A kind of artificial diamond drill bit material and its drill bit, production process

A synthetic diamond and production process technology, applied in drill bits, metal processing equipment, earthwork drilling, etc., can solve the problems of difficult production process, high sintering temperature, easy to slip, etc., to ensure the alloying degree of the matrix and reduce the sintering. temperature, the effect of reducing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

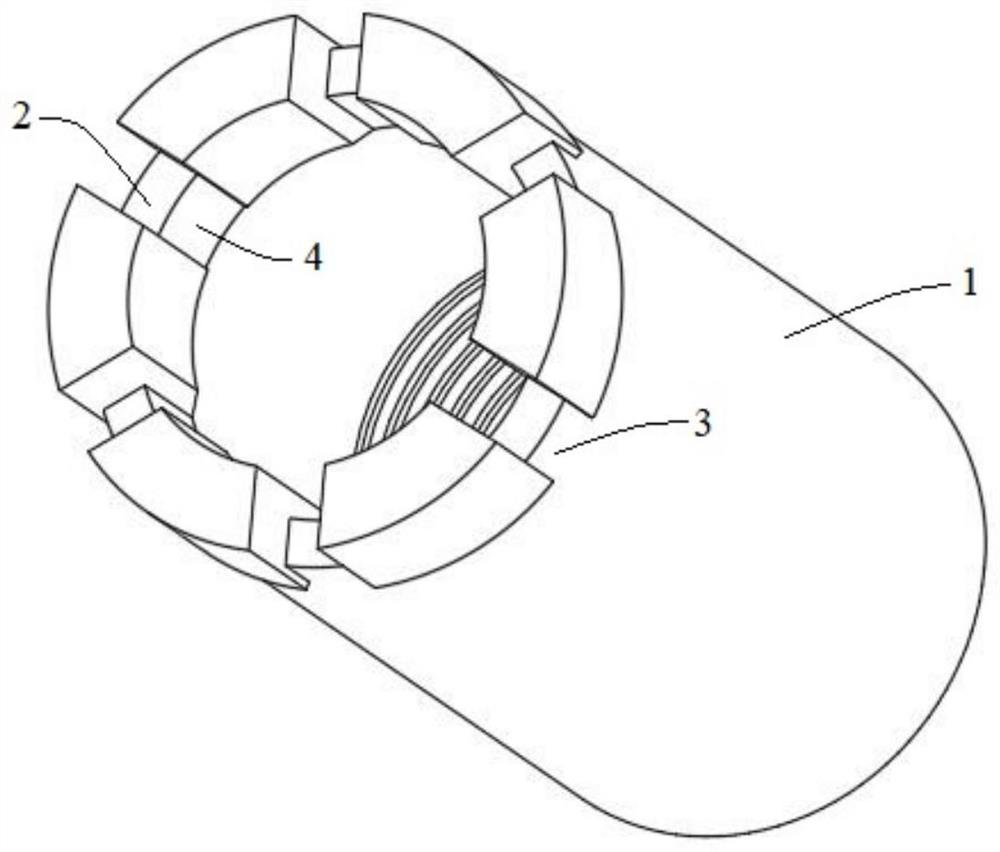

Image

Examples

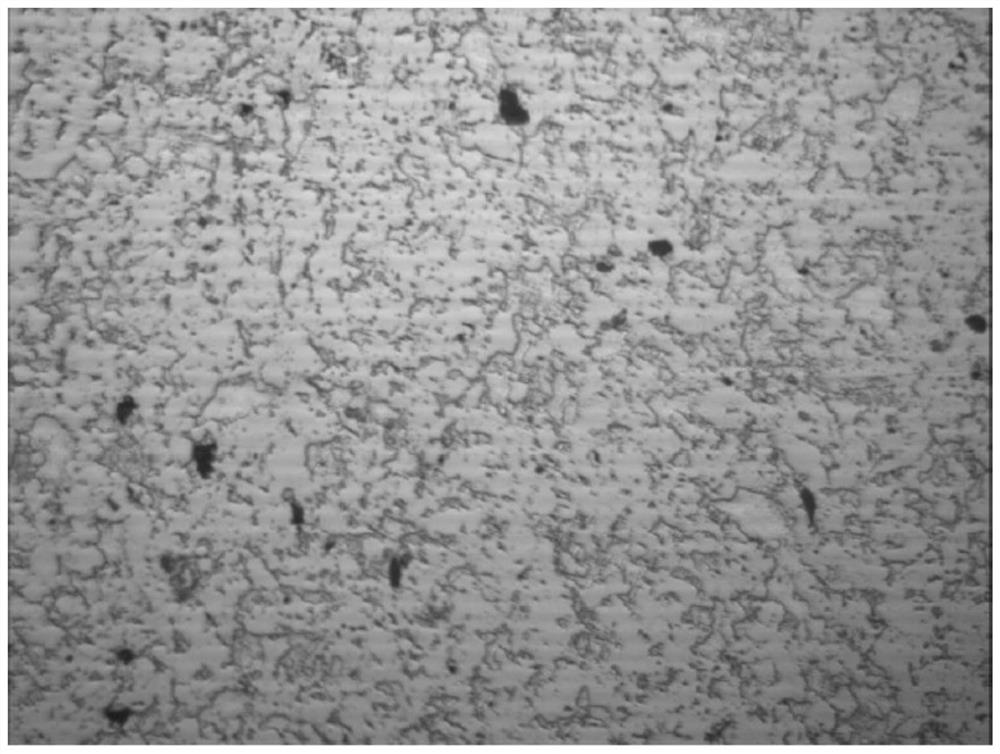

Embodiment 1

[0051] A kind of artificial diamond bit material of this embodiment comprises matrix powder and cutting diamond coarse powder. Carcass powder includes pre-alloyed powder and diamond powder, and its material composition and mass parts of each component are: 73.5 parts of Fe, 16.5 parts of Cu, 1.5 parts of C, 0.4 parts of Si, 2 parts of Sn, 200 mesh diamond powder 4 Among them, C is the content of C in SiC. It is worth noting that SiC and 200-mesh diamond can replace the traditional WC as the framework material, and the content of C in SiC is more than that of Si, which can be combined with other metals The element reacts, such as forming iron carbide, forming pores on the matrix layer, which plays a role in creating pores. Adding a small amount of pores can improve the cutting edge of the diamond drill bit, and during hot pressing, some pores will be filled, so don’t worry about too much impact The hardness of the drill bit; while the 200-mesh diamond is fine enough, the mixing...

Embodiment 2

[0062] This embodiment is basically the same as the embodiment 1, the difference lies in: the addition amount of each component of the drill bit material is different, and the process parameters are different.

[0063] A kind of artificial diamond bit material of this embodiment comprises matrix powder and cutting diamond coarse powder. Carcass powder includes pre-alloyed powder and diamond powder, its material composition and the mass parts of each component are: 71 parts of Fe, 15 parts of Cu, 1 part of C, 0.3 parts of Si, 1.5 parts of Sn, 170 mesh diamond powder 3 Among them, the 170-mesh diamond is fine enough, the mixing uniformity of the powder is good, the hardness is high, and the melting point is high, which can improve the service life of the drill bit. The concentration of cutting diamond coarse powder is 70%, which is 35 / 40 mesh nickel-plated diamond, which can effectively guarantee the ability of the drill bit to cut and drill diamond materials.

[0064] Here, "t...

Embodiment 3

[0074] This embodiment is basically the same as the embodiment 1, the difference lies in: the addition amount of each component of the drill bit material is different, and the process parameters are different.

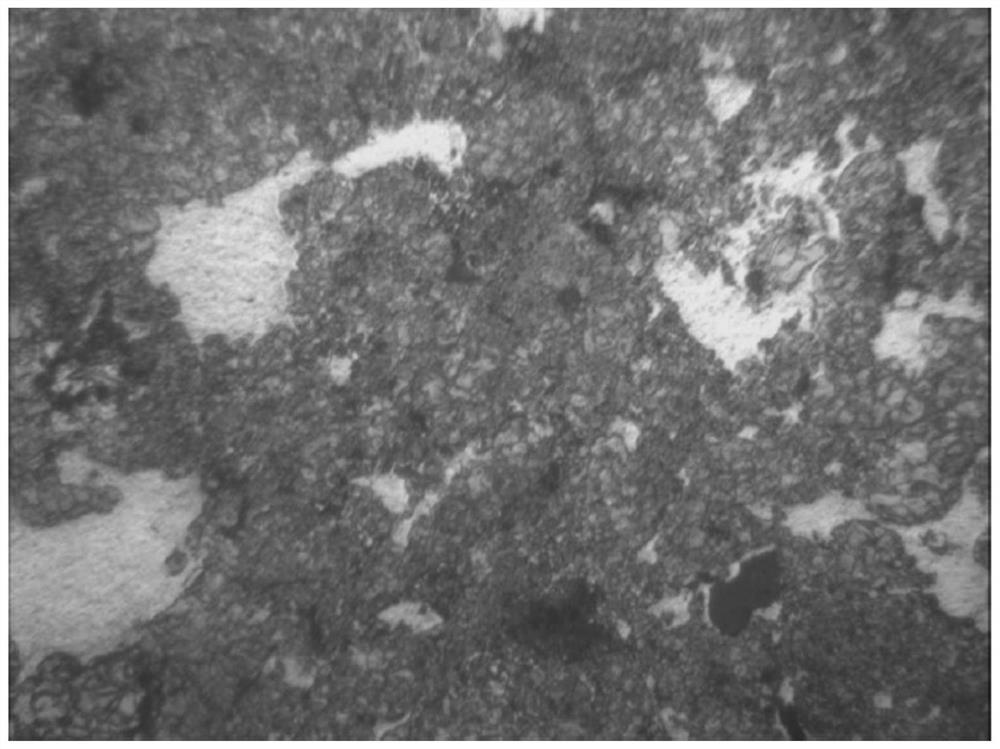

[0075] A kind of artificial diamond bit material of this embodiment comprises matrix powder and cutting diamond coarse powder. Carcass powder includes pre-alloyed powder and diamond powder, and its material composition and mass parts of each component are: Fe 76 parts, Cu 18 parts, C 2 parts, Si 0.5 parts, Sn 2.5 parts, 200 mesh diamond powder 5 Part; Wherein, the concentration of cutting diamond coarse powder is 80%, is the nickel-plated diamond of two grain sizes of 40 / 45 order and 50 / 60 order, and wherein, mixing mass ratio is 40 / 45 order: 50 / 60 order=2: 1. It can effectively guarantee the ability of the drill bit to cut and drill diamonds.

[0076] Here "the concentration of coarse diamond powder is 80%" means that the volume of coarse diamond powder in the matrix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com