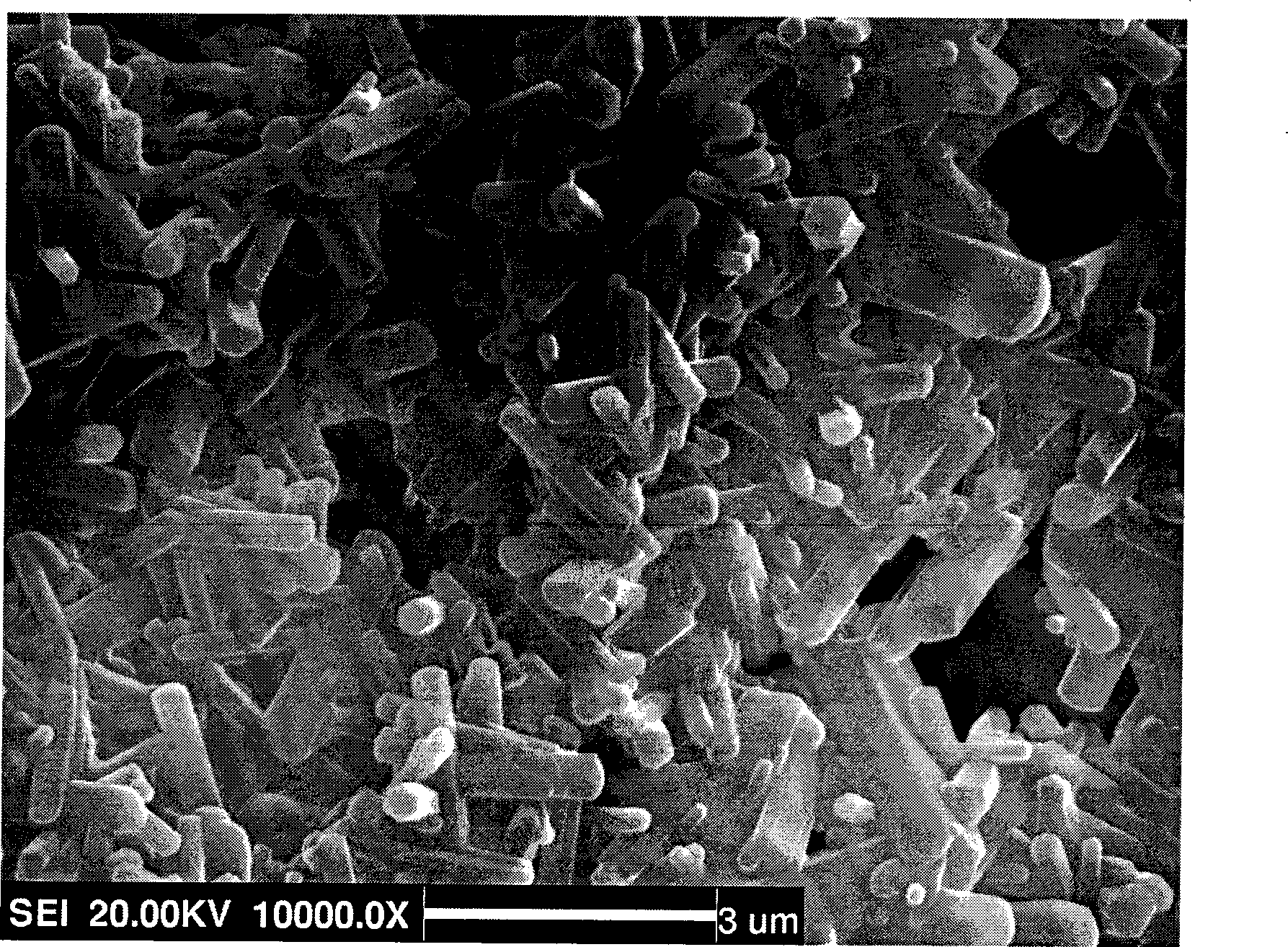

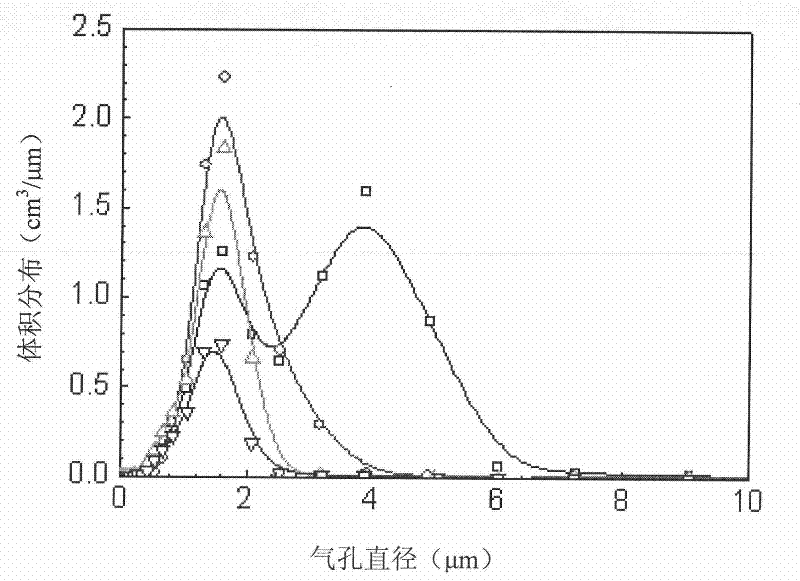

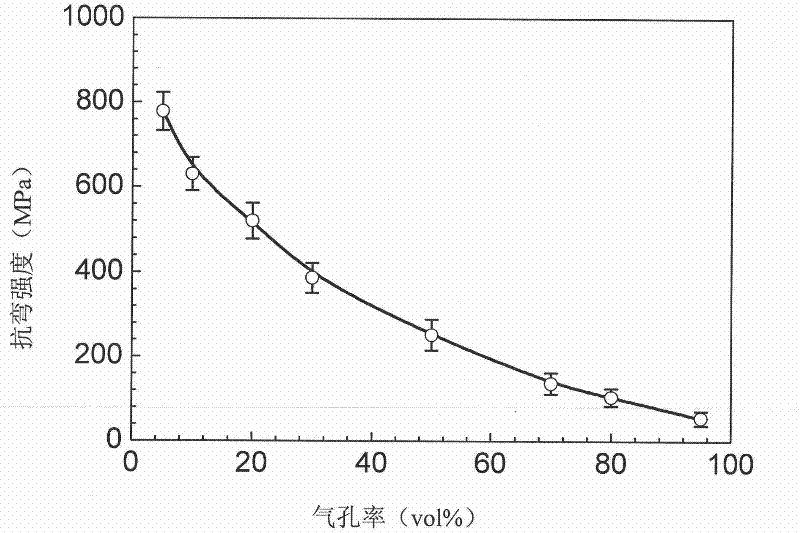

Process for producing stephanoporate Si3N4

ActiveCN101508592AImprove high temperature resistanceImprove corrosion resistanceCeramicwareCombustionPolyvinyl alcohol

A porous Si3N4 ceramics preparation method solves the problem of low porosity of porous Si3N4 ceramics prepared by the prior art. The method is as follows: mixing alpha-Si3N4 powder and combustion assistant evenly; making the mixture and aqueous polyvinyl alcohol solution into slurry; refrigerating the slurry until the slurry completely freezes; carrying out low-temperature vacuum dehydration; moulding the slurry to green body with various shapes based on requirement before refrigeration; and sintering the dried green body to obtain porous Si3N4 ceramics. The porous Si3N4 ceramics prepared by the method have adjustable pore diameter and porosity which can reach as high as 95%. Process of the method is simple with good repeatability.

Owner:HARBIN INST OF TECH

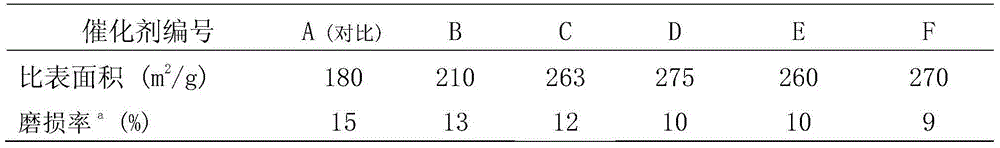

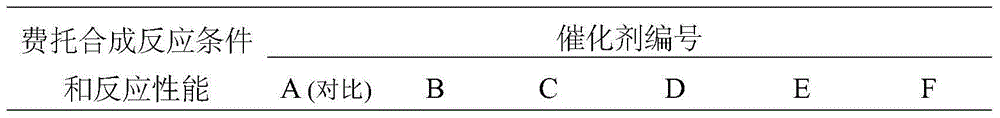

High-specific-surface-area Fischer-Tropsch synthesis catalyst and preparation method and application of high-specific-surface-area Fischer-Tropsch synthesis catalyst

ActiveCN104624196AHigh activityEasy extractionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsCooking & bakingCoprecipitation

The invention provides a high-specific-surface-area Fischer-Tropsch synthesis catalyst and a preparation method and application of the high-specific-surface-area Fischer-Tropsch synthesis catalyst. Organisms with different types and contents are added into different stages of catalyst preparation by a traditional coprecipitation method, for example, micromolecule organisms are added in the precipitation process so as to inhibit the aggregation of particles in the precipitation process, so that the dispersion degree of the whole system is improved; macromolecule organisms are introduced into a filter cake so as to inhibit the clustering of particles in the thermal treatment process, and can play a role of pore forming when being removed in a baking process; meanwhile, with the combination of the use of a high-thermal-stability additive, the contraction and collapse of a framework of the catalyst in the thermal treatment process can be prevented effectively; the method can be used for obviously improving the specific surface area of the Fischer-Tropsch synthesis ferrous catalyst, so that the activity of the catalyst can be improved greatly.

Owner:SYNFUELS CHINA TECH CO LTD

Fine ferric oxide desulfurizing agent and preparation method and application method thereof

ActiveCN106268219AHigh precisionHigh sulfur capacityDispersed particle separationSodium BentoniteCopper sulfate

The invention discloses a fine ferric oxide desulfurizing agent and a preparation method and an application method thereof. The fine ferric oxide desulfurizing agent is prepared from ferrous sulfate septihydrate, calcium hydroxide, copper sulfate pentahydrate, sodium hydroxide, bentonite and sodium carboxymethylcellulose through mixing, strip extrusion and drying, and comprises, by mass, 57%-68% of ferrous sulfate septihydrate, 18%-25% of calcium hydroxide, 3%-8% of copper sulfate pentahydrate, 6.5%-18% of sodium hydroxide, 3%-10% of bentonite and 1%-3% of sodium carboxymethylcellulose. The fine ferric oxide desulfurizing agent is applied to removal of natural gas, coke-oven gas, oil field gas, synthesis gas, methane, carbon dioxide and organic sulfur such as H2S, COS and mercaptan in liquid hydrocarbon feed gas under the normal-temperature anaerobic condition and is high in desulfurization precision and sulfur capacity. The environment-friendly fine ferric oxide desulfurizing agent is prepared without washing and filtering, and the preparation method has the advantages of simple production technology, low equipment investment and maintenance cost and suitability for large-scale industrial production.

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

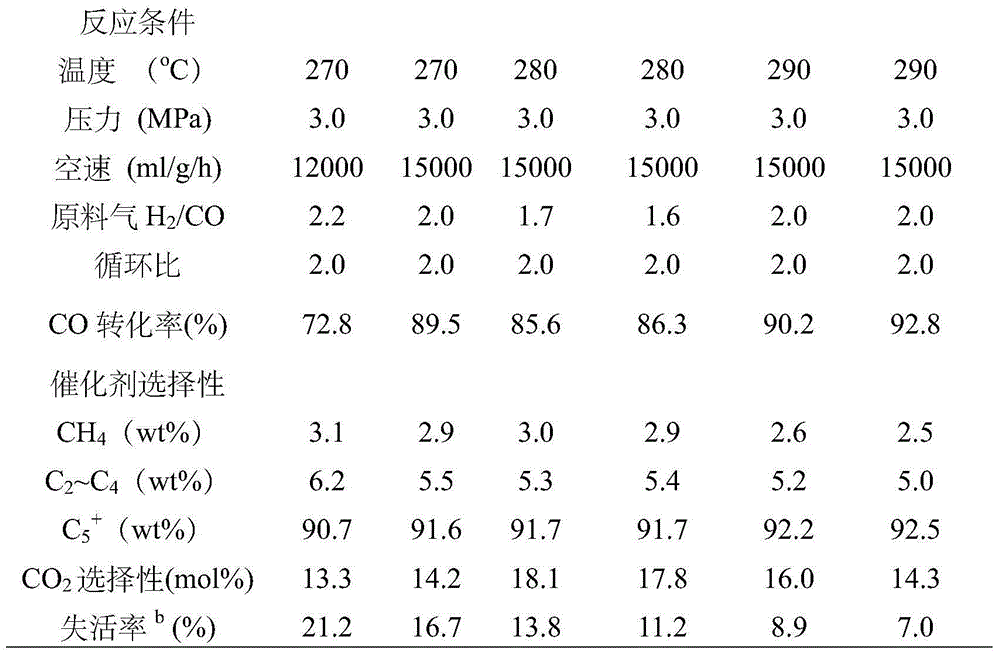

Stably-operating continuous flow micro electrolytic reaction system

The invention discloses a stably-operating continuous flow micro electrolytic reaction system. The system comprises a feed inlet, a discharge outlet and a deslagging hole and consists of a plurality of micro electrolytic reaction units which are connected in series, wherein each micro electrolytic reaction unit is provided with a packing layer; one side of the packing layer is provided with a packing replacement hole; a porous sieve plate is arranged below the packing layer; and an aeration back-flushing pipe is arranged below the porous sieve plate. For a micro electrolytic material used in the packing layer, the porosity and the specific surface area of the material are improved and the effect of removing pollutants in waste water by the micro electrolytic material is improved by using the effect of pore forming of NH3 generated by NH4Cl at a high temperature. Due to the designs of grading packing and aeration, the whole reaction system can effectively prevent the packing from being passivated and hardened, promote the waste water to contact the packing, improve treatment efficiency and effectively prevent bottom packing from being compacted and agglomerated due to overhigh micro electrolytic towers. Each stage of packing layer can be independently replaced, so that the simplicity and convenience of the operation and the maintenance of the whole reaction system are ensured.

Owner:EC PRECISION TECHJIANGSUCORP

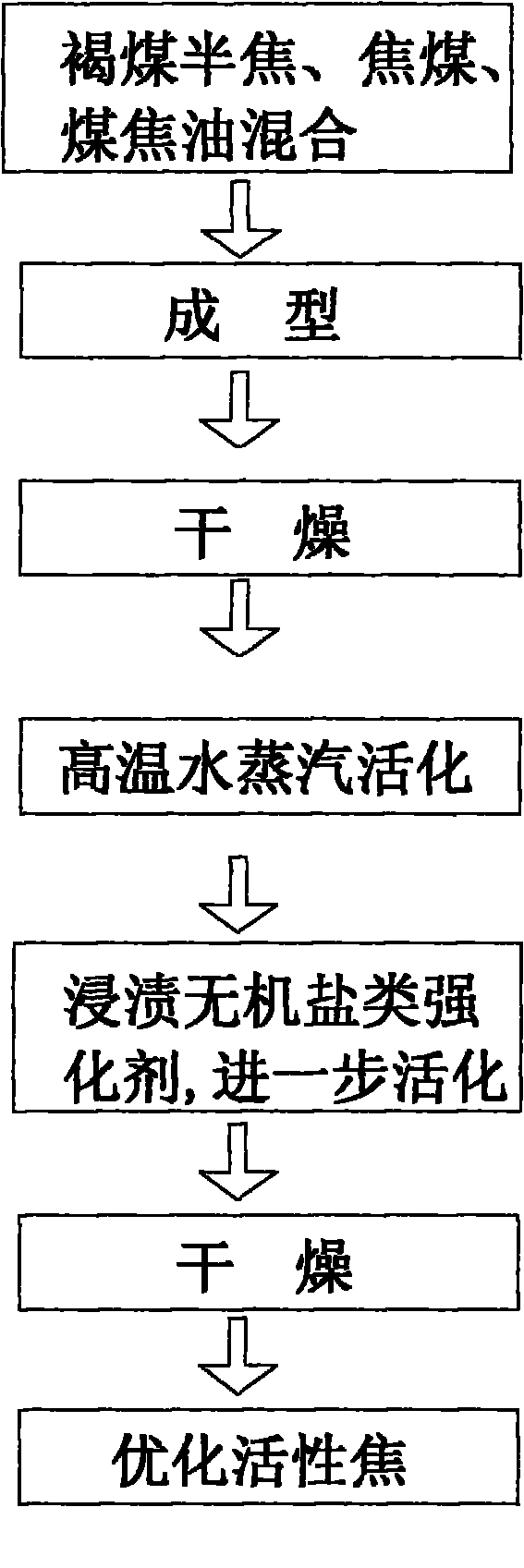

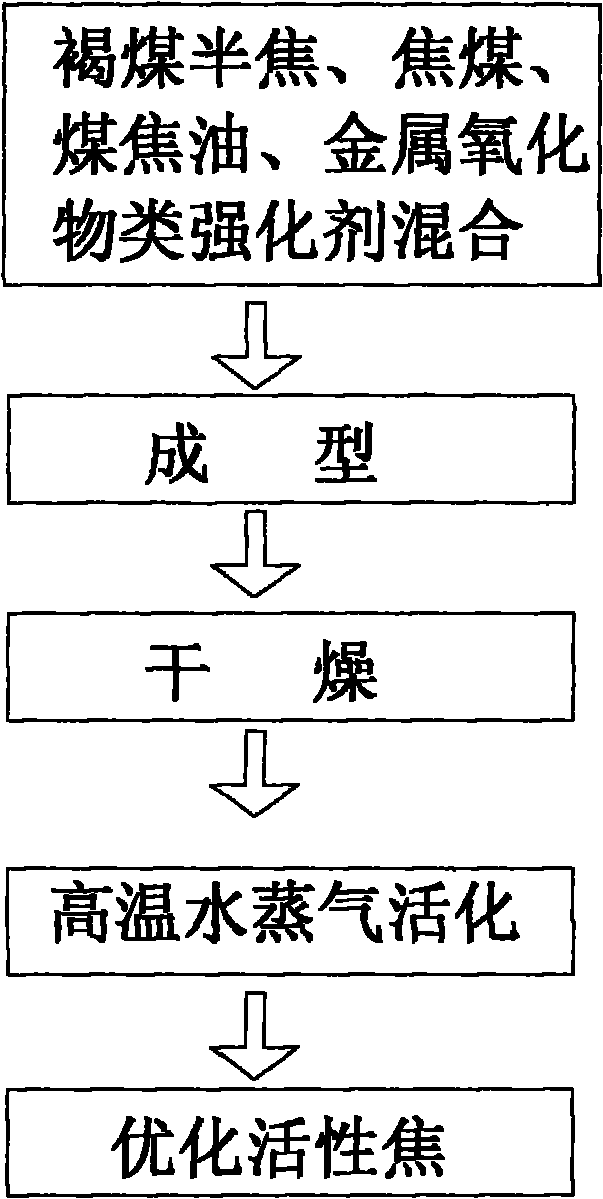

Preparation method of flue gas denitration catalyst

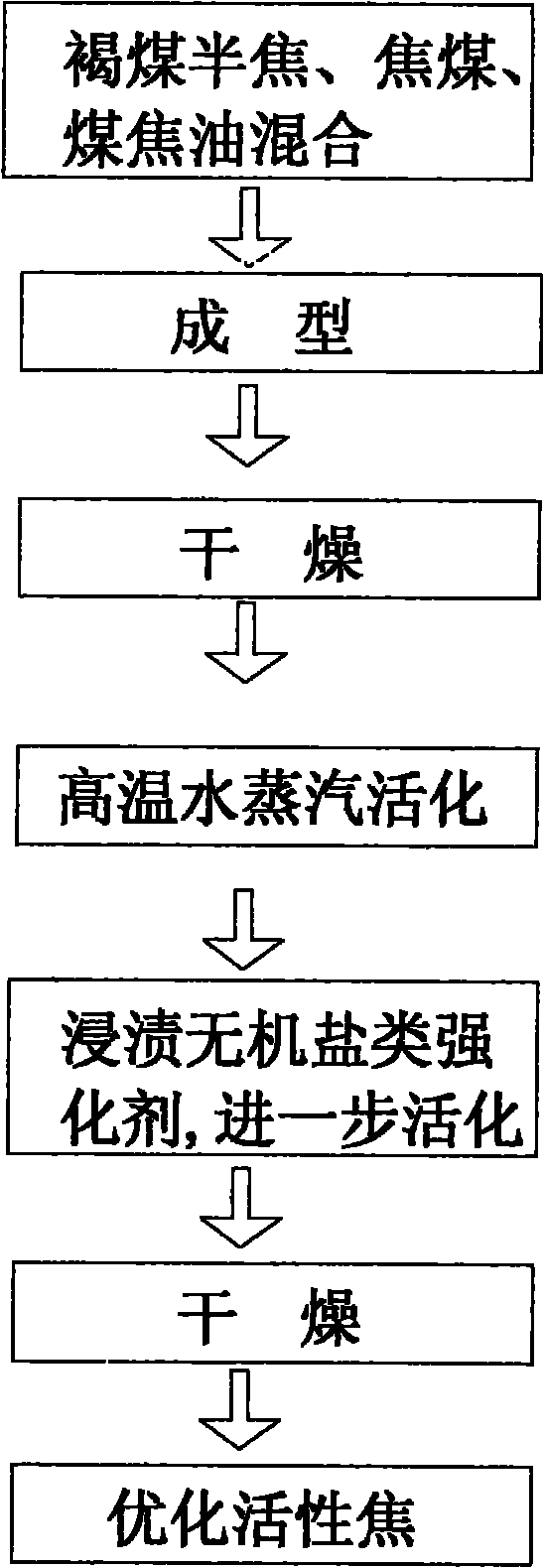

InactiveCN101767041AIncrease oxygen contentLow degree of coalificationDispersed particle separationCatalyst activation/preparationInorganic saltsFlue gas

The invention discloses a preparation method of flue gas denitration catalyst, which solves the problem of expensive denitration catalyst and low denitration efficiency in the prior art. The adopted technical scheme is as follows: the method comprises the processing process and method of lignite char, which comprise the following steps and sequence: preparing the lignite char through using lignite as raw material, according to weight percentage of 47-75% :10-35%:5-24%, mixing, forming, drying the lignite char, the lignite, and the coal tar to prepare active coke, adding the enhancer to the active coke for further activation, in order to prepare the optimized active coke. The invention uses the lignite as main raw material, uses the inorganic salt or metal oxide as the enhancer; the advantages of the invention are as follows: the manufacturing cost is low, and the product catalytic effect is good.

Owner:王向明

Preparation method of hydrophilic polyacrylonitrile nanofiltration membrane with polyhydroxy

ActiveCN105854642AImprove throughputStrong anti-pollutionMembranesSemi-permeable membranesSolventFilm material

A hydrophilic polyacrylonitrile nanofiltration membrane with polyhydroxy is designed and prepared with a metal chloride saline solution as the solvent in order to solve the problems that almost all polymer film materials come from non-renewable petroleum resources, lots of organic solvents and pore-forming agents difficult to recover are used in a traditional membrane forming process, membrane aperture distribution is wide and a membrane is prone to contamination. Polymers with polyhydroxy are homogeneously grafted with polyacrylonitrile to obtain a membrane casting solution, the membrane casting solution is put in a coagulation bath, metal ions and chloride ions are gradually diffused in the coagulation bath, and phase transformation happens between the polymers with polyhydroxy and polyacrylonitrile to form the membrane. Metal ions and chloride ions have a pore forming effect; micro-phase separation happens between the polymers with polyhydroxy and polyacrylonitrile, and a hydrophilic channel is formed on the interface of the polymers and polyacrylonitrile. The nanofiltration membrane is simple in preparation process, low in time consumption and low in cost and can be expected to be applied to the fields of fine separation, protein separation, sewage treatment and the like.

Owner:HUNAN KEENSEN TECH CO LTD

Method for preparing boron-doped porous carbon material with high specific surface area from biomass

ActiveCN111994907AWide variety of sourcesSimple processCarbon compoundsPorous carbonBoron containing

The invention relates to a method for preparing a high-specific-surface-area boron-doped porous carbon material from biomass, which comprises the following steps: pulverizing biomass into fine particles, proportionally and uniformly mixing the pulverized biomass particles with a boric acid-containing water solution to form a mixture, and putting the mixture into a hydrothermal reaction kettle to perform hydrothermal reaction; dehydrating and drying hydrothermal carbon obtained after the hydrothermal reaction; putting the dried hydrothermal carbon into a pyrolyzing furnace, and carrying out rapid pyrolysis under the protection of an inert atmosphere to obtain a biomass source boron-doped porous carbon material with high specific surface area after rapid pyrolysis; the method has the advantages of wide sources of raw materials, simple and green process, lower equipment requirements, short time consumption in the production process and high efficiency, and is suitable for industrial large-scale production.

Owner:HEFEI UNIV OF TECH

Multi-layer macropore-mesopore-micropore polymer-derived ceramic adsorption material and preparation method thereof

ActiveCN108176355AWide range of sourcesSimple processOther chemical processesAlkali metal oxides/hydroxidesAcid etchingSewage treatment

The invention provides a preparation method of a multi-layer macropore-mesopore-micropore polymer-derived ceramic adsorption material. The preparation method comprises the following steps: preparing solid polysiloxane; grinding and screening wood chips and rice husks, performing ball milling, and taking out and drying powder; performing ball milling on solid polysiloxane, wood powder and rice huskpowder uniformly after mixing; placing a uniform mixture in a tubular furnace, sintering the mixture at high temperature under the protection of inert gas, and performing heat preservation and cooling with the furnace; performing acid etching on the obtained porous SiOC ceramic powder with a hydrofluoric acid solution, washing a product with water to be neutral and then performing drying to obtain the macropore-mesopore-micropore polymer-derived ceramic adsorption material. Multi-layer porous polymer-derived ceramic with high specific surface area can be synthesized by in-situ reaction and has abundant micropores and mesopores, and larger storage space and evacuation channels can be formed; rapid transport rate of reactants and products in the sewage treatment process is increased as a result of enough large pores, and larger adsorption space and transport channels can be formed.

Owner:JIANGSU UNIV

Wear-resistant ceramic roller and preparation method thereof

InactiveCN111575568AReasonable structural designImprove wear resistanceMetallic material coating processesPolyvinyl alcoholAdhesive

The invention discloses a wear-resistant ceramic roller and a preparation method thereof. The ceramic roller comprises a roller core and a wear-resistant layer from inside to outside, and the roller core is prepared from the following components of, in parts by mass, 70 to 80 parts of ceramic particles, 20 to 30 parts of a metal matrix, 15 to 20 parts of active elements and 1 to 5 parts of an adhesive, wherein the ceramic particles are prepared from the following components of, in parts by mass, 80 to 85 parts of Al2O3, 10 to 15 parts of ZrO2 and 1 to 5 parts of polyvinyl alcohol; the metal matrix is prepared from the following components of, in parts by mass, 20 to 15 parts of Cr, 2.0 to 2.5 parts of C, 1.0 to 2.2 parts of Ni, 1.0 to 1.5 parts of Mo, 0.5 to 1.0 part of Mn, 0.2 to 0.6 partof Si, 0 to 0.1 part of P, 0 to 0.05 part of S and the balance of Fe; and the wear-resistant layer is prepared from the following components of, in parts by mass, 85 to 95 parts of Fe55 powder and 5to 15 parts of TiC particles. According to the wear-resistant ceramic roller and the preparation method thereof, the formula is reasonable, the preparation method is simple, the cost is low, the yieldis high, large-scale batch production is easy to realize, and the prepared ceramic roller has the advantages of good wear resistance, long service life and wide application prospect.

Owner:徐州华焰特种陶瓷有限公司

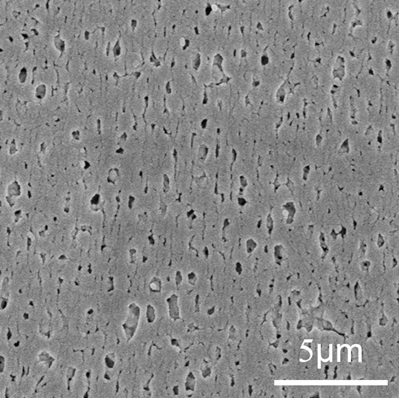

Narrow pore size distributed hydrophilic filtering membrane sensitive to temperature and pH and preparation method thereof

ActiveCN105854646AWide pore size distributionAct as a poreSemi-permeable membranesMembranesSolventContamination

For the problems that a large quantity of organic solvents and pore-foaming agents which are difficult to recycle are used in the traditional membrane preparing process, environmental contamination is caused, the pore size distribution of membranes is wide, and the membranes lack of responsiveness, the invention provides a narrow pore size distributed hydrophilic filtering membrane sensitive to temperature and pH on the basis of the idea of bionics by taking a metal chloride saline solution as the solvent. A preparation method of the membrane comprises the steps that fibroin is grafted with polyacrylonitrile and poly(N-isopropylacrylamide) in a homogeneous mode, and a membrane casting solution is obtained; the membrane casting solution is put into a water coagulating bath, metal ions and chloride ions are gradually scattered in water, an the fibroin grafted with poly(N-isopropylacrylamide) and polyacrylonitrile is subjected to phase transformation to form the membrane. The metal ions and the chloride ions play the role of hole forming, the fibroin, poly(N-isopropylacrylamide) and polyacrylonitrile are subjected to microphase separation, and water channels subjected to ion hole forming are formed in the interface. By means of the fibroin and poly(N-isopropylacrylamide), the pH value sensitivity and temperature sensitivity of the membrane are achieved. By means of the hole forming effect of the metal ions and the chloride ions, the hole size of the membrane is smaller, and the hole size distribution is narrow.

Owner:HUNAN KEENSEN TECH CO LTD

Preparation method of porous polyvinyl chloride-graphene composite material

InactiveCN107213880AImprove hydrophobicityThe ratio of ingredients is scientific and reasonableFatty/oily/floating substances removal devicesOther chemical processesN dimethylformamideSurface layer

The invention discloses a preparation method of a porous polyvinyl chloride-graphene composite material. According to the preparation method, hydrophobic modified nano-graphene, an N,N-dimethylformamide solution of polyvinyl chloride and sodium chloride are mixed by virtue of a high energy ball milling method, and finally, the mixture is dropwise added into distilled water to form porous polyvinyl chloride-graphene particles; a pore-foaming agent is compatible with water to form a surface layer with less pore structures, the compatiblility speed of the pore-foaming agent with water in a sphere is decreased due to the blockage of the surface layer and generates a pore forming effect in a slow dissolving-out process, and formed holes are uniformly distributed and uniform in particle sizes and have good through-hole and opening performance; meanwhile, by adding hydrophobic modified nano-graphene, the prepared composite material has good hydrophobic property, and a porous structure can be applied to oil-water separation such as water pollution treatment; and furthermore, a process of the preparation process is convenient to industrial control, and the application field of polyvinyl chloride is expanded.

Owner:CHUZHOU HONGYUAN SPRAYING

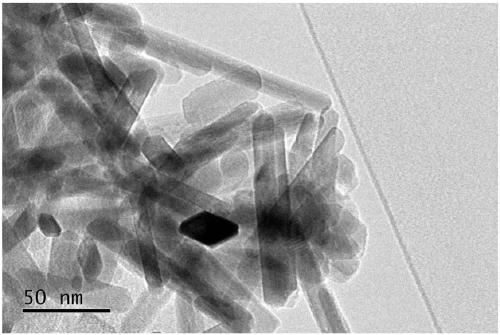

Nano hierarchical pore BEA structure molecular sieve catalyst and preparation method and application thereof

PendingCN113694961ALarge specific surface areaShort channel lengthMolecular sieve catalystsMolecular sieve catalystPtru catalystPolyamide

The invention discloses a nano hierarchical pore BEA structure molecular sieve catalyst as well as a preparation method and application thereof, and relates to the technical field of a catalyst for a process of preparing ethylbenzene by alkylation. The preparation method specifically comprises the following steps: fully mixing a silicon source, an aluminum source, an inorganic alkali source, a template agent, a co-auxiliary agent and deionized water, slowly evaporating excessive water in an aging process to obtain concentrated sol, and performing low-temperature-high-temperature two-stage hydrothermal crystallization to obtain the molecular sieve catalyst. The used co-auxiliary agent is a binary co-auxiliary agent consisting of a water-soluble polyamide and a water-soluble small organic molecule containing amino and carboxyl. The molecular sieve catalyst disclosed by the invention has a BEA framework topological structure, a grain size of 50-200nm, a micropore-mesopore hierarchical pore channel and a core-shell structure, has a relatively high mesopore volume ratio, and shows excellent selectivity and catalytic stability in industrial production of ethylbenzene by liquid phase alkylation of benzene and ethylene.

Owner:JILIN INST OF CHEM TECH +1

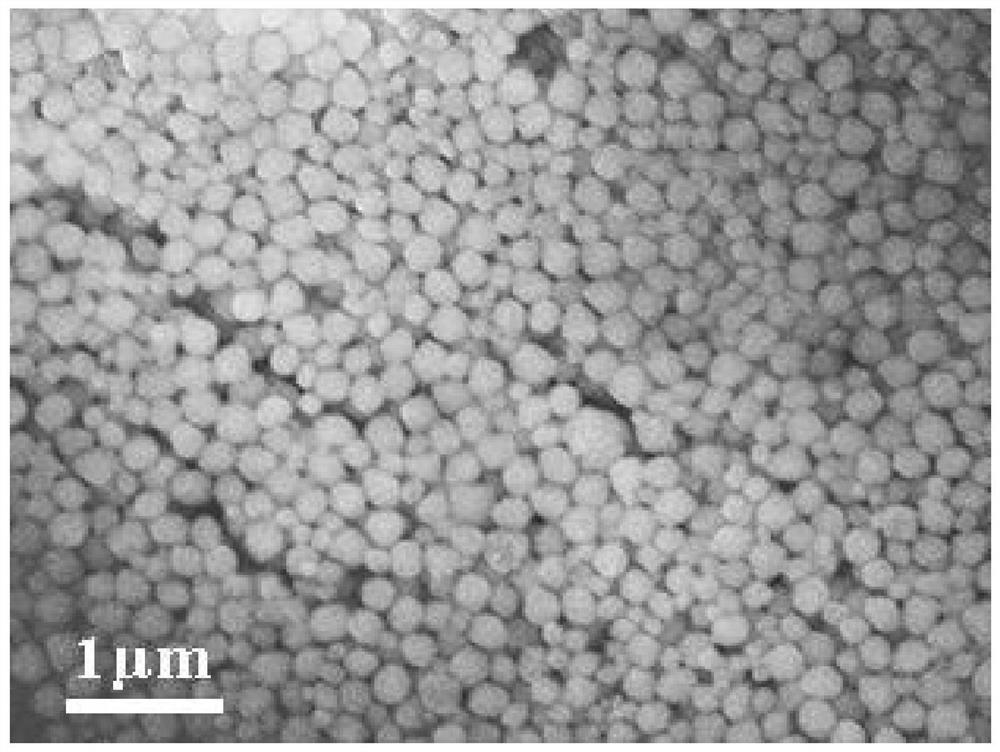

Macromolecule engram phosphoric acid/polyacrylic acid/calcium alginate multi-hybrid polymer micro-sphere and preparation method thereof

The invention relates to a macromolecular engram of multiple hybridigation polymeric compound microsphere of phosphoric acid / polyacrylic acid / calcium alginate and process for preparation. The protein engram of multiple hybridigation polymeric compound microsphere of phosphoric acid or polyacrylic acid or calcium alginate comprises the following raw materials and parts by weight: 20%-40% of calcium alginate, 1%-10% of diammonium phosphate, 0.5%-5% of poly-sodium acrylate, 50%-65% of calcium chloride and 0.1%-10% of protein. The prepared multiple hybridigation polymeric compound microsphere of phosphoric acid or polyacrylic acid or calcium alginate is tested by protein multiple binding, the test result indicates that the multiple binding content of engram microsphere can reach at least 3 times of the multiple binding content of non-engram microsphere which protein is not added, the result of electric conductivity titration and infrared spectrum testing indicate that a model multiple hybridigation component is produced under the joint action of diammonium phosphate, calcium alginate and CaCl2. The invention is simple and easy in the process for preparation and easy controllable in process of reaction and the like, the invention solves the shortcomings of low in mechanical strength and engram efficiency of the pure calcium alginate and astable in property and the like, thereby the applying foreground is wide.

Owner:TIANJIN UNIV

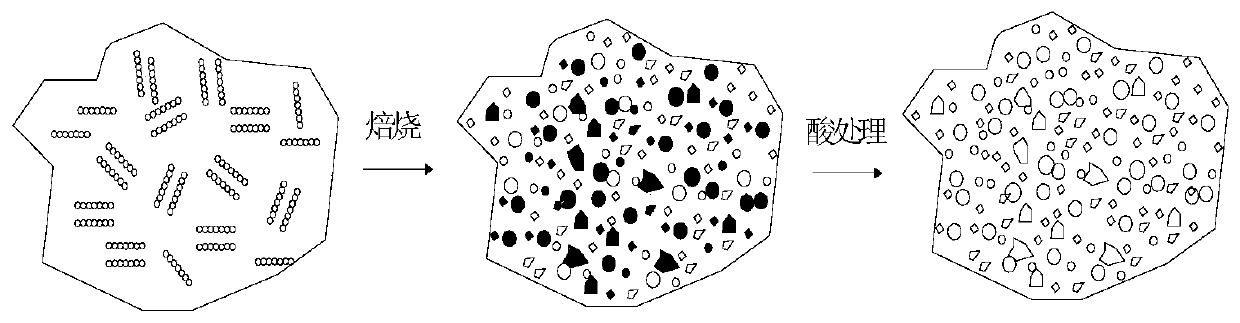

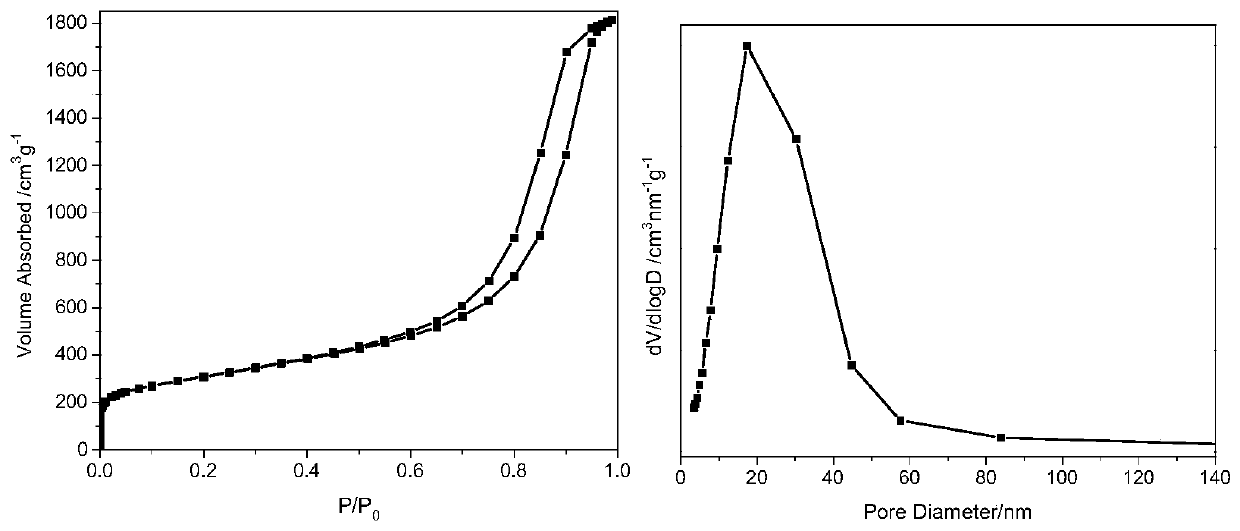

In-situ nitrogen-doped porous carbon material and preparation method thereof

ActiveCN111517323APlay the role of auxiliary hole makingGood hole making effectCarbon preparation/purificationMeth-Porous carbon

The invention relates to a preparation method of an in-situ nitrogen-doped porous carbon material, belonging to the technical field of material science. According to the method, magnesium-aluminum hydrotalcite synthesized in situ serves as an auxiliary pore forming agent, phenols or methyl substituted phenols, formaldehyde and nitrogen-containing monomers are copolymerized, a nitrogen-doped carbonprecursor is generated through a one-pot hydrothermal method, and then high-temperature roasting and acid treatment are carried out to prepare the porous carbon material. The specific surface area, pore size distribution and nitrogen doping amount of the nitrogen-doped porous carbon are regulated and controlled by controlling the molar ratio of phenolic aldehyde, the dosage of nitrogen-containingpolymeric monomers, the ratio of magnesium-aluminum to a phenol polymeric monomers and hydrothermal reaction conditions; and the prepared material is high in carbon residue rate and narrow in pore size distribution range. The method can avoid usage of hydrofluoric acid, and is high in operability and friendly to environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

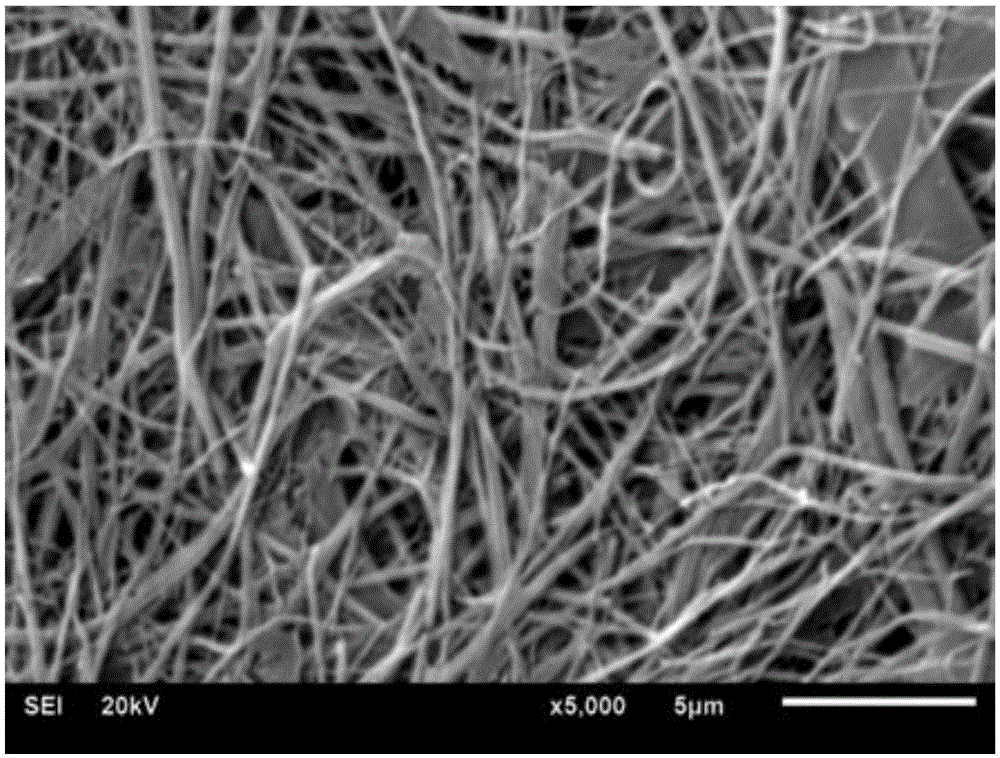

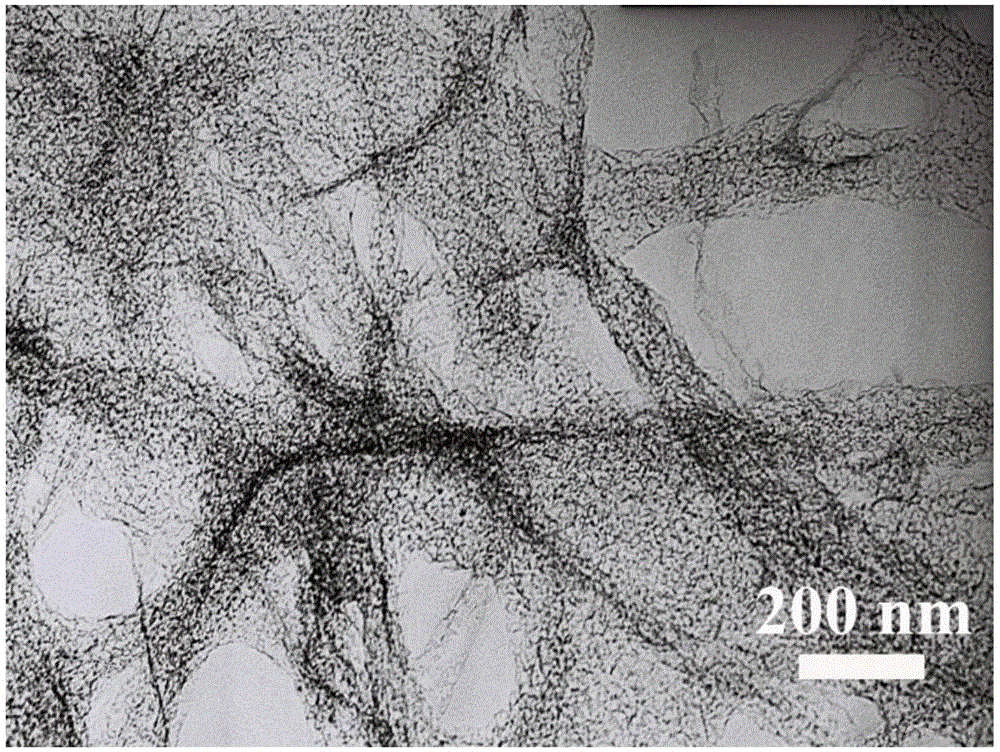

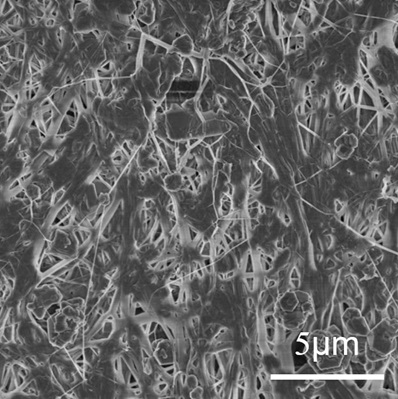

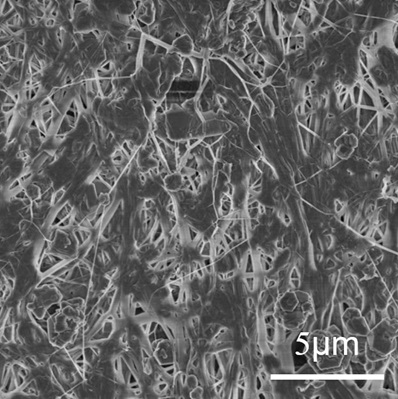

High-capacity mesoporous carbon nanofiber for lithium-ion battery and preparation method of high-capacity mesoporous carbon nanofiber

InactiveCN106450308ALarge specific surface areaMeet capacityCell electrodesNanotechnologyFiberCarbon fibers

The invention discloses a high-capacity mesoporous carbon nanofiber for a lithium-ion battery and a preparation method of the high-capacity mesoporous carbon nanofiber, and belongs to the technical field of nano materials and new energy. According to the method, fibrous calcium citrate is adopted as a raw material and the mesoporous carbon nanofiber can be obtained through carbonization and template removal; an activating agent does not need to be added; and the operation process is simple. The mesoporous carbon nanofiber has relatively large specific surface area; and a lot of pore and channel structures are uniformly distributed in the fiber. The mesoporous carbon nanofiber is used as a negative electrode material of the lithium-ion battery, so that, compared with a traditional negative electrode material and an existing carbon fiber material, the high-capacity mesoporous carbon nanofiber has obvious advantages in the specific capacity, the cycle stability and the rate capability, and can meet the requirements of the fast-developing power lithium-ion battery.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Big molecular engram calcium orthophosphate/calcium alginate hybridized micro-balloon and method for preparing the same

The invention relates to a protein macromolecule imprinted calcium phosphate / calcium alginate hybrid microsphere and a preparation method thereof. The composition and weight percentage of calcium phosphate / calcium alginate hybrid microspheres for western blotting are as follows: sodium alginate 20%-40%, diammonium hydrogen phosphate 1%-10%, calcium chloride 50%-65%, Protein 0.5-10%. The calcium phosphate / calcium alginate hybrid microspheres prepared by the present invention show that the adsorption capacity of the imprinted microspheres is 1.8 to 5 times that of the non-imprinted microspheres, that is, the microspheres prepared without adding protein, according to the protein adsorption test results. Conductivity titration and infrared spectroscopy tests show that diammonium hydrogen phosphate and sodium alginate can interact with CaCl2 to produce new hybrid components. The invention has the advantages of simple preparation method, easy control of the reaction process, etc., solves the shortcomings of pure calcium alginate such as low mechanical strength and imprinting efficiency, unstable performance, difficult diffusion of protein macromolecules, and the like, and has broad application prospects.

Owner:TIANJIN UNIV

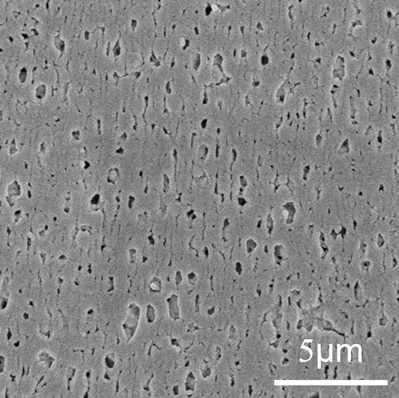

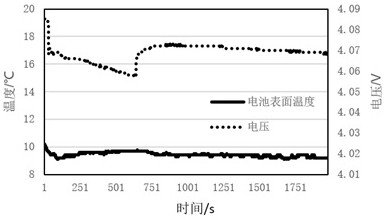

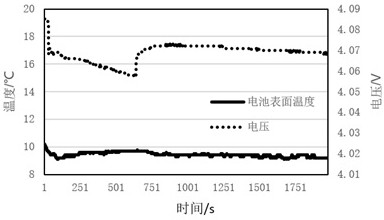

High-safety diaphragm as well as preparation method and application thereof

ActiveCN113904061AImprove securityAvoid stickingCell component detailsSecondary cells servicing/maintenancePlasticizerSlurry

The invention relates to a high-safety diaphragm as well as a preparation method and application thereof. The preparation method comprises the steps of (I) mixing a fluorocarbon polymer, an inorganic ceramic material and a plasticizer, and heating to obtain mixed granules; (II) laminating the mixture to obtain flaky blanks; (III) rolling the flaky blanks to obtain diaphragms; (IV) coating the surfaces of the diaphragms with an isolating agent, and stacking and laminating a plurality of diaphragms of which the surfaces are coated with the isolating agent to obtain a multi-layer diaphragm; (V) rolling the multi-layer diaphragm to obtain multiple films; and (VI) performing extraction pore-forming on each film, and heating to obtain the high-safety diaphragm. According to the preparation method, the requirement of fluidity of slurry can be avoided, the diaphragm with relatively high inorganic ceramic material content can be generated, and the safety of the diaphragm is effectively improved; and the yield can be improved, and the thickness and pores of the diaphragm are easy to control.

Owner:北京金羽新材科技有限公司

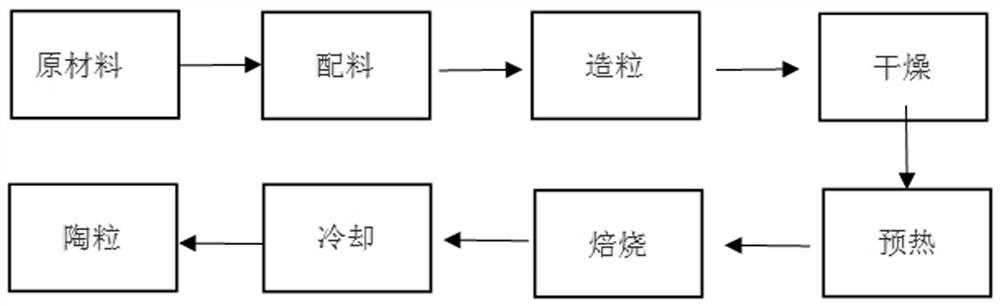

Ceramsite fired by doping high-silicon iron tailings and preparation method thereof

PendingCN112811926ARealize the utilization of solid waste resourcesImprove liquidityCeramic materials productionCeramicwareSilicon ironBuilding material

The invention belongs to the field of comprehensive utilization of building materials and solid wastes, and particularly relates to a method for firing ceramsite by doping high silicon iron tailings and other solid wastes. The invention relates to ceramsite fired by doping high-silicon iron tailings, wherein the ceramsite is prepared from the following raw materials in parts by mass: 60-70 parts of high-silicon iron tailings, 10-15 parts of red mud, 5-12 parts of montmorillonite, 5-8 parts of pulverized coal and 5-10 parts of kitchen garbage. Various performance index values of the ceramsite prepared only in the north provided by the invention meet the standard requirements of GBT17431.1-2010 "Lightweight Aggregate and Test Method Thereof". According to the invention, in the ceramsite doped with the high-silicon iron tailings for firing, the high-silicon iron tailings are used as main raw materials; so that from the perspective of treatment of a large amount of solid waste, the problem that a large amount of tailings are accumulated is efficiently solved, solid waste resource utilization is achieved, waste is turned into wealth, and the influence of the solid waste such as the tailings on the environment is reduced. The technical scheme has certain ecological benefits and social benefits.

Owner:SHENYANG POLYTECHNIC UNIV

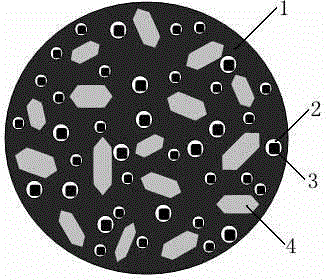

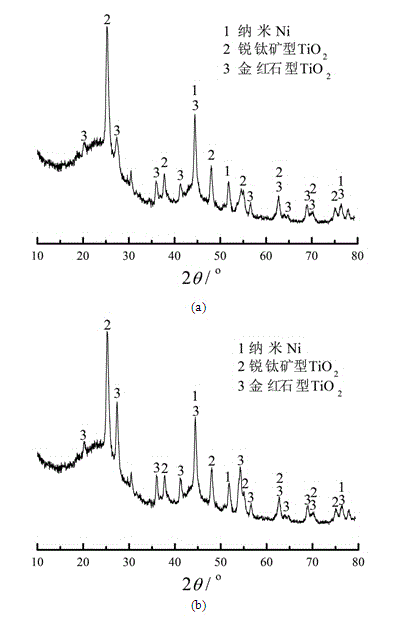

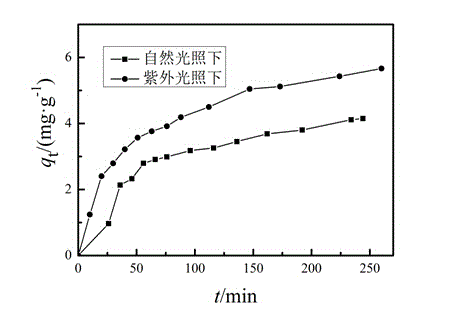

Magnetic mesoporous carbon/nano TiO2 compound adsorbent and preparation method thereof

InactiveCN104801275AControlled crystal transformationAchieve separationOther chemical processesAlkali metal oxides/hydroxidesSorbentCarbonization

The invention belongs to the technical field of nanometer materials and preparation thereof and particularly relates to a magnetic mesoporous carbon / nano TiO2 compound adsorbent and a preparation method thereof. The compound adsorbent contains 50 to 80 percent of nano TiO2, 10 to 20 percent of magnetic metal nanoparticles and 10 to 30 percent of mesoporous carbon, wherein the mesoporous carbon is taken as a carbonaceous substrate; the nano TiO2 is distributed on the carbonaceous substrate; the magnetic metal nanoparticles are embedded in mesopores of the carbonaceous substrate. The preparation method of the magnetic mesoporous carbon / nano TiO2 compound adsorbent comprises the following steps of dispersing TiO2 nanoparticles in resin; adding transition metal hydroxide colloidal particles as a template agent; performing resin impregnation, heating curing, high temperature carbonization, washing and purifying and the like to obtain the magnetic mesoporous carbon / nano TiO2 compound adsorbent. According to the magnetic mesoporous carbon / nano TiO2 compound adsorbent disclosed by the invention, organic pollutants can be quickly and efficiently absorbed to be nearby the surface of the nano TiO2, and organic matters are decomposed into small-molecule gases or soluble substances, so that the biological toxicity and the environment pollution of the organic matters are reduced; the adsorbent can be separated and recovered by magnetic particles, so that secondary pollution to a water body is avoided, and the recycling of the adsorbent is facilitated.

Owner:SHENYANG JIANZHU UNIVERSITY

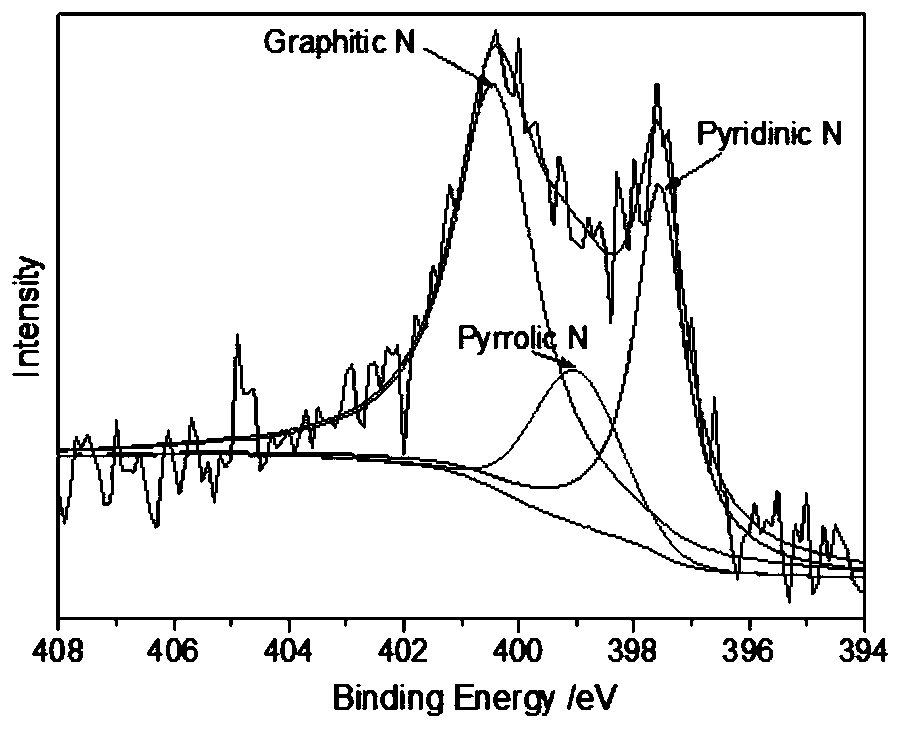

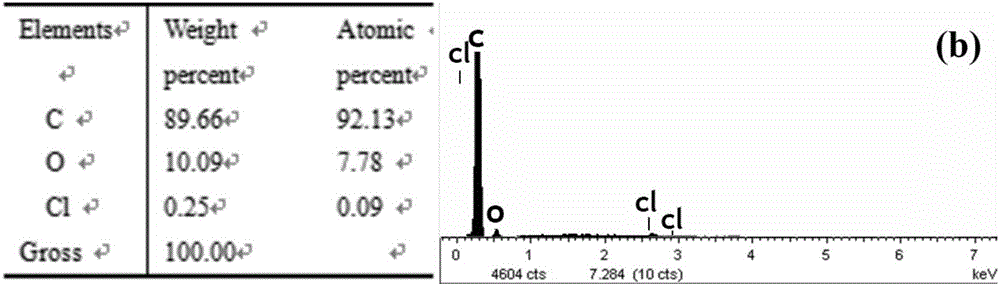

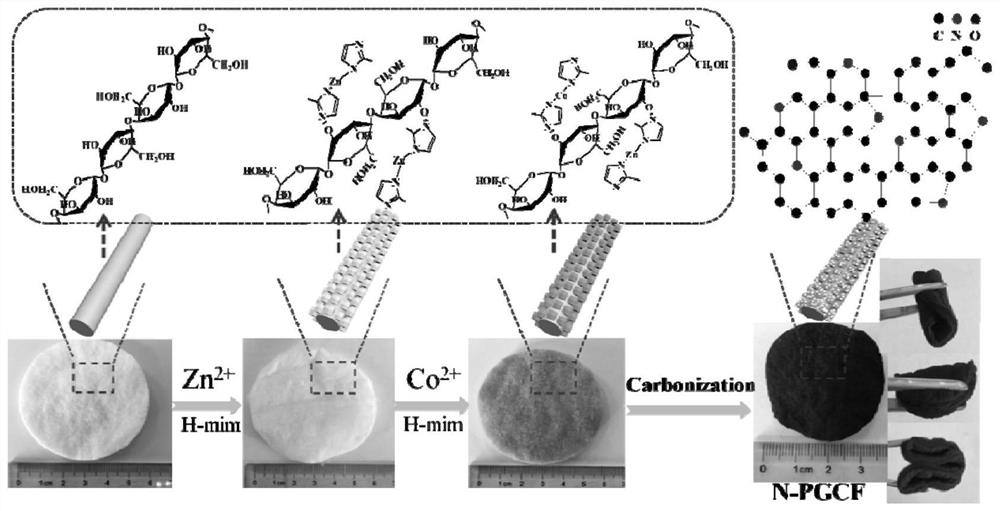

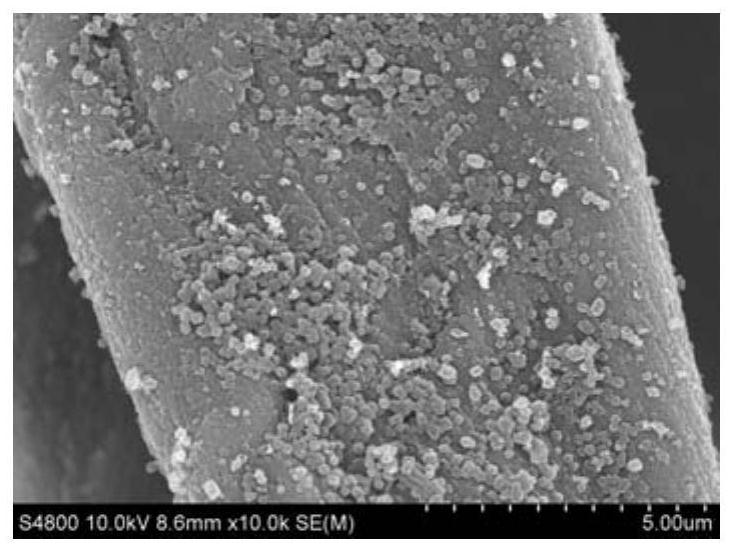

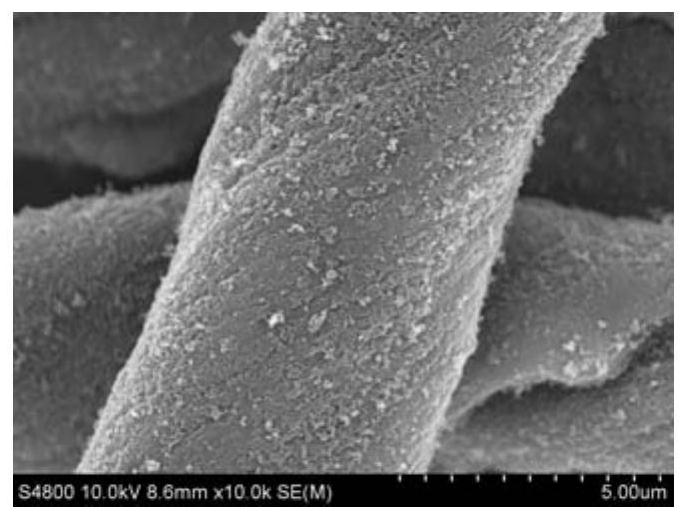

Preparation method and application of highly graphitized biomass-based porous nitrogen-doped carbon fiber material

ActiveCN112820547AAvoid damageAchieving a high degree of graphitizationHybrid capacitor electrodesHybrid/EDL manufactureFiberCarbon fibers

The invention discloses a preparation method of a highly graphitized biomass-based porous nitrogen-doped carbon fiber electrode material, which is used in the field of flexible supercapacitors. The preparation method comprises the following steps: growing an organic metal framework of Zn in situ, growing one or more organic metal frameworks of Fe or Co or Ni in situ again, and then carbonizing and pickling. The prepared highly graphitized carbon fiber material has excellent electrochemical performance and flexibility. The preparation method has the main advantages that 1) the specific surface area of the highly graphitized carbon fiber material is large, and more adsorption sites are provided; 2) heteroatoms (nitrogen atoms) are introduced, so that the pseudocapacitance can be increased, and the hydrophilicity of the material can be improved; and 3) high graphitization can improve the conductivity of the material.

Owner:BEIHUA UNIV

Process for producing stephanoporate Si3N4

A porous Si3N4 ceramics preparation method relates to a method for preparing the Si3N4 ceramics, and solves the problem of low porosity of porous Si3N4 ceramics prepared by the prior art. The method is as follows: mixing alpha-Si3N4 powder and combustion assistant evenly; making the mixture and aqueous polyvinyl alcohol solution into slurry; refrigerating the slurry until the slurry completely freezes; carrying out low-temperature vacuum dehydration; moulding the slurry to green body with various shapes based on requirement before refrigeration; and sintering the dried green body to obtain porous Si3N4 ceramics. The porous Si3N4 ceramics prepared by the method have adjustable pore diameter and porosity which can reach as high as 95%. Process of the method is simple with good repeatability.

Owner:HARBIN INST OF TECH

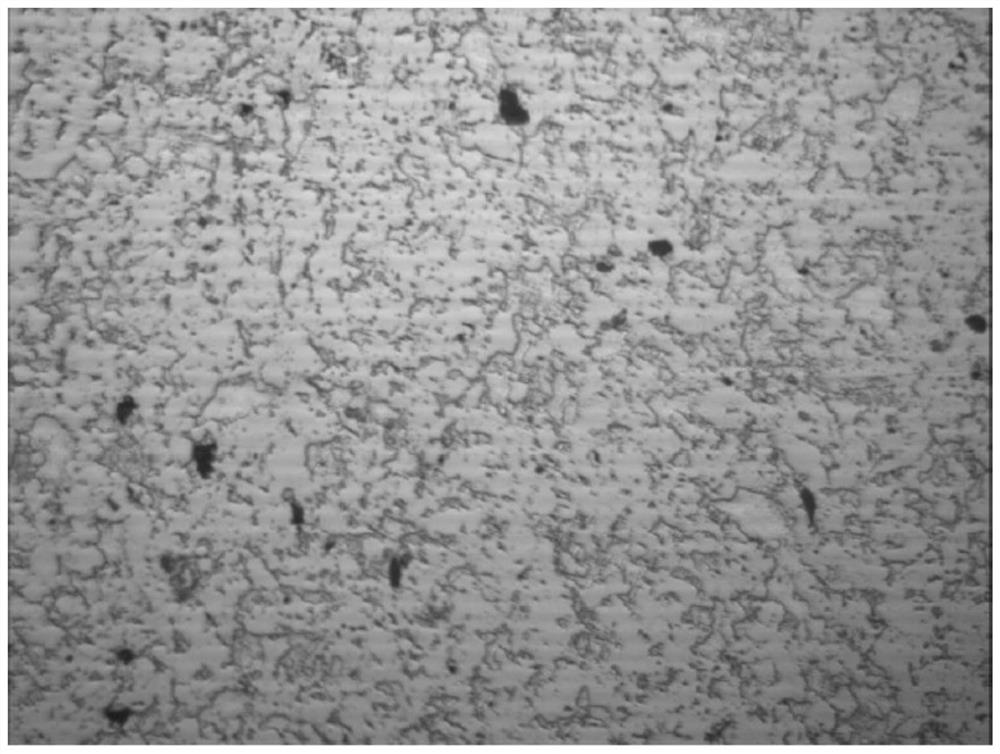

High efficiency hardening resistant micro-electrolysis material and preparation method thereof

ActiveCN101838034BHigh porosityIncrease the areaWater/sewage treatment by sorptionPorosityElectrolysis

The invention discloses a high efficiency hardening resistant micro-electrolysis material. The porosity is 0.5 to 0.8 and the specific surface area is 0.4 to 1.0m2 / g. The preparation method is that at first ferrous powder, active carbon powder, sodium bentonite and NH 4Cl are mixed fully, water is added and stirred evenly, in the second place, small balls the diameter of which is 2 to 5mm are made through a ball forming mill and then dried and finally the dried spherical material is roasted and cooled to room temperature naturally. Compared with the traditional micro-electrolysis material, the invention has the advantages that NH3 generated by NH4Cl at high temperature is used to create pores, the porosity and the specific surface area of material are increased, the elimination effect of the micro-electrolysis material on pollutant in waste water is improved, meanwhile because the material is spherical regular material, the invention has good mechanical strength, the compaction of thematerial in the use process is avoided, the material does not tend to be hardened and passivated, the service life is long and consequently the long-term stable running of the micro-electrolysis technology is ensured.

Owner:EC PRECISION TECHJIANGSUCORP

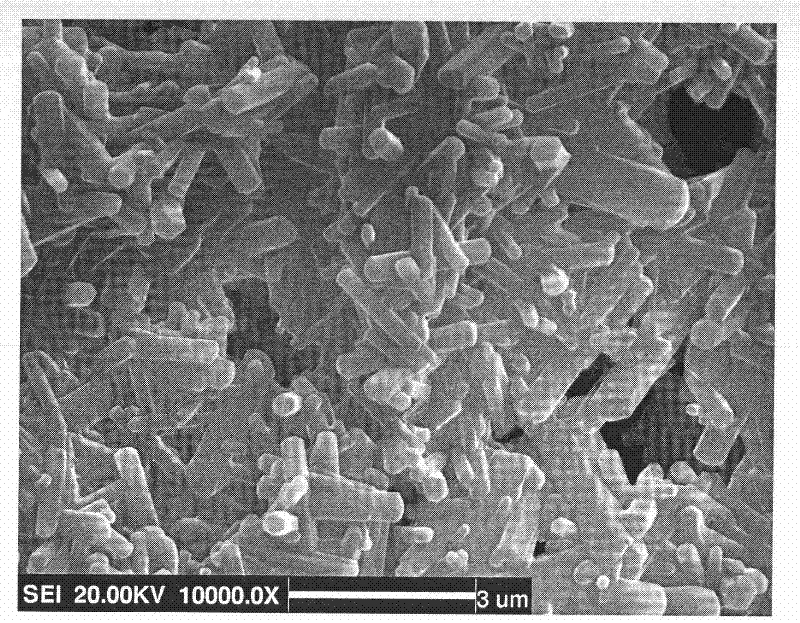

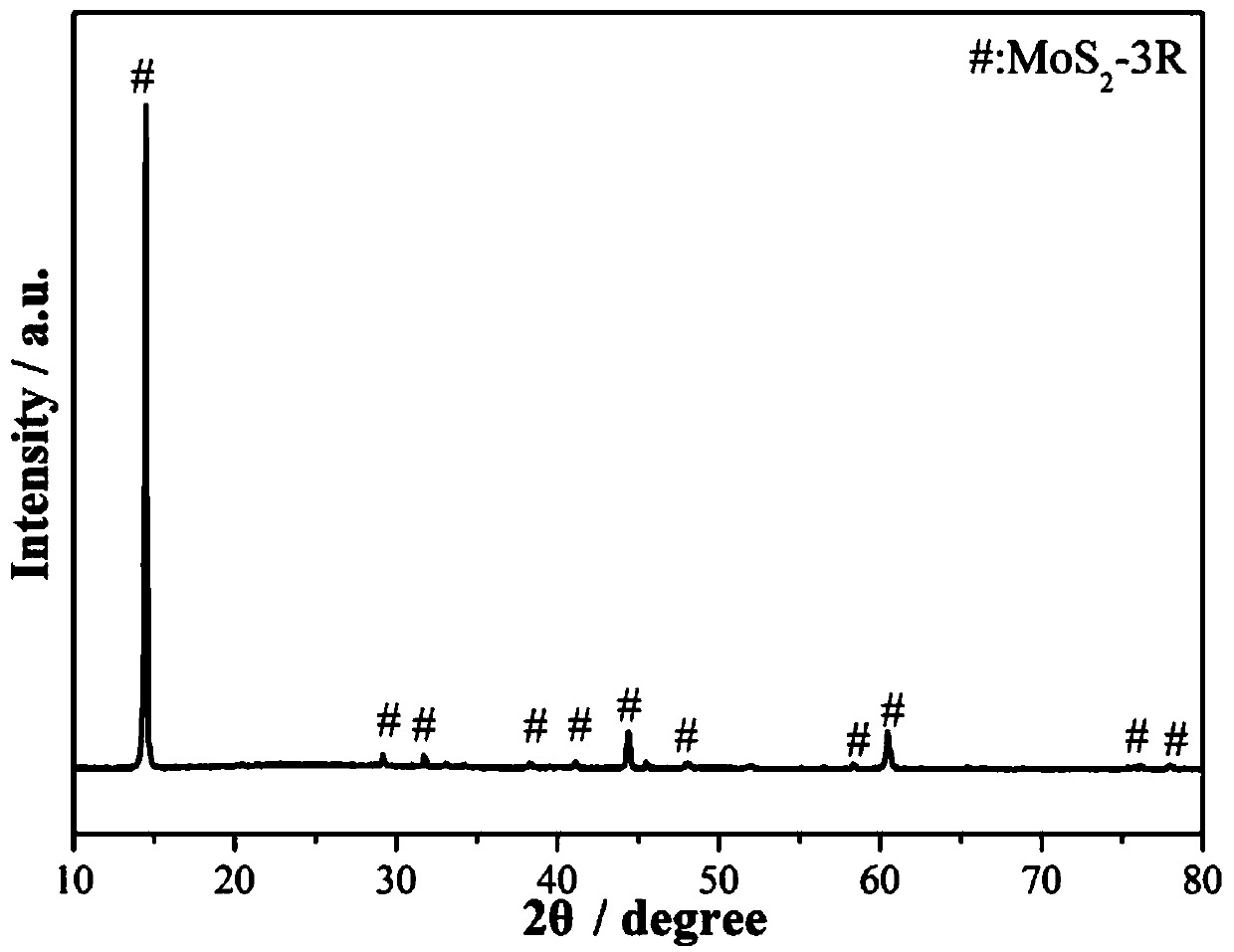

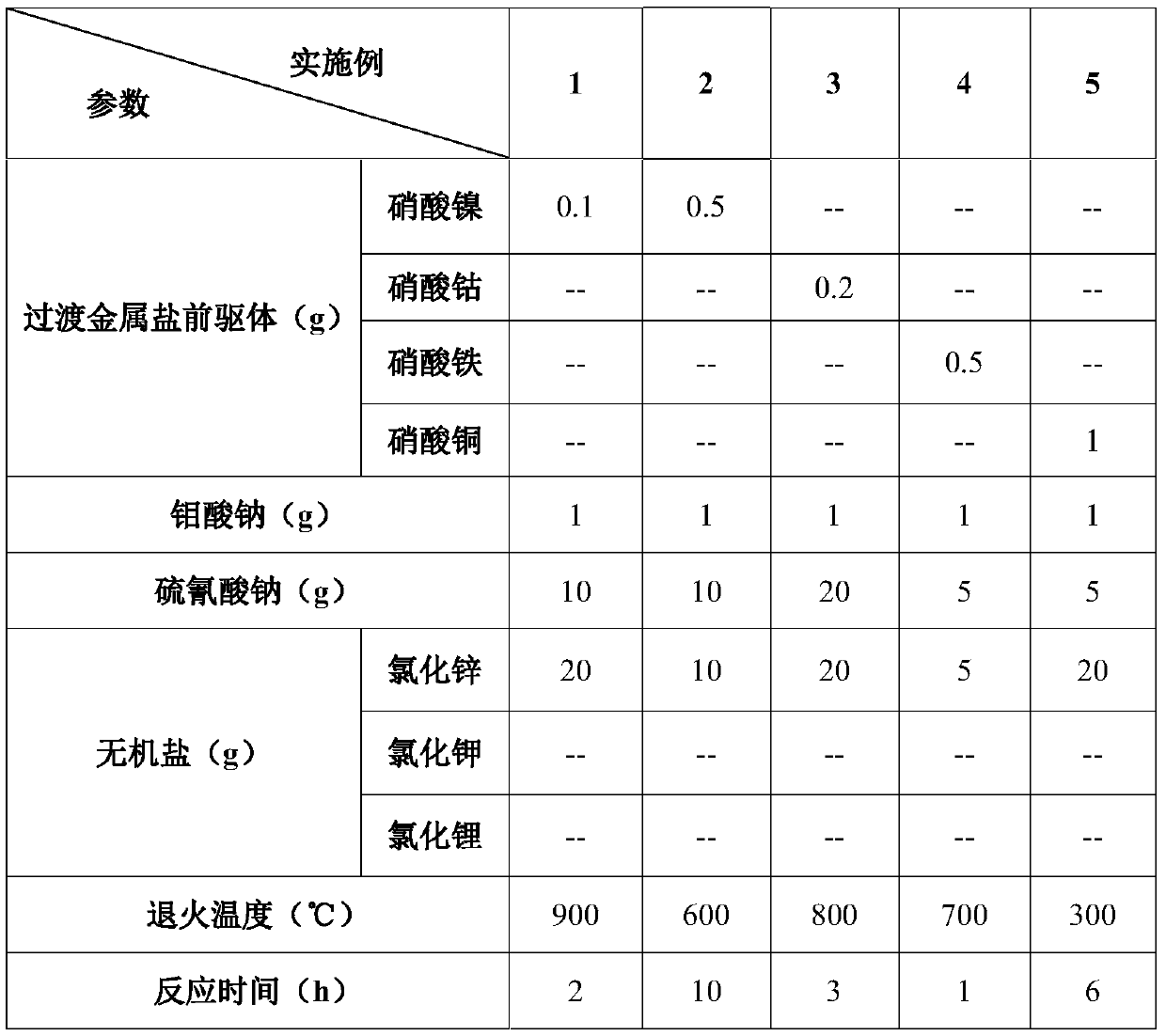

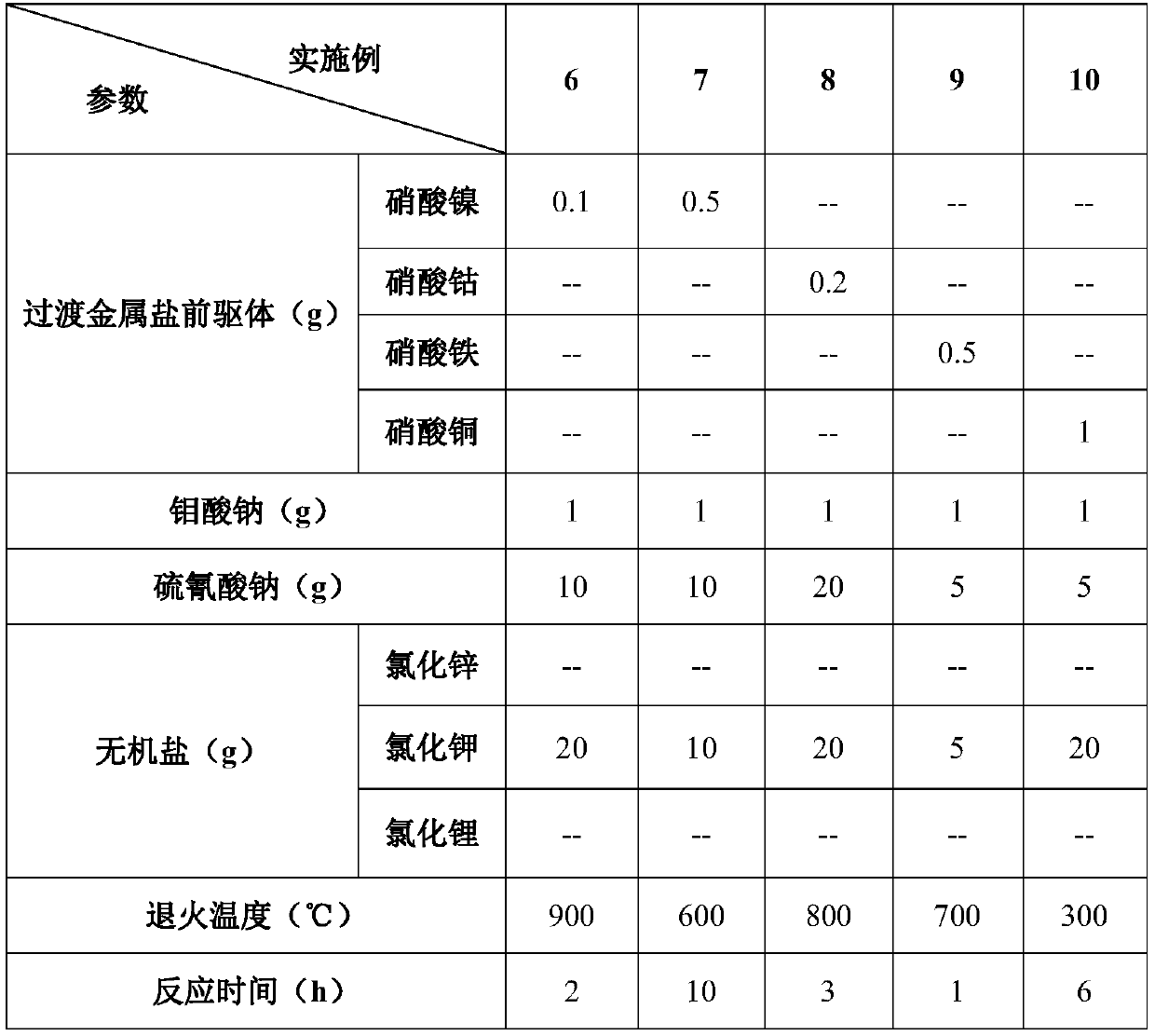

Preparation method of transition metal doped 3R type molybdenum disulfide catalyst

ActiveCN111558383ALarge specific surface areaIncrease the number of active sitesFatty acid hydrogenationCatalyst activation/preparationPtru catalystSodium thiocyanate

The invention relates to the technical field of oleic acid hydrogenation, and particularly discloses a preparation method of a transition metal doped 3R type molybdenum disulfide catalyst. The preparation method comprises the following steps: 1, grinding and mixing sodium molybdate, a transition metal salt precursor, sodium thiocyanate and inorganic salt by using a ball mill for not less than 6 h;and 2, carrying out annealing treatment on the mixture obtained in step 1 at an annealing temperature of not less than 300 DEG C, cooling to room temperature after the reaction is finished, dissolving and washing the reacted mixture with a solvent, and drying the reacted mixture to obtain the transition metal doped 3R type molybdenum disulfide catalyst. The transition metal doped molybdenum disulfide with the crystal form of 3R prepared by adopting the technical scheme in the patent has better hydrogenation reaction capability compared with a commercial doped molybdenum disulfide catalyst.

Owner:CHONGQING TECH & BUSINESS UNIV

A kind of fine iron oxide desulfurizer and its preparation and application method

ActiveCN106268219BHigh precisionHigh sulfur capacityDispersed particle separationCelluloseEngineering

Owner:HUNAN HUANDA ENVIRONMENTAL PROTECTION

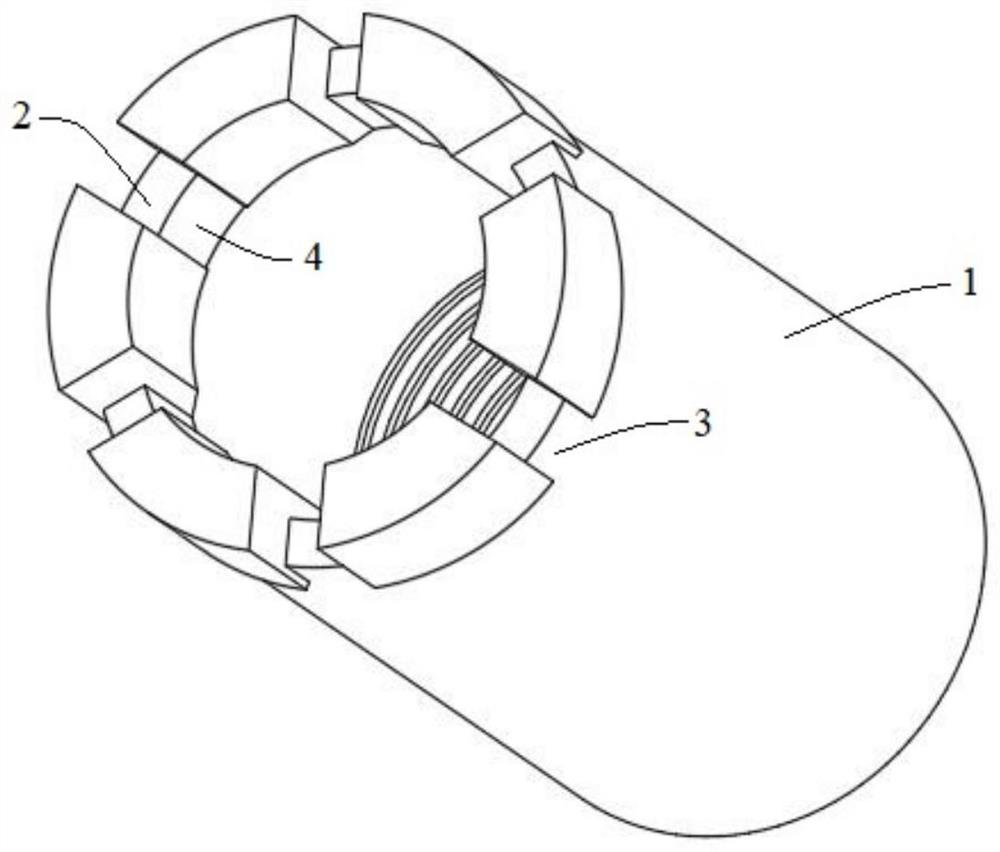

A kind of artificial diamond drill bit material and its drill bit, production process

ActiveCN110408828BStrength is not destroyedReduce erosionDrill bitsTransportation and packagingFine powderDrill bit

The invention discloses an artificial diamond drill material, a drill and a production process thereof, and belongs to the technical field of diamond drills. The artificial diamond bit material of the present invention comprises matrix powder and cutting diamond coarse powder, and said matrix powder comprises pre-alloyed powder and diamond micropowder, and its material composition and the mass fraction of each component are: Fe 71.00~76.00 parts , 15.00-18.00 parts of Cu, 1.00-2.00 parts of C, 0.30-0.50 parts of Si, 1.50-2.50 parts of Sn, 3.00-5.00 parts of diamond powder; among them, the particle size of cutting diamond coarse powder is 35-60 mesh, and the concentration is 70- 80%; the particle size of the diamond powder is at least 170 mesh. According to the above-mentioned materials, the production process steps of the diamond drill bit include: powder making, material mixing, mold loading, sintering, machining and grinding, and water planing. In the sintering process, the sintering temperature is reduced and heated according to a specific sintering curve to obtain An artificial diamond drill bit can improve the slipping phenomenon of the drill bit and increase the abrasiveness of the drill bit.

Owner:马鞍山市华东超硬材料有限责任公司

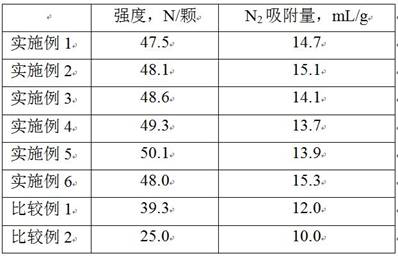

Preparation method of 5A molecular sieve adsorbent

ActiveCN114433014AImprove mass transfer effectEmission reductionOther chemical processesAlkali metal oxides/hydroxidesMolecular sieveSorbent

The invention discloses a preparation method of a 5A molecular sieve adsorbent. The method comprises the following steps: mixing and kneading 4A molecular sieve raw powder, clay, sodium carbonate, an auxiliary agent and water according to a ratio to obtain a wet material mass; forming the lumps to obtain strip-shaped particles, and rounding the strip-shaped particles to obtain spherical particles; drying and roasting the spherical particles; carrying out crystallization reaction on the roasted material, so that the binder is subjected to solid-state crystal transformation; and carrying out ion exchange on the obtained product in a calcium solution, and then drying and roasting to obtain the 5A molecular sieve adsorbent. The method omits an alkali treatment step, reduces waste liquid discharge, and is easy to operate; the prepared spherical 5A molecular sieve adsorbent has the characteristics of high adsorption capacity, high mass transfer rate, high compressive strength and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A high-safety diaphragm and its preparation method and application

ActiveCN113904061BImprove securityAvoid stickingCell component detailsSecondary cells servicing/maintenanceMultilayer membranePolymer science

The invention relates to a high-safety diaphragm and its preparation method and application. The preparation method includes: (I) mixing fluorocarbon polymers, inorganic ceramic materials and plasticizers, and heating to obtain mixed granular materials; (II) Laminate the mixture to obtain a sheet-like blank; (III) Roll the sheet-shaped blank to obtain a diaphragm; (IV) Coat the surface of the diaphragm with a release agent, and coat multiple surfaces with a release agent stacking and laminating the sheets to obtain a multi-layer diaphragm; (V) rolling the multi-layer diaphragm to obtain multiple films; (VI) extracting and heating each film to obtain the high-safety diaphragm . The preparation method can not be required by the fluidity of the slurry, can generate a diaphragm with a high content of inorganic ceramic materials, effectively improves the safety of the diaphragm, can improve the yield, and is easy to control the thickness and pores of the diaphragm.

Owner:北京金羽新材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com