Heavy calcium carbonate filling preparation method

A technology of heavy calcium carbonate and heavy calcium carbonate powder, which is applied in the treatment of fibrous fillers and dyed low-molecular organic compounds, which can solve the problems of inability to guarantee paper strength, stiffness, surface strength, and high abrasion, and achieve smoothness Increase, reduce wear, improve the effect of adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0007] The preparation method of heavy calcium carbonate filler of the present invention comprises the following steps: a, heavy calcium carbonate powder is mixed with water 2-4: 1 by weight percentage, makes heavy calcium carbonate slurry; b, above-mentioned Add a surface treatment agent accounting for 0.1-10% by weight of the heavy calcium carbonate powder in the slurry, and stir, wherein the surface treatment agent is sulfonated fatty acid methyl ester or dodecyl to docosyl phosphate; c, stirring The final slurry is put into the peeling machine for multi-stage peeling. The multi-stage peeling here refers to at least three stages of peeling treatment, so as to obtain low-wear heavy calcium carbonate slurry. The fineness of heavy calcium carbonate powder is 100-400 mesh; the stirring speed is 800 rpm, and the time is 20-30 minutes.

[0008] The preparation method of described heavy calcium carbonate filler comprises the following steps: a, heavy calcium carbonate powder and w...

Embodiment 1

[0010] The ground calcium carbonate powder of 100 mesh to 400 mesh is pulped, and the water accounts for 40.0% by weight of the heavy calcium carbonate slurry. Make heavy calcium carbonate slurry with a content of 40.0-75.0% of heavy calcium carbonate powder, fully stir to make the slurry obtain good fluidity, and then use a wet ultrafine grinding (flaking) machine for multi-stage grinding, grinding After the particle size of the formed calcium carbonate is 2 μm and the content is 30.0-80.0%, a surface treatment agent sulfonated fatty acid methyl ester is added to the slurry for surface treatment. The addition amount of the surface treatment agent is 0.01%-10.0% relative to the dry powder of heavy calcium carbonate. The indicators of the prepared low-abrasion heavy calcium carbonate slurry are: the -2 μm content of the calcium carbonate particles is 30.0-80.0%; the solid content is 40.0-75.0%; the abrasion is less than 3mg / 2000 times; the pH value is 9.0-10.0; the viscosity is...

Embodiment 2

[0016] The heavy calcium carbonate powder of 100 mesh to 400 mesh is made into pulp, and the heavy calcium carbonate powder is added into water. The water accounts for 25.0-60.0% by weight of the heavy calcium carbonate slurry, and the most suitable is 25.0%-40.0%. And adding the surface treatment agent stearyl phosphate into the water, the addition amount is 0.01%-10.0% relative to the dry powder of heavy calcium carbonate. The content of being made into heavy calcium carbonate powder is 40.0-75.0% heavy calcium carbonate slurry, fully stirred, stirring speed is 800 rev / mins, and the time is 20-30 minutes, makes slurry obtain good fluidity, then Using a wet ultra-fine grinding (flaking) machine for multi-stage grinding (flaking), the physical indicators of the low-wear heavy calcium carbonate slurry are: calcium carbonate particle size 2 μm, content 30.0-80.0%; solid content 40.0-75.0% ; Abrasion-20.

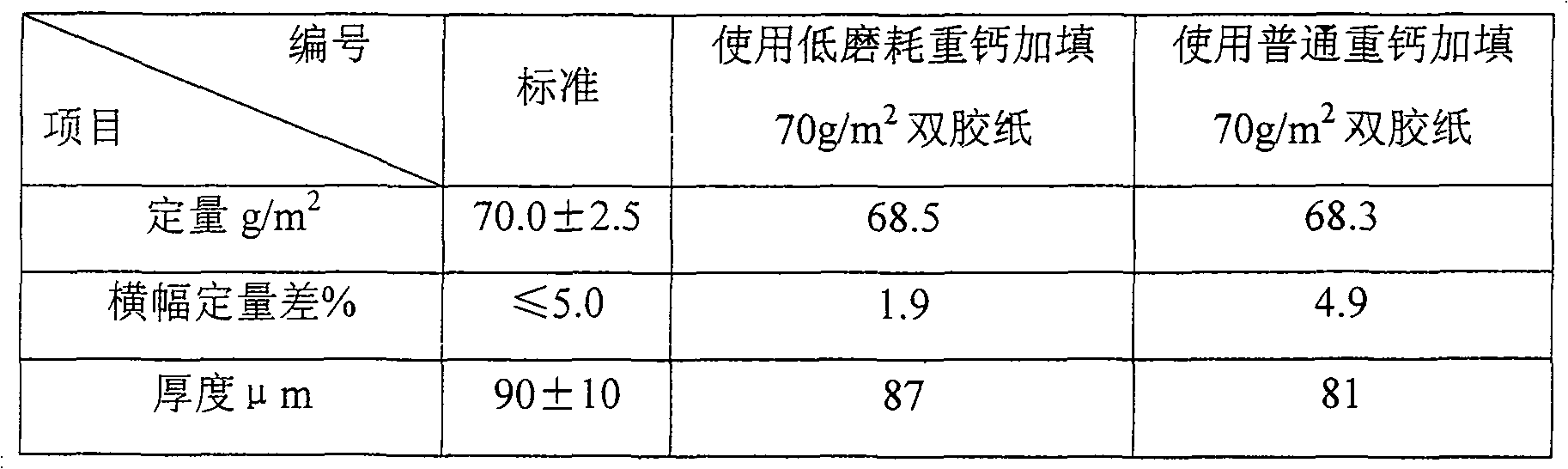

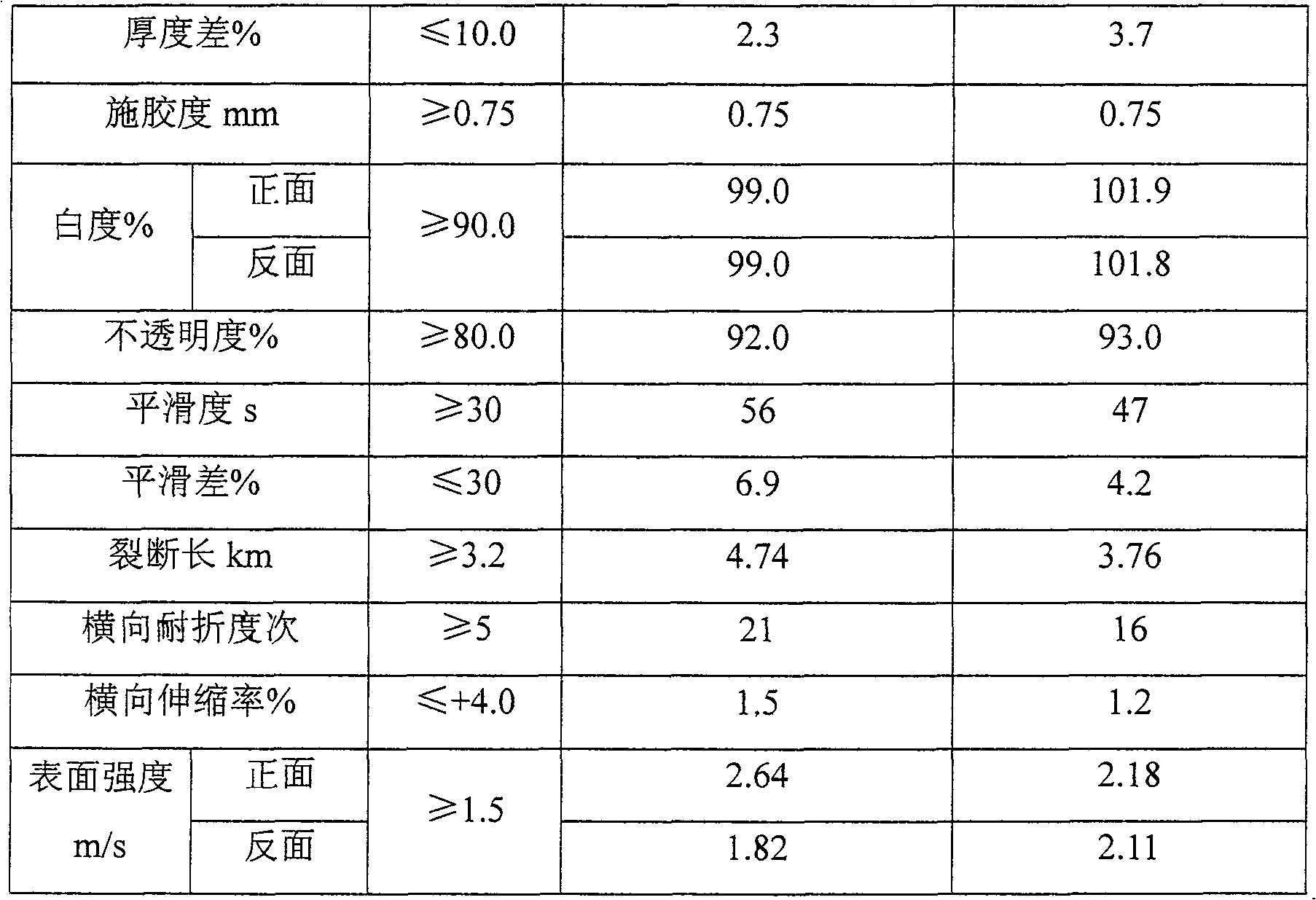

[0017] The low-abrasion heavy calcium carbonate filler of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com