Multi-hole fuel gas jet flow burner

A gas nozzle, gas technology, applied in the direction of burner, combustion type, combustion method, etc., can solve problems such as combustion instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

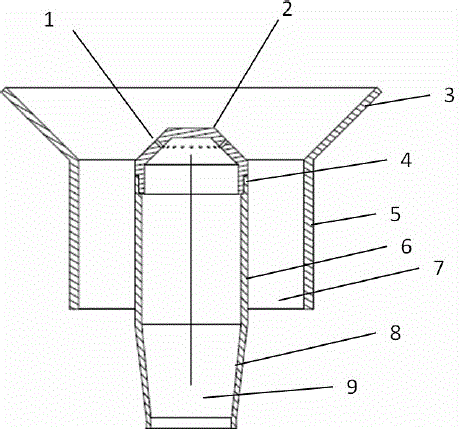

[0034] Such as figure 1 As shown, a porous gas jet burner includes a gas pipeline 6, a gas nozzle 2, an air pipeline 5 and an air pipeline outlet 3, the gas pipeline 6 is connected to the gas nozzle 2, the air pipeline 5 is connected to the air pipeline outlet 3, and the air pipeline 5 is coaxially installed with the gas pipeline 6, the air pipeline 5 is located outside the gas pipeline 6, the gas pipeline 6 is a gas flow channel 9, and the cavity between the air pipeline 5 and the gas pipeline 6 is an air flow channel 7; the gas nozzle 2 Located at the center of the outlet 3 of the air duct.

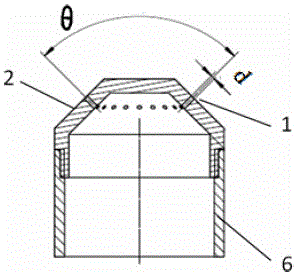

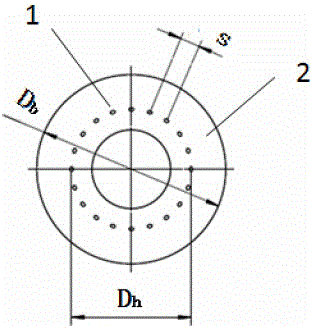

[0035] Such as Figure 2-3 As shown, a circle of fire holes 1 is evenly arranged on the wall of the gas nozzle 2, and the annular ring formed by the fire holes 1 takes the axial centerline of the gas nozzle 2 as the center.

[0036] The structure of the porous gas jet burner needs to meet:

[0037] (1)D h / D b The ratio range is 0.4-0.8, where D h is the annular diameter formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com