High-specific-surface-area Fischer-Tropsch synthesis catalyst and preparation method and application of high-specific-surface-area Fischer-Tropsch synthesis catalyst

A Fischer-Tropsch synthesis and catalyst technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve problems such as limiting catalyst activity, reducing system disorder, reducing catalyst surface area, etc., to achieve Avoid shrinkage and collapse, simple and easy to operate, and improve the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

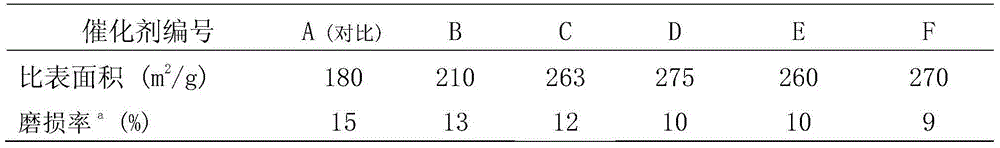

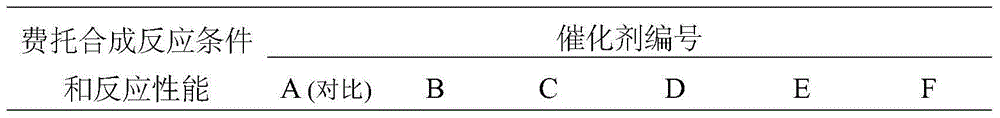

Examples

Embodiment 1

[0074] Take by weighing 28.0 kilograms of iron nuggets, 0.28 kilograms of electrolytic chromium sheet, 0.28 kilograms of electrolytic copper and make concentration be the mixed nitrate solution of 10.18wt% standby with nitric acid dissolving, and its composition is: Fe:Cr:Cu=100:1.00:1.00( mass ratio); take by weighing 14.0 kilograms of silica sol with a solid content rate of 30wt%, join in the above-mentioned mixed solution, fully stir; take by weighing 0.14 kilograms of glucose and join in the above-mentioned mixed solution, so that the mass ratio of iron and glucose is 100: 0.5, stir well and evenly, and heat up to 80°C; take a certain amount of ammonia solution with a concentration of 5.5wt%, preheat to 60°C, and continuously co-precipitate at 80°C with a pH value of 6.0 under stirring; After aging for 5 minutes, wash until the ammonium nitrate content in the slurry is less than 0.1wt%, and filter to obtain a filter cake with a solid content rate of 16.5%; add 5L of deioniz...

Embodiment 2

[0078] Take by weighing 212.6 kilograms of ferric nitrate nonahydrate, 5.7 kilograms of copper nitrate trihydrate, 35.8 kilograms of 50wt% manganese nitrate solution and be dissolved in deionized water, and the obtained concentration is that 29.57wt% mixed nitrate solution is standby, and it is composed of: Fe:Mn: Cu=100:19.6:5.3 (mass ratio); 14 kilograms of silica sols with a solid content rate of 30.0wt% are weighed and added in the mixed nitrate solution, fully stirred evenly; 0.28 kilograms of oxalic acid are weighed and added in the above mixed solution, so that The mass ratio of iron to oxalic acid is 100:1.0 and the temperature is raised to 50°C; a certain amount of ammonia solution with a concentration of 19.6wt% is taken, preheated to 20°C, and continuously co-flowed at 50°C and a pH value of 9.0 under stirring Co-precipitation; aging for 120 minutes after precipitation, washing until the ammonium nitrate content in the slurry is less than 0.5wt%, and filtering to obt...

Embodiment 3

[0080] Take by weighing 212.6 kilograms of ferric nitrate nonahydrate, 7.0 kilograms of nickel nitrate hexahydrate, 5.7 kilograms of copper nitrate trihydrate, and 17.7 kilograms of 50wt% manganese nitrate solution are dissolved in deionized water, and the obtained concentration is a 20.00wt% mixed nitrate solution for subsequent use. The composition is: Fe: Ni: Mn: Cu = 100: 5.0: 9.7: 5.3; weigh 18.6 kg of silicon solution with a solid content rate of 30.0 wt%, add it to the mixed nitrate solution, and stir evenly; weigh 0.28 kg of sucrose and add In the above mixed solution, the mass ratio of iron to sucrose is 100:1.0, and the mixed salt solution is heated up to 80°C; a certain amount of ammonia solution with a concentration of 10.0wt% is taken, preheated to 50°C, and heated at 80°C under stirring. ℃, pH value of 8.5 continuous co-precipitation; aging for 10 minutes after precipitation, washing until the ammonium nitrate content in the slurry is less than 0.2wt%, and filteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com