A method for preparing high-quality kaolin by high-efficiency calcination of coal gangue by increasing oxygen

A technology of coal gangue and kaolin, which is applied in the field of high-quality kaolin prepared by high-efficiency calcination of coal gangue, which can solve the problems of low quality and poor performance of kaolin, and achieve quick results, low sieve residue, and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

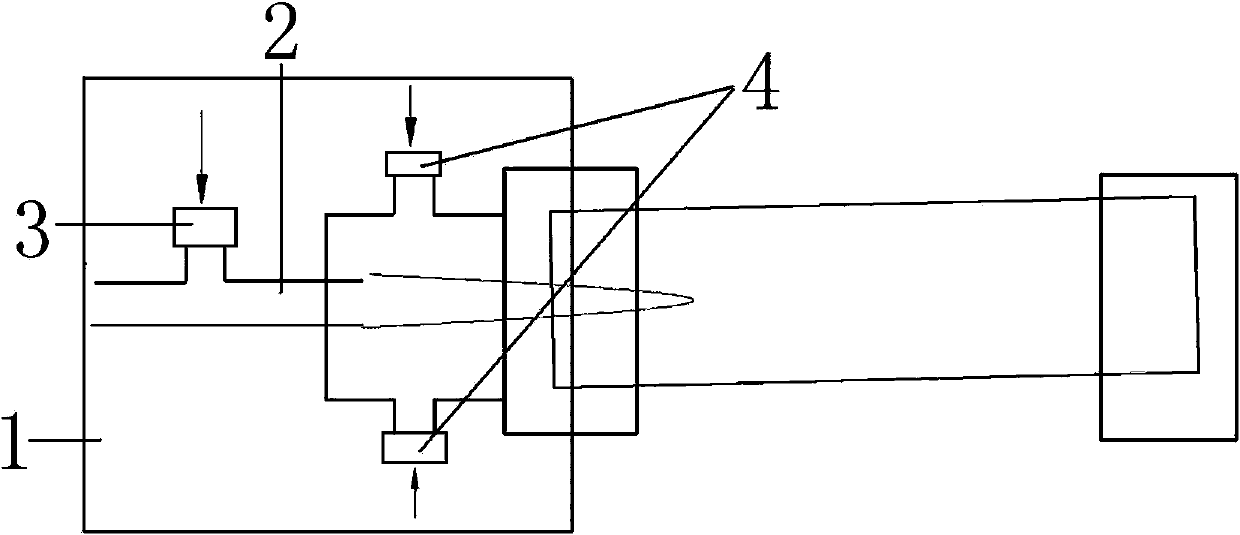

[0030] Embodiment 1: A method for preparing high-quality kaolin by increasing the aeration of coal gangue with oxygen and high efficiency, including hand-selected ore washing, crushing and crushing, ultra-fine grinding, drying and breaking up, calcining and cooling, breaking up and grading, specifically including the following steps:

[0031] (1) Hand-selected ore washing: remove iron-titanium-infected raw materials and other impurities in the raw ore stockyard, then wash with water to remove coal ash and soil on the surface of the raw ore, and manually crush until the ore particle size is ≤ 200mm;

[0032] (2) Crushing and crushing: choose ore with a Mohs hardness of 3-5, use a conventional hammer crusher to crush the ore to a particle size of ≤15mm, and then use a hurricane mill to crush it to make the particle size 45 microns or 325 mesh;

[0033] (3) Ultra-fine grinding: the material crushed to 325 mesh is mixed with water to make slurry, the slurry concentration is 40-50%,...

Embodiment 2

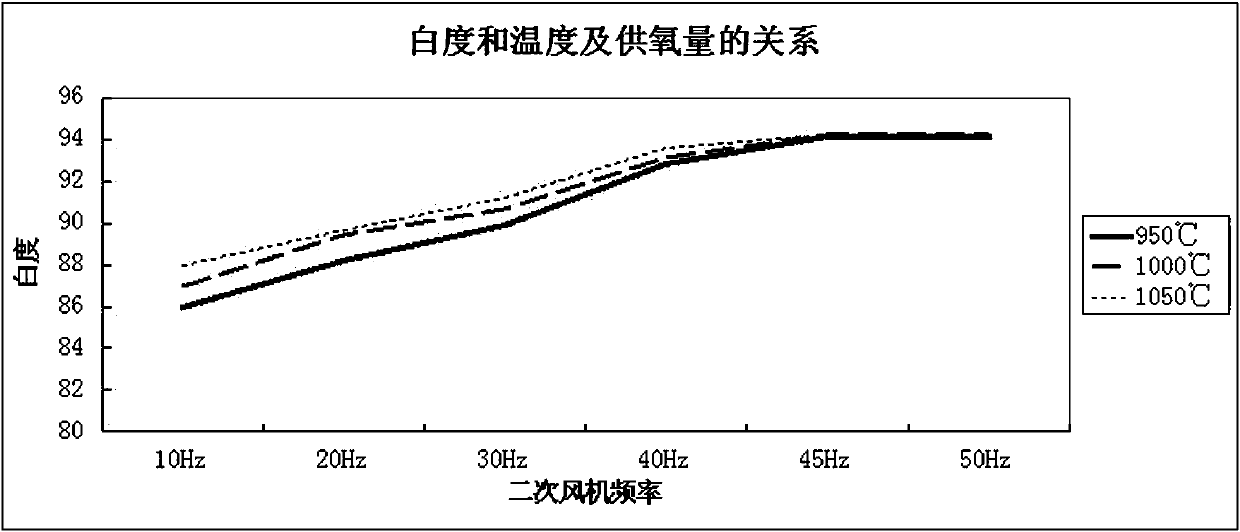

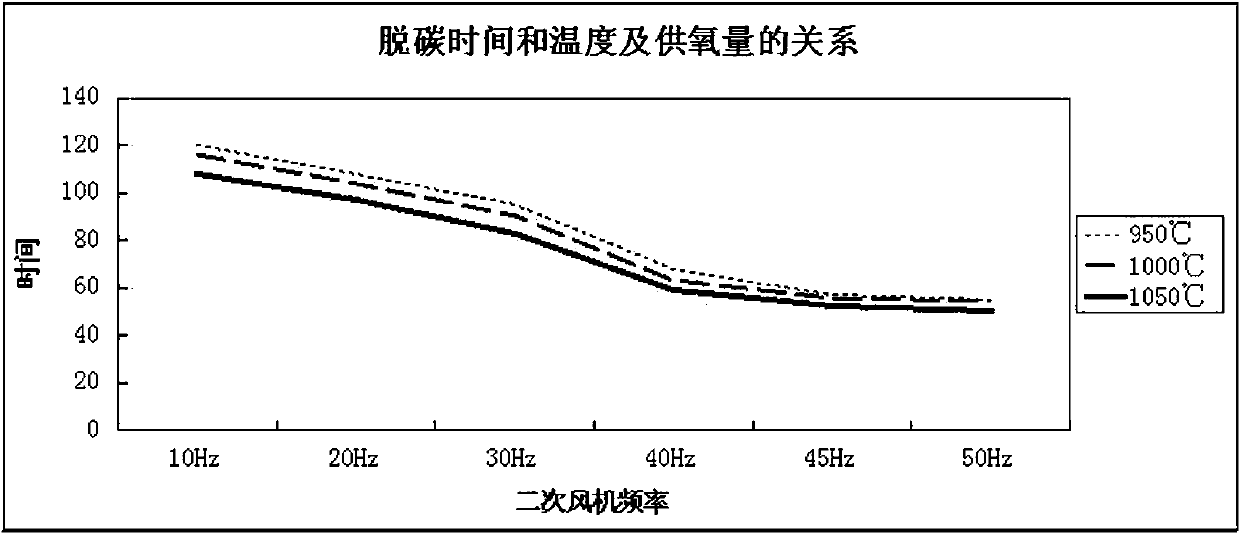

[0041] Example 2: A method for preparing high-quality kaolin by increasing the oxygenation of coal gangue. When calcining and cooling, an internal heating type rotary kiln is used, and the calcining temperature is controlled at 1000°C. After 56 minutes of calcining, the hot material is cooled by exhaust and transported under negative pressure. The kiln head of the internal heating rotary kiln is equipped with a combustion chamber, a burner is installed in the combustion chamber, a combustion-supporting fan is installed at the front end of the combustion chamber, and an oxygen supply fan is installed at the burner. The burner is a natural gas burner. The frequency of the oxygen fan is 45Hz. All the other methods are with the method described in Example 1.

Embodiment 3

[0042] Example 3: A method for preparing high-quality kaolin by increasing the oxygenation of coal gangue. When calcining and cooling, an internal heating rotary kiln is used, and the calcining temperature is controlled at 1050°C. After 50 minutes of calcining, the hot material is cooled by exhaust and transported under negative pressure. The kiln head of the internal heating rotary kiln is equipped with a combustion chamber, a burner is installed in the combustion chamber, a combustion-supporting fan is installed at the front end of the combustion chamber, and an oxygen supply fan is installed at the burner. The burner is a natural gas burner. The frequency of the oxygen fan is 50Hz. All the other methods are with the method described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com