A kind of preparation method of high wear-resistant rubber material for tire

A technology for rubber materials and tires, applied in the field of high wear-resistant rubber materials for tires, can solve the problems affecting service life and safety, high mechanical strength, poor wear resistance, etc., and achieves optimized comprehensive use performance, high tensile strength The effect of improving strength and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

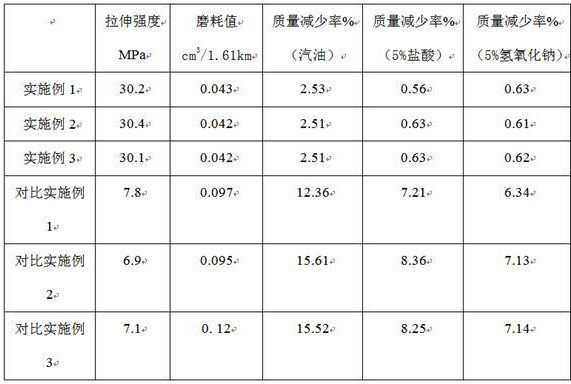

Examples

Embodiment 1

[0018] A method for preparing a high wear-resistant rubber material for tires, comprising the following steps:

[0019] (1) Put 10 parts by weight of potassium hexatitanate whiskers and 5 parts of boron nitride into a ball mill, mill for 20 minutes, then put them into a calciner, and heat up to 500°C at a rate of 2°C / min. Calcination for 2h, then lowered to 300°C at a rate of 4°C / min, kept for 3h, then lowered to room temperature;

[0020] (2) Heat 10 parts of sulfur to melt to obtain a sulfur melt, add the product of step (1) to it, keep the temperature at 120°C, stir at a rate of 100rpm for 1h, then lower the temperature at a rate of 1°C / min while stirring. to room temperature to obtain potassium hexatitanate whiskers-boron nitride uniformly wrapped in sulfur;

[0021] (3) Add the product obtained in step (2) to a modified polytetrafluoroethylene emulsion that is 5 times its volume, and use ultrasonic treatment for 20 minutes, and then place it in a vacuum box at 30°C for 5...

Embodiment 2

[0029] A method for preparing a high wear-resistant rubber material for tires, comprising the following steps:

[0030] (1) Put 12 parts by weight of potassium hexatitanate whiskers and 7 parts of boron nitride into a ball mill, mill for 25 minutes, then put them into a calciner, and heat up to 510°C at a rate of 3°C / min. Calcined for 3h, then lowered to 310°C at a rate of 5°C / min, kept for 4h, and then lowered to room temperature;

[0031] (2) Heat 15 parts of sulfur to melt to obtain a sulfur melt, add the result of step (1) to it, keep the temperature at 122°C, stir at a rate of 150rpm for 2h, then lower the temperature at a rate of 2°C / min while stirring. to room temperature to obtain potassium hexatitanate whiskers-boron nitride uniformly wrapped in sulfur;

[0032] (3) Add the product obtained from step (2) to a modified polytetrafluoroethylene emulsion whose volume is 8 times its volume, and use ultrasonic treatment for 25 minutes, and then place it in a vacuum box at ...

Embodiment 3

[0040] A method for preparing a high wear-resistant rubber material for tires, comprising the following steps:

[0041] (1) Put 15 parts by weight of potassium hexatitanate whiskers and 10 parts of boron nitride into a ball mill, mill for 30 minutes, then put them into a calciner, and heat up to 520°C at a rate of 4°C / min. Calcined for 3h, then lowered to 320°C at a rate of 6°C / min, kept for 5h, and then lowered to room temperature;

[0042] (2) Heat 20 parts of sulfur to melt to obtain a sulfur melt, add the result of step (1) to it, keep the temperature at 125°C, stir at a rate of 200rpm for 2h, then lower the temperature at a rate of 2°C / min while stirring. to room temperature to obtain potassium hexatitanate whiskers-boron nitride uniformly wrapped in sulfur;

[0043] (3) Add the resultant of step (2) to the modified polytetrafluoroethylene emulsion whose volume is 10 times its volume, and use ultrasonic treatment for 30 minutes, and then place it in a vacuum box at 40°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com