Big molecular engram calcium orthophosphate/calcium alginate hybridized micro-balloon and method for preparing the same

A technology for hybridizing microspheres and calcium alginate, which is applied in the field of material science and achieves the effects of simple and easy preparation method, easy control of reaction process and wide application prospect.

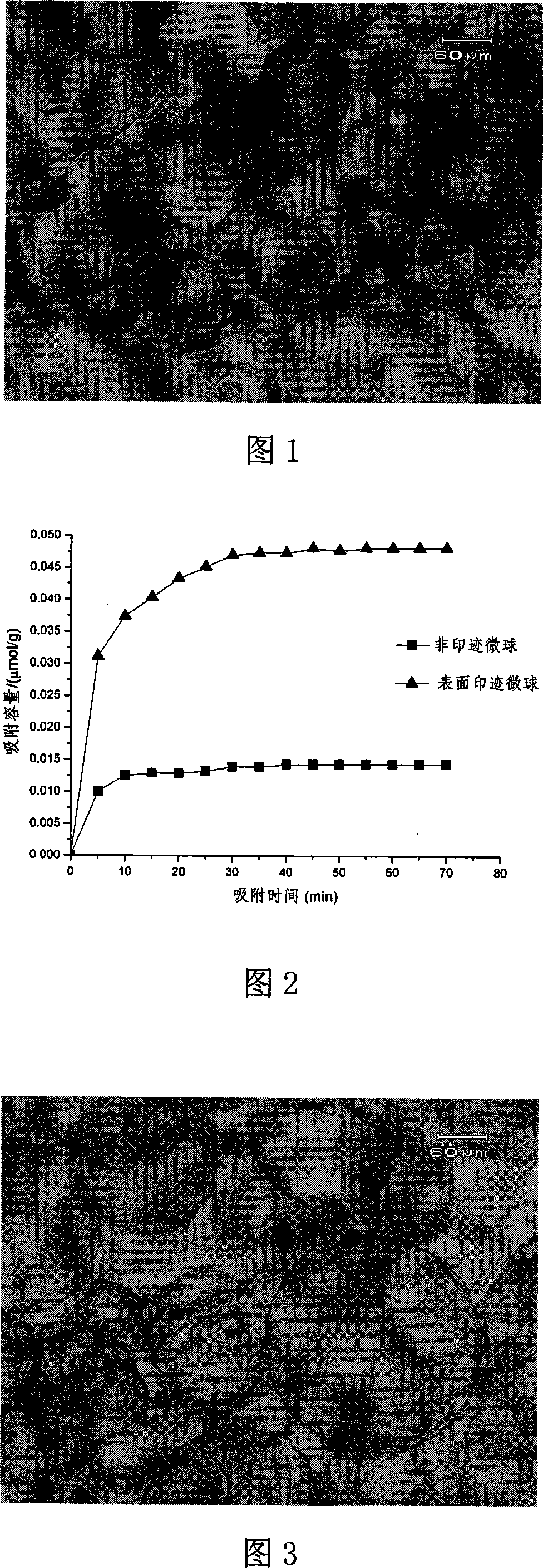

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

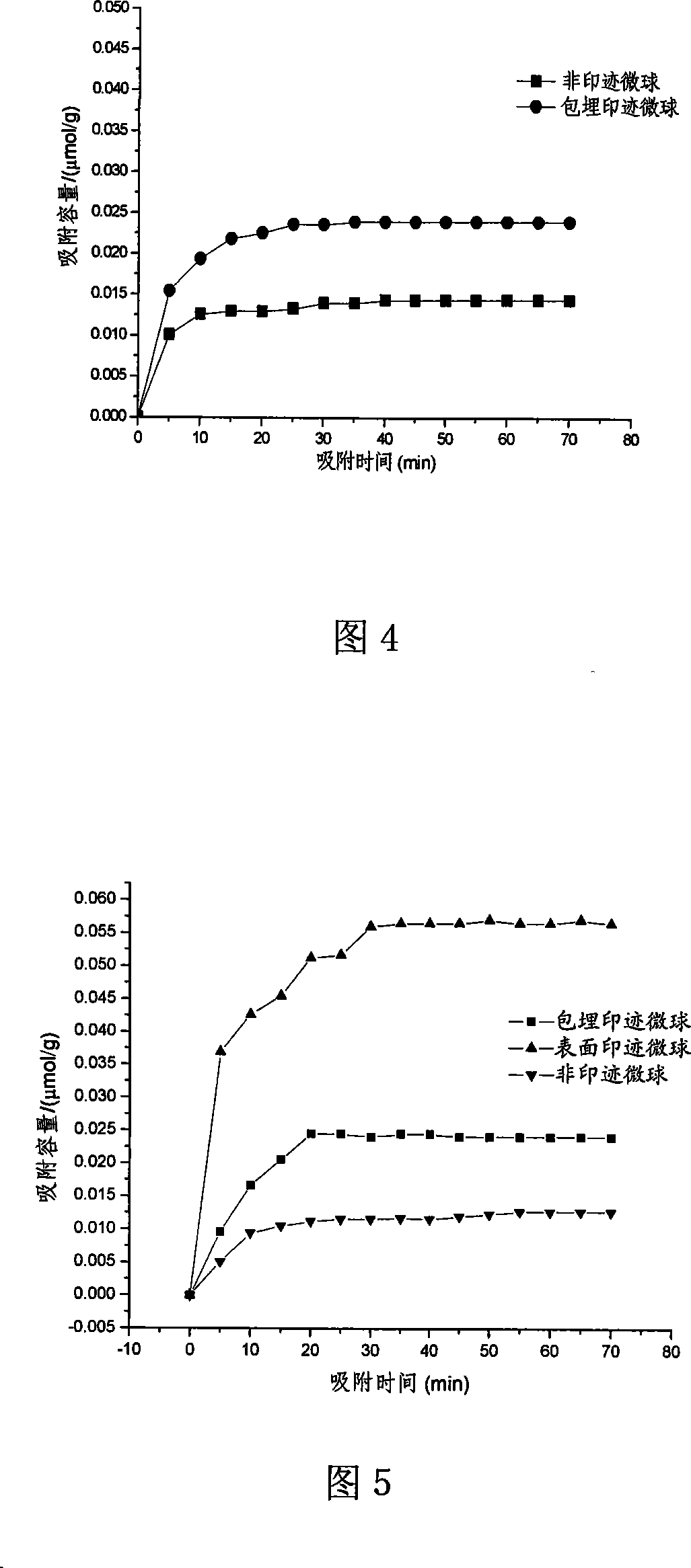

Embodiment 1

[0034] Example 1. Preparation of bovine serum albumin surface imprinted calcium phosphate / calcium alginate hybrid microspheres, comprising the following steps:

[0035] 1) Add 0.5128g of sodium alginate and 0.15g of diammonium hydrogen phosphate solid into 20ml of deionized water, stir to fully dissolve, and obtain solution A;

[0036] 2) Measure 40ml of organic phase toluene, pour it into a beaker, add 0.8g sorbitan monooleate to it, stir for 5min to fully dissolve it; slowly pour solution A into the beaker containing the organic phase while stirring , stirred for 10 minutes to disperse the viscous solution A into microspheres;

[0037] 3) Add bovine serum albumin with a mass percentage concentration of 0.134% to 1.34% and a calcium chloride mixed aqueous solution B with a mass percentage concentration of 5% to the above mixing system under stirring for gelation reaction, and continue stirring for 45 minutes to obtain Microspheres; the protein template is eluted by the metho...

Embodiment 2

[0039]Example 2. Preparation of bovine serum albumin-embedded imprinted calcium phosphate / calcium alginate hybrid microspheres, comprising the following steps:

[0040] 1) Add 0.5128 g of sodium alginate and 0.15 g of diammonium hydrogen phosphate solid to 20 μmol / L bovine serum albumin solution dissolved in 20 ml of deionized water, stir to fully dissolve, and obtain solution A1;

[0041] 2) Measure 40ml of the organic phase composed of 20ml of chloroform and 20ml of n-hexane, pour it into a beaker, add 0.8g of sorbitan monooleate to it, stir for 5min to fully dissolve it; slowly dissolve the solution A1 under stirring Pour it into the beaker containing the organic phase, and stir for 15 minutes to disperse the viscous solution A1 into microspheres;

[0042] 3) Add calcium chloride mixed aqueous solution B1 with a mass percentage concentration of 5% to the above mixing system under stirring for gelation reaction, continue stirring for 45 minutes to obtain microspheres; use th...

Embodiment 3

[0044] Example 3. Preparation of phosphoric acid / calcium alginate hybrid microspheres imprinted on the surface of ovalbumin, comprising the following steps:

[0045] 1) Add 0.6186g of sodium alginate and 0.15g of diammonium hydrogen phosphate solid into 20ml of deionized water, stir to dissolve it fully, and obtain solution A; 15-30ml of butyl acetate, 25-50ml of castor oil;

[0046] 2) Measure 40ml of the organic phase composed of 15ml butyl acetate and 25ml castor oil, pour it into a beaker, add 0.04g ethyl cellulose to it, stir for 5min to fully dissolve it; slowly pour solution A into In the beaker containing the organic phase, stir for 10-15 minutes to disperse the viscous solution A into microspheres;

[0047] 3) Add ovalbumin with a mass percentage concentration of 0.134% to 1.34% and a calcium chloride mixed aqueous solution B with a mass percentage concentration of 5% to the above mixing system under stirring for gelation reaction, and continue stirring for 50 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com